6

INSTALLATION AND ASSEMBLY

- CAUTION -

Do NOT connect the power source until after the

air cleaner is completely assembled.

If the air cleaner must be turned on for an

electrical check, be extremely careful in avoiding

electrical shock. Also, take care to avoid the air

cleaner’s moving parts.

INSPECTION

The MistBuster®Infinity air cleaner should be

checked for any shipping damage that may have

occurred during shipping. Any damage should be

noted and the carrier notified immediately.

TOOLS & EQUIPMENT REQUIRED

The following is a list of tools that would be needed

for typical installations:

•Reciprocating saw

•Drill

•Screwdriver

•Fork truck / Crane

PLANNING THE INSTALLATION

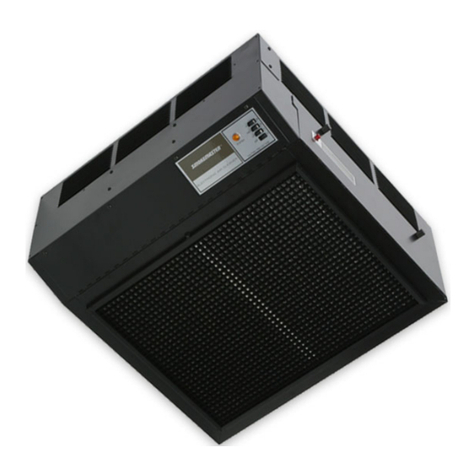

1. The MistBuster®Infinity mist collector

should be located with consideration for

convenience of maintenance and electrical

compartment access.

2. The filter access door on the MistBuster®

Infinity should not be obstructed. You need

a minimum of 26” clear in front of the filter

access door.

3. Mount the MistBuster®Infinity as far from the

chip conveyor opening as possible. This will

minimize the amount of clean outside shop air

from being drawn into the enclosure.

The MistBuster®Infinity can be mounted directly to

the enclosure on a machine tool. The collected

mist droplets simply drain back into the machine

tool through the air inlet of the MistBuster®Infinity.

INSTALLATION DIRECT MOUNT

Remove all filters from the MistBuster®Infinity.

Carefully position the MistBuster®Infinity on the

machine tool in the desired location. Refer to

Planning the Installation for guidelines in

positioning the MistBuster®Infinity on the machine

tool.

1. Use the inlet opening and the mounting hole

pattern on the bottom of the MistBuster®Infinity

as a template to mark the inlet opening and

holes to be drilled into the machine tool

enclosure. If the machine tool enclosure has

been designed with a provision for mist

collection, you may not need to cut an inlet

opening. NOTE: The inlet opening in the

machine tool does not need to be as large

as the inlet of the MistBuster®Infinity. It is

recommended that the inlet opening be a

minimum of 80 square inches.

2. Use a .437 diameter drill bit to drill the

mounting holes for the 3/8-16 bolts used to

secure the MistBuster®Infinity to the machine

tool.

3. There are four mounting holes in the

MistBuster®Infinity. It is recommended that a

minimum of four holes be drilled to secure the

MistBuster®Infinity to the machine tool.

Figure 2