AirCom HT Series User manual

AIRCOM®- INSTRUCTION MANUAL - 2022 - v. 1.0

AVAILABLE MODELS

mod. HT

Versatile gun with reduced weight and incumbrance

mod. HT-X

Stainless steel internal passages

mod. HT-XC

Stainless steel inner passages and spray head

HT series

EN

Index

WARNINGS!

Carefully read and follow all instructions and safety precautions before

using the product.

MANUALS

Our manuals are available at aircom.it/en/support/manuals/

Or, by scanning the QR Code on this page.

Instruction Manual

Warnings

Maintenance and cleaning

Installation and start-up

Technical data

Troubleshooting

Spare parts and components

Certified quality

Support

.04

.04

.05

.08

.10

.11

.18

.18

HT series

4 - Instruction Manual aircom.it

HT series

EN

WARNINGS

MAINTENANCE AND

CLEANING

CORROSIVE PRODUCT

WARNINGS

Our guns can be used with the majority

of water, or solvent-based pigments for

coating and nishing all types of surfaces.

However, they are not designed to spray

abrasive and/or corrosive products. If

abrasive and/or corrosive products are

used, guns with components made of the

appropriate material can be ordered.

MAINTENANCE

Before any maintenance work, empty

the gun and disconnect it from both,

the compressed air supply, and the

liquid supply. Use only original AIRCOM®

accessories, spare parts, and related

components: any other product not

supplied by AIRCOM®is not approved or

authorized. AIRCOM®is not liable for any

damage caused by using non-original

spare parts and accessories.

HEALTH HAZARD

Some chemicals, once sprayed, may

be harmful and cause irritation or

health disorders. Careful reading of all

labels and instructions on how to use

the product are necessary. Use of the

product is restricted to trained technical

personnel, with the use of special safety

glasses when adjusting the gun and,

while the system is operating.

CLEANING

Use exclusively appropriate liquid

cleaners with neutral pH 6-8. Do not use

acids, alkaline solutions or other cleaning

agents containing sodium hydroxide,

which are aggressive for cleaning the

exterior of the gun. Do not immerse

the gun in liquid cleaners that may

cause corrosion of the product. Clean

all material passages by propagating

water within the paint circuit: inadequate

cleaning can cause damages to the fan

shape. While cleaning, avoid scratching

the surfaces of the air nozzle holes and

the dipstick.

aircom.it Instruction Manual - 5

HT series

EN

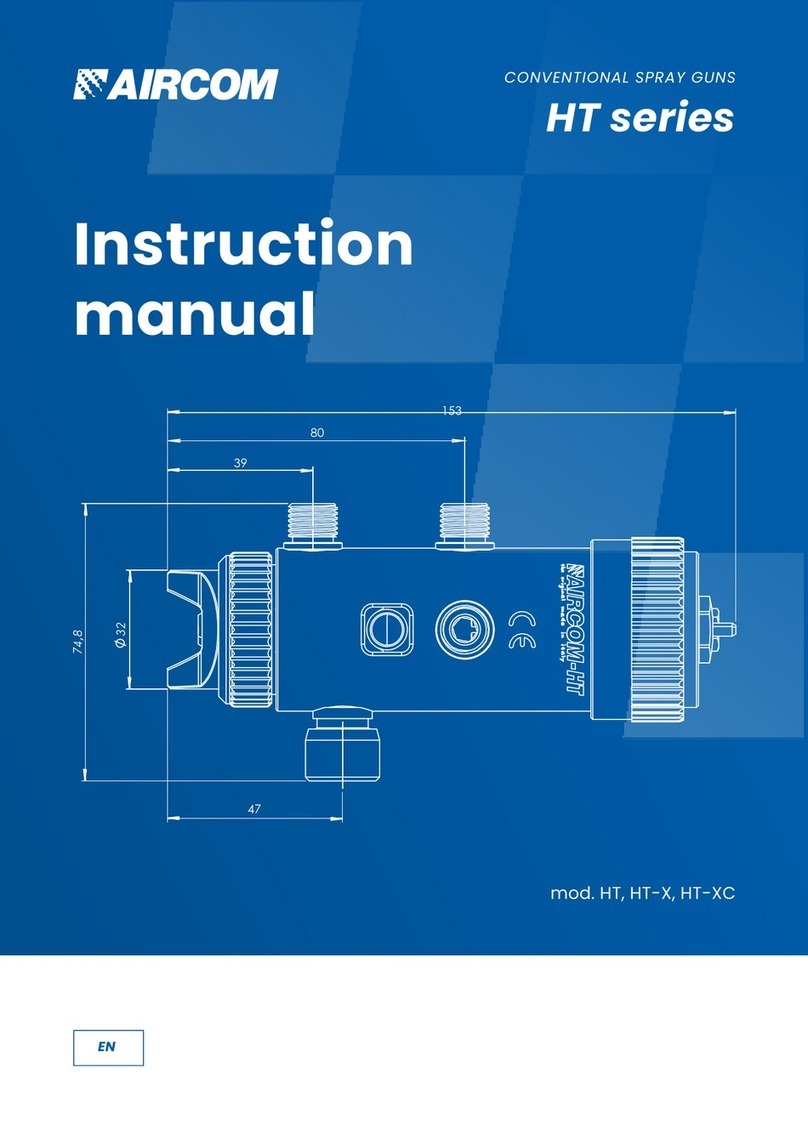

INSTALLATION

TECHNICAL SPECIFICATIONS

Connection hole diameter: 10,5 mm.

Size of pipe junctions:

• Control air inlet: A= ¼ gas

• Atomizing air inlet: B= ¼ gas

• Product inlet: C= ¼ gas

Gun weight: 0,79 kg

Gun size: see dimensioned views

VIDEO TUTORIALS ►

Our video tutorials are available at aircom.it/en/support/tutorials/

Or, by scanning the QR Code on this page.

39

47

153

32

74,8

80

C

B

74,5

50

85

80

10,5

A

6 - Instruction Manual aircom.it

HT series

EN

INSTALLATION AND STARTUP

Before using a new gun or a new product, clean the gun thoroughly

with an appropriate solvent. Powering should be done with dry, ltered

air and regulated to constant pressure.

DIRECTIONS FOR GUN

OPERATION

A

Pipe Ø 6 ÷ 8

Plunger opening ≥ 4.0 to 4.5 bar

B

Pipe Ø 6 ÷ 8

Atomization: 1,5 - 3,5 bar

C

Pipe Ø 6 ÷ 8

Pigment inlet

B

A

C

aircom.it Instruction Manual - 7

HT series

EN

ADJUSTMENT SEQUENCE

1. Lock the gun to the system using

the fastening bracket and orient

the head towards the appropriate

coverage direction.

2. Connect the atomization air, control

air and product piping to the

junctions shown on the previous

page.

3. Screw the handwheel part. [G25]

as far as it will go (do not force

when reaching the stop). Act on the

control air. If no drop of pigment

comes out, remove the control air,

and open the handwheel part. [G25]

with one click. Repeat the process

until the rst drop appears.

4. Open the handwheel part. [G25]

with the necessary clicks to

determine the desired amount of

pigment.

5. Act on the adjustment screw part.

[7] to obtain the desired atomization

range.

20 shots per revolution

1

2

3

4

5

6

7

9

10

11

12

13

14 15

8

16

17

18

19

20 0

8 - Instruction Manual aircom.it

HT series

EN

TECHNICAL DATA

HEAD

ø NOZZLE

SHOTS FLOW RATE OF

THE FLUID

(g/min)

ATOMIZATION

PRESSURE

(kg/cm²)

AIR

CONSUMPTION

(L/min)

K-I ø 0,8

472 1,4 115

6 117 1,65 129

K-I ø 1,0

5 107 1,7 132

7 160 2,0 148

K-I ø 1,2

6 137 2,25 166

8 197 2,65 190

K-I ø 1,5

7 229 2,9 207

10 311 3,3 230

HEAD K-I

NOTES

Pump pressure 0.8 to 1.0 Kg/cm².

Liquid used for testing: water. Ford cup viscosity 4 = 11 sec.

1/2

aircom.it Instruction Manual - 9

HT series

EN

TECHNICAL DATA

HEAD

ø NOZZLE

SHOTS FLOW RATE OF

THE FLUID

(g/min)

ATOMIZATION

PRESSURE

(kg/cm²)

AIR

CONSUMPTION

(L/min)

W-I ø 0,8

472 1,2 103

6 117 1,5 122

W-I ø 1,0

5 107 1,65 130

7 160 1,8 140

W-I ø 1,2

6 137 2,0 147

8 197 2,35 168

W-I ø 1,5

7 229 2,7 200

10 311 3,0 217

2/2

HEAD W-I

NOTES

Pump pressure 0.8 to 1.0 Kg/cm².

Liquid used for testing: water. Ford cup viscosity 4 = 11 sec.

10 - Instruction Manual aircom.it

HT series

EN

TROUBLESHOOTING

Anomaly Problem /Solution

No atomization

No pressure is getting to the gun

Check air system

Valve part. [43] worn out

Replace valve part. [43] worn out

The head part. [30], the nozzle part, [2] and

the rod part, [1] are worn out.

Replace the head part. [30], nozzle part. [2] and the

rod part. [1]

The product is exceeding the amount needed

Reduce the product passage

Lack of product (ow rate too low)

Add product or reduce atomization air pressure

Missing product in tank or clogged pipes

Fill tank or clean up with solvent

Leakage from the

nozzle

Mounted handwheel part. [G25] worn out

Replace mounted handwheel part. [G25] worn out

Air leakage from the

adjustment screw

Gasket part. [B]

Replace gasket part. [B]

Leakage of product

from the vent

Gasket kit part. [46 and 48] worn out

Replace gasket kit part. [46 and 48]

12 - Spare parts and components aircom.it

HT series

EN

SPARE PARTS

DETAILS LIST mod. HT

NOTES

The head protection stopper is also available as a

spare part. You can refer to the CNN table below for

compatible heads for your model.

1[x1] Rod

2 [x1] Nozzle

3[x1] Ferrule

7[x1] Adjusting screw

11 [x1] Mounted Plunger

12 [x1] Spring

13 [x1] Stopper

30 [x1] Head

34 [x1] Gasket cover ring

35 [x1] Valve

37 [x1] Seeger

38 [x1] Gasket

39 [x1] Gasket

43 [x1] Mounted Valve

46 [x1] Gasket kit

48 [x1] Gasket kit

100 [x1] Plunger

B[x1] Gasket

E[x1] Gasket

G18-X [x1] Body with internal bushing

stainless steel, regulating

valve, block

bracket and plug.

G25 [x1] Mounted Hand wheel

L[x2] Gasket

N[x2] Gasket

R1 [x3] Junction

13

12

1

100

E

11

37

34

38

L

N

35

43

39

48

R1

B

7

30

3

2

46

R1

R1

G25

G18-X

aircom.it Spare parts and components - 13

HT series

EN

SPARE PARTS

mod. HT-X

1[x1] Rod

2 [x1] Nozzle

3[x1] Ferrule

7[x1] Adjusting screw

11 [x1] Mounted Plunger

12 [x1] Spring

13 [x1] Stopper

30 [x1] Head

34 [x1] Gasket cover ring

35 [x1] Valve

37 [x1] Seeger

38 [x1] Gasket

39 [x1] Gasket

43 [x1] Mounted Valve

46-X [x1] Stainless steel gasket kit

48 [x1] Gasket kit

100 [x1] Plunger

B[x1] Gasket

E[x1] Gasket

G18-X [x1] Body with internal bushing

Stainless steel, regulating

valve, block

bracket and plug

G25 [x1] Mounted Hand wheel

L[x2] Gasket

N[x2] Gasket

R1-X [x3] Stainless steel junction

DETAILS LIST

13

12

1

100

E

2

30

3

48

B

7

37

34

38

L

N

35

39

43

11

46-X

R1-X

R1-X

R1-X

G18-X

G25

NOTES

The head protection stopper is also available as a

spare part. You can refer to the CNN table below for

compatible heads for your model.

14 - Spare parts and components aircom.it

HT series

EN

SPARE PARTS

DETAILS LIST mod. HT-XC

1[x1] Rod

2 [x1] Nozzle

3[x1] Ferrule

7[x1] Adjusting screw

11 [x1] Mounted Plunger

12 [x1] Spring

13 [x1] Stopper

30-X [x1] Stainless steel head

34 [x1] Gasket l cover ring

35 [x1] Valve

37 [x1] Seeger

38 [x1] Gasket

39 [x1] Gasket

43 [x1] Mounted Valve

46-X [x1] Stainless steel gasket kit

48 [x1] Gasket kit

100 [x1] Plunger

B[x1] Gasket

E[x1] Gasket

G18-X [x1] Body with internal bushing

Stainless steel, regulating

valve, block

bracket and plug

G25 [x1] Mounted Hand wheel

L[x2] Gasket

N[x2] Gasket

R1-X [x3] Stainless steel junction

L

13

12

1

100

E

2

3

48

B

7

37

34

38

N

35

39

43

11

46-X

R1-X

R1-X

R1-X

30-X

G18-X

G25

NOTES

The head protection stopper is also available as a

spare part. You can refer to the CNN table below for

compatible heads for your model.

aircom.it Spare parts and components - 15

HT series

EN

COMPATIBLE CNN

Cap-Nozzle-Needle

1/2

mod. HT, HT-X

K-I NOZZLE NEEDLE

0,8 0,8

1,0 1,0

1,2 1,2

1,5 1,5

1,8 1,8

2,0 2,0

2,2 2,2

2,5 2,5

3,0 3,0

Z-I NOZZLE NEEDLE

0,8 0,8

1,0 1,0

1,2 1,2

1,5 1,5

1,8 1,8

2,0 2,0

2,2 2,2

2,5 2,5

3,0 3,0

N-I NOZZLE NEEDLE

0,8 0,8

1,0 1,0

1,2 1,2

1,5 1,5

1,8 1,8

2,0 2,0

2,2 2,2

2,5 2,5

3,0 3,0

T-I NOZZLE NEEDLE

0,8 0,8

1,0 1,0

1,2 1,2

1,5 1,5

1,8 1,8

2,0 2,0

2,2 2,2

2,5 2,5

3,0 3,0

16 - Spare parts and components aircom.it

HT series

EN

L-E NOZZLE NEEDLE

0,8 0,8

1,0 1,0

1,2 1,2

1,5 1,5

1,8 1,8

2,0 2,0

2,2 2,2

2,5 2,5

3,0 3,0

S-I* NOZZLE NEEDLE

0,8 0,8

1,0 1,0

1,2 1,2

1,5 1,5

COMPATIBLE CNN

NOTES

*The S-I model is compatible with

diameters from 0.8 to 1.5.

2/2

mod. HT, HT-X

Cap-Nozzle-Needle

W-I NOZZLE NEEDLE

0,8 0,8

1,0 1,0

1,2 1,2

1,5 1,5

1,8 1,8

2,0 2,0

2,2 2,2

2,5 2,5

3,0 3,0

18 - Instruction Manual aircom.it

HT series

EN

CERTIFIED QUALITY

SUPPORT

CERTIFICATIONS

All AIRCOM® products are certied

according to norm EN 13 966 - 1 (VDMA-

Einheisblatt 24 366) and therefore

also according to transfer efciency

parameters.

DO YOU NEED HELP?

We are at your disposal.

THREE-COLOR INSERT

Each gun is marked with a three-color

three-dimensional seal. It represents an

additional guarantee of authenticity and

Italianity because it is present exclusively

in original AIRCOM®guns.

Online support+39 0124 5154 44 [email protected]

AIRCOM SRL © 2022 - ALL RIGHTS RESERVED

Other manuals for HT Series

1

This manual suits for next models

3

Table of contents

Other AirCom Paint Sprayer manuals

AirCom

AirCom HT Series User manual

AirCom

AirCom LR Series User manual

AirCom

AirCom MG1349 Series User manual

AirCom

AirCom 50TH HVLP Series User manual

AirCom

AirCom AB HVLP Series User manual

AirCom

AirCom 50TH.2 HVLP Series User manual

AirCom

AirCom LR Series User manual

AirCom

AirCom MG Series User manual

AirCom

AirCom DA Series User manual

AirCom

AirCom ECO Series User manual