TOOLS LIST

Description......................................................................Qty

7/16” and 9/16” Open-end or box wrenches.......................2

Crescent wrench.................................................................1

Ratchet with 3/8”, 9/16”, & 1/2” deep well sockets.....................1

5/16” drill bits (very sharp)..................................................1

DIR grinder .........................................................................1

Hacksaw.............................................................................1

Heavy duty drill...................................................................1

Torque wrench....................................................................1

Standard, metric and SAE sockets and wrenches .............1

Hose cutter, razor blade, or sharp knife .............................1

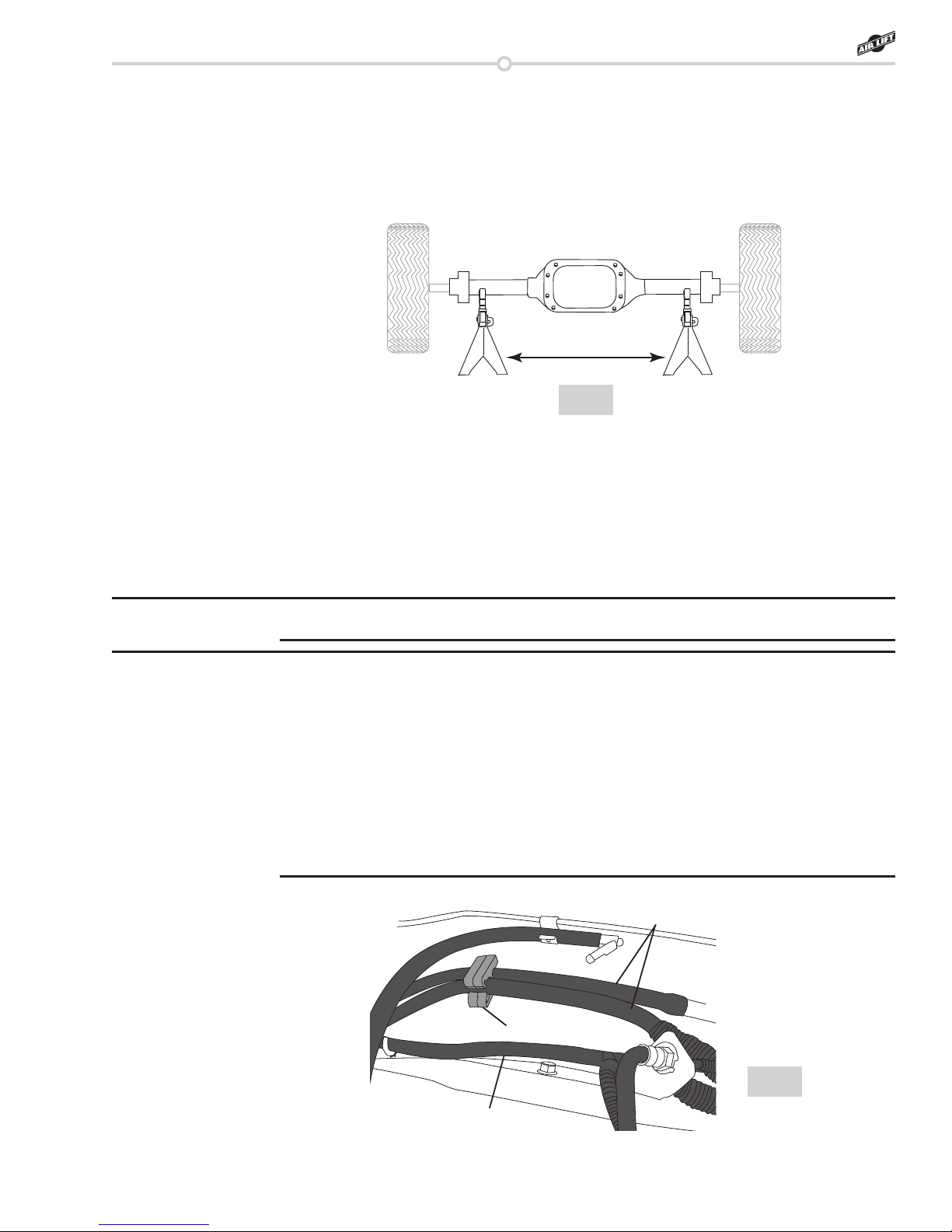

Hoist or oor jacks..............................................................1

Safety stands......................................................................1

Safety glasses ....................................................................1

Air compressor or compressed air source..........................1

Spray bottle with dish soap/water solution .........................1

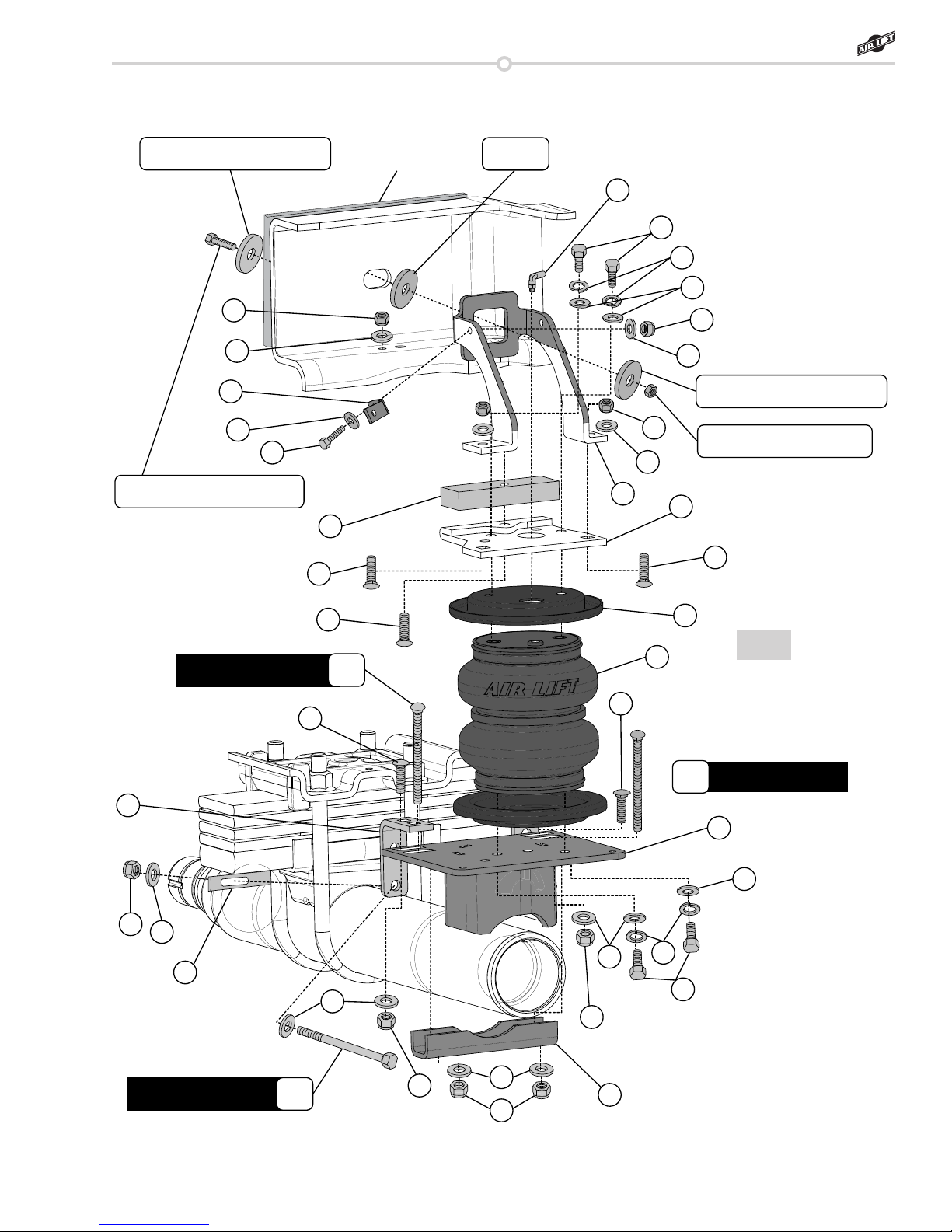

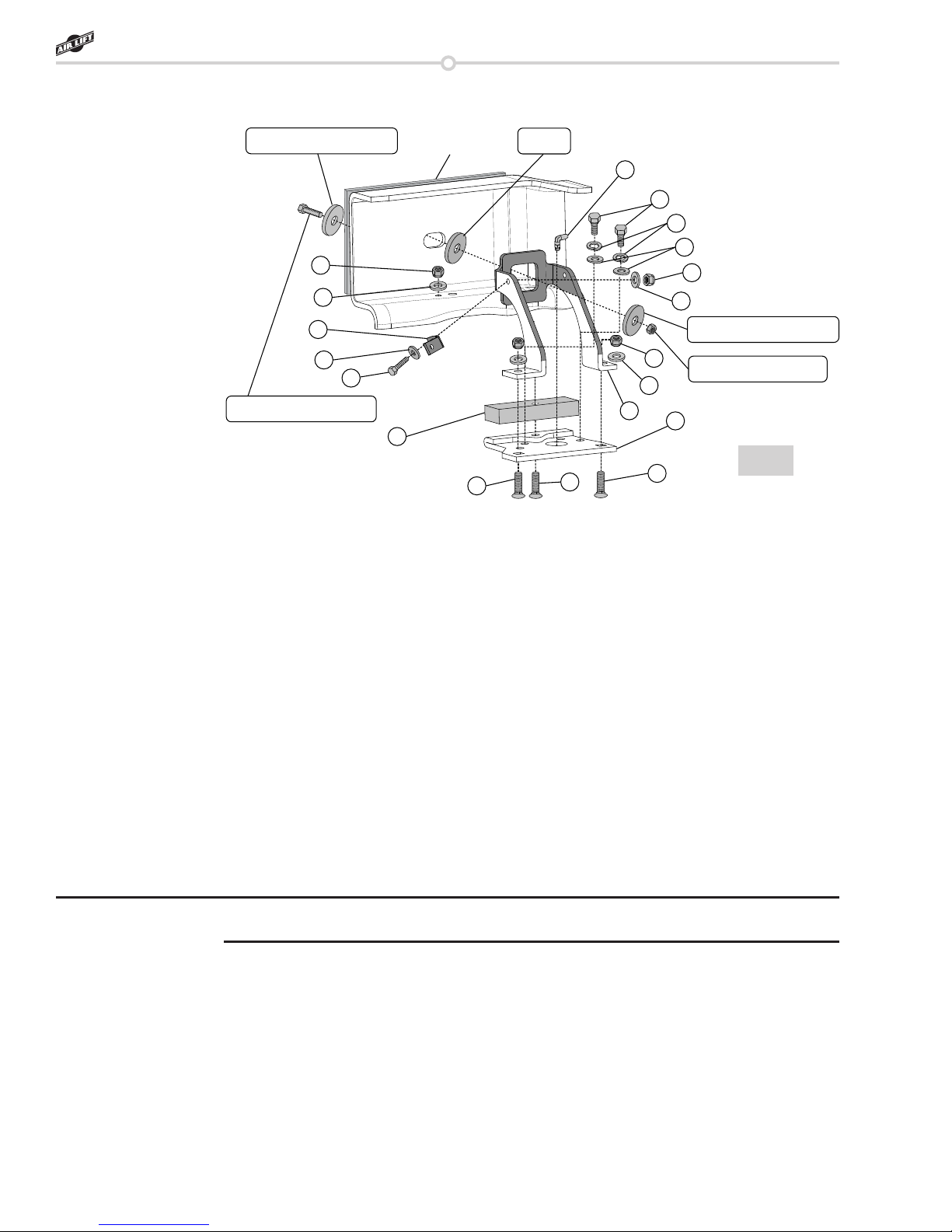

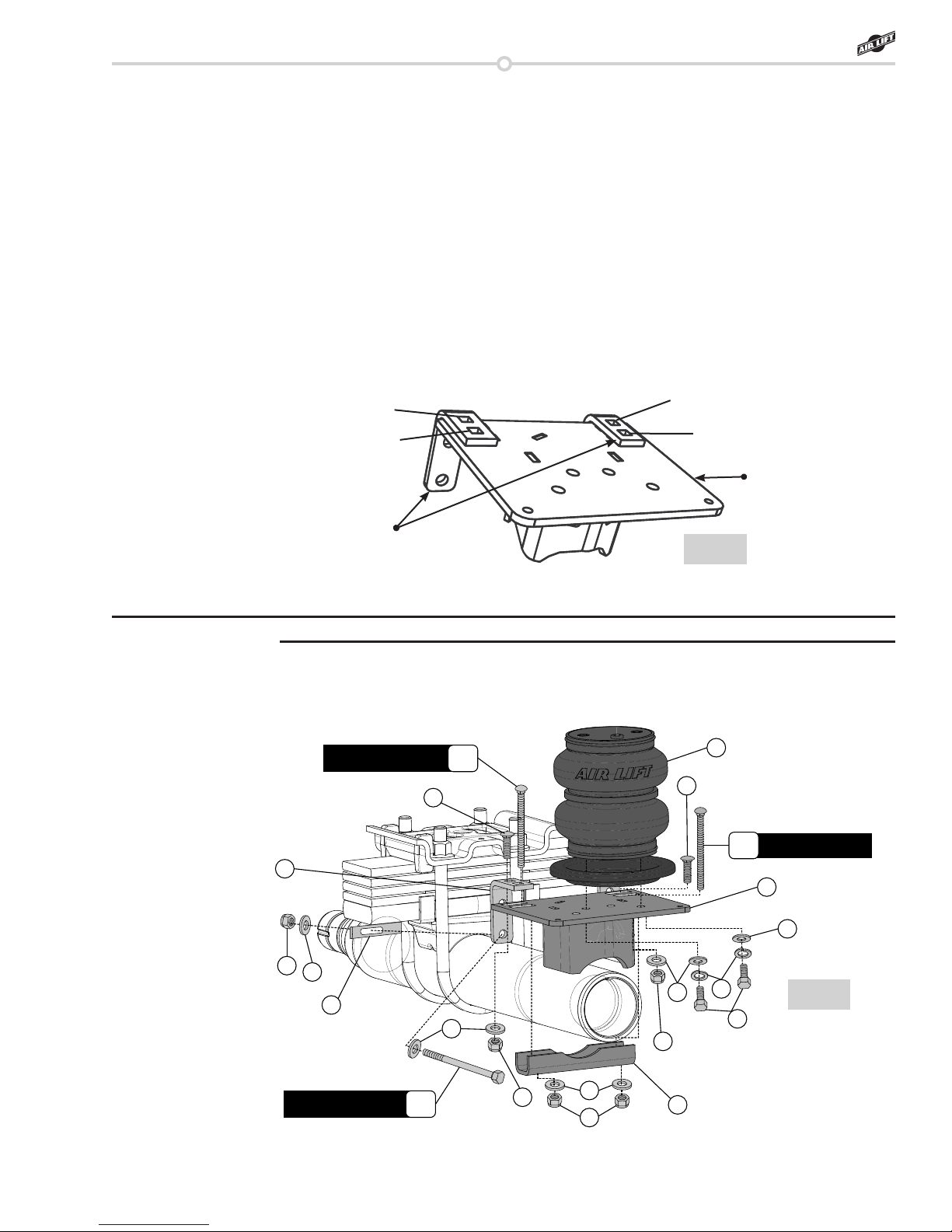

Item Part # Description ............................... Qty

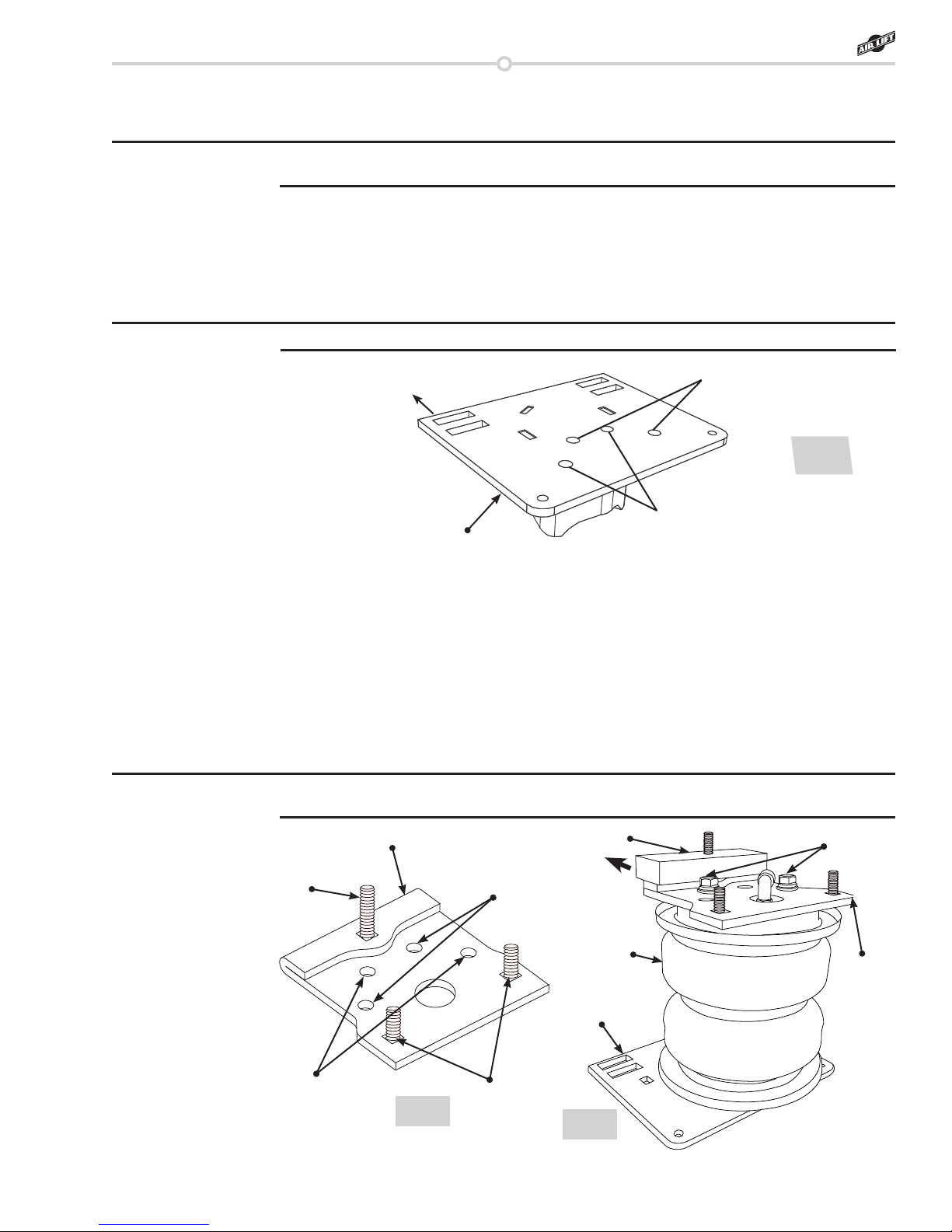

A 03991 Lower Bracket.....................................2

B 07996 Upper Brace........................................1

C 07997 Upper Bracket.....................................1

D 01531 Clamp Bar...........................................2

E 10861 Spring Clamp Bar................................2

F 13966 Spacer.................................................2

G 11951 Roll Plate.............................................4

H 58437 Bellows................................................2

I 10880 Four Hole Locating Bracket ................4

J 10886 “L” Bracket ..........................................1

K 17110 3/8-16 x 5.5 Hex Head Cap Screw .....4

L 17135 1/4”-20 x 1” Hex Cap Screw................1

M 17141 3/8-16 x 2.5” Carriage Bolt..................2

N 17203 3/8-24 x 7/8” Hex Head Cap Screw ....8

O 17271 1/2”-13 x 3” Hex Cap Screw................2

P 17361 3/8-16 x 1.25” Carriage Bolt................8

Q 17387 3/8-16 x 10” Carriage Bolt...................4

Item Part # Description ............................... Qty

R 18207 1/2” Thick Flat Washer........................6

S 18419 Flat Washer #12..................................2

T 18425 1/4”-20 Nyloc Nut................................1

U 18427 3/8” Lock Washer................................8

V 18435 3/8”-16 Nyloc Nut...............................18

W 18444 3/8” Flat Washer ................................34

X 18460 1/2-13” Nyloc Nut................................2

Y 18556 3/4” Flat Washer .................................2

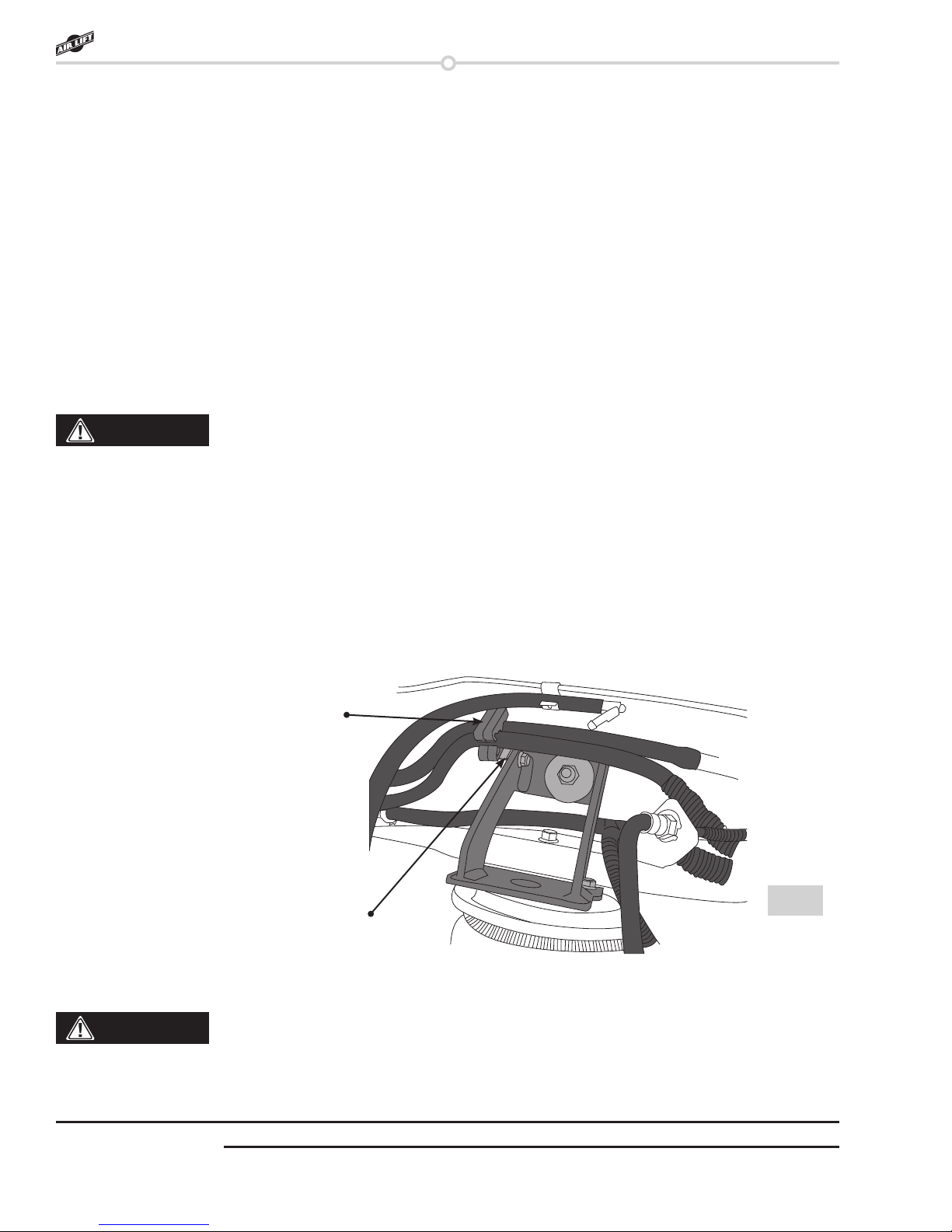

Z 21837 90 ˚ Swivel Air Fitting ..........................2

AA 10466 Zip Ties ...............................................6

BB 18411 5/16” Lock Washer..............................2

CC 21230 Valve Caps..........................................2

DD 21233 5/16” Hex Nut......................................2

EE 21234 Rubber Washer...................................2

FF 20086 Air Line Assembly ...............................1

GG 34924 Heat Shield Kit ....................................1

HH 17208 1/2-13 x 2” Hex Head Cap Screw .......2

HARDWARE LIST

Hardware and Tools Lists

LoadLifter 5000