© Copyright AirBench Ltd 2021 Page

7 of 24

Installation

General

•Installation must only be performed by an authorized Technician/Electrician who has carefully

read the installation guide. This is to prevent electric shock or damage to the machine and a

trouble free installation.

•To ensure correct performance, the air cleaner should be properly installed on the machine

tool. The installation area must be stable and vibration-resistant. If the machine is not capable

of supporting the weight of the AOF, use a stand or mount to a wall.

•To maintain efficiency, maintain high bend radius in hoses.

•The electric wiring must comply with electrical standards and should be completed by a

qualified and competent Electrician or Technician.

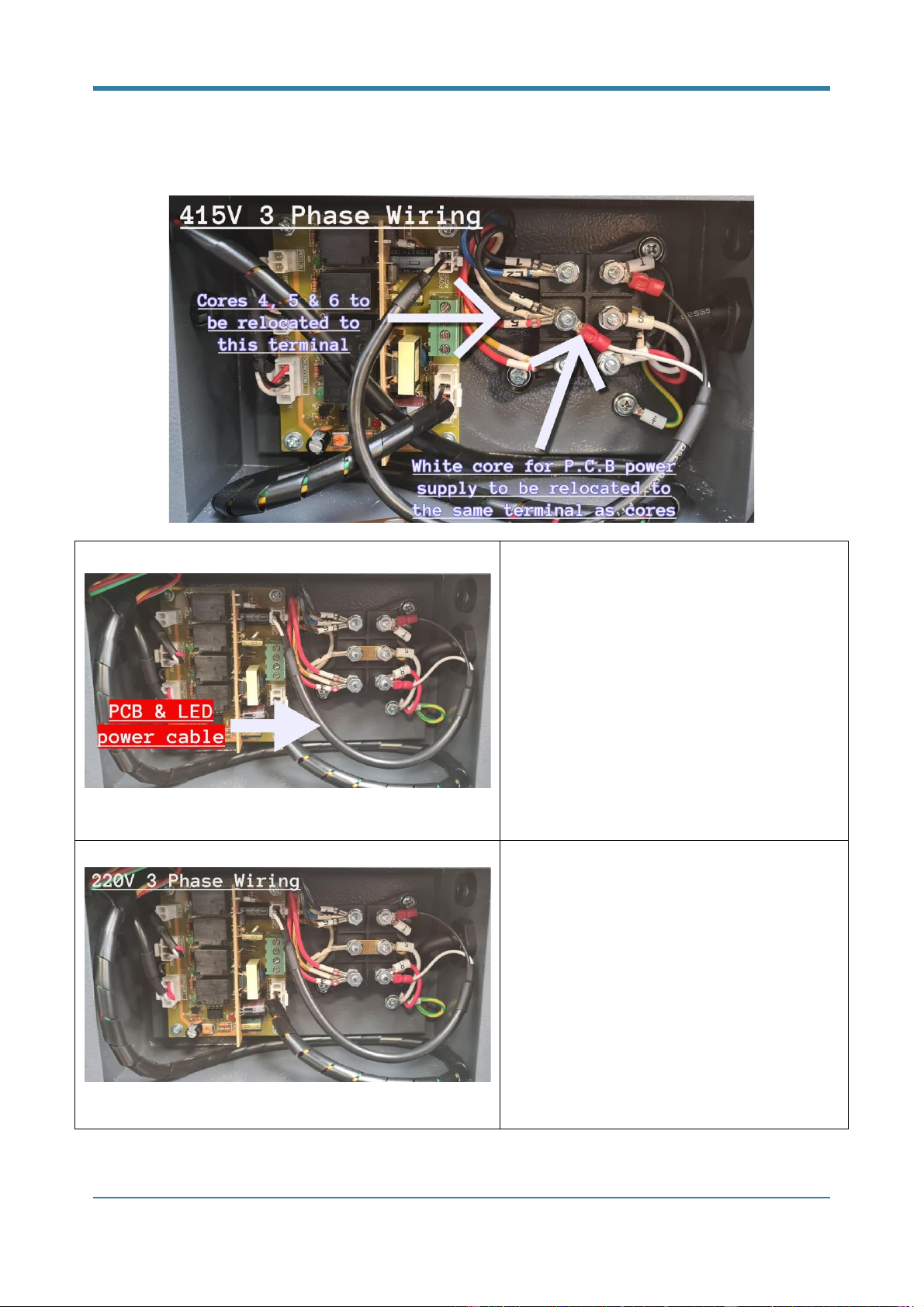

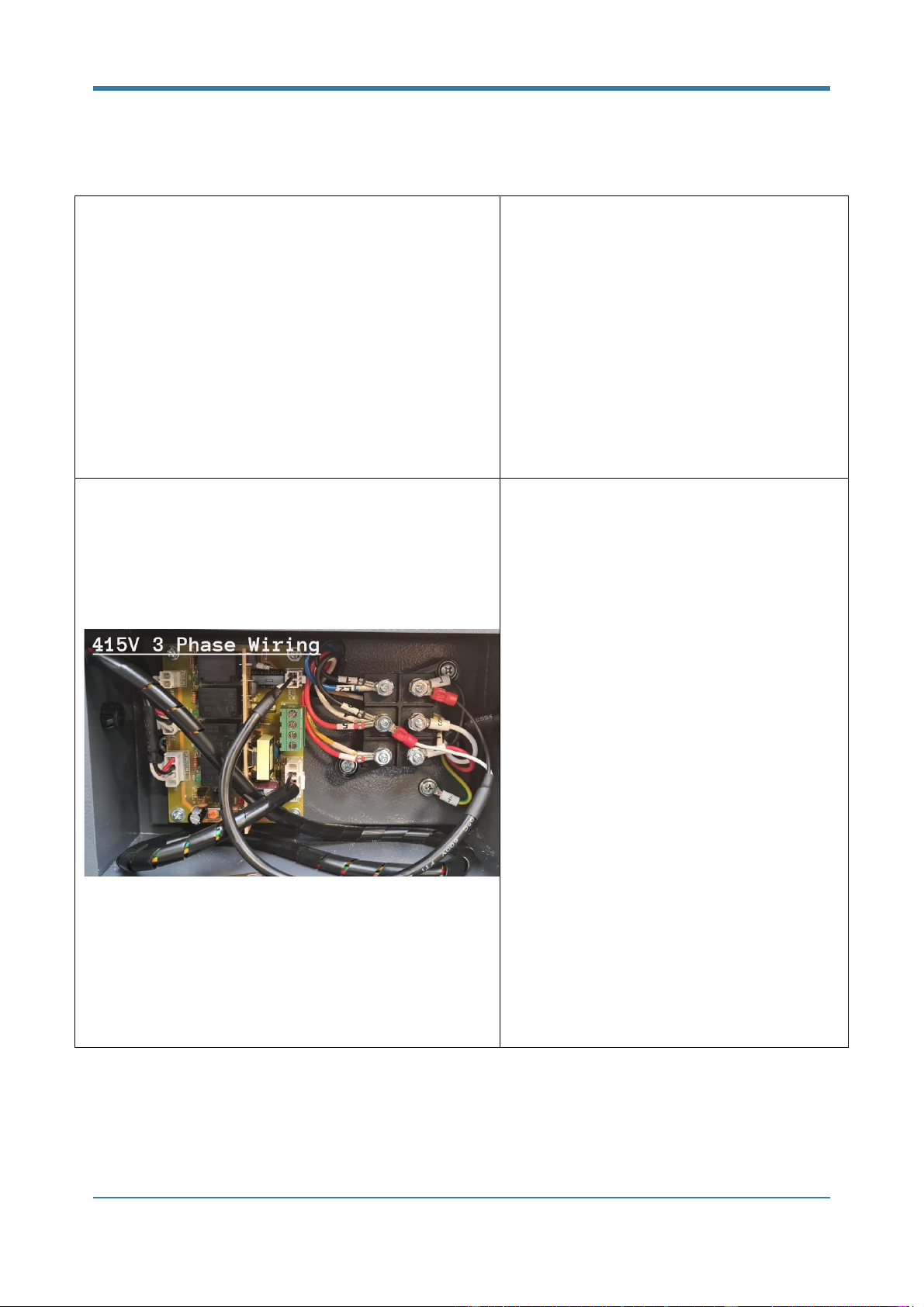

•Our AOF units come pre-wired for 220V 3 phase supply (220/3/50) and may also be

configured for 415V 3 phase (415/3/50). For further electrical information, refer to the

following guidance in this manual.

•When installing the unit, motor / overload protection must be provided. A suitably sized DOL

starter or motor protection circuit breaker should be used.

•Do not change the power wire length or use extension wire.

•After installation, the installer should complete commissioning tests as detailed within this

document.