airleader Master-4 User manual

WF STEUERUNGSTECHNIK

Operation manual for Compressor-Management

AIRLEADER Master-4

Zeppelinstr. 7-9, 75446 WIERNSHEIM

Tel. +49 7044 911100, Fax +497044 5717

www.airleader.de info@airleader.de

5460 33rd Street SE

Grand Rapids, MI 49512

Phone 616 828-0716

www.airleader.us info@airleader.us

SUMMARIES

AIRLEADER Master MODUL

Page 2 Summaries

Page 3 Almost the best strategy to sava energy // Program version serial number

Page 4 Funvtional description

Page 5 Main Menu, System information, Symbol Legend

VARIABLE SPEED COMPRESSOR

Page 6 Control and interpretation of regulated compressors

Page 7 Configuration of regulation range and regulation buffer

Page 8 Minimum flow rate and remote pressure supply

Page 9 Station with 2 variable speed compressors

PROGRAMMING COMPRESSOR CONTROL

Page 10 Programming variable speed compressors

Page 11 FU-Control for variable speed compressos

Page 12 Programming load / unload compressors

Page 13 Programming pressure, rank profiles and system parameter

Page 14 Control Parameter

Page 15 Programming of analog inputs of Master Module

Page 16 Programming analog and digital inputs of connection modules (17-24)

REAL TIME CLOCK

Page 17 Programming real time clock

Page 18 Clock programming notes

STATUS DATA and COMMISIONING

Page 19 Status data of compressors and connection modules

Page 20 IP-address and network settings, // Global settings

Page 21 Alarm messages // Data Manager // Diagram

Page 22 Commisioning and switching functions

2

AIRLEADER combines compressors of different sizes to an optimum unit

For program version, serial number and network touch >Status >Control and SD Card

Almost the best strategy to save energy

Pmax

Pmin

25

25

25

13

7

m³/min

Load

Energy

- only program the compressor capacities

- set the common pressure switch points

- mount the pressure transducer

- connect the cables

The compressors will be controlled by the real air consumption

Within only 1 pressure difference for all compressors

Un-load saving

Load energy saving

3

FUNCTIONAL DESCRIPTION

4

AIRLEADER combines compressors of different sizes

to an optimum unit which automatically adapts to the production based on the current compressed air consumption. It is

made sure that it is always the most efficient compressor combination which generates the compressed air necessary for

production, independent of the manufacturer and the performance. The system pressure remains within the smallest

limits. It is seen that the costs are kept as low as possible. The compressor performances and a common pressure

difference are programmed in for all the compressors. Based on this information, AIRLEADER permanently calculates the

current compressed air consumption and the volume of the compressed air system. The self-learning 8-fold calculation

depth makes it possible to adapt the compressors to the changes in consumption in a dynamic way.

Automatic compressor change as per compressed air consumption

If all the compressors are on the same rank, they are working fully automatically and based on real air consumption. The

priority of the compressors is adapted to the production process in real time with a useful hysterisis calculation. It is always

the compressor combination with the lowest cycle rates which is running and thus with the lowest idle times. Big

compressors are only running when needed. The smaller compressors are running under load instead of idling the big

compressors. The compressors auto-regulate the motor start limitations.

The status of the compressors is constantly monitored.

If a running compressor displays a malfunction within the pressure range or is switched off for service, its performance is

taken over by other compressors. If several compressors are needed to do this, addition is made time-delayed. Load and

total running times are stored for the individual compressors. The operating hours are deleted, if required.

Connecting of compressors

is effected using the connecting moduls this being installed in the electrical housing of the compressor on the DIN-rail. The

connection to the Master control is made over the industry us RS 485 bus. The operating voltage of 24 volts AC/DC can

be attached to the tension supply of the compressor. If a power supply of 24V AC or DC is available from the

compressor electric.

Compressor fault

If a compressor goes on fault the display shows a symbolic cross. On fault of reported compressor the performance gets

the compressed air consumption the most favorable compressors combination replaces through this one. The fault report

for the compressors is activated at the AIRLEADER an common fault signal.

Faults from the connection modules will be given out over the digital output „General fault of external equipment.

Compressor motor running

If these inputs get connected, AIRLEADER receives the motor running time. The total hours are also stored as the load

hours. The advertisement of the hours can be retrieved over the display. The running time compensation provides equally

running times of compressors with same capacity.

Compressor ready input

These input must be connected so that compressor management AIRLEADER recognizes the readiness of the

compressors. If these input don't get connected, the compressor cannot be in operation. A fault signal isn't activated.

der Kompressor nicht bereit und kann nicht angewählt werden. Eine Störmeldung wird nicht aktiviert.

If the fault input is not connected

and one of the compressors stops due to a malfunction, the display will show a wrong compressed air consumption (too

high = by the value of the faulty compressor). For this reason it is advisable to connect the malfunction signal inputs, so

that the compressed air consumption is always shown correctly and the capacity is also corrected and immediately after

reaching the P min.

Main Menu, System information, Symbol Legend

5

Touch „Program“ to enter the control settings

Status and Systeminformation -Touch „Status“-

Kompressor Status Symbole

Control and interpretation of regulated compressors

6

The various speed regulated compressor is integrated actively

The VSD compressor send the information about the motor speed over an analog output to AIRLEADER. This parameter must be

programmed to the minimal and maximum capacity of the delivered compressed air. The analog output of the VSD

compressor have to be 4-20 mA. VSD Compressors with an analog output of 0-10 VDC must be changed from 0-10 VDC with a re-

ceiving multicoupler to 4-20 mA.

The pressure Setpoint of the VSD compressor must be centrically programmed between the AIRLEADER switch points.

The right combination of compressor capacities

together with speed regulated and normal compressors with a firm performance is decisive for good results in regulation. Is the various

speed regulated compressor the smallest in combination with only bigger compressors there are only small section regulated by the vari-

ous speed compressor. Big mechanical hurdle cannot be regulated directly.

Example of the right interpretation of the performances:

4 - 20 mA

4536271890

2,5-16 m³/min 10 m³/min 20 m³/min

0

9

18

27

36

45

4536271890

0

9

18

27

36

45

m³/min m³/min

Pmin

Pmax

Pmin

Pmax

2,5-16 m³/min 20 m³/min

20 m³/min

Correct combination Incorrect combination

Configuration of regulation range and regulation buffer

7

Examble with a VSD Compresor with a regaulation range between 2,5 - 16 m³/min -

The free definable regulation range max

switches load/unload compressors ON and OFF within the pressure settings of AIRLEADER. The regulation limits are defined with the

regulation range max and the regulation buffer. Is the regulation range max adjusted lower than the maximum capacity of the VSD, the

regulation range max and the regulation buffer will be activated.

Setting the "regulation range max"

Examble: the regulation range max will be programmed to 15 m of m³/min. If than the compressed air consumption is going higher

than 15 m³/min a time flexible trend calculation watches the compressed air consumption and switches another compressor on (10 m

³/min like example). Within the pressure switch points of AIRLEADER. If the speed's regulated compressor reaches the regulation

range max the second time together with the 10 m ³/min compressor at 25 m ³/min air consumption again, the 10 m ²/min compres-

sor will be replaced with the 20 m ³/min compressor directly.

The 10 m ³/min compressor will be switched on if air consumption reaches the regulation range max of the regulated compressor at 35

m of ³/min together with the 20 m ³/min compressor.

Setting the "regulation buffer"

Examble: the regulation buffer will be programmed to 1,5 m³/min. If the compressed air consumption is getting lower and the regulated

compressor comes to the point "lower than 15 m³/min" together with the 10 and 20 m³/min compressor the regulation buffer of 1,5 m³/

min will be activated. The air consumption get again 1,5 m³/min lower a time flexible trend calculation stops the 10 m³/min compressor

inside the adjusted pressure switch points at the AIRLEADER. The VSD compressor regualtes to the capacity of 13,5 m³/min.

Correct setting of regulation buffer incorrect setting of regulation buffer

Regulation range max = 15,0 m³/min Regulation range max = 15,0 m³/min

Regulation buffer = -1,5 m³/min Regulation buffer = -3,5 m³/min

Min compressor capacity = -2,5 m³/min Min compressor capacity = -2,5 m³/min

Control sum = 11,0 m³/min Control sum = 9,0 m³/min

Note:

- the regulation range max will be activ if the control sum is smaller than the capacity of the load/unload compressor

- the regualtion buffer is active if the controll sum is higher than the capacity of the load/unload compressor

The VSD compressor will be run in his best specific range.

regulation range

0

6,6

Switch off with regulation buffer

4536271890

2,5-16 m³/min

m³/min

Pmin

Pmax

max

18

27

36

09182736

max

10 m³/min 20 m³/min

max

buffer

max max max

buffer

buffer

15

m³/min

Pmin

Regulation range

max

min

minimized

capacity

examble 15 m³/minexamble 4,5 m³/min

0

Pmin

16128

4

0

2,5-16 m³/min

0

4

8

12

Pmin

Pmax

Minimum flow rate and remote pressure supply

8

Settings „minimum flow rate“ of variable speed compressor

By setting the minimum capacity in the menu of the speed regulated compressor

can be determined whether or below the minimum delivery amount of a normal

compressor compressor in load / idle to run mode.

Setting the minimum flow rate of 0 m / min causes:

The speed controlled compressor is running in start / stop operation as long as the

consumption of compressed air is from 0 to 2.5 m³ / min.

Setting the minimum flow rate of 2.5 m³ / min causes:

Below 2.5 m³/min compressed air consumption a normall compressor is running in

a load / unload mode. The downshift is receding in consumption with a hysteresis

This mode is only economic if the air station with a small compressor as 2.5 to 4 m /

min is installed in addition

Pressure differences caused by dryers and filters

cause may be between the pressure transmitter

of the controlled compressor, and the master

control rule up to 0.4 bar difference.

A precise control of pressure within very close

limits is not possible. The pressure difference at

the higher level control must be expanded by

the pressure value can be set. This results in a

pressure differential of 0.7 bar.

(More than at a station without a regulated com-

pressor)

With the remote control actual pressure value

ensure that the regulated compressor can be operated in conjunction with the master control in a narrow pressure limit.

The analog output of the connection module, deliver the current actual pressure of AIRLEADER via 4-20 mA.

If the compressor pressure transmitter has an different range, than the output has to be adjusted accordingly.

Examble:

AIRLEADER 0-16 bar = 4-20 mA

Compressor 1-20 bar = 4-20 mA or Compressor -1-15 bar = 4-20 mA

An offset value setting for remote actual pressure

can be programmed via the menu of regulated compressor to the pressure setpoint of the controlled compressor to adjust the pressure

difference.

This is especially important when more than 1 controlled compressor is installed in the compressed air network and the analog values

do not match the individual compressors

Remote pressure supply through analog output at the RS-485 connection module

0,4 bar

Capacity of regulated compressor

Station with 2 variable speed compressors

9

In a station with 2 regulated compressors

the pressure transducer of regulated compressors in the same place as the pressure transmitter of the AIRLEADER feel, because differ-

ences in pressure of compressed air dryers and filters, the control behavior can influence each other greatly.

The configuration is described on page 4.

Settings „regulation range max“ und regulation buffer

examble 1: 2 variable speed compressors with same capacity

examble 2: 2 variable speed compressors with different capacities

In examble 2

- if compressor 1 reach the regualation range max - it changes to compressor 2

- if compressor 2 reach the regualation range max - compressor 1 start again

- if both compressors reach the regulation gange max - one of th load / unload compressor will be started

- the controller decides, dependent of air consumption tha one of the regulated compressor can be switched off

The regulation range max

ensure that regulated compressors are always in the correct specific area. If an varaiable speed compressor delivers more air than the

setting of the regulation range max, the control started a flexible trend calculation to start the next load/unload compressor. Dependent of

the compressed air consumption.

compressor compressor type m³/min Regulation range max Regulation buffer Min. flow rate

1 Variable speed 5-30 28 m³/min 5 m³/min 0

2 Variable speed 5-30 28 m³/min 5 m³/min 0

3 load / unload 15 - - -

4 load / unload 25 - - -

compressor compressor type m³/min Regulation range max Regulation buffer Min. flow rate

1 Variable speed 1,5-10 9 m³/min 1,5 m³/min 0

2 Variable speed 5-20 18 m³/min 4 m³/min 0

3 load / unload 15 - - -

4 load / unload 25 - - -

max max max max max

regul. buffer

regul. buffer

Regulation range Downshift with regulation buffer

5-30 m³/min 5-30 m³/min

25 m³/min

15 m³/min

max max

regul. buffer

max

regul. buffer

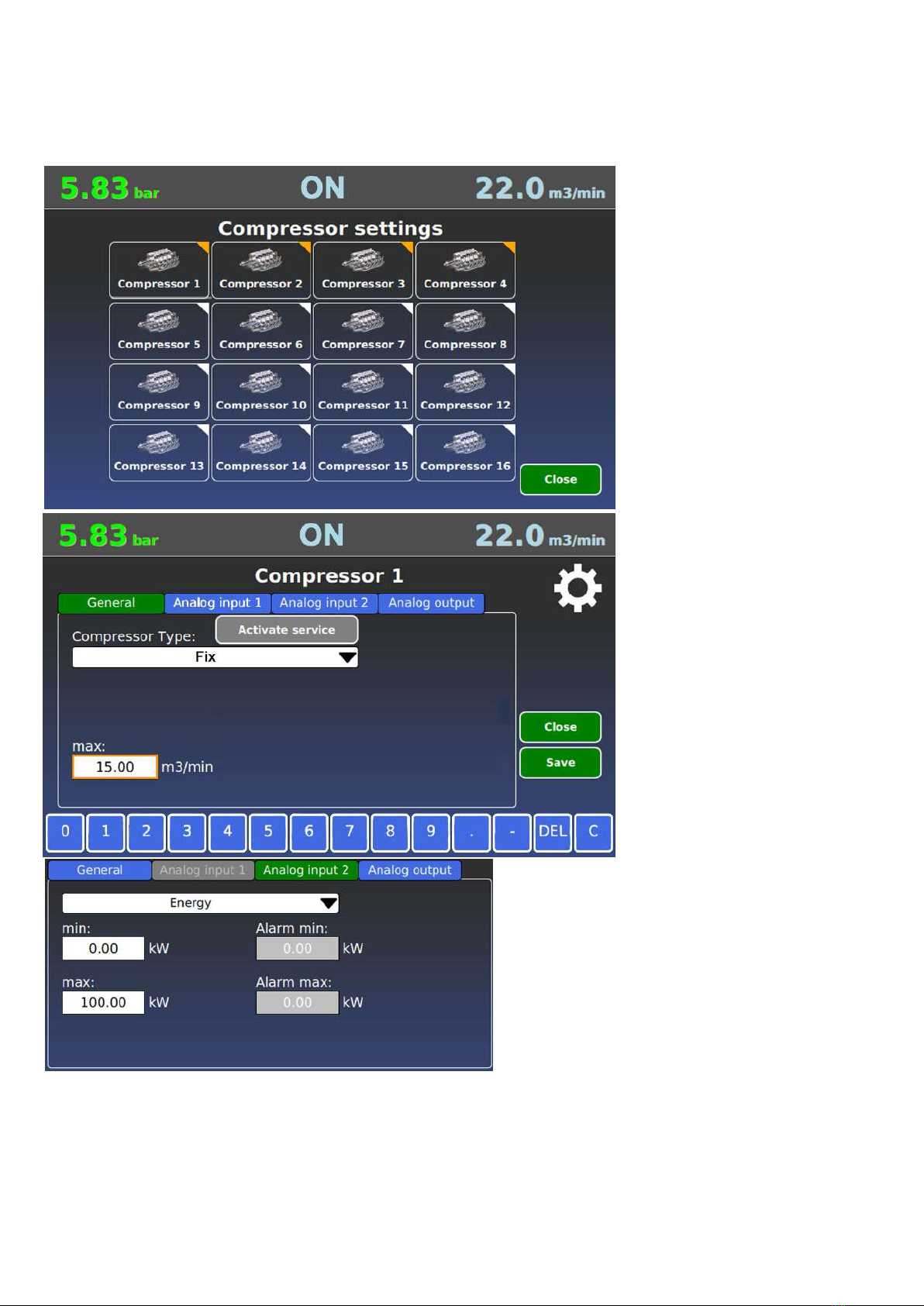

Programming variable speed compressors

10

Touch >Settings >compressor

than

Touch > on compressor symbol

> set min capacity

> set max capacity

> set Imax

> set Imin

> set regulation range max

> set regulation buffer

> compressor min air flow

Attention:

Activate servise for maintenance

the signal "Ready" is deactivated and

the compressor goes into idle when it

is running on load

Install Senor on Analog Input 2

Touch on Analog input 2

> select type of installed sensor

> set min range of sensor at 4 mA

> set max range of sensor at 20 mA

> set min Alarm point

> set max Alarm point

Following sensors are possible:

> Amperé

> Universal sensor

> Power (kW)

>Temperatur

> Bearing monitor

If the sensor value is out of the Alarm

setpoints, you will get an alarm on the

Web-Server Visualisation

Touch on Analog output „AO“

> set min and max range of the

compressor pressure sensor

at 4 mA and 20 mA

> set max range of sensor at 20 mA

> set pressure offset if it is neccessary

Don´t select !Average value output

If average value output is selected

the analog output signal ist the

average between Pmin and Pmax of

Airleader pressure setting

Fault input selection

Standart is C-NC

If neccessary change to

C-NO

FU-Control for variable speed compressors

11

Setting the offset correction

> maximum limit,

> minimum limit,

> Sampling frequency with

FU-Control,

controls the frequency of possible

corrections

> offset increment,

Change in pressure values

> maximum offset,

Maximum change in print offset

FU-Control: (Switch on via the menu of the control parameters)

This function can be activated when several regulated compressors are working in the compressed air network. The condition here is

that the controlled compressors are controlled via the analog output of the compressor module according to the network pressure.

(ACTUAL pressure value) As a result, the compressors and the Airleader have the same pressure. Is one of the regulated

compressors running in the uneconomic area, -e.g. at 100% or 30% for a longer period of time, the actual pressure value is changed

slightly by 0.05 bar until the compressors are running in the good range again. Maximum adjustment 0.2 bar.

Diagram with – and without FU-Control

FU-Control switched „ON“

Net pressure

Programming load / unload compressors

12

Touch >Settings >compressor

than

Touch > on compressor symbol

> set capacity

Touch on Analog input 1 „Ai-1“

> set type of sensor

> set min range of sensor at 4 mA

> set max range of sensor at 20 mA

> set min Alarm point

> set max Alarm point

Following sensors are possible:

> Amperé

> Power (kW)

Install Senor on Analog Input 2

Touch on Analog input 2

> select type of installed sensor

> set min range of sensor at 4 mA

> set max range of sensor at 20 mA

> set min Alarm point

> set max Alarm point

Following sensors are possible:

> Universal sensor

> Temperatur

> Bearing monitor

If the sensor value is out of the Alarm

setpoints, you will get an alarm on the

Web-Server Visualisation

If current measuremet is selected

> set min range of sensor at 4 mA

> set max range of sensor at 20 mA

If energy measuremet is selected

> set min range of kW meter at 4 mA

> set max range of kW meter at 20 mA

OPTION: Vibration sensor

Bearing monitor if Alarm and Service

management is installed

Pressure and rank profiles + system parameter

13

RANK PROFILES

Menu „compressor rank profile

“

Examble: Follwing compressors shall

be controlled

- compressor 1+2 with 20,0 m³/min

- compressor 3+4 with 18,0 m³/min

- compressor 5+6 with 12,5 m³/min

Special request

> Compressor 1 + 6 is connected to

an heat recovery

> Compressor 3 as standby only

Recommended programming

compressor 1+6 rank 1

compressor 2+4+5 rank 2

compressor 3 rank 3

PRESSURE PROFILE

Menu „pressure switch points“.

4 different pressure profile can be

programmed. The pressure profi-

le 2, 3, and 4 can be selected

over:

real time clock

digital input 1, 2 and 3

New function: "set compressors to manual mode"

If -0.0 bar- is entered in the two fields "lower Pmin" and "higher Pmax", this function is not active.

If the pressure in the "lower Pmin" field is entered as 0.5 bar, Airleader switches the compressors to manual operation,

when this value is undershot. (Control compressor's with their own control)

If the pressure in the "higher Pmax" field is entered as 0.5 bar, Airleader switches the compressors to manual operation if this va-

lue is exceeded. (Control compressor's their own control)

If the "automated manual mode" function is active, The "MAN" key switch has to be switched to "1" for a few seconds.

Then switch back to "0" to activate automatic operation via Airleader,

Compressors in the rank stage 1will be controlled denpendent on the actual air consumption.

If this is not enough, the compressors of the rank 2 and helps rank 1

ATTENTION: Only compressor on the same rank stage will be controlled automaically by the dependent airconsumption.

Time cycle compressor order

In this menu equal hour for compressors

with the same capacity can be pro-

grammed.

Control system parameter:

changing of this settings only with

coordination by the manufacturer.

Delay time start:

If Airleader is activated via the "Start key switch or real time clock" and the network pressure is lower than the settings of

Pmin value, a compressor is switched on immediately. All other compressors will be switched on individually after the programmed

time. Programmed rank profiles are taken into account. order from large to small.

Security zone below:

If the demand for compressed air suddenly increases and the pressure drops below Pmin, further compressors switch on after

calculating an additional demand. Or small compressors are replaced by compressors with greater capacity.

Security zone high:

If the demand for compressed air drops suddenly down and the pressure rises above Pmax, more compressors will be switched off

after programmed time and calculating a reduced demand.

Or larger compressors are replaced by compressors with smaller capacity.

Delay time below:

This function prevents several compressors from being started when they are not required, becaus compressors start only after

approx. 15-30 seconds producing compressed air. If a compressor was switched on in the below ssecurity zone, the next compressor

will only be switched on after the programmed time has been elapsed.

Delay time high:

If a compressor has been switched off at the high security zone, the next compressor will only be switched off after the progammend

time. Setting information: large receiver volume = longer time, small receiver volume = shorter time

FU average:

The analog output signal from the frequency inverter will be averaged with the programmed time.

The control process becomes more harmonious.

Fixed compressors if possible: (Fixed capacity compressors – if possible)

If several speed-controlled compressors are installed in the compressed air network, in combination with compressors with a fixed

output, these will be switched on as early as possible in order to increase the specific power.

The prerequisite for this is a sufficient large regulation range of variable speed compressors.

FU Control: See page 11

This function can be activated when several variable speed compressors are working in the same compressed air network.

The condition here is that the variable speed compressors get the net pressure via the analog output of the compressor module

according to the network pressure. (ACTUAL pressure value)

As a result, the compressors and the Airleader have the same pressure level.

Is one of the regulated compressors running in the uneconomic area, -e.g. at 100% or 30% for a longer period of time,

the actual pressure value is changed slightly by 0.05 bar until the compressors are running in the good range again.

Maximum adjustment 0.2 bar.

Control Parameter

14

Analog - Inputs of Master

15

ANALOG inputs on Master Module AIRLEADER Master has as standart 4 analog inputs

TO program the analog inputs > touch on the button of analog input

Anlog input „Ai1“

only for pressure transducer. The pressure transducer extend the supply of AIRLEADER and is includet. No other sensor should be

connected to the system. The pressure is displayed in the display on the left head line.

Analog input Ai2, Ai3, und Ai4

can be used for following sensors:

> Dew point

> Temperature

> Flow

> Extra pressure

> Current measuring

> Energy measuring

For each analog input is an digital output available for alarm signals

Programming of alarm signals:

> for minimum signal

> for maximum signal

can be programmed for each connected analog sensor. The measurements of these sensors are displayed permanently.

.

Parameter setting of analog inputs for examble:

> 4 mA upper data (Tmin)

> 20 mA lower data (Tmax)

The window for the alarm specification is programmable vacant within the sensor values.

Analog and digital-inputs of connection modules

16

ANALOG and DIGITAL inputs

Up to 8 connection modules can be

connected for external analog sensors

and digital potential free contacts of

dryers, condensate drains etc. The

digital signals can be used as fault or

running signals.

The modules get the number 17-24.

Address settings by the 8 DIP

switches

Every connection module

has following out and inputs:

> 2 analog inputs for analog sensors

with 4-20 mA Signal

> 3 digital inputs for fault an running

signal of external equipment

> 1 analog output 4-20 mA over the

range of the connected net pressure

transducer

> 2 digital outputs (C-NO-NC 230VAC

2A) for signal output of connected

Analog sensors (alarm set points)

Possible sensors for analog inputs:

> Dewpoint

> Temperature

> Extra pressure

> Flow

> Current measurement

> Energy measurement

> Vibration for bearings

Analog output at the connection

module It is the actual pressure signal

from the AIRLEADER as long as the

average output is in No (N) position. .

(See page 6)

Note: If average value output is

programmed to „Y“ it belongs an

another connection module for the

pressure signal of the control.

The digital inputs S - M - B

Can be selected as:

> fault signal—with alarm message

> run signal for external equipment

Running hour will be displayed in

the Web-Server visualisation

On all connection modules (up to 8)

can be connected –up to

> 24 digital messages

> 16 analog inputs for sensors

Digital output R1 and R2 on the connection module

If the digital output function is activated on a module (17-24), the timer outputs are

connected synchronously with those on the master. Timer output R1 on the master

corresponds to digital output 7. R2 on master digital output 8

PROGRAMMING REAL TIME CLOCK

17

Note down all attitudes

for all program switching functions so

that no being missing programming

arise.

Key switch „CLOCK“

The real time clock is only activated if

the the key switch is in position „1“

Up to 16 switching points can be

programmed in the menu clock

Set date and time

Touch on each field and set the date and

Time of the real time clock.

Examble:

1. Monday to Friday from 6:00-22:00h

> Control system ON

> Pressure profil 1

> Rank profil 1

> Digital output R1 ON for dryer

2. Monday to Friday from 22:00-24:00 h

> Lower pressure with pressure profil 2

and rank profil 2

> At the same time switching to a

smaller dryer switched by digital

output R2

3. At 00:00 h

The compressed air equipment can be

switched OFF by the real time clock

Key switch „CLOCK“

deactivated the clock relay functions. If

the position is ín position „0“.

The compressors management is

switching the compressors to the

> 1st pressure profile and

> 1st rank profile

That is programmed in the basic menu

over the data of the 1st pressure and

1st rank profile.

The clock relay permits following time

controlled functions

> Switchung compressors ON/OFF

> 4 pressure profiles, > 4 rank profiles,

> 2 digital outputs for relays to switch

ON/OFF additional equipment like

(Dryer, ball valves, etc.)

The dates for the 2nd, 3rd. and 4th

pressure profil and rank profil must be

configurated in the main menu

CLOCK - PROGRAMMING - NOTES

18

SP=switching point LS=Management Leadsystem digital output =R1 digital output t= R2

Compressor chanels

Nr. 1 2 3 4 5 6 7 8

Name

Nr. 9 10 11 12 13 14 15 16

Name

Pressure profile = PP

Nr. P min P max P Alarm

1 bar bar bar

2 bar bar bar

3 bar bar bar

4 bar bar bar

Compressor rank profile = RP

Kompr. 1 2 3 4 5 6 7 8

1.RF

2.RF

3.RF

4.RF

Clock relay switching times and functions

SP Day of the week Time LS PP RP R1 R2

1 M T M T F S S

2 M T M T F S S

3 M T M T F S S

4 M T M T F S S

5 M T M T F S S

6 M T M T F S S

7 M T M T F S S

8 M T M T F S S

9 M T M T F S S

10 M T M T F S S

11 M T M T F S S

12 M T M T F S S

13 M T M T F S S

14 M T M T F S S

15 M T M T F S S

16 M T M T F S S

STATUS DATA

19

Touch on Status to see the status

of all connected modules an sensors

Status of compressor modules

(MK) No. 1-16

and extra connected modules

(AM) No. 17-24

See the status of:

> relay 1

> relay 2

> analog input 1 Ai-1 in mA and selected

sensor data

> analog input 2 Ai-2 in mA and selected

sensor data

Condition of the sensor values

By selecting the sensor function, all

sensor values connected to the

controller are displayed by category.

The connection location is also

displayed.

e.g.

- MM AE1 analog input on the master

- AM 17 AE1 stands for

Analog module 17

Analog input 1 AE1 sensor data

IP-address settings:

Touch: > Program > Network

> set IP-address

> set Subnet Mask

> set Standart Gateway

Integrated Airleader COM server

can control up to 10 compressor stations

via COM-Server.

If compressor modules are connec-

ted via COM server the COM servers

each receive a separate IP address.

The communication speed needs to be

adjusted –see Global settings

IP-address, Network and factory settings

20

Communikation via Ethernet

The connection between AIRLEADER

and the connection modules for com-

pressors and other components can be

done via the Ethernet by using the COM

server.

The RS-485 interface AIRLEADER is

connected to a COM server.

The COM server gets an IP address that

matches the IP address range.

More COM-server can be connected to

the Ethernet with different IP addresses.

Program waiting time for slave

response

Touch: >Settings >Global

RS485 response time

set to "190 ms"

Changeable If necessary

also from 100-300 ms

This manual suits for next models

1

Table of contents

Popular Control System manuals by other brands

Rockwell Automation

Rockwell Automation Allen-Bradley CENTERLINE 2100 installation instructions

Intelligent instrumentation

Intelligent instrumentation EDAS CE manual

Cooper

Cooper Aspire RF user guide

Sea Recovery

Sea Recovery Aquamatic Quick start & troubleshooting guide

Condor

Condor 900 191 - V1.0 operating instructions

MSD Ignition

MSD Ignition 7AL-3 7230 installation instructions