4User manual |airLPT113

Version v1.0 |Status 24.11.2016

Explanation of the symbols

used

Danger from electricity. This sym-

bol warns of the dangers posed

by electric currents and dangerous

voltages.

Caution/important. This symbol

provides important information on

how to handle the equipment cor-

rectly.

Quick guide - a quick start guide to

using the airtightness testing de-

vice.

GENERAL INFORMATION

General information

The information provided in this

operating manual will enable you

to operate the airLPT113 safely.

Read this operating manual care-

fully and retain it for further refe-

rence.

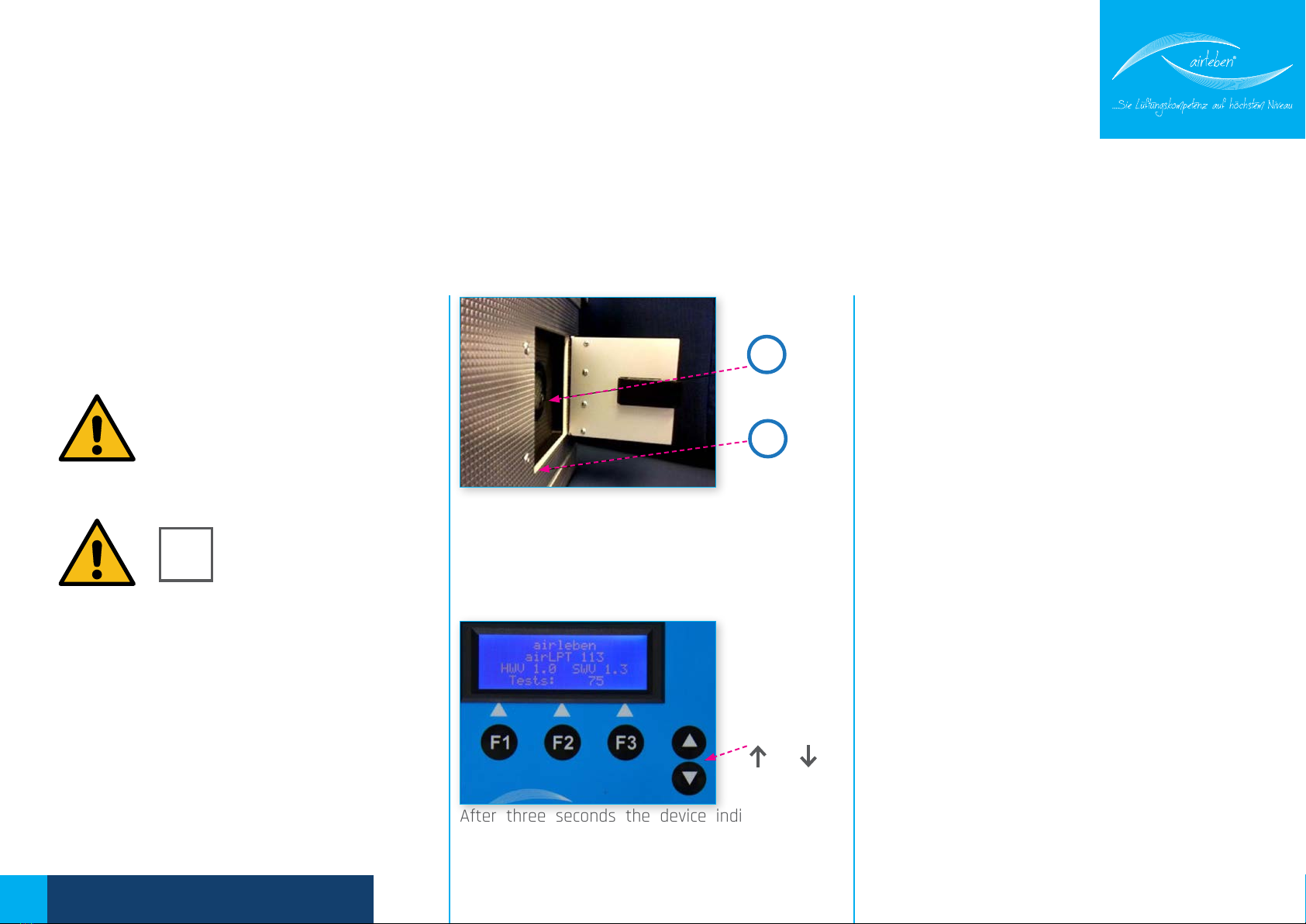

The airtightness testing device air-

LPT113 must be used solely by com-

petent personnel and used solely

for its intended purpose. The de-

vice was designed for testing the

airtightness of air duct systems,

especially in air conditioning sys-

tems and is intended to be used

as a measuring device. An exten-

ded search for leaks must be made

only in the leak search mode.

The device should be transpor-

ted, stored and used under dust-

free and dry conditions. Avoid the

connections for the air hose and

the pressure measuring hose beco-

ming contaminated (e.g. with dust

or moisture).

The device should never be opened

by the user.

Caution: Danger to life: 230 V, 50

Hz!

The device must be opened only

by a qualified and skilled person. If

the device fails to function, follow

the instructions in the section on

troubleshooting or contact the ma-

nufacturer.

Any modification to the original

condition of the device is not per-

mitted.

Sole responsibility rests with the

user and not the manufacturer for

any personal injury or material da-

mage caused by using the device

other than for its intended purpo-

se, or by a failure to follow the ins-

tructions in this operating manual.

Manufacturer

airleben GmbH

Goldbacher Straße 37

99867 Gotha

Tel.: 03621/51445-0

Fax: 03621/51445-219

www.airleben.de

Electronic devices must not be di-

sposed of with household waste.

They must be disposed of in ac-

cordance with the applicable en-

vironmental regulations. Defective

batteries are classed as hazardous

waste and must be disposed of at

the designated collection points.

K