D-17-174-01-rev.3 17-174-01-rev.3 11/16/20

Survey: Installed in Lloyd’s Type-approved Tank, CS235

Sealcast™Depth Transducer

Model: M192

Patent http://www.airmar.com/patent.html

Tools & Materials

Safety glasses

Dust mask

Ear protection

Water-based antifouling coating (mandatory in salt water)

Cable gland

Junction box

Underwater lubricant such as Aqualube®

Hex wrench: 8M

Marine sealant

NOTE: The terms tank and housing are used interchangeably.

Antifouling Coating

Surfaces exposed to salt water must be covered with anti-fouling

coating. Use a water-based anti-fouling coating made for

transducers only. Never use ketone based paint, since ketones

can attack many plastics possibly damaging the transducer. It is

easier to brush on antifouling coating before installation, but allow

sufficient drying time.

Installation

CAUTION: Do not remove the rubber retaining rings.The

transducer’s mounting screws utilize rubber retaining rings to hold

the screws in place during installation.

CAUTION: Lubricate the screw threads.Lubrication is necessary

for removing the screws, if the transducer needs to be replaced.

1. Inspect the transducer, cable, and connectors carefully before

installing. All parts must be clean and free of oil, grease, paint,

solvents, and other foreign material that may hinder

performance.

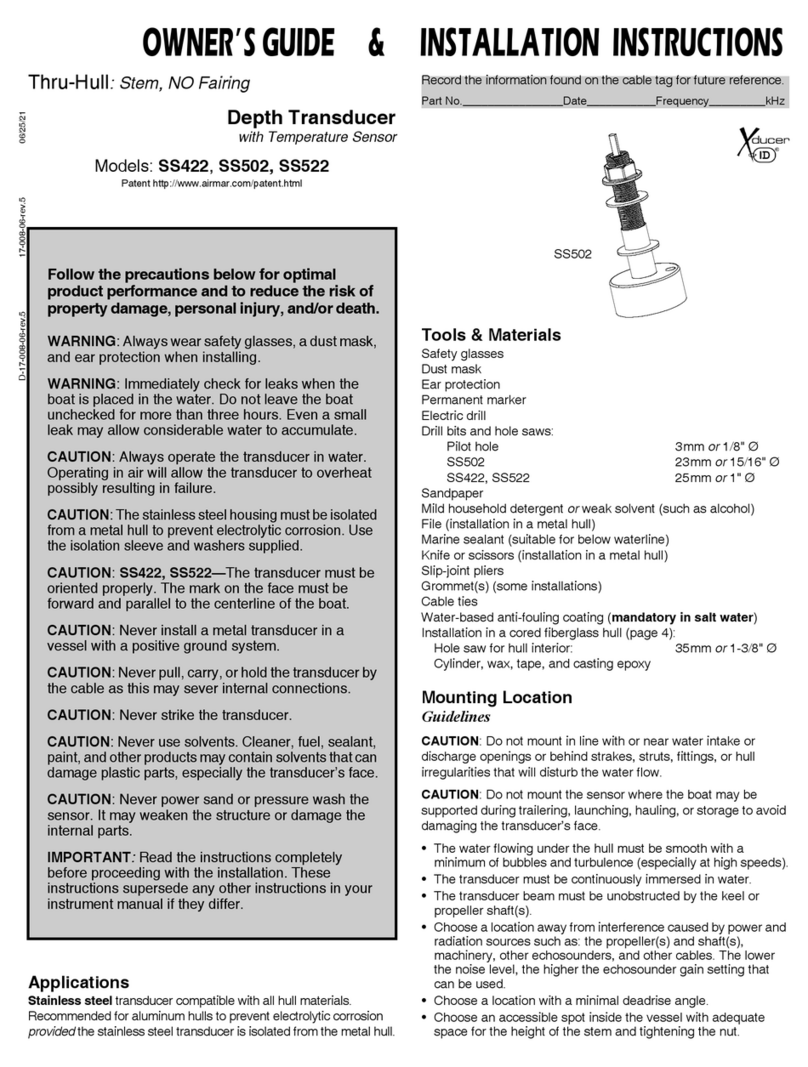

2. Pull the tagged end of the transducer cable (P/N 22-136-01)

through the housing cable passage and the seamless pipe until

the cable stop is seated firmly against the cable passage

opening (Figure 1). Approximately 305mm (12") of cable will

remain in the housing with the male connector attached.

3. Use a suitable cable gland at the top of the pipe to support and

clamp the cable.

4. Secure the free end of the cable in a junction box located in a

dry, gas free environment within the ship.

5. Carefully push the socket head end of each mounting screw

into the counterbore of the transducer to fully expose the

threaded end of the screw. Sparingly apply a uniform coat of

Aqualube®or other similar underwater lubricant to the screw

threads.

6. Push the threaded end of each screw back into the transducer

until approximately 7mm (0.25") of the lubricated threads are

exposed and held in place by the retaining ring.

7. While supporting the weight of the transducer, plug the mating

connectors together until they are fully engaged. The connector

faces must touch.

8. Slowly rotate the transducer approximately 1 to 2 turns as it is

raised into the housing to properly dress the cable and joined

connectors in the cable storage cavity. The transducer face will

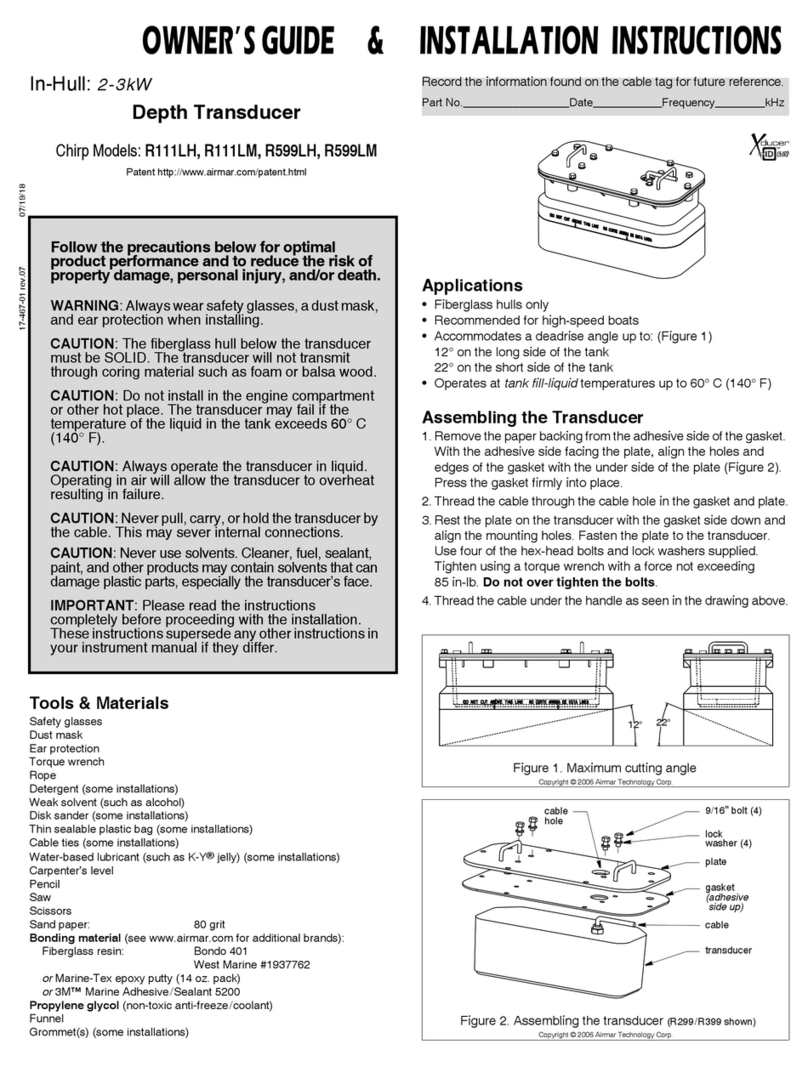

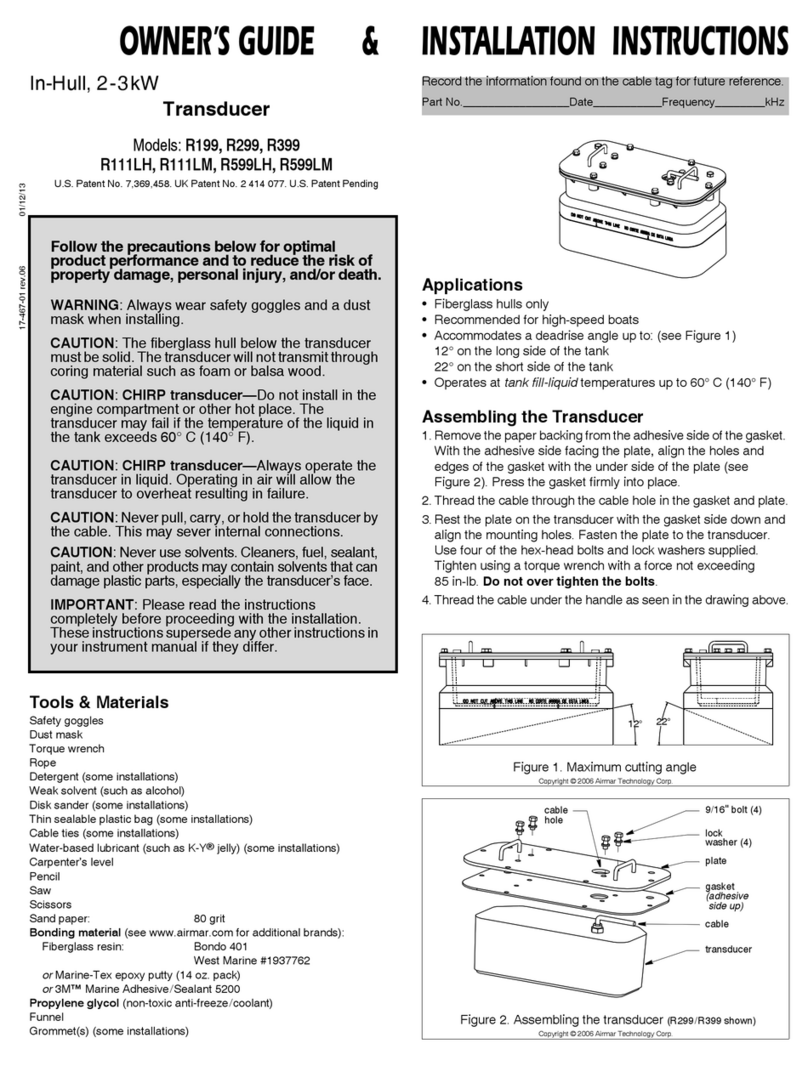

Figure 1. Installation

seamless

pipe

tank

cable

connectors

cable

cable

loop storage

cavity

stop

transducer

rubber

retaining

ring (3)

mounting

screw (3)

radiating face counterbore (3) flange

cable

passage

(housing)

Follow the precautions below for optimal product

performance and to reduce the risk of property

damage, personal injury, and/or death.

WARNING: Always wear safety glasses, a dust

mask, and ear protection when installing.

CAUTION: Never pull, carry, or hold the transducer

by the cable as this may sever internal

connections.

CAUTION: Never use solvents. Cleaner, fuel,

sealant, paint, and other products may contain

solvents that can damage plastic parts, especially

the transducer’s face.

CAUTION: Never power sand or pressure wash

the transducer. It may weaken the structure or

damage the internal components.

IMPORTANT:Please read the instructions

completely before proceeding with the installation.

These directions supersede instructions in your

instrument manual if they differ.

Copyright © 1999 Airmar Technology Corp.

OWNER’ S GUIDE & INSTALLATION INSTRUCTIONS

Record the information found on the cable tag for future reference.

Part No._________________Date___________Frequency________kHz