GDMUNU15-1G Version 0030 2

1 Table of Contents

1Table of Contents................................................................... 2

2Amendment Record Sheet..................................................... 4

2.1 Table of Amendments.......................................................................... 4

2.2 Amendments........................................................................................ 4

3General ................................................................................... 5

3.1 About this Document............................................................................ 5

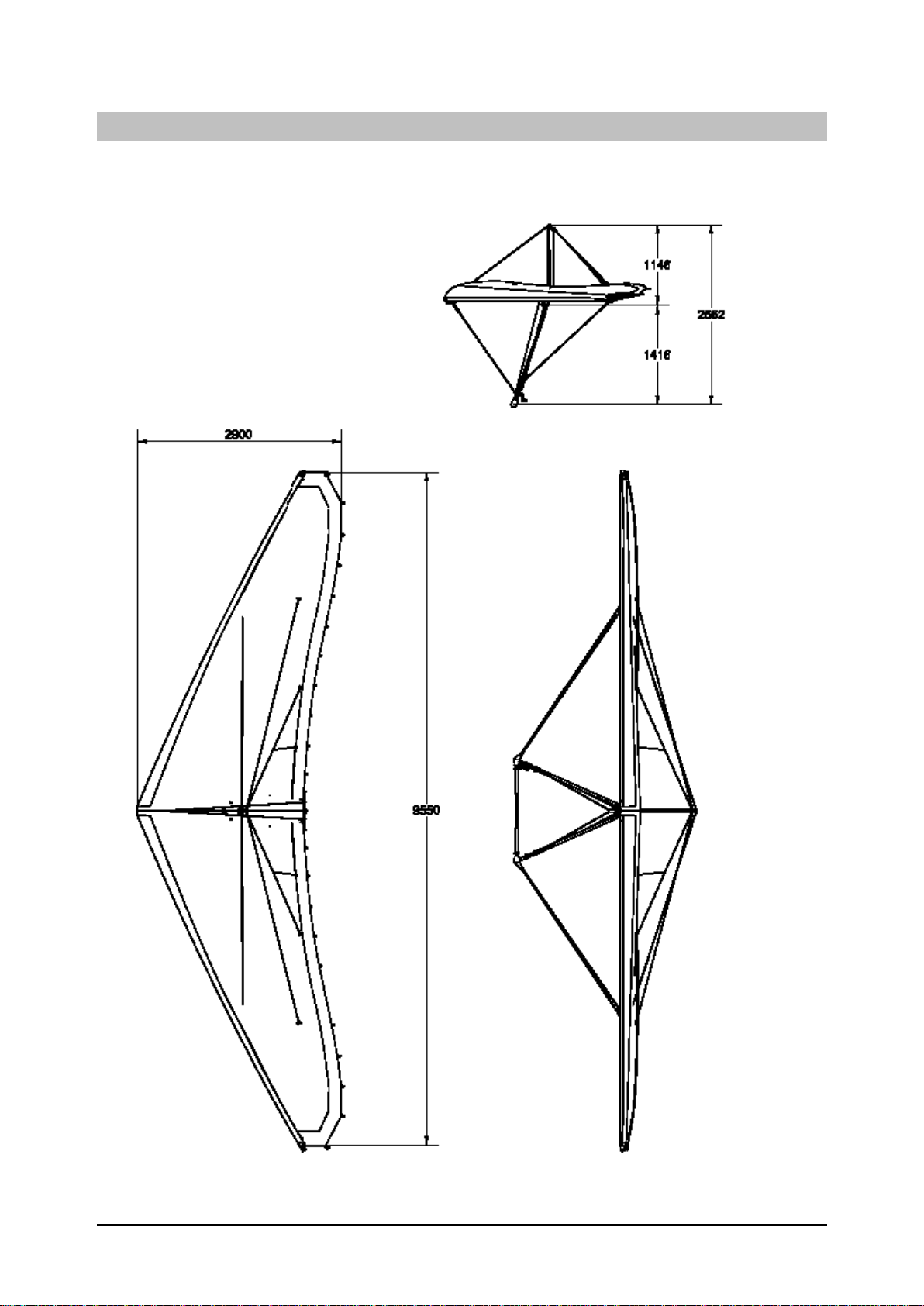

3.2 3-Perspective Diagram......................................................................... 6

Figure 3-1: NuviX in 3 Perspectives..........................................................................................6

4Technical Specifications –Performance.............................. 7

4.1 Technical Specifications....................................................................... 7

4.2 Maximum Added Load / Trikes Adjustment ......................................... 7

4.3 Performance at Maximum Take-Off Weight......................................... 9

5Instructions for Use ............................................................. 10

5.1 Rigging............................................................................................... 10

5.1.1 Assembly..............................................................................................................10

Figure 5-1 : EasyFit Tighteners................................................................................................10

Figure 5-2 : Path of Tensioning Cables ...................................................................................10

5.1.2 Disassembly.........................................................................................................11

5.2 Preflight Check................................................................................... 11

5.3 Flight Specifications........................................................................... 13

5.3.1 Operational Limitations.........................................................................................13

5.3.2 Controls ................................................................................................................13

Figure 5-3 : CORSET Control..................................................................................................15

5.3.3 Flight Techniques .................................................................................................15