BEFORE YOU START

INTRODUCTION TO THE AIRHAVN PRO

Thank you very much for purchasing the AirHavn Pro. Nearly all of us are affected by poor air quality

caused by airborne pollution and contamination: in traffic, in cities, outdoors, indoors, and inside the

car. AirLabs’ mission is to minimise air pollution exposure for people around the world and to drive

down the number of air pollution related deaths. The AirHavn Pro in-building air cleaning unit floods

rooms with large amounts of clean air, reducing exposure to airborne pollutants, contamination and

viruses.

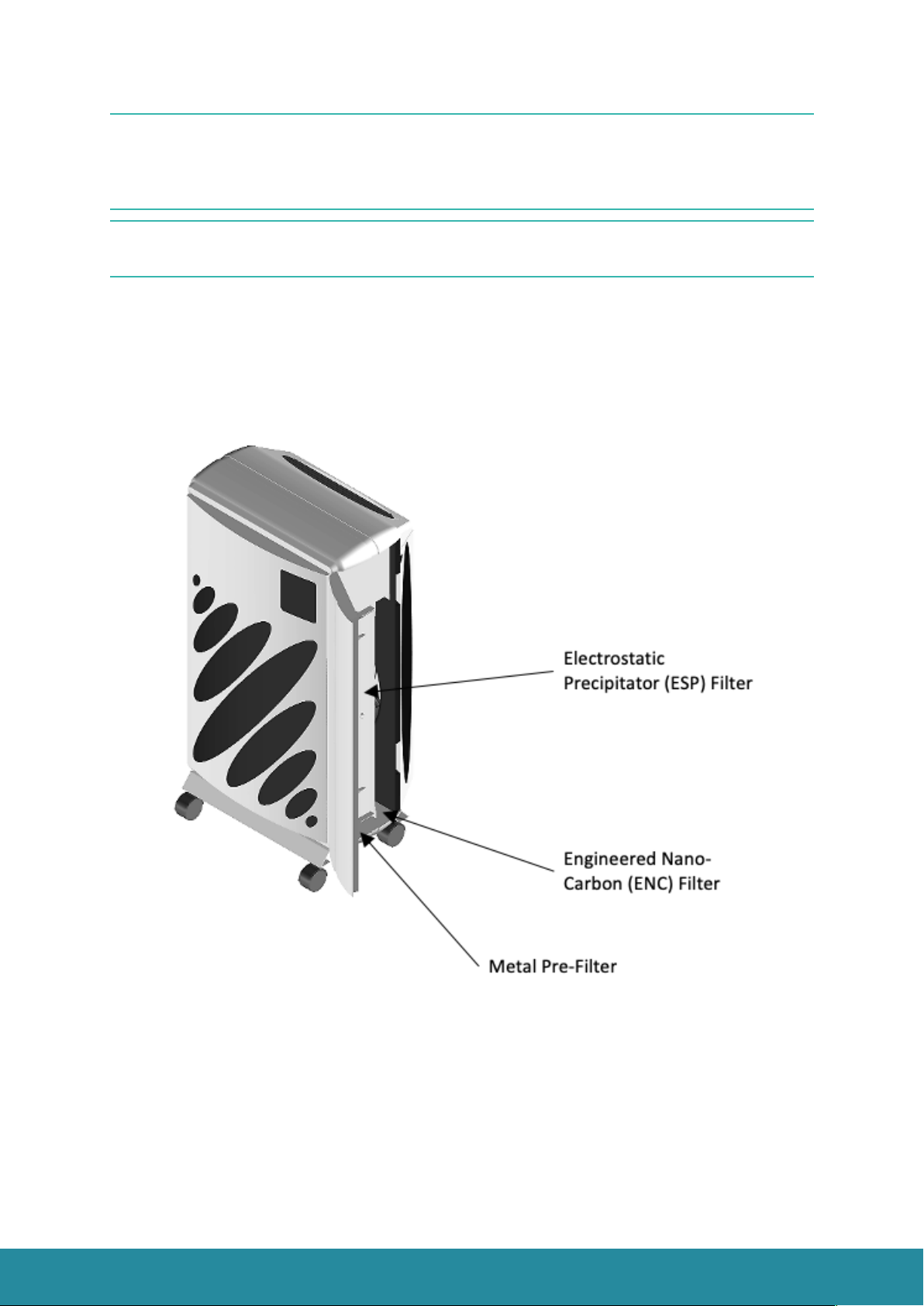

The three-stage layer filtration system uses a metal pre-filter, a high-grade electrostatic precipitator

filter, to remove fine airborne particles, and an engineered nano-carbon filter, developed by AirLabs

in partnership with the University of Copenhagen, to remove gas pollution.

AirHavn Pro creates a healthier indoor environment for all occupants by removing up to 99% of indoor

airborne particles and gases. Particulate matter can include pollen, mould spores, soot, dander and

can vary in size from PM10 (10μm) and PM2.5 (2.5μm) down to particles below 0.1μm in diameter. It

removes the smallest nanoparticles, thought to be the greatest risk to health, along with particles

which carry bacteria or viruses. In addition to these particulates, the patented nano-carbon filter

element will remove up to 95% of nitrogen dioxide, ozone and sulphur dioxide, along with many

volatile organic compounds.

The AirHavn Pro is a portable stand-alone unit that requires no changes to the room’s ventilation

system or interior configuration and is easily installed within minutes. The AirHavn Pro is powered by

mains electricity using the power lead provided.

Air is drawn into the AirHavn Pro, cleaned, and then specifically directed around the room providing

clean air to anyone within the space. The design of the AirHavn Pro ensures that the clean air

efficiently reaches all areas of the room. It is equipped with a powerful fan that is capable of delivering

up to 705 cubic meters of clean air per hour.

Please read this user guide thoroughly before installation and operation and retain it for future

reference.

Register your AirHavn Pro at www.airlabs.com/register.