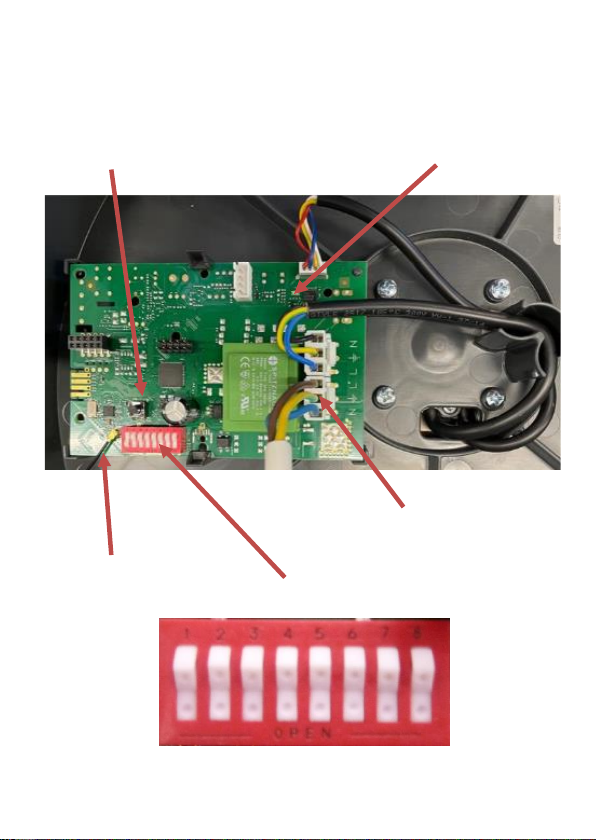

All cables should be suitably retained and

enclosed where necessary to prevent damage

taking place. A 3 x pole lockable isolation switch with

a 3mm contact gap should be used on the mains

supply to the unit.

The unit is supplied already fitted with a 1 x metre

long, three core cable as standard. Brown = Live.

Blue = Neutral. Green / Yellow = Earth. This unit

should be protected by using a 3amp inline fuse.

Before function testing the fan, ensure the impeller

runs freely. Also refer to page 12, Pairing Remote

Controls. Function testing should be carried out by

switching the fan on for a short time. When the fan is

running, checks should be carried out for: impeller

rotation direction, undue noise or vibration and

power consumption. Immediately switch off the fan

should any problems be found, and contact Airflow

Developments Ltd. Fan motors used are suitable for

continuous running and have a rated duty type S1

(motor is suitable to this duty type and rating at which

the fan may be operated for an unlimited period).