Intelligent instrumentation EDAS CE User manual

EDAS CE Manual

www.edasce.com

855M536

Copyright 2001-07 by Intelligent Instrumentation Incorporated, Tucson, Arizona, U.S.A.

All rights reserved.

ii

Warranty and Repair Policy Statement

General

Seller warrants that its products furnished hereunder will, at the time of delivery, be free from defects in material and

workmanship and will conform to Seller's published specifications applicable at the time of sale. Seller's obligation or

liability to Buyer for products which do not conform to above stated warranty shall be limited to Seller, at Seller's sole

discretion, either repairing the product, replacing the product with a like or similar product, or refunding the purchase

price of the nonconforming product, provided that written notice of said nonconformance is received by Seller within the

time periods set forth below:

a. For all software products, including licensed programs, ninety (90) days from date of initial delivery to

Buyer;

b. For all hardware products (excluding batteries), including complete systems, fifteen (15) months from date

of initial delivery to Buyer, subject to the additional conditions of paragraph c) below;

c. In the event that Buyer's returned product is a Discontinued product and is not repairable for any reason,

Seller may elect to replace it with like or similar product that is, in Seller's sole judgment, the closest

equivalent to the returned product. Seller does not warrant that such replacement product will be an exact

functional replacement of the returned product.

Further, all products warranted hereunder for which Seller has received timely notice of nonconformance must be

returned FOB Seller's plant no later than thirty (30) days after the expiration of the warranty periods set forth above.

These warranties provided herein shall not apply to any products which Seller determines have been subjected, by

Buyer or others, to operating and/or environmental conditions in excess of the limits established in Seller's published

specifications or otherwise have been the subject of mishandling, misuse, neglect, improper testing, repair, alteration or

damage. THESE WARRANTIES EXTEND TO BUYER ONLY AND NOT TO BUYER'S CUSTOMERS OR USERS OF

BUYER'S PRODUCT AND ARE IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS, IMPLIED OR

STATUTORY INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT SHALL SELLER BE LIABLE FOR INCIDENTAL, SPECIAL OR CONSEQUENTIAL

DAMAGES. Seller's liability for any claim of any kind shall in no case exceed the obligation or liability specified in this

Warranty clause.

Technical Assistance and Service

Seller's warranty as herein set forth shall not be enlarged, diminished or affected by, and no obligation or liability shall

arise or grow out of, Seller's rendering of technical advice, facilities or service in connection with Buyer's order of the

goods furnished hereunder. Products returned for warranty service, but which are found to be fully functional and in

conformance with specifications may be subject to a nominal service charge and return freight charges. Periodic re-

calibration of products, if required, is the responsibility of Buyer and is not provided under this Warranty.

Online Support

Online support is available through technical support links on Intelligent Instrumentation’s 24-hour World Wide Web site

at http:// www.EDASce.com. The site contains information on Intelligent Instrumentation’s products, new

developments, announcements, application notes, application examples, and other useful information. The site and

support areas continue to grow as new products, updates, and features are added.

Email Support

Intelligent Instrumentation’s technical support can be reached via email. When sending an email message, be sure to

include complete contact information as well as a detailed description of the problem and the products being used to:

iii

Static Sensitivity

Seller ships all static-susceptible products in anti-static packages. Seller's Warranty as herein set forth shall not cover

warranty repair or replacement for products damaged by static due to Buyer's failure to use proper protective procedures

when handling, storing, or installing products.

Trademarks

FactoryView®, DASport™, EDAS®, EDAS® CE, UDAS™, Intelligent Instrumentation® are trade names and/or

trademarks of Intelligent Instrumentation®, Inc.

Other products or brand names are trademarks or registered trademarks of their respective companies.

se of Equipment

Intelligent Instrumentation Inc., assumes no responsibility for any direct, indirect or consequential loss or damages

resulting from misuse of the equipment or for improper or inadequate maintenance of the equipment or for any such

damage or loss resulting from the use of other equipment, attachments, accessories, and repairs at any time made to or

placed upon the equipment or any replacement thereof. Furthermore, Intelligent Instrumentation Inc., makes no

representations or warranties, either expressed or implied, in connection with the use of the equipment in the event it is

improperly used, repaired or maintained.

FCC Radio Frequency Interference Statement

This equipment generates and uses radio frequency energy, and may cause interference to radio or television reception.

Per FCC rules, Part 15, Subpart J, operation of this equipment is subject to the conditions that no harmful interference is

caused and that interference must be accepted that may be caused by other incidental or restricted radiation devices,

industrial, scientific or medical equipment, or from any authorized radio user.

The operator of a computing device may be required to stop operating his device upon a finding that the device is

causing harmful interference and it is in the public interest to stop operation until the interference problem has been

corrected.

The user of this equipment is responsible for any interference to radio or television reception caused by the equipment.

It is the responsibility of the user to correct such interference.

Revision History

Version Date Revision

1.0 10-30-2006 Initial Release

1.1 8-21-2007 Added EDAS-2005M-2

iv

Table of Contents

Chapter 1: Hardware and Installation ......................................... 1

1.1 Modules................................................................. 1

1.1.1 Base Unit ........................................................... 1

1.1.2 Power Supply ........................................................ 6

1.1.3 Digital I/O Module .................................................. 8

1.1.4 Analog Input Module ................................................ 12

1.1.5 Digital Input Module ............................................... 17

1.1.6 Digital Output Modules ............................................. 19

1.1.7 Analog Output Module ............................................... 21

1.1.8 Serial Module ...................................................... 23

1.1.9 Relay Output Module ................................................ 25

1.1.10 Digital Output (Triac) Module ..................................... 27

1.1.11 Quadrature Module ................................................. 29

1.2 Installation........................................................... 31

1.2.1 DIN rail Mounting ................................................. 31

1.2.2 Attaching a module to a DIN Rail ................................... 31

1.2.3 Removing Modules from a DIN Rail ................................... 32

Chapter 2: Utilities ........................................................ 34

2.1 Summary of Utilities................................................... 34

2.1.1 MonitorCE .......................................................... 35

2.1.2 LCmdSet ............................................................ 35

2.1.3 Remote Manager ..................................................... 35

2.1.4 DebugLauncher ...................................................... 35

2.1.5 TimeSync ........................................................... 35

2.1.6 SerialSocket ....................................................... 36

2.1.7 CEFlush ............................................................ 36

2.2 MonitorCE.............................................................. 37

2.2.1 Required Tools ..................................................... 37

2.2.2 Configuring the Communications Program ............................. 37

2.2.3 Starting a MonitorCE Program Session ............................... 38

2.2.4 MonitorCE Program Commands ......................................... 39

2.3 LCmdSet................................................................ 41

2.3.1 Running LCmdSet .................................................... 41

2.3.2 Making a Telnet Connection using HyperTerminal ..................... 41

2.3.3 Issuing Commands ................................................... 41

2.3.4 Set Commands ....................................................... 42

2.3.5 Show Commands ...................................................... 42

2.3.6 Change Commands .................................................... 44

2.3.7 Operational Commands ............................................... 46

2.4 Remote Manager......................................................... 47

2.4.1 WebDevice .......................................................... 47

2.4.2 Using the Remote Manager ........................................... 48

2.4.3 Remote Manager Home Page ........................................... 49

2.4.4 Application Manager ................................................ 52

2.4.5 File Manager ....................................................... 53

2.4.6 Module Manager ..................................................... 54

2.4.7 System Manager..................................................... 55

2.4.8 Security Manager ................................................... 55

2.4.9 Update Manager ..................................................... 58

2.4.10 Developer’s Guide ................................................. 58

2.5 DebugLauncher.......................................................... 59

2.5.1 Setting Up DebugLauncher ........................................... 59

2.5.2 debugworkstations.txt File Format .................................. 59

2.5.3 Changing the contents of debugworkstations ......................... 60

2.6 TimeSync............................................................... 61

2.6.1 Running TimeSync ................................................... 61

2.6.2 Command Line Arguments ............................................. 61

2.7 SerialSocket........................................................... 63

2.7.1 Configuring the COM ports .......................................... 63

2.7.2 Running the SerialSocket Utility ................................... 63

v

2.7.3 Testing SerialSocket with Hyperterminal ............................ 63

2.8 CEFlush................................................................ 65

2.8.1 Saving Registry Settings ........................................... 65

Chapter 3: Developing Custom Programs ....................................... 67

3.1 Setting up your Development Computer................................... 67

3.1.1 System Requirements ................................................ 68

3.1.2 Installing eMbedded Visual Tools ................................... 68

3.1.3 Installing the EDAS CE SDK ......................................... 68

3.1.4 Setting up Communications to the EDAS CE ........................... 69

3.2 Writing Custom Programs................................................ 76

3.2.1 Generating an EDAS CE Application .................................. 76

3.2.2 Sample Programs .................................................... 83

3.3 Loading Custom Programs................................................ 84

3.3.1 Remote File Viewer ................................................. 84

Chapter 4: CE Link API for EDAS CE .......................................... 85

4.1 Overview............................................................... 85

4.1.1 Interfacing to the I/O system ...................................... 85

4.1.2 Function Calls ..................................................... 86

4.1.3 Header Files ....................................................... 90

4.1.4 DLLs on the EDAS CE ................................................ 90

4.1.5 Registry Entries on the EDAS CE .................................... 91

4.2 CE Link API Function Descriptions...................................... 92

4.2.1 Initialization and De-initialization Calls ......................... 92

4.2.2 Unpaced Analog Input Calls ......................................... 94

4.2.3 Paced Analog Input Calls .......................................... 101

4.2.4 Analog Output ..................................................... 112

4.2.5 Digital Input and Output (Port or Byte) ........................... 114

4.2.6 Digital Input and Output (Individual Bit) ......................... 120

4.2.7 Rate Generator Functions .......................................... 130

4.2.8 Quadrature Functions .............................................. 132

4.2.9 Alarm Functions ................................................... 141

4.2.10 System and Utility Functions ..................................... 152

4.2.11 System Calibration ............................................... 156

4.2.12 Memory Management ................................................ 160

4.3 Return Error Codes for CE Link and EDAS CE API Functions.............. 163

Index ...................................................................... 179

vi

This page intentionally left blank.

Hardware and Installation 1

Chapter 1:Hardware and Installation

The EDAS CE is an open-architecture monitoring and control system based

on the Windows CE operating system. The EDAS CE features a 32-bit

processor with built-in 10/100BaseT Ethernet connectivity and a modular

I/O system. This combination makes the EDAS CE suitable for a wide range

of monitoring and control systems. The EDAS CE’s open architecture allows

the user to develop a wide range of embedded control, machine and process

monitoring applications using C/C++ or WebDevice development tools.

The built-in 10/100BaseT network, including a TCP/IP stack, enables

applications running on the EDAS CE unit to communicate with other

computers and other EDAS CE units on a network. The EDAS CE can operate

as a stand-alone system or as part of a plant-or factory-wide

monitoring/control system.

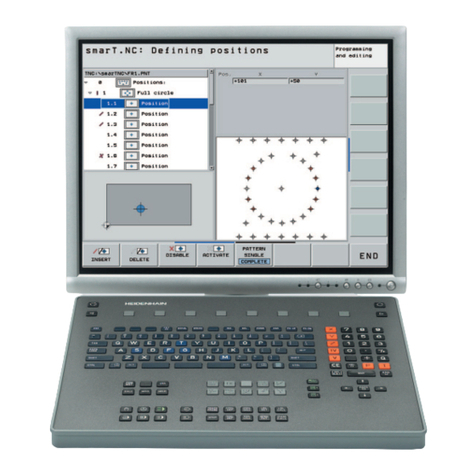

FIGURE 1.1 Typical EDAS CE System

1.1 Modules

An EDAS CE system consists of a power module, a base unit and I/O modules

as needed to meet the specific needs of the targeted application. All the

modules are plug-and-play, requiring no system configuration. Up to 12

I/O modules may be used, allowing for systems of up to 192 I/O points.

1.1.1 Base nit

Each system requires one EDAS-2000E base (processor) unit. The base unit

includes the CPU, Ethernet connectivity, and an RS-232 port. The 32-bit

Hardware and Installation 2

embedded processor runs the Windows CE 3.0 operating system, providing

real-time and multi-tasking capabilities.

FIGURE 1.2 EDAS-2000E Base Unit

The EDAS-2000E base unit includes the following features:

o32 Bit embedded processor

oWindows CE Operating System

o64 MB RAM

o64 MB CompactFlash (1GB maximum)

o1 RS-232 serial port

oOptional Non-volatile Battery RAM (128 kB)

oNetwork standards (TCP/IP, UDP, SNMP, DHCP)

oWebDevice (embedded Web server)

1.1.1.1 Application Development

Applications may be developed to execute on the EDAS CE using Microsoft’s

eMbedded Visual Tools and the eMbedded Visual C/C++ programming language.

Applications developed in C/C++ use the CE Link API for reading and

writing I/O points on the optional modules. Network and serial port

communications use the standard Windows 32 API. See Chapter 3:

Developing Custom Programs.

The EDAS CE includes a program (suprcate.exe) that runs on the EDAS CE as

a data server. A PC or other computer can open a connection and issue

commands to read and write the EDAS CE I/O points. Applications which

communicate with suprcate.exe use the Net Link API. The Net Link API

supports Visual C/C++ and Visual Basic on the Windows (98/Me/NT/2000)

Hardware and Installation 3

Platform and C on Unix platforms. See the Net Link Manual for more

information.

1.1.1.2 EDAS-2000E Base nit Specifications

All specifications are typical at 25°C unless otherwise noted.

Parameter Condition Specification

Processor AMD Elan SC400

Operating System Windows CE 3.0

DRAM Memory 64 MB

72-pin EDO SIMM 60 ns

Compact Flash 64 MB (1GB maximum)

Ethernet 10/100BaseT (RJ-45)

Serial Port 1 RS-232 (up to 115 k Baud)

Power consumption +5 VDC 1.5 A maximum

Dimensions inches

mm 4.55D x 5.9H x 3.35W

116D x 150H x 85W

Temperature Range Operating 0-60 °C

TABLE 1.1 EDAS-2000E-1 Base Unit Specifications

1.1.1.3 Ethernet

The base unit features a 10/100BaseT port. The unit has 5 red LED’s used

to display information about the Ethernet connection.

1. Link: Good link when on.

2. Collision: Collision detected when on.

3. 100BaseT: Indicates 100BaseT connection when on. When off,

connection is 10BaseT or no connection exists.

4. TX: Transmitting.

5. RX: Receiving.

1.1.1.4 Serial Port

The unit has a single serial port, COM1. The serial port can be used to

configure the unit’s network settings and real-time clock. See section

2.2 MonitorCE.

An application may read and write data to this port (COM1) using the

standard Win32 API.

Hardware and Installation 4

1.1.1.5 Real-Time Clock Battery

The base unit contains a 3.0 V lithium battery that powers the Real-Time

Clock when external power is absent. Battery life is approximately two

years when the unit is not powered. When the unit is on external power,

battery life is longer since the battery does not have an appreciable

power draw in this condition. To replace the battery, remove the right

hand cover of the unit.

FIGURE 1.3 Real-time Clock Battery and DRAM Access

Hardware and Installation 5

1.1.1.6 DRAM

The EDAS-2000E can use up to 64 Mbytes of DRAM. The DRAM is industry

standard 5 V, 72-pin EDO or FPM. To change the DRAM module, remove the

right hand cover of the unit.

1.1.1.7 Compact Flash

The EDAS-2000E uses standard Compact Flash memory for non-volatile

storage of the operating system and drivers. The remaining memory can be

used by the applications for non-volatile application or data storage.

The CompactFlash is accessed as part of the unit’s file system. The

CompactFlash can be replaced with a larger card to providing additional

storage capability.

1.1.1.8 Reset/Watchdog Timer

The unit has a watchdog timer that may be activated by an application.

When the watchdog timer is activated, an application must "tickle" the

timer every 2000 ms or the unit will reboot.

1.1.1.9 NV-RAM Option

The EDAS-2000E is available with an optional 128 kbytes of battery RAM.

The NV-RAM provides high speed non-volatile storage. Applications such a

fast control loops can use the NV-RAM to hold state variables, allowing

an application to recover variables after a power loss.

The NV-RAM is memory mapped to 0xA0000 to 0xBFFFF.

Hardware and Installation 6

1.1.2 Power Supply

The EDAS-2001E power supply module provides power for the base unit and

attached modules. The EDAS-2001E can accept line voltages of 90 -260

VAC @ 50 -60 Hz.

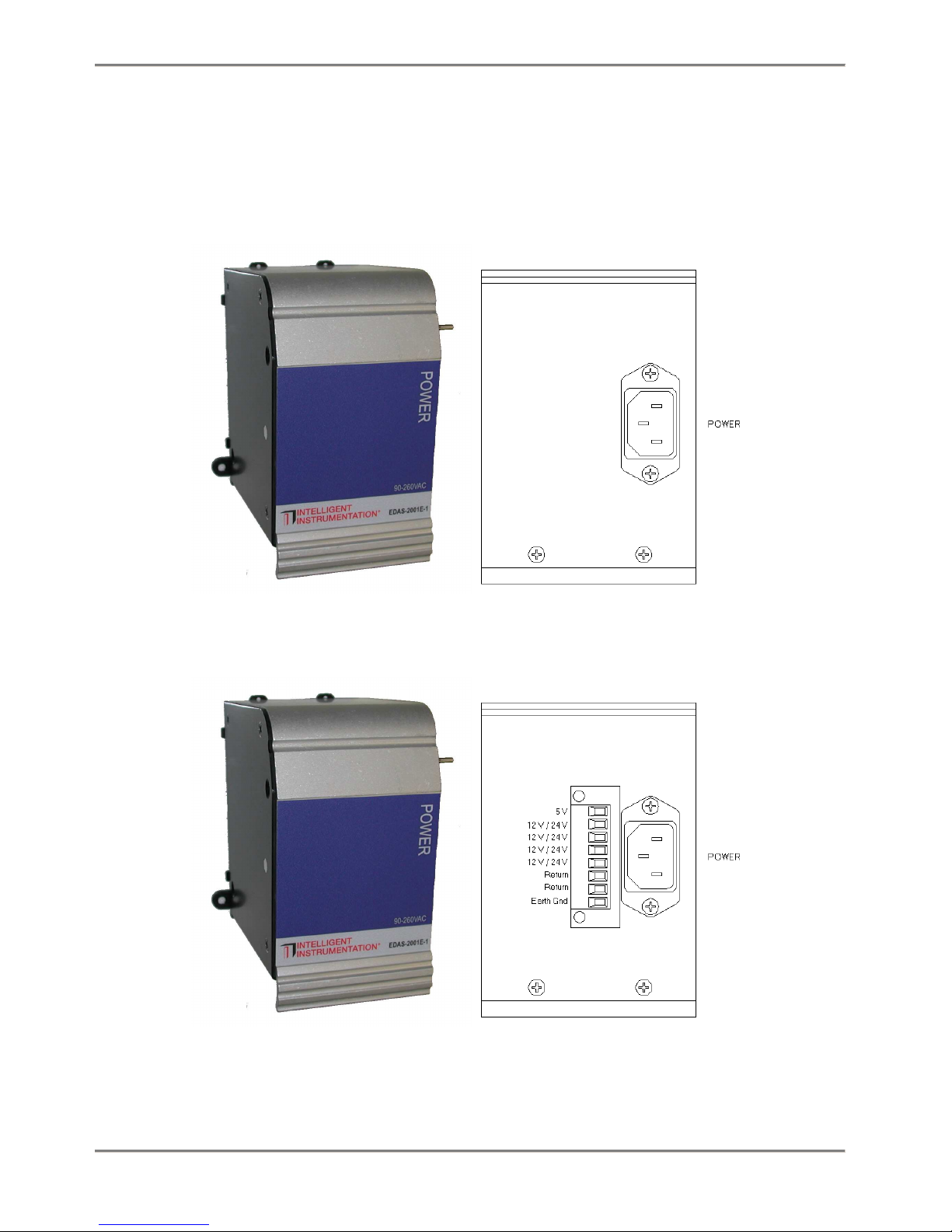

FIGURE 1.4 EDAS-2001E-1 Power Supply Module

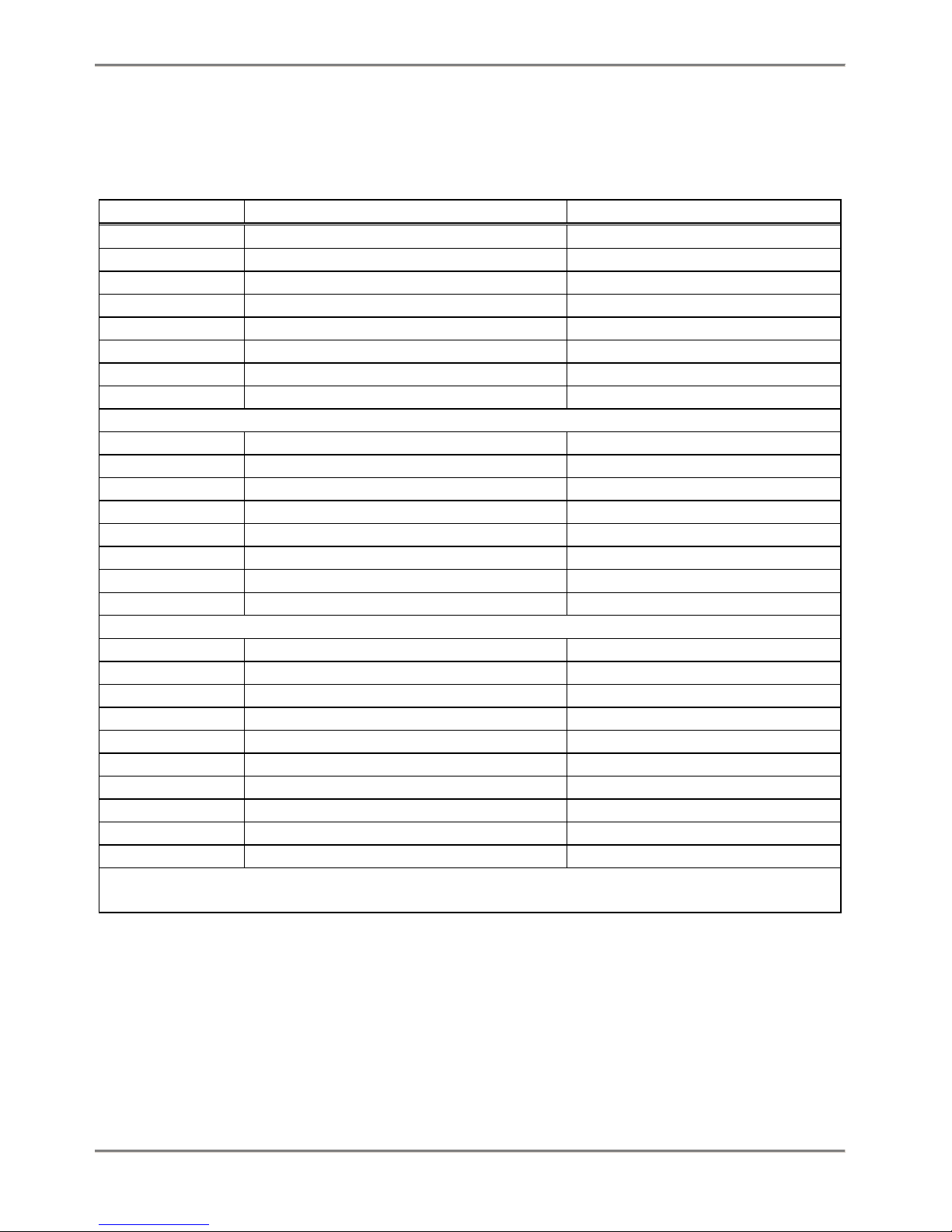

FIGURE 1.5 EDAS-2001E-2 and -3 Power Supply Module

Hardware and Installation 7

1.1.1.10 EDAS-2001E Power Supply Specifications

The EDAS-2001E supplies 5 VDC power to the CPU module which in turn

supplies power to the I/O modules. The -2 and -3 have quick a disconnect

connector that can be used to pull 5VDC and 12 VDC (-2) or 24 VDC (-3)

power from the supply to power other components in your system.

All specifications are typical at 25°C unless otherwise noted.

Parameter Condition Specification

Input Voltage 90 -260 VAC

Input Frequency 50 -60 Hz

Output Voltage

EDAS-2001E-15.0 V +/-5%

EDAS-2001E-25.0 V +/-5%

12.0 V +/-5%

EDAS-2001E-35.0 V +/-5%

24.0 V +/-5%

Output Current

EDAS-2001E-15 V 10.0 A max

EDAS-2001E-25 V

12 V 7.0 A max

2.5 A max

EDAS-2001E-35 V

24 V 7.0 A max

2.0 A max

Agency Approvals Tested to UL 60950

Dimensions inches

mm 4.55D x 5.9H x 3.35W

116D x 150H x 85W

Temperature Range Operating 0-60 °C

TABLE 1.2 EDAS-2001E Power Supply Specifications

1.1.1.11 Power Connector

The EDAS-2001E has a standard IEC power connector. Due to the wide range

of power sources and distance from the EDAS system a power cord is not

included with this module.

Hardware and Installation 8

1.1.3 Digital I/O Module

The EDAS-2002M Digital I/O Module has 8 digital inputs and 4 digital

outputs. The digital inputs and outputs are designed for 24 VDC

operation. All of the digital inputs and outputs provide 500 V channel

to channel isolation with one return per channel. LEDs provide visual

feedback on the channels’ current states. The digital inputs can be

individually configured for normal (high/low), counter or latched

operation. The digital outputs can individually configured for normal

(open/closed), pulsed, delayed and square wave output.

Hardware and Installation 9

FIGURE 1.6 EDAS-2002M Digital I/O module

1.1.1.12 Input Functions

The Digital I/O Module provides the following digital input functions.

The inputs can be configured on a channel by channel basis.

oNormal: Reads the current sates of the input (low/high).

oCounter: 24 bit up/down counter, 250 Hz maximum count rate.

oLatched: The input is latched on a low-to-high, high-to-low, or any

change of state.

Hardware and Installation 10

oHigh Speed Counter: Channel 0 only, 16-bit counter at 20 kHz maximum

count rate.

1.1.1.13 Output Functions

The Digital I/O Module provides the following digital output functions.

The outputs can be configured on a channel by channel basis.

oNormal: Set output to desired state (open/closed)

oPulsed: Set output active for a specified amount of time.

oDelayed: Set output active after the specified time delay.

oSquare wave: Generate a square wave with the specified period, 250 Hz

maximum.

1.1.1.14 EDAS-2002M Digital I/O Module Specifications

All specifications are typical at 25°C unless otherwise noted.

Parameter Condition Specification

Digital Input 8 inputs

Input Voltage Low 3.0 V max

Input Current Low Vin = 0.5 V > 500 nA

Input Voltage High 9 V min, 30 V max

Input Current High Vin = 24 V 5 mA max

Low Speed Counter Ch 0 through 7

Size 24 bit

Frequency 250 Hz max

High Speed Counter Channel 0 only

Size 16 bit

Frequency 20 kHz max

Digital Output FET output 4 Outputs

On resistance 0.03 Ω

On current 0.5 A max

On Voltage 0.8 V max

Off Voltage 27 V max

Isolation Inputs and Outputs

Channel -Channel 500 V max

Channel -Bus 1500 V max

Current Consumption 5 V 200 mA max

Dimensions inches

mm 4.55D x 5.9H x 1.74W

116D x 150H x 42W

Temperature Range Operating 0-60 °C

Hardware and Installation 11

TABLE 1.3 EDAS 2002M-1 Digital I/O Module Specifications

Hardware and Installation 12

1.1.4 Analog Input Module

The EDAS-2003M Analog Input Module can read voltage, current and

thermocouple inputs. Voltage, current or thermocouple readings can be

configured on a channel by channel basis, allowing one analog input

module to read a combination of voltage, current or thermocouple inputs.

FIGURE 1.7 EDAS-2003M Analog Input module

Hardware and Installation 13

The analog input stage consists of a 16 channel multiplexer (MUX),

followed by a programmable gain amplifier (PGA), feeding a 12-bit analog

to digital converter (ADC). The output of the ADC is isolated and

presented to the system bus. The MUX is capable of providing 16 single-

ended inputs, 8 differential inputs or a mixed combination to the PGA.

The PGA has gains of 1, 10 and 100. The ADC supports 0-10 V and ±10 V

ranges.

Current Readings: the module has 16 resistors (500 Ω) that may be

switched between the individual input channels and ground allowing the

unit to make current measurements in the range 0-20 mA.

Thermocouple readings: the module features a built-in Cold Junction

Compensator (CJC), which may be switched in to channel zero.

Additionally the module has 100 kΩ input bias return resistors that may

be switched in to provide an input bias current path for the PGA

1.1.1.15 Configuring Inputs

Each Analog Input channel can be configured for voltage input, current

input, or thermocouple input.

To configure a channel for voltage input:

1: Set the appropriate switches to disable current mode (SW2-1

through SW2-8 and SW3-1 through SW3-8). See the table below.

2: Set the appropriate switches to disable input ground return

resistor (SW1-1 through SW1-8).

3: The gain and range are set through software control.

To configure a channel for 0-20 mA current input:

1: Set the appropriate switches to enable current mode (SW2-1 through

SW2-8 and SW3-1 through SW3-8). See the table below. This

configuration requires the channel to be read as a single-ended

input.

2: Set the appropriate switches to disable ground return (SW1-1

through SW1-8).

3: In software set the PGA gain to 1 and the ADC Range to 0-10 V.

To configure an input for thermocouple input:

Note: Thermocouple can only be read on differential input channels 1

through 7. Channel 0 is used to read the CJC value.

1: Enable the differential ground return switches for the appropriate

channels (SW1-1 through SW1-8). See table below.

Hardware and Installation 14

2: Enable the CJC circuit (SW3-9). This will connect the CJC circuit

to channel 0 to be read as a single-ended analog input. If SW3-10

is turned on with SW3-9, the CJC may be read in differential mode.

Switch Number Switch ON Switch OFF

SW1-1GND return for differential Channel A0 No GND return

SW1-2GND return for differential Channel A1 No GND return

SW1-3GND return for differential Channel A2 No GND return

SW1-4GND return for differential Channel A3 No GND return

SW1-5GND return for differential Channel A4 No GND return

SW1-6GND return for differential Channel A5 No GND return

SW1-7GND return for differential Channel A6 No GND return

SW1-8GND return for differential Channel A7 No GND return

SW2-1Current mode enable Channel 8 Voltage mode enable Channel 8

SW2-2Current mode enable Channel 9 Voltage mode enable Channel 9

SW2-3Current mode enable Channel 10 Voltage mode enable Channel 10

SW2-4Current mode enable Channel 11 Voltage mode enable Channel 11

SW2-5Current mode enable Channel 12 Voltage mode enable Channel 12

SW2-6Current mode enable Channel 13 Voltage mode enable Channel 13

SW2-7Current mode enable Channel 14 Voltage mode enable Channel 14

SW2-8Current mode enable Channel 15 Voltage mode enable Channel 15

SW3-1* Current mode enable Channel 0 Voltage mode enable Channel 0

SW3-2Current mode enable Channel 1 Voltage mode enable Channel 1

SW3-3Current mode enable Channel 2 Voltage mode enable Channel 2

SW3-4Current mode enable Channel 3 Voltage mode enable Channel 3

SW3-5Current mode enable Channel 4 Voltage mode enable Channel 4

SW3-6Current mode enable Channel 5 Voltage mode enable Channel 5

SW3-7Current mode enable Channel 6 Voltage mode enable Channel 6

SW3-8Current mode enable Channel 7 Voltage mode enable Channel 7

SW3-9CJC enable CJC Disable

SW3-10 CJC differential mode CJC single-ended mode

* must be OFF when CJC circuit is enabled

Ground return resistors are 100 kΩ

TABLE 1.4 Current and Ground Return Resistor Switch Settings

1.1.1.16 Hardware / Software Pacing

The Analog Input Module has provisions for pacing (starting) conversions

by software or by one of two hardware start convert sources. These two

hardware sources are an internal 24-bit Rate Generator and a digital

input (EXT INT). The EXT INT input may also be used as a trigger signal

Table of contents

Popular Control System manuals by other brands

Helm

Helm PTM LOADGARD Series user manual

Audemo SYSTEMS

Audemo SYSTEMS PADES 2000 Series user manual

Gecko

Gecko in.xm2 Quick start card

Rinnai

Rinnai MANIFOLD ELECTRONIC CONTROL SYSTEM MSB-C1 installation instructions

DAHAO

DAHAO BECS-185 owner's manual

DELTA DORE

DELTA DORE TYPHONE 2 SV - GUIDE D Installation