4

1.2.4 Clock

When programmed as a digital clock the BA364D

will display local time within a hazardous area.

The two optional solid state outputs may be

programmed to turn on and off twice during each

24 hour period.

See section 5 of this manual for a detailed

description of the clock functions.

1.3 INITIALISATION

Each time power is applied to the BA364D

initialisation is performed. After a short delay the

following display sequence occurs:

All segments of the display are activated

for about 2 seconds.

The product firmware and versionnumber

are shown on the top display and the

current instrument function i.e. Countr,

ELAPSE, tACHO or CLOC are displayed

on the lower display for 2 seconds.

The BA364D starts to function using the

calibration information stored in the

permanent memory.

1.4 INTRINSIC SAFETY CERTIFICATION

1.4.1 ATEX certification

The BA364D has been issued with EC-Type

Examination Certificate number ITS01ATEX2003

by Notified Body Intertek Testing Services (ITS)

confirming compliance with the European ATEX

Directive 94/9/EC for Group II, Category 1, gas

and dust atmospheres, EEx ia IIC T5. The

instrument bears the Community Mark and

subject to local codes of practice, may be

installed in any of the European Economic Area

(EEA) member countries. ATEX certificates are

also acceptable for installations in Switzerland.

This manual describes installations in explosive

gas atmospheres which conform with BS

EN60079:Part14:2003 Electrical Installation in

Hazardous Areas. When designing systems for

installation outside the UK, the local Code of

Practice should be consulted.

For use in the presence of combustible dust,

please refer to Appendix 1 which describes

installations complying with BS EN 50281-1-

2:1999.

1.4.2 Power supply

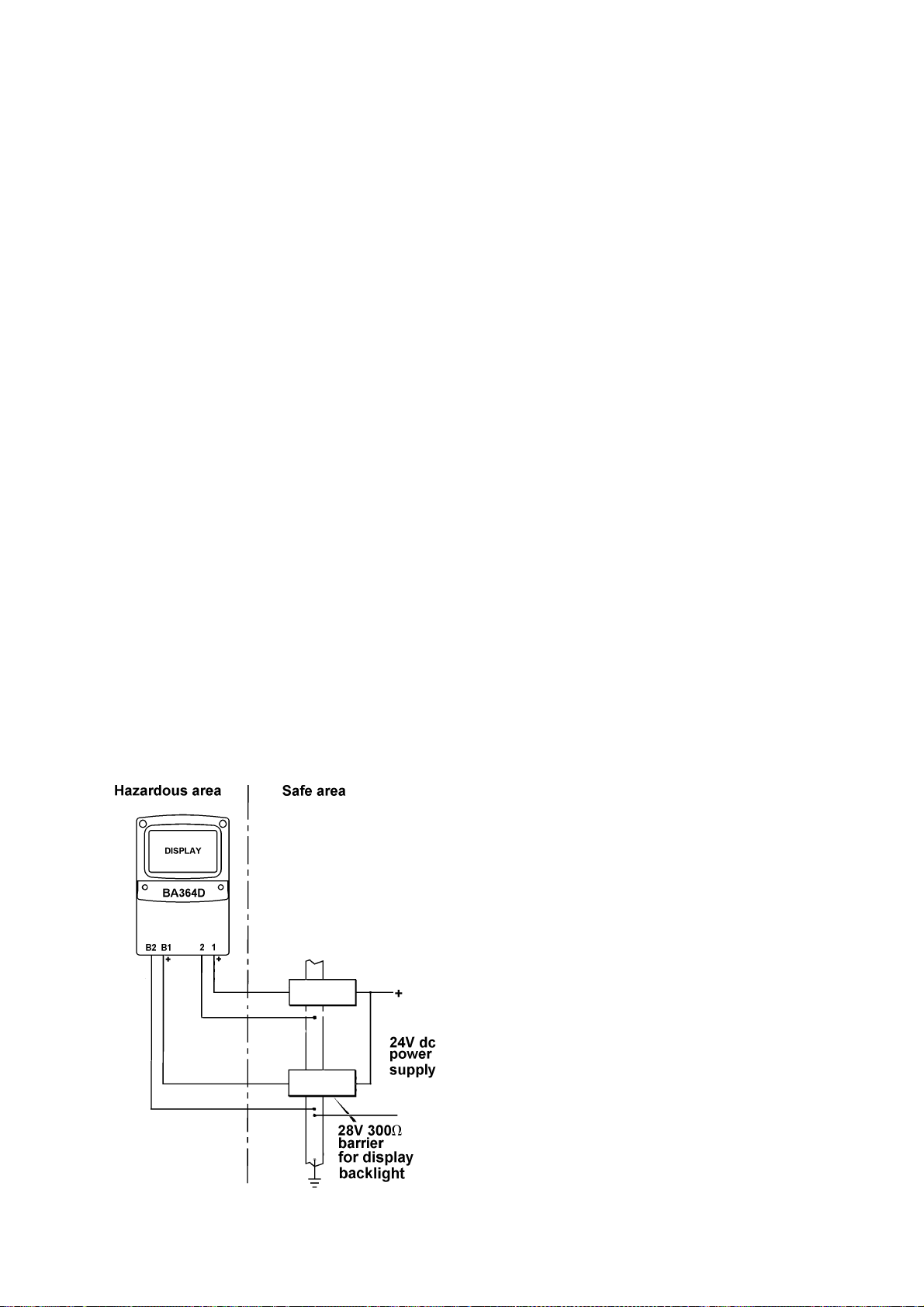

When installed in a hazardous area the BA364D

must be powered via a Zener barrier or galvanic

isolator from a dc supply located in the safe area.

The input safety parameters for terminals 1 and 2

are: Ui = 28V dc

Ii = 100mA dc

Pi = 0.7W

Any certified Zener barrier or galvanic isolator

with output safety parameters within these limits

may be used. Two system certificates provide

guidance to help selection of suitable devices.

The maximum equivalent capacitance and

inductance between terminals 1 and 2 is:

Ci = 20nF

Li = 20 H

When installing a system not covered by the

BA364D system certificates, these figures must

be subtracted from the maximum cable

parameters for the certified device powering the

BA364D.

1.4.3 Pulse input terminals

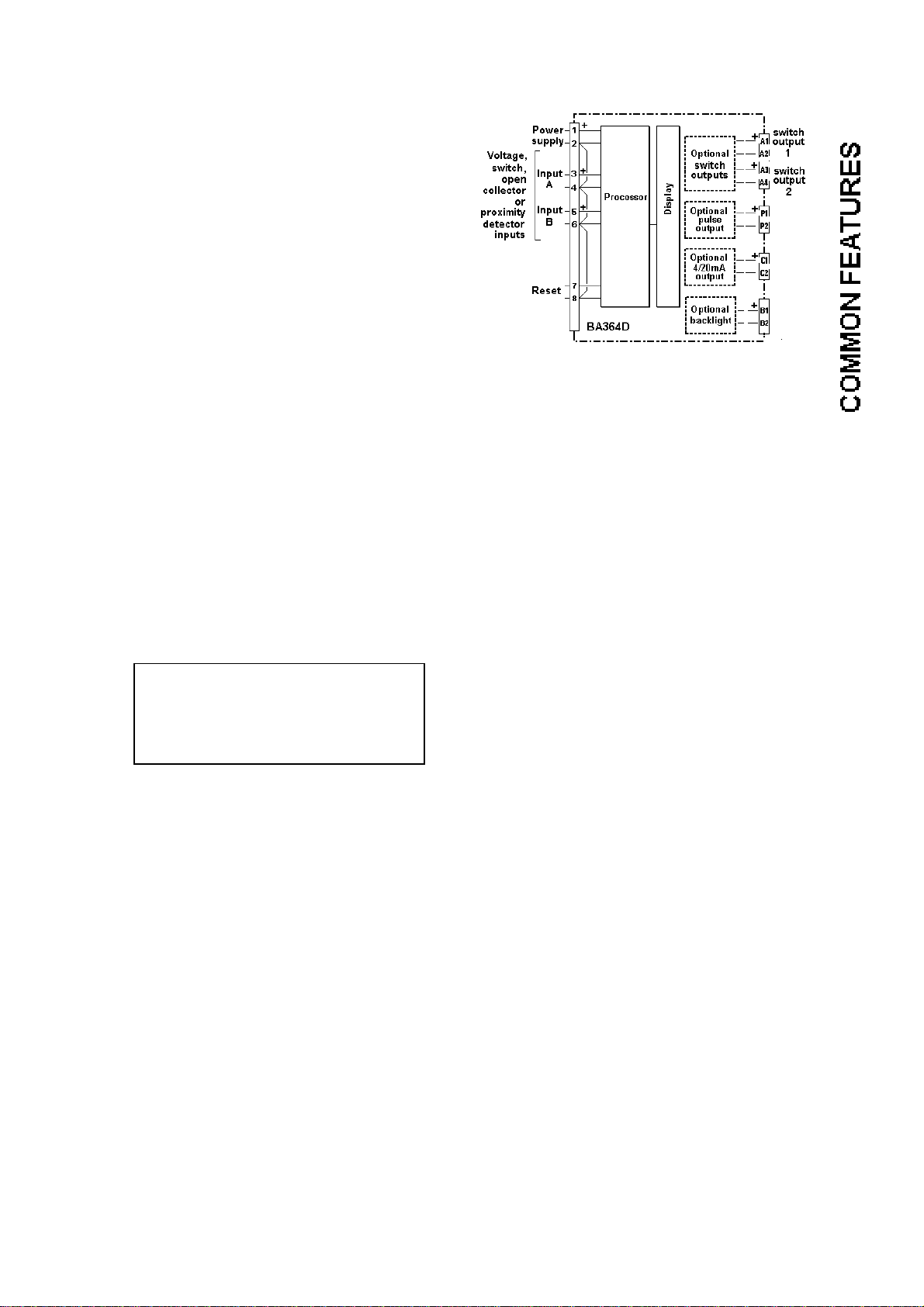

The BA364D has two identical inputs designated

A (terminals 3 & 4) and B (terminals 5 & 6).

Each may be connected to a voltage pulse,

switch, open collector or certified intrinsically safe

2-wire proximity detector. The safety parameters

of each input are:

Ui = 28V dc

Ii = 100mA dc

Pi = 0.7W

Uo = 10.5V dc

Io = 9.2mA dc

Po = 24mW

Note: when programmed as a tachometer only

one input may be used and when programmed

as a clock neither of the inputs are available.

Hazardous area mechanically operated switches

comply with the requirements for simple

apparatus and may be directly connected to

either input. Similarly, optically isolated open

collector outputs that comply with the

requirements for simple apparatus may also be

directly connected to either input.

The BA364D system certificates specify some of

the intrinsically safe 2-wire proximity detectors

that may be connected directly to the two

instrument inputs. Other certified intrinsically

safe detectors may be used providing their input

safety parameters less than the BA364D output

parameters.