GDMMTA582-1G Version 0010 2

1 Table of Contents

1Table of Contents................................................................... 2

2Amendment Record Sheet .................................................... 4

2.1 Table of Amendments.......................................................................... 4

2.2 Amendments........................................................................................ 4

3Introduction............................................................................ 5

3.1 Skills..................................................................................................... 5

3.2 Tools .................................................................................................... 5

3.3 Air Creation Directives ......................................................................... 6

3.4 Units..................................................................................................... 6

3.4.1 Use of Metric/Imperial Units...................................................................................6

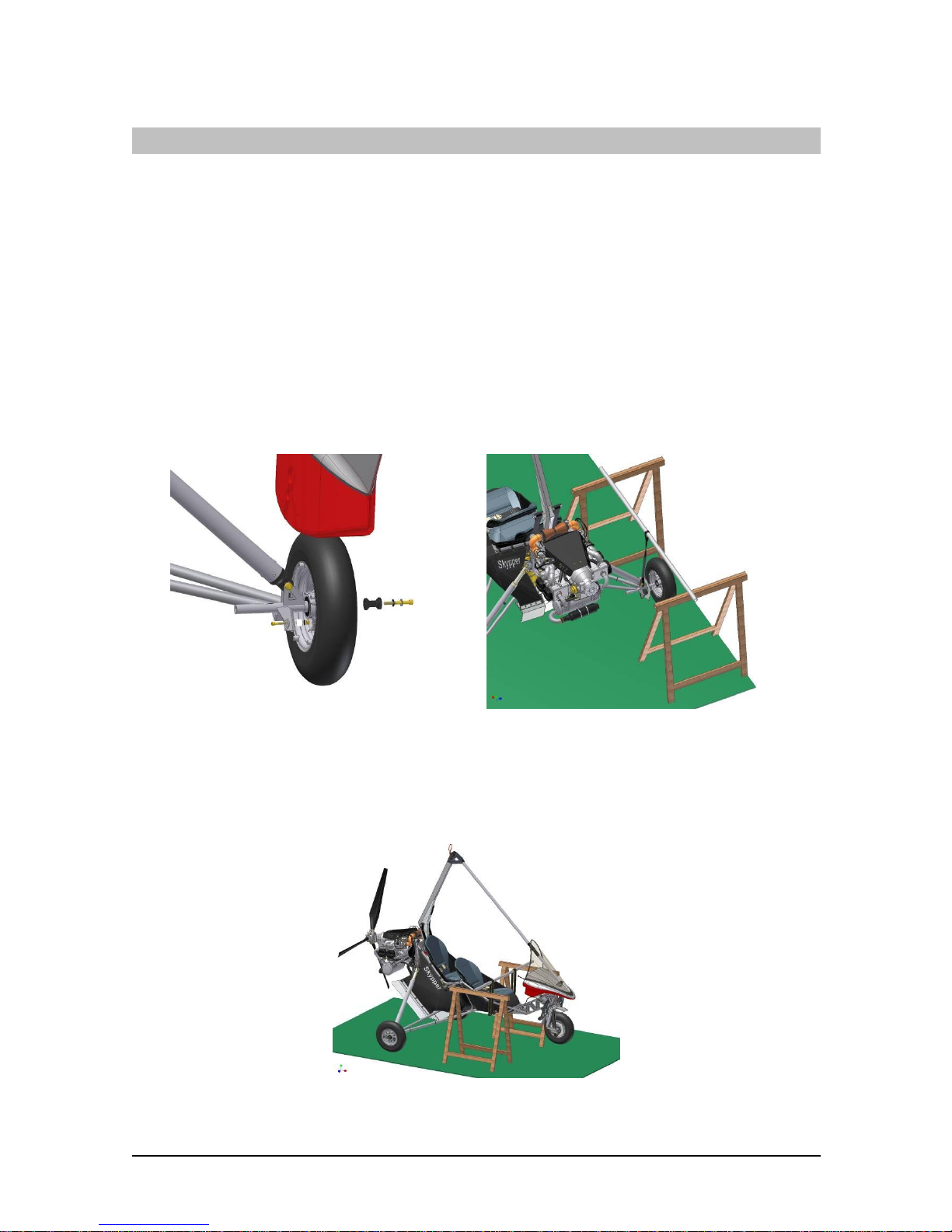

3.5 Lifting & Shoring................................................................................... 7

3.5.1 Lifting the Entire Trike ............................................................................................7

3.5.2 Lifting One Rear Wheel..........................................................................................7

3.5.3 Lifting the Front Wheel ...........................................................................................7

3.6 Transportation & Storage..................................................................... 8

3.6.1 Towing....................................................................................................................8

3.6.2 Taxiing....................................................................................................................8

3.6.3 Ground Transportation ...........................................................................................8

3.6.4 Long-Term Hangarage...........................................................................................8

4Servicing................................................................................. 9

4.1 General ................................................................................................ 9

4.2 Replenishing ........................................................................................ 9

4.2.1 Fuel System Replenishment ..................................................................................9

4.2.2 Fuel Sampling/Draining..........................................................................................9

4.2.3 Coolant Replenishment........................................................................................10

4.3 Tire Inflation ....................................................................................... 10

4.4 Instrumentation .................................................................................. 10

5Maintenance Checks............................................................ 11

5.1 General .............................................................................................. 11

5.2 Time Limits......................................................................................... 11

5.3 Scheduled Maintenance Checks........................................................ 11

5.3.1 Trike Maintenance Schedule................................................................................12

5.3.2 Powerplant Maintenance Schedule......................................................................13