| VF, DHT, AES Series Manual

Refrigerated Air Dryer User Manual

4

2.1 Introduction

Refrigerated air dryers are designed to remove moisture

from compressed air by use of mechanical refrigeration

and are used to protect industrial compressed air systems,

machinery, and tools. They are designed to deliver the

required dew point at specified inlet air temperature,

inlet air pressure, inlet flow, and ambient temperature

conditions.

2.2 System

The VFS, DHT, and AES Series refrigerated air dryer

products cover the flow range listed on the manual front

cover and provides reliable dew point performance in

all flow conditions. Through optimization of critical dryer

components – heat exchanger, separator, and condensate

removal – the system ensures the highest performance at

full- and partial load conditions.

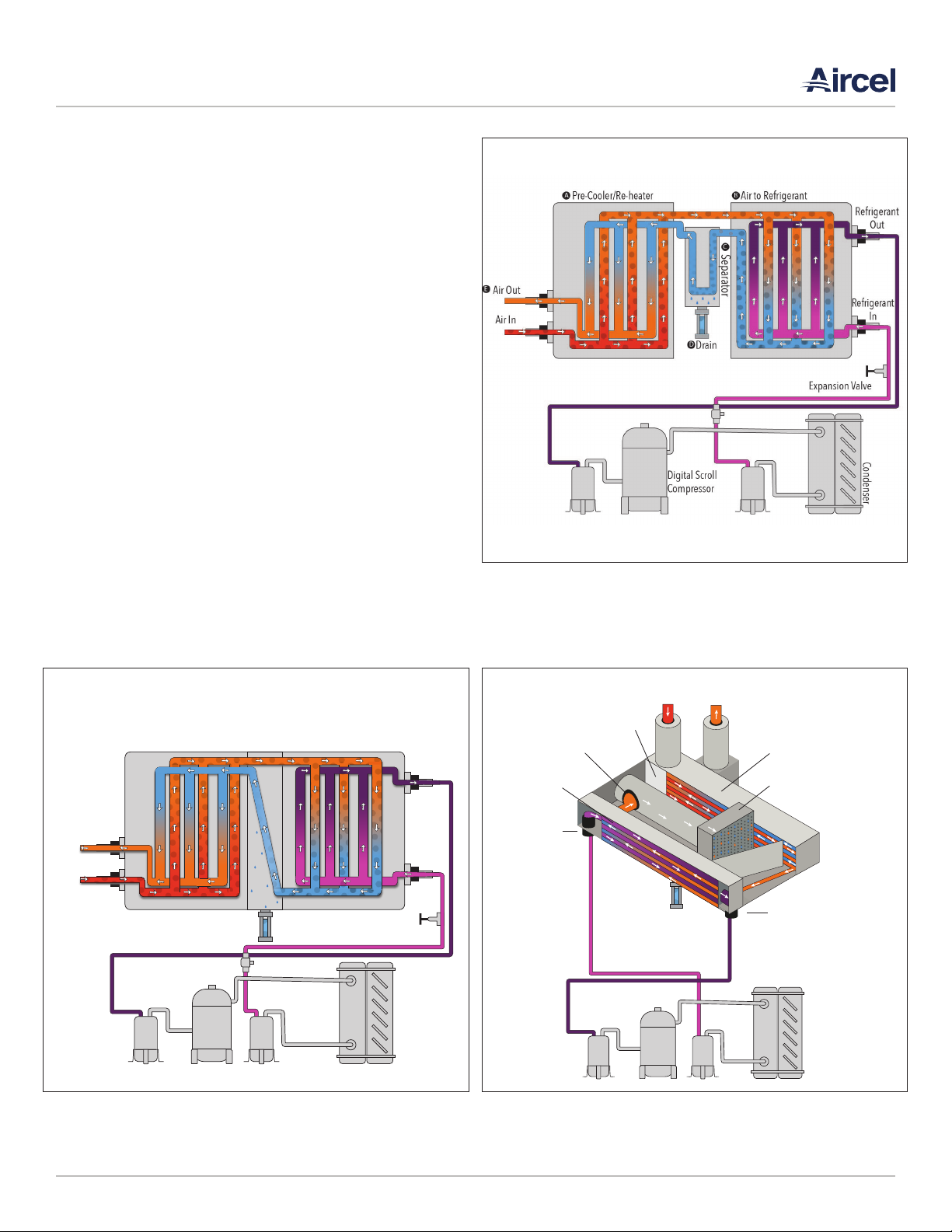

Hot saturated air enters the air-to-air heat exchanger of the

refrigerated air dryer and is pre-cooled by the outgoing dry

air. Pre-cooling saves energy by reducing the heat load on

the dryer’s compressor. The cool saturated air enters the

air-to-refrigerant heat exchanger where air temperature is

lowered to the 38 to 42°F range. This dramatic temperature

drop condenses water and oil.

The mixture of cold air and condensation then flows into the

two-stage separator filter where liquids and contaminants

are removed by centrifugal action, directional flow change,

and velocity reduction. Once bulk liquids have been

removed, the compressed air goes through a stainless steel

mist eliminating filter that coalesces oil aerosols and oil

vapors within the 50-micron range, and then separates and

removes them. At this point, the compressed air is dry and

virtually oil-free.

Cold, dry air exits through the pre-cooler heat exchanger

and is reheated by incoming hot air. Reheating restores

energy and also prevents condensation from forming on

the outside of air distribution piping. In the refrigeration

unit, the compressor pumps hot, high-pressure gaseous

refrigerant to the condenser where it is cooled and liquefied

by ambient air. From the condenser, liquid refrigerant first

flows through the receiver, then through a filter/dryer, and

finally through the expansion valve where pressure and

temperature are reduced. This reduction in pressure causes

the liquid refrigerant to boil until it reaches the saturation

temperature that corresponds to its pressure. As the low-

pressure refrigerant passes through the evaporator, heat

flows from the compressed air to the refrigerant, causing

the boiling to continue until all refrigerant is vaporized.

Refrigerant gas is returned to the compressor and the cycle

is repeated.

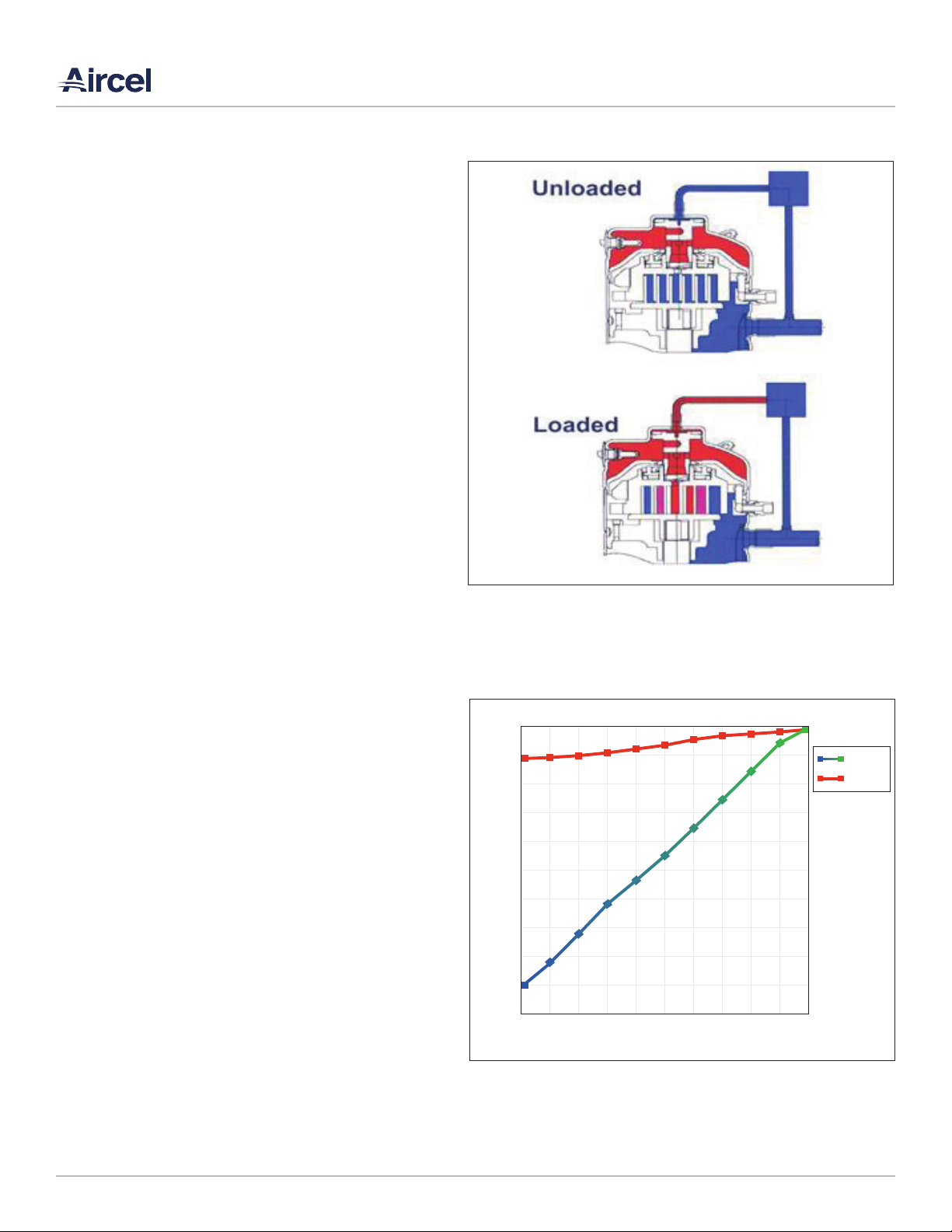

In the VF and DHT Series dryers, a hot gas by-pass valve is

used to control temperature in the evaporator. In the AES

Series, the Copeland Scroll Digital™ compressor allows the

system to eliminate the need for a hot gas by-pass valve.

The closed loop digital controller continuously monitors the

evaporator temperature and modulates the loading and

unloading of the refrigeration compressor based on current

load conditions.

2.3 Refrigeration Circuit

Refrigerant is cycled through a closed loop system commonly

known as high pressure and low pressure. Refrigerant

is compressed by the compressor to a gas with high

temperature and high pressure, which then travels to the

condenser (air- or water-cooled) to lower the temperature

and condense the gas into a liquid. Liquid travels to the

evaporator (refrigerant-to-air part of the heat exchanger)

and back to the compressor suction side. The process then

repeats. A hot gas by-pass valve is used on the non-cycling

VF Series dryers as a freeze protector in low load conditions

(100 scfm rated models [1/2 Hp] and up).

2.3.1 TYPES OF REFRIGERANT USED

R-134a refrigerant is used in dryer models rated 1200 scfm

and below, while R-404A is used in the VF-1600 and higher.

R-134a is a pure refrigerant providing consistent

performance (zero temperature glide) and easy service (no

mixture of different refrigerants). R-404A is a blend of three

pure refrigerants: 52% R-143A, 44% R-125, and 4% R134A

(by mass). This blend is nearly azeotropic meaning it has a

negligible temperature glide. R404A is well suited to larger

is nearly azeotropic meaning it has a negligible temperature

glide. R404A is well suited to larger equipment as the higher

operating pressures and improved heat transfer properties

allow for smaller condensers, which leads to air dryers with

smaller footprints.

2.4 Compressed Air Circuit

The compressed air dryer circuit uses a patented air-to-air

heat exchanger (VF Series 50 scfm and up, DHT Series 40

scfm and up), and stainless steel brazed plate air-to-air heat

exchanger (AES Series). These heat exchangers act as a pre-

cooler/reheater. Hot, saturated, compressed air first enters

the air-to-air heat exchanger, where it is pre-cooled by

outgoing air from the air-to-refrigerant heat exchanger. This

energy saving heat exchanger provides several advantages,

SECTION 2: DESCRIPTION