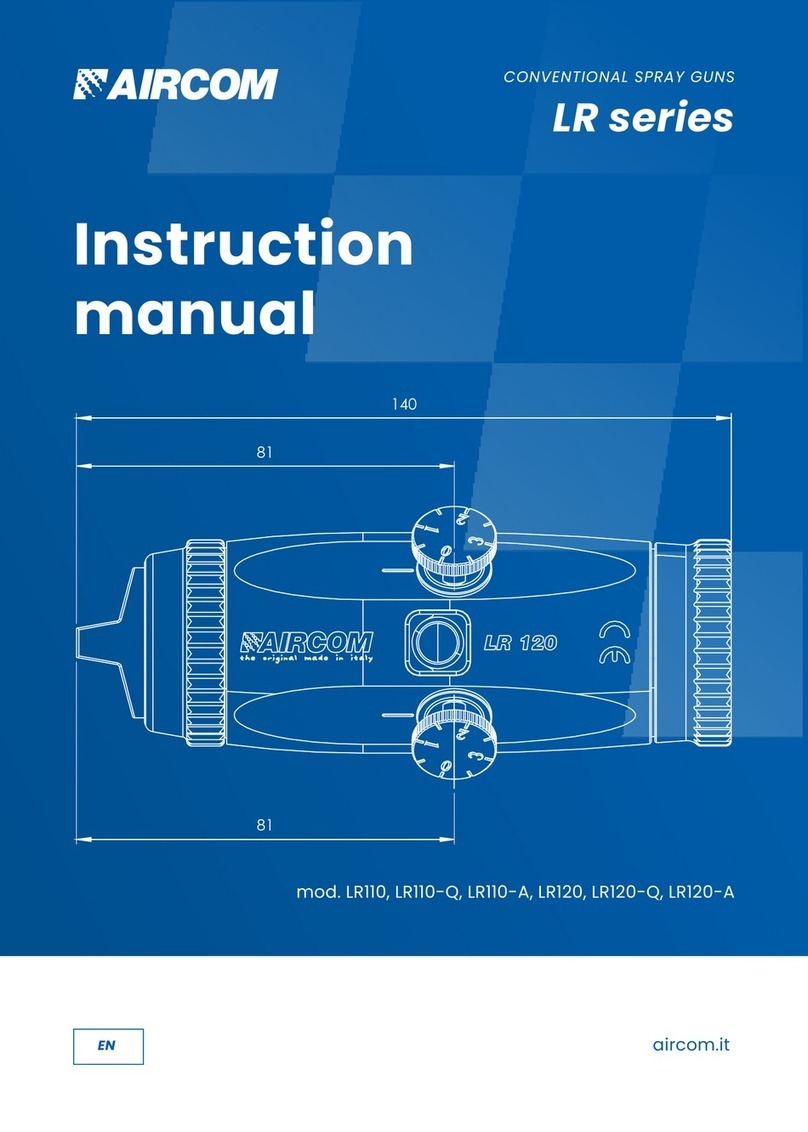

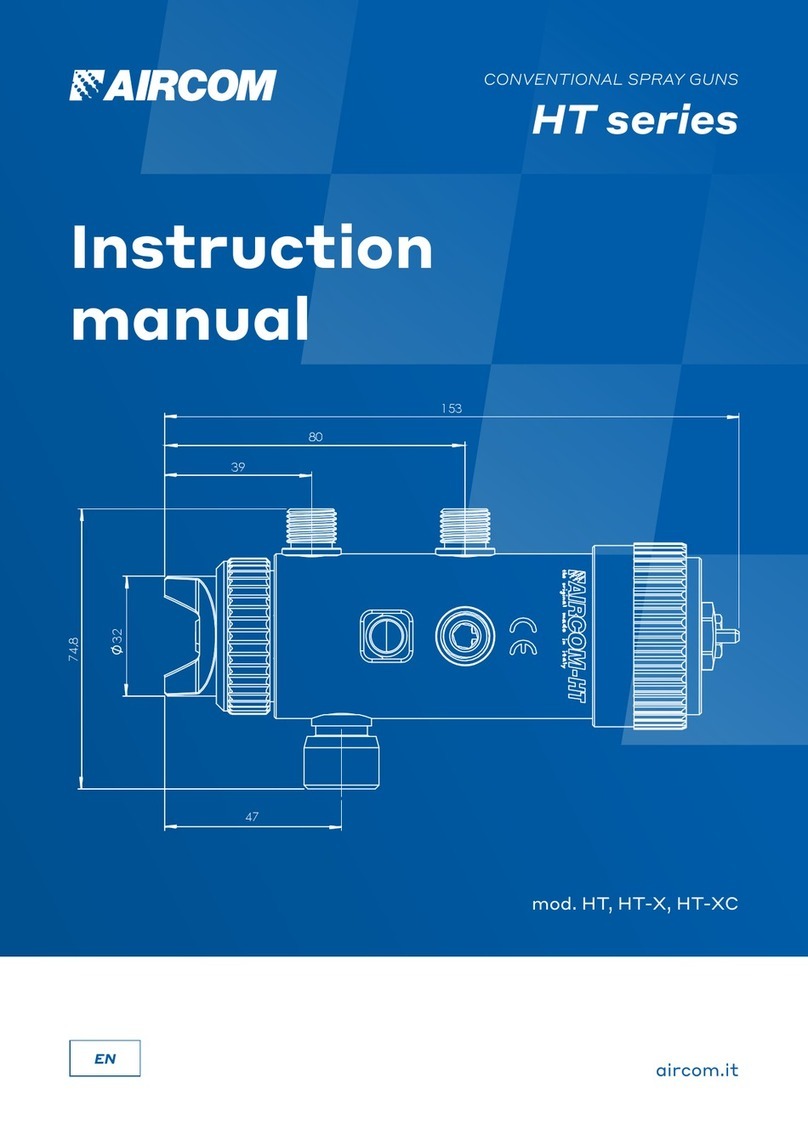

AirCom HT Series User manual

Other manuals for HT Series

1

This manual suits for next models

3

Table of contents

Other AirCom Paint Sprayer manuals

AirCom

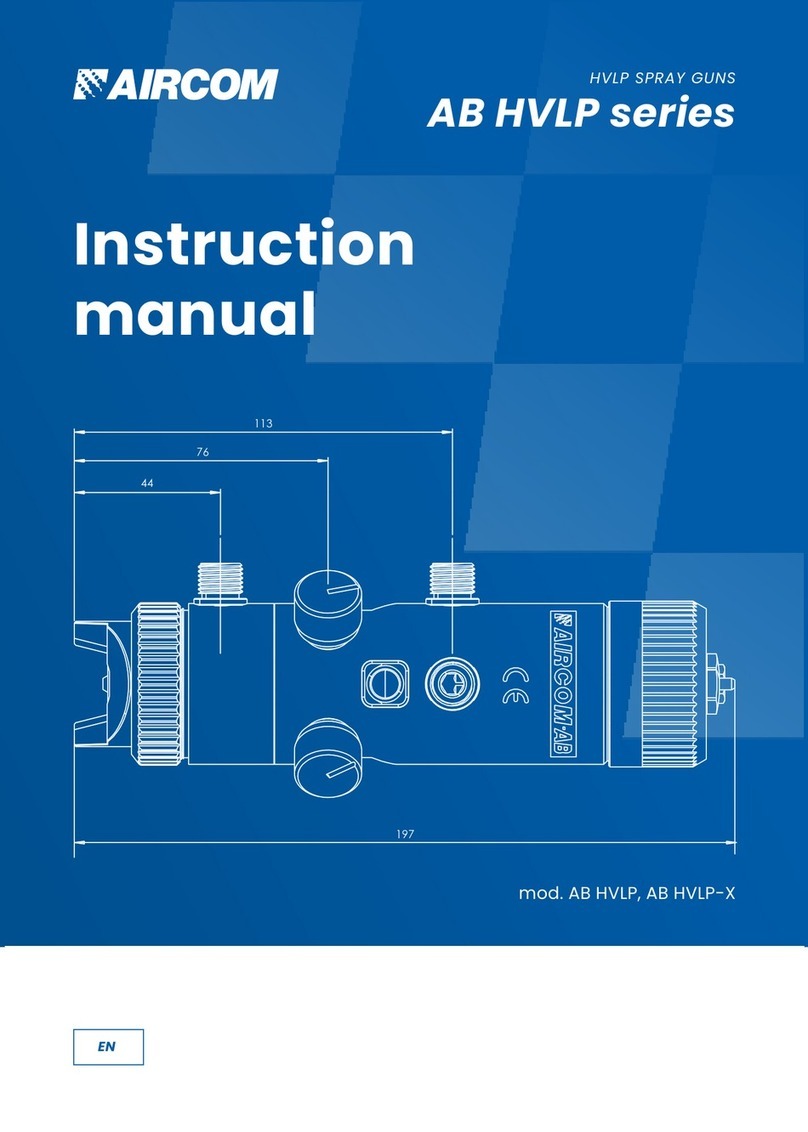

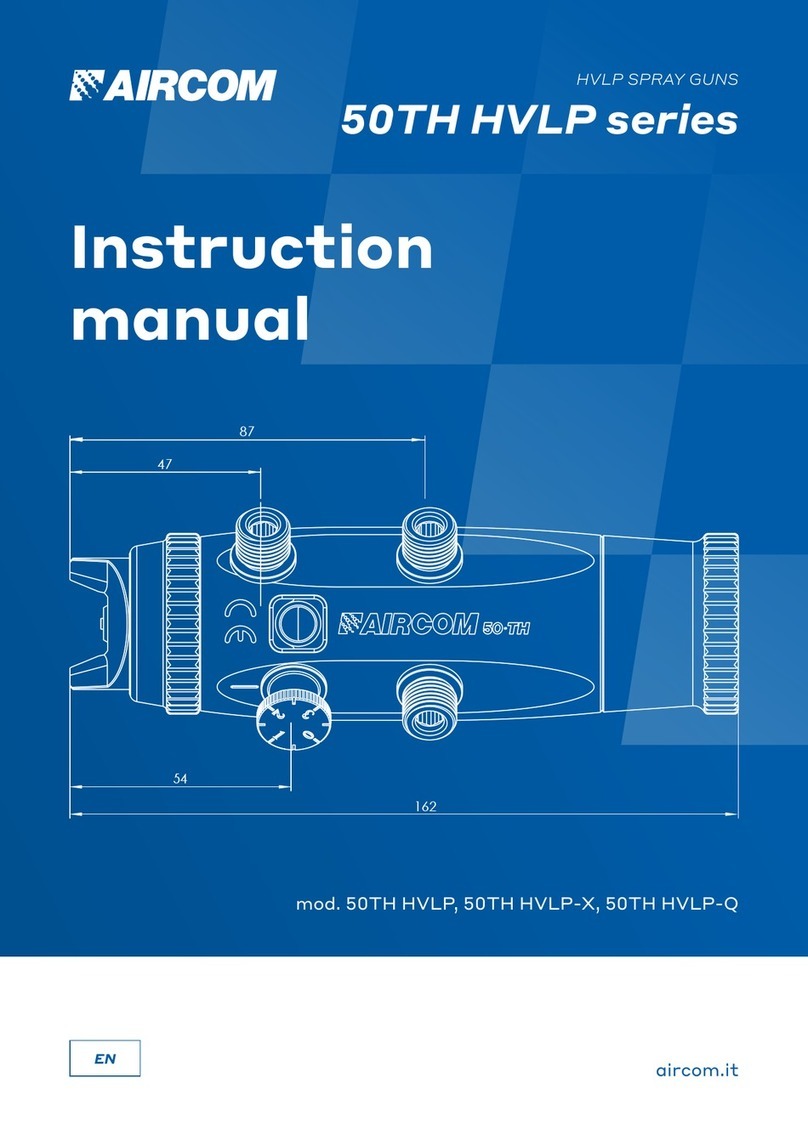

AirCom 50TH HVLP Series User manual

AirCom

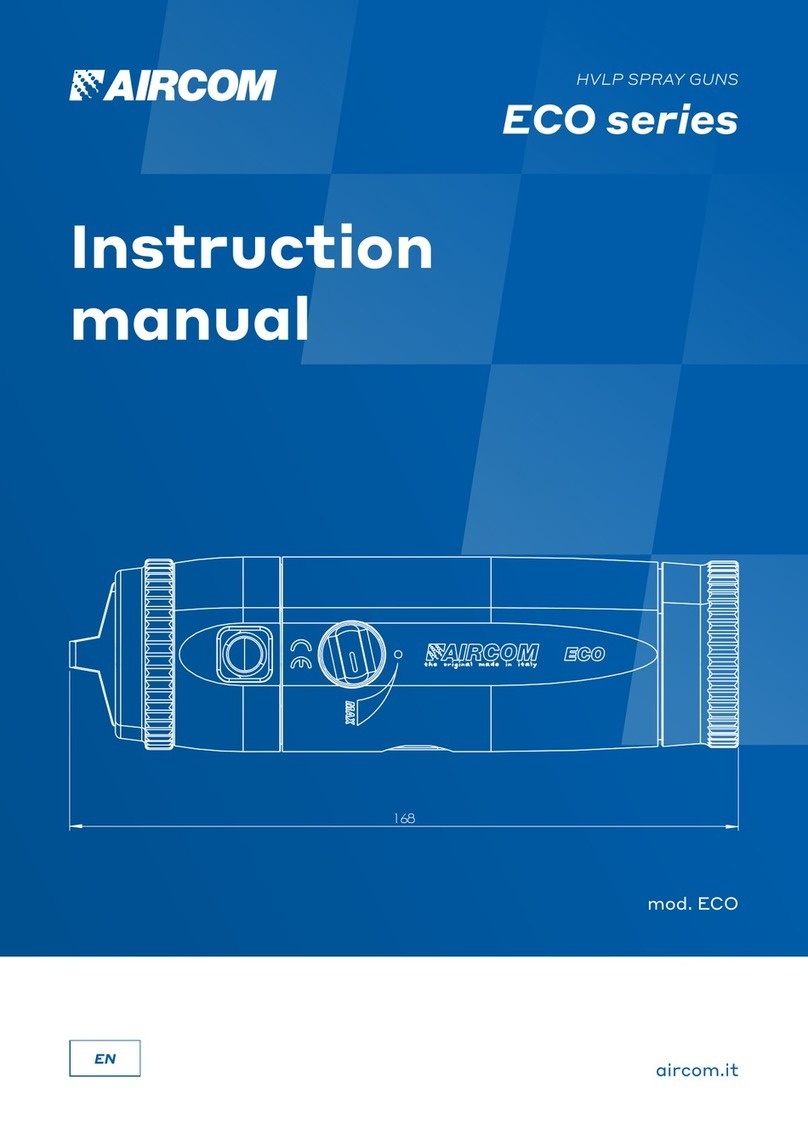

AirCom ECO Series User manual

AirCom

AirCom HT Series User manual

AirCom

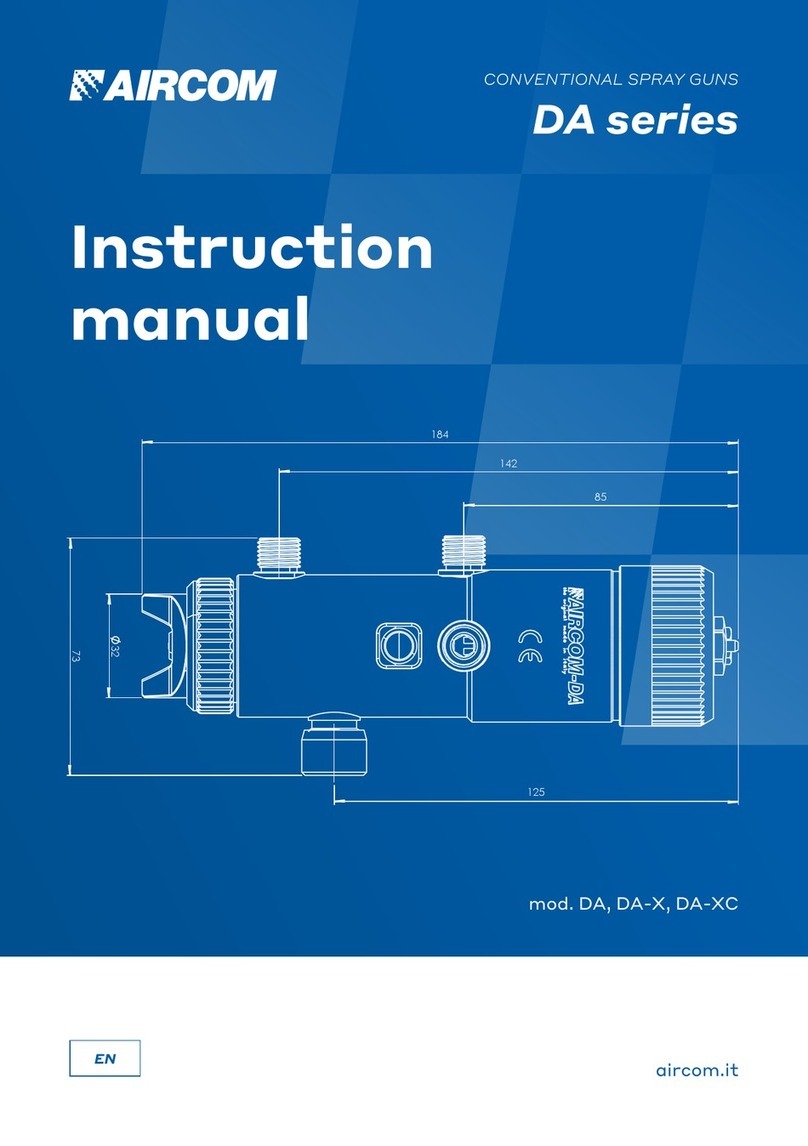

AirCom DA Series User manual

AirCom

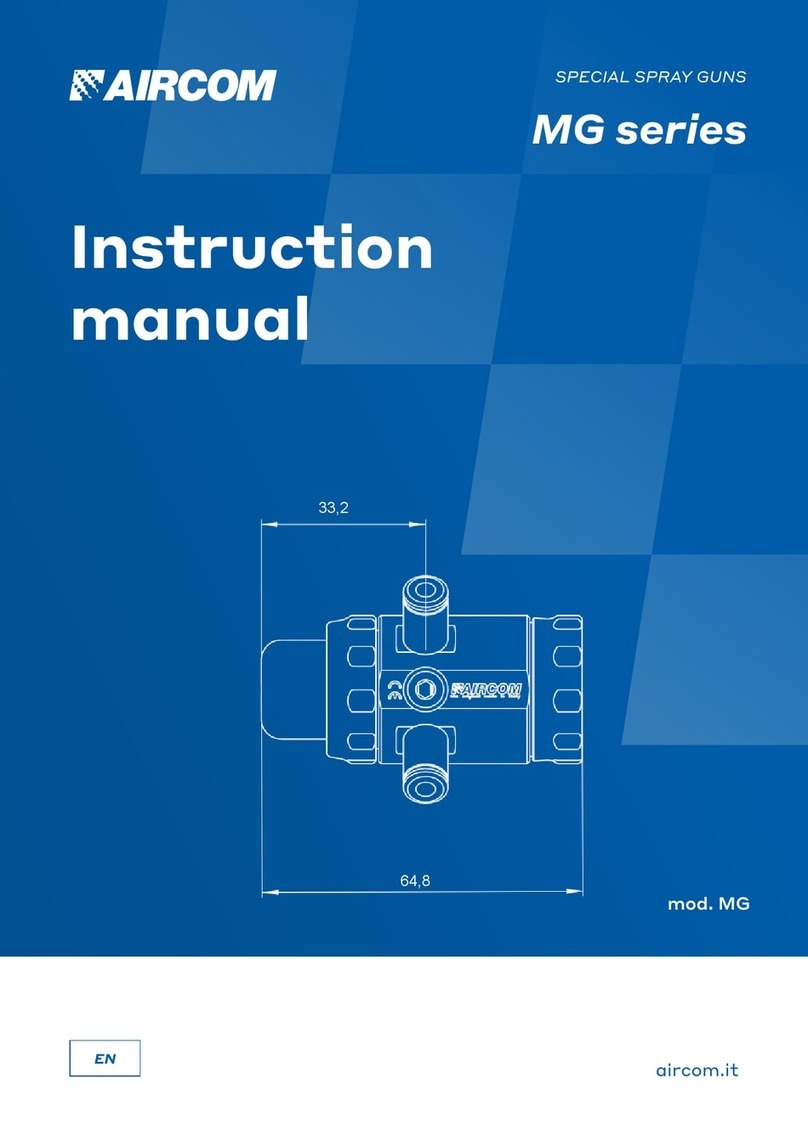

AirCom MG1349 Series User manual

AirCom

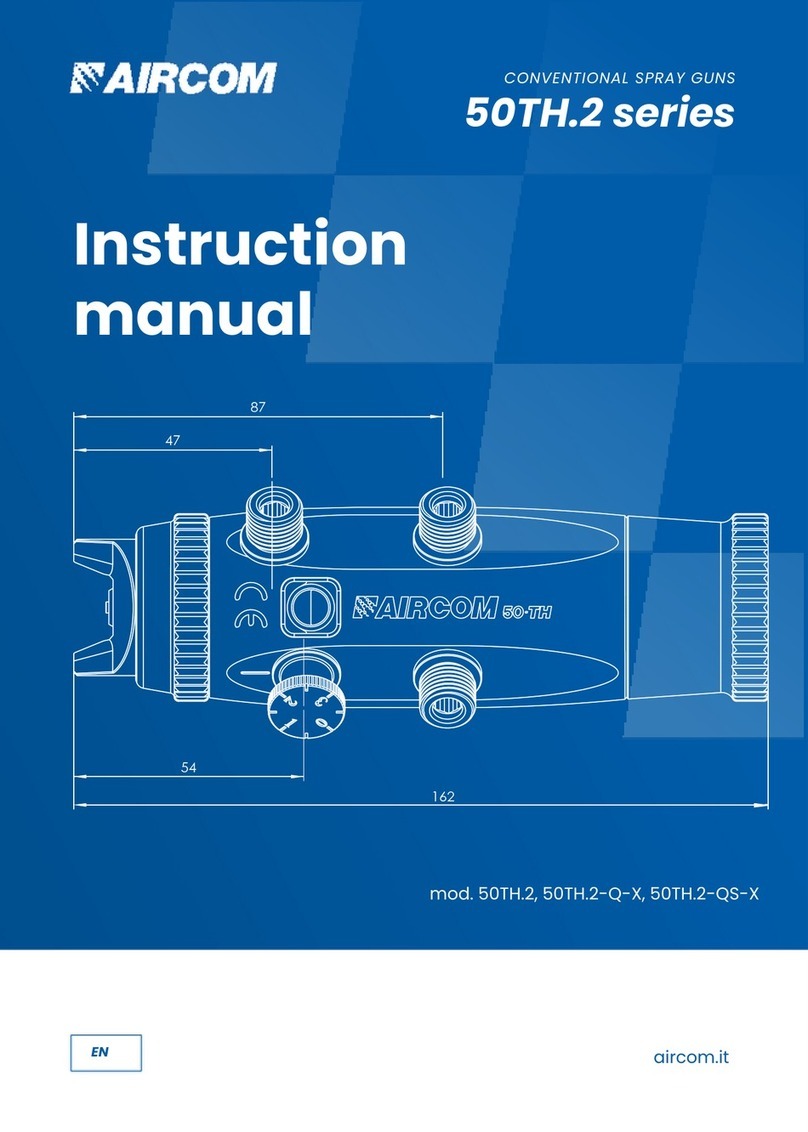

AirCom 50TH.2 HVLP Series User manual

AirCom

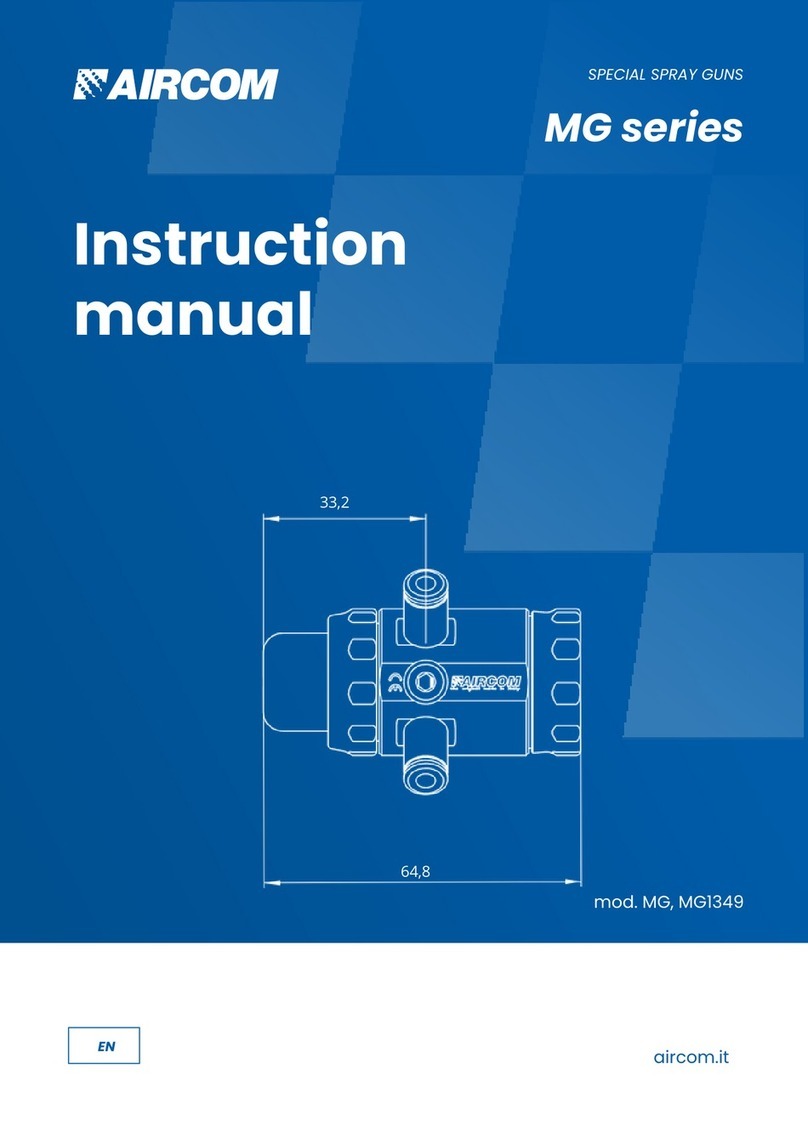

AirCom MG Series User manual

AirCom

AirCom ECO Series User manual

AirCom

AirCom A16 Series User manual

AirCom

AirCom 50TH.2 HVLP Series User manual

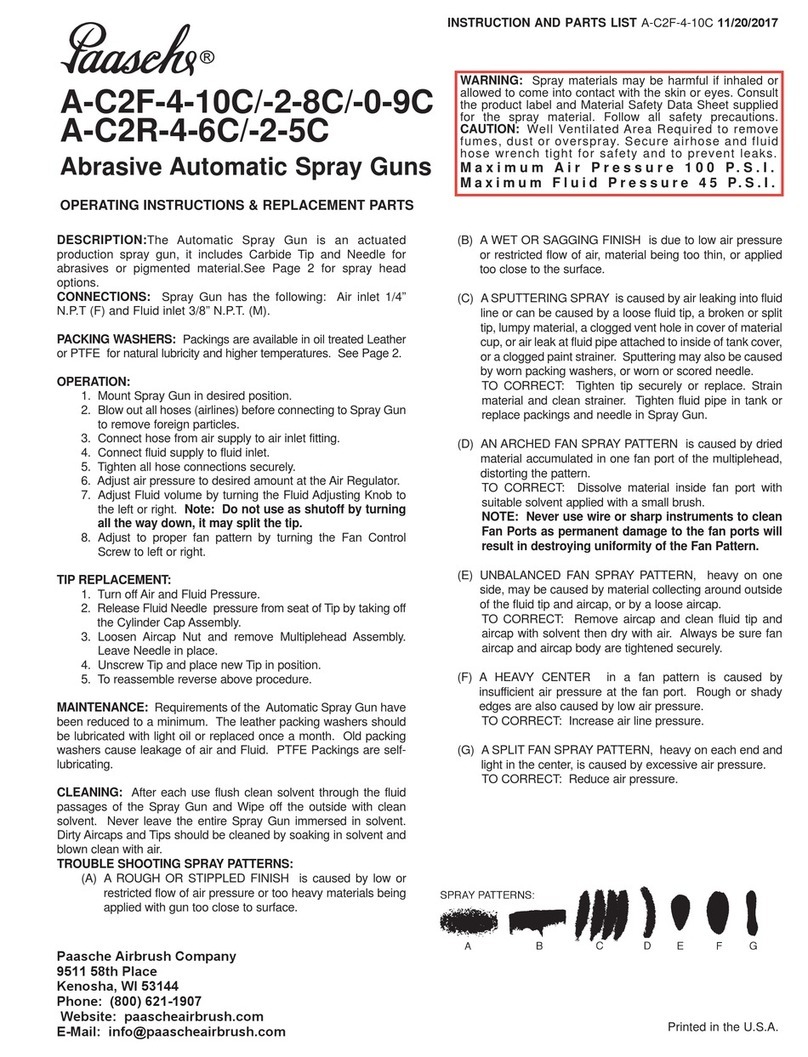

Popular Paint Sprayer manuals by other brands

Dramm

Dramm MS071EH Owner's/operator's manual

Lube Shuttle

Lube Shuttle mato LubeJet-eco operating instructions

Fast Mover

Fast Mover FMT3000 Product instruction manual

RainMaker

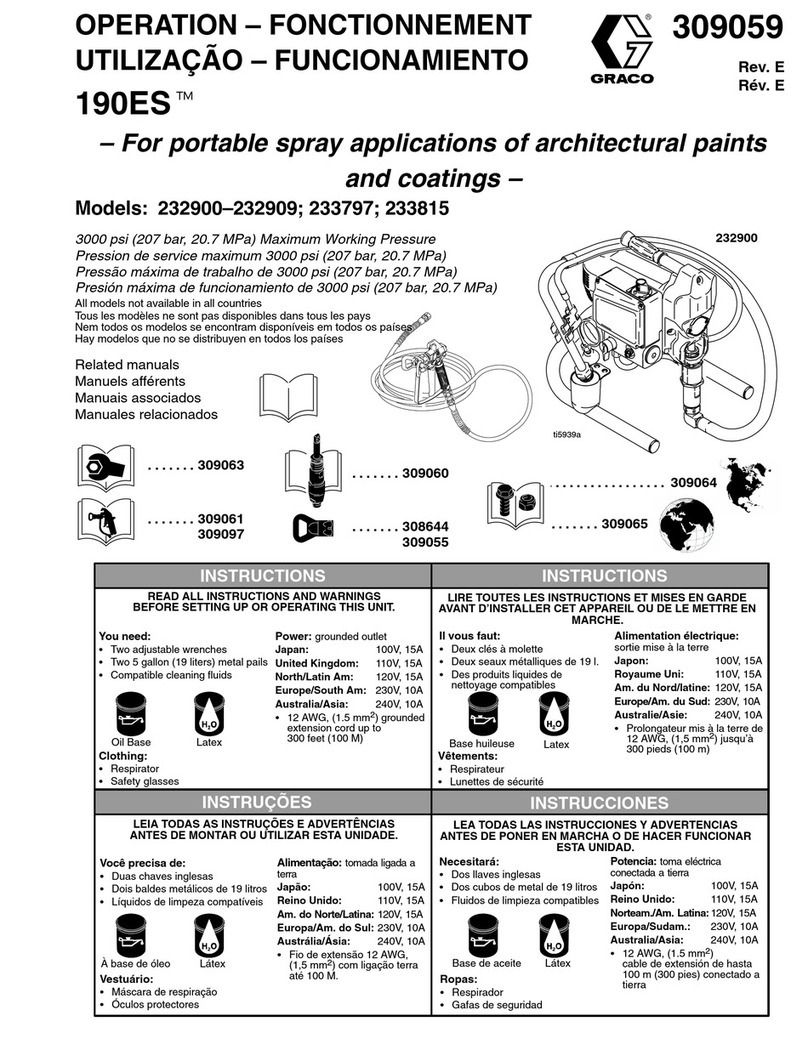

RainMaker 708908 Assembly and operating instructions manual

Chapin

Chapin Commercial DUTY 63900 use and care manual

BESTWAY AG

BESTWAY AG EC-15 owner's manual