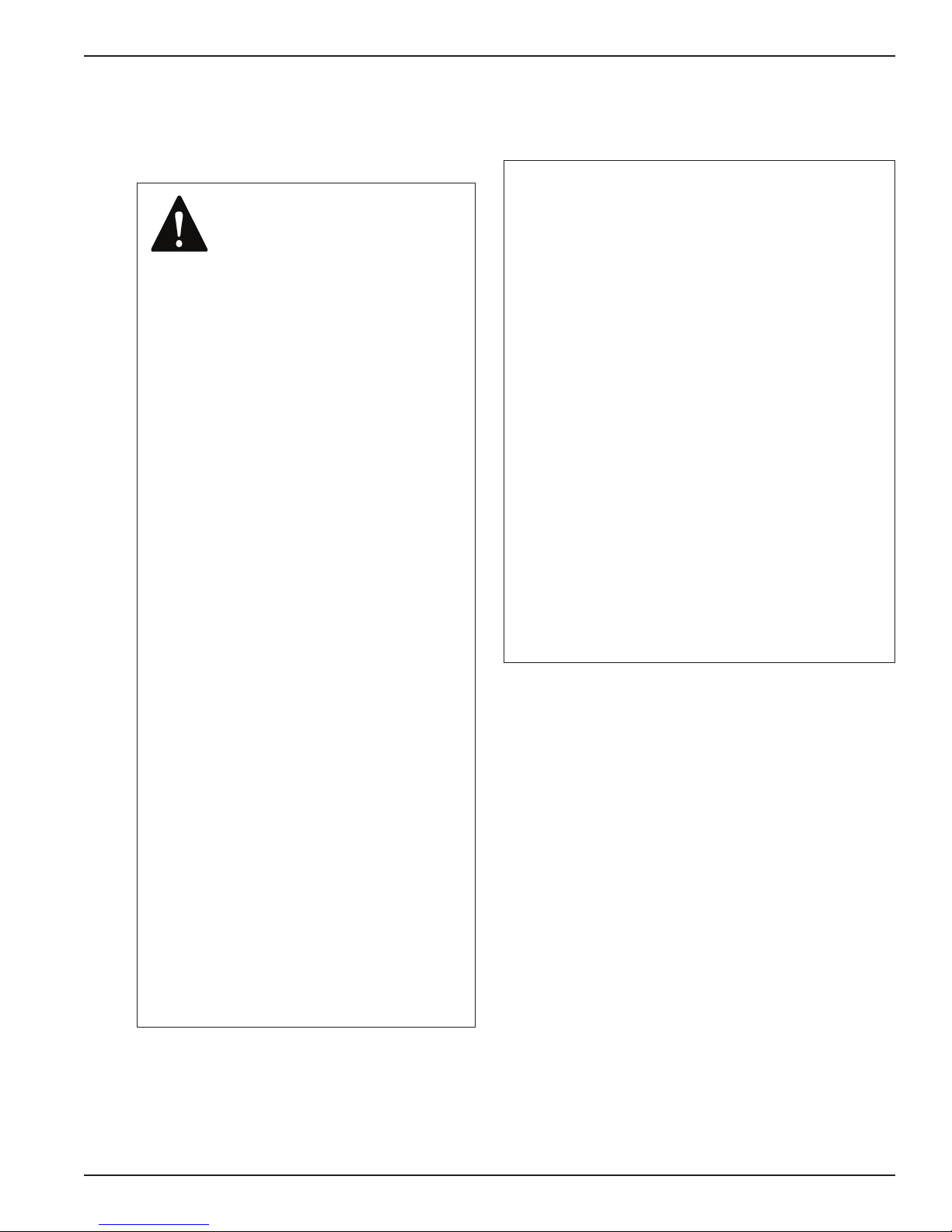

Design Parameters

Typeofdryer:Refrigerated

Powersupply:115,230,460Volt/singleorthree

phase/60Hz

Refrigeranttype:R-134A&R-404A

ChemicalComposition:HFC

Parameter

Description

Optimum Maximum Minimum

AirPressure

(PSIG) 100-125 200 80

AirInlet

Temperature(°F) 80-100 100 40

Ambient

Temperature(°F) 75 100 32

SuctionGauge

Reading(psig) 28-40 60 28

DischargeGauge

Reading(psig) 160-250 350 80

Evaporator

Temperature(°F) 38-42 60 33

Description

System

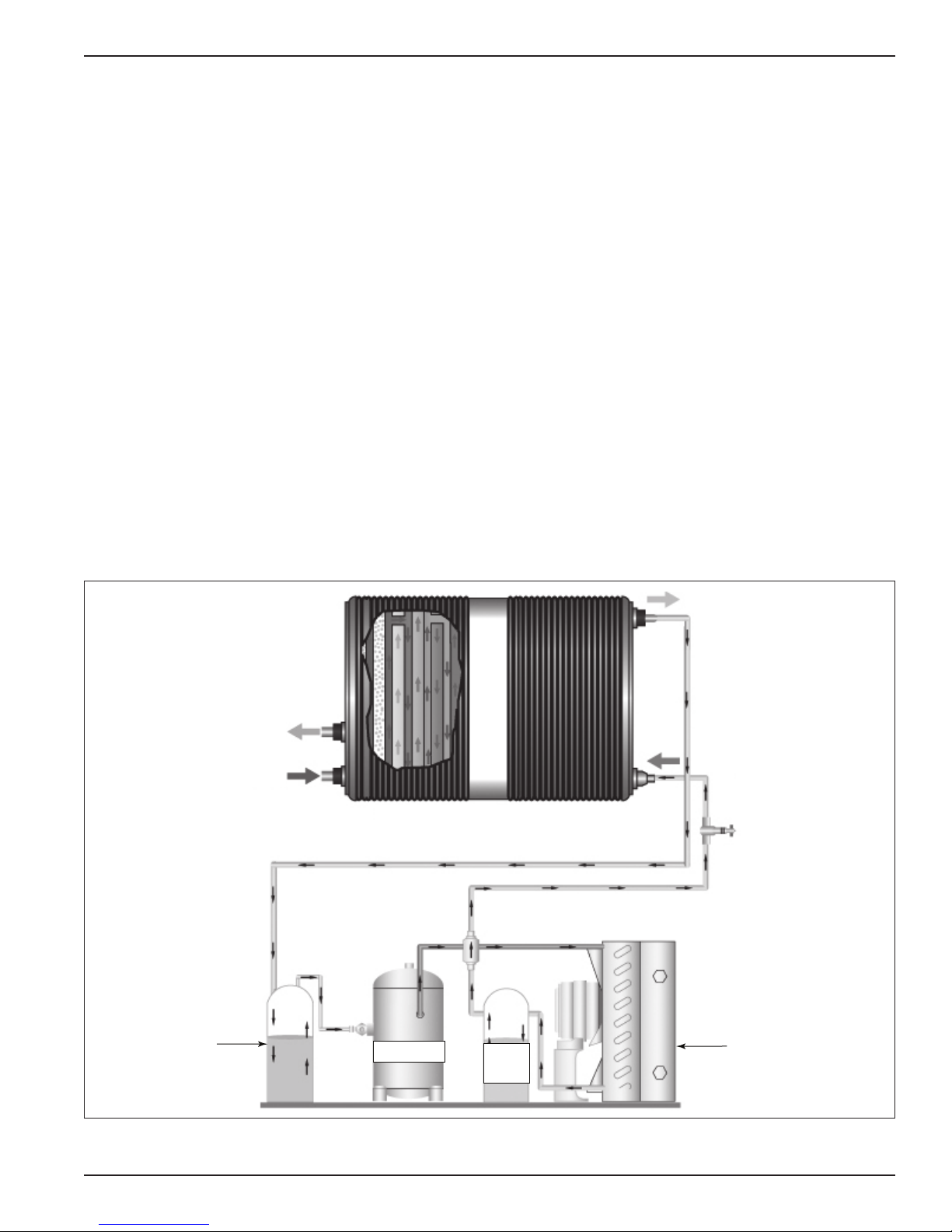

The non-cycling refrigerated air dryer product

covers the flow range listed on the manual front

cover and provides reliable, dew point performance

in most flow conditions. Through optimization

ofcriticaldryercomponents–heatexchanger,

separator, and condensate removal – the system

ensures the highest performance at full- and partial-

load conditions. Environmentally refrigerant is

used in all refrigerated compressed air dryers. the

refrigerants used provide consistent performance

(zero temperature glide) and easy service.

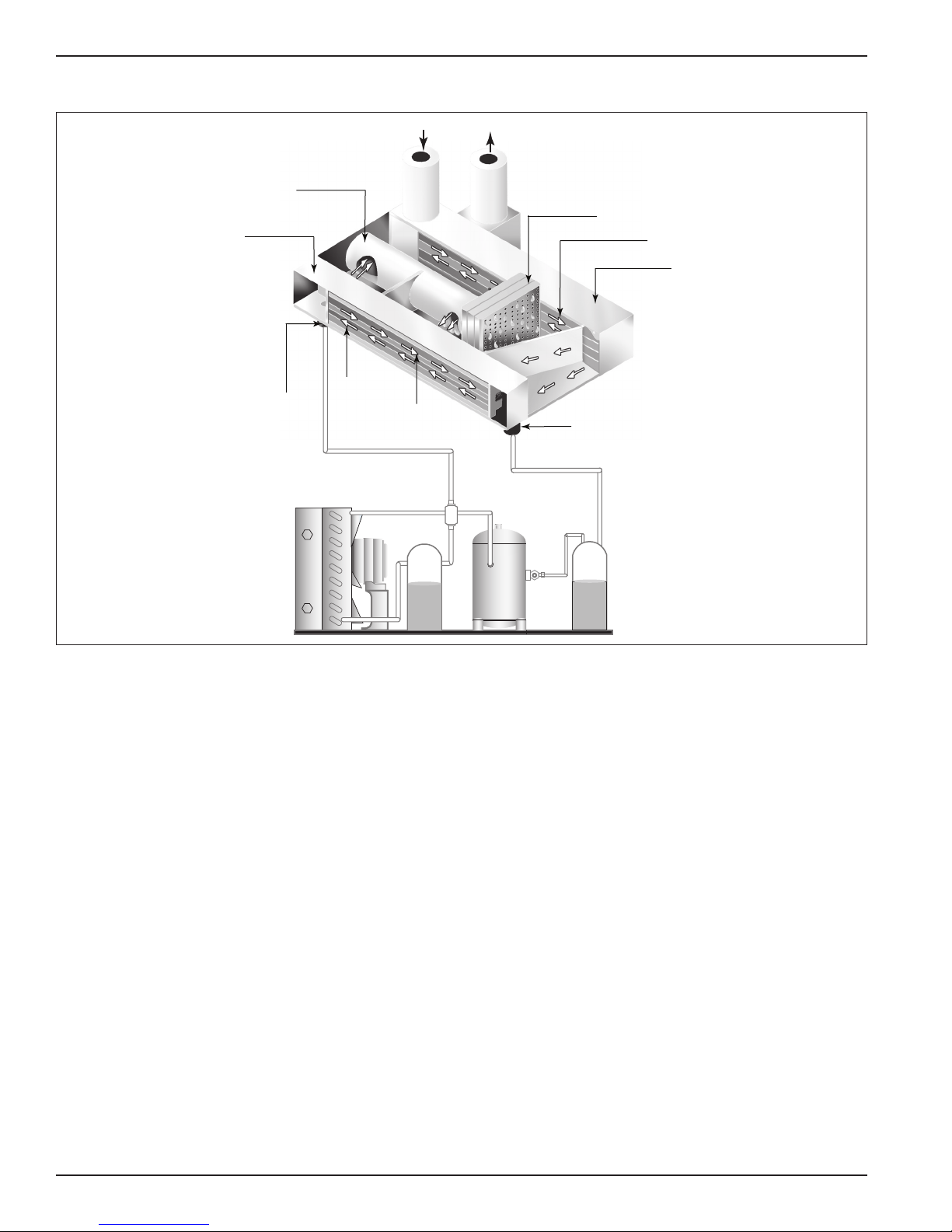

Hot saturated air enters the air-to-air heat

exchangeroftheNon-CyclingRefrigeratedAir

Dryerandisprecooledbytheoutgoingdryair.

Precoolingsavesenergybyreducingtheheatload

on the dryer’s compressor. The cool saturated air

enterstheair-to-refrigerantheatexchangerwhere

airtemperatureisloweredtothe38to42°Frange.

This dramatic temperature drop condenses water

and oil.

Themixtureofcoldairandcondensationthen

flows into the two-stage separator filter where

liquids and contaminants are removed by

centrifugal action, directional flow change, and

velocityreduction.Oncebulkliquidshavebeen

removed, the compressed air goes through a

stainless steel mist eliminating filter that coalesces

oilaerosolsandoilvaporswithinthe50-micron

range, and then separates and removes them. At

this point, the compressed air is dry and virtually

oil-free.

Cold,dryairexitsthroughtheprecoolerheat

exchangerandisreheatedbyincominghotair.

Reheatingrestoresenergyandalsoprevents

condensation from forming on the outside of air

distributionpiping.Intherefrigerationunit,the

compressor pumps hot, high-pressure gaseous

refrigerant to the condenser where it is cooled

andliquefiedbyambientair.Fromthecondenser,

liquid refrigerant first flows through the receiver,

then through a filter/dryer, and finally through the

expansionvalvewherepressureandtemperature

are reduced. This reduction in pressure causes

the liquid refrigerant to boil until it reaches the

saturation temperature that corresponds to its

pressure. As the low-pressure refrigerant passes

through the evaporator, heat flows from the

compressed air to the refrigerant, causing the

boiling to continue until all refrigerant is vaporized.

Refrigerantgasisreturnedtothecompressorand

the cycle is repeated. A hot gas by-pass valve is used

to control temperature in the evaporator.

6

AircelVFSeries-Models10-1200