4

9. After the sealant on the base has cured, pour 71ml (2.4 fl. oz.)

of propylene glycol into the base. Do not over fill. Be sure to

follow the manufacturer’s directions for use.

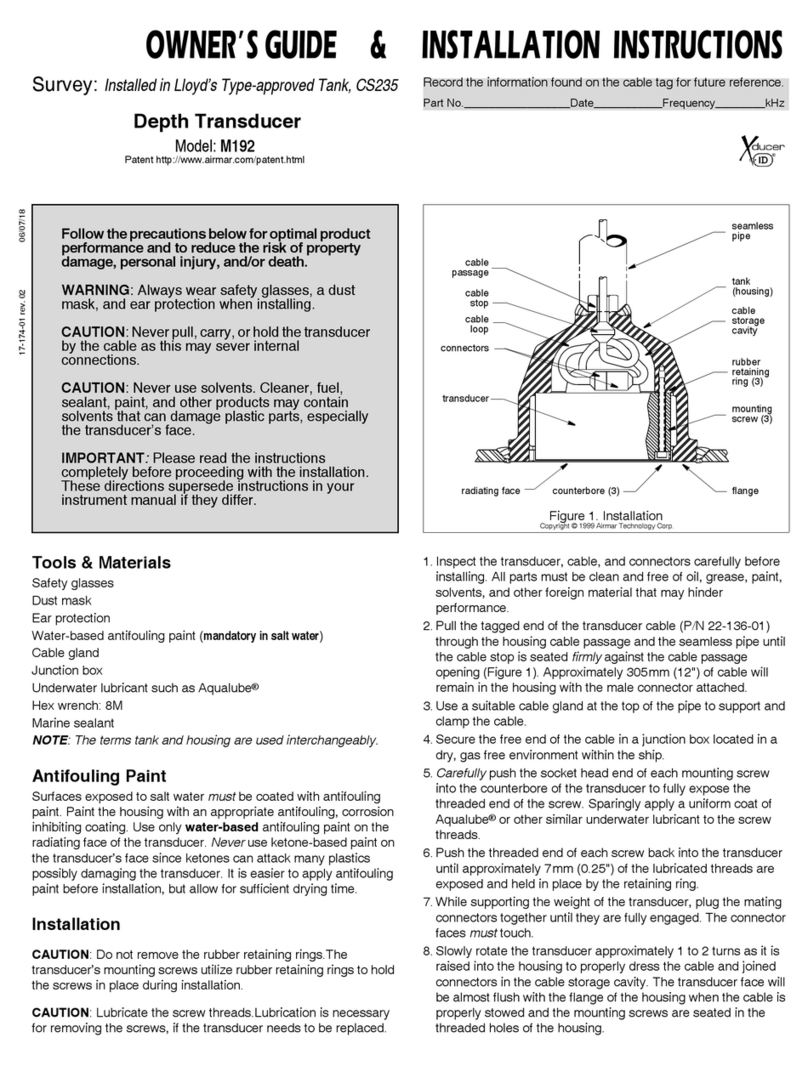

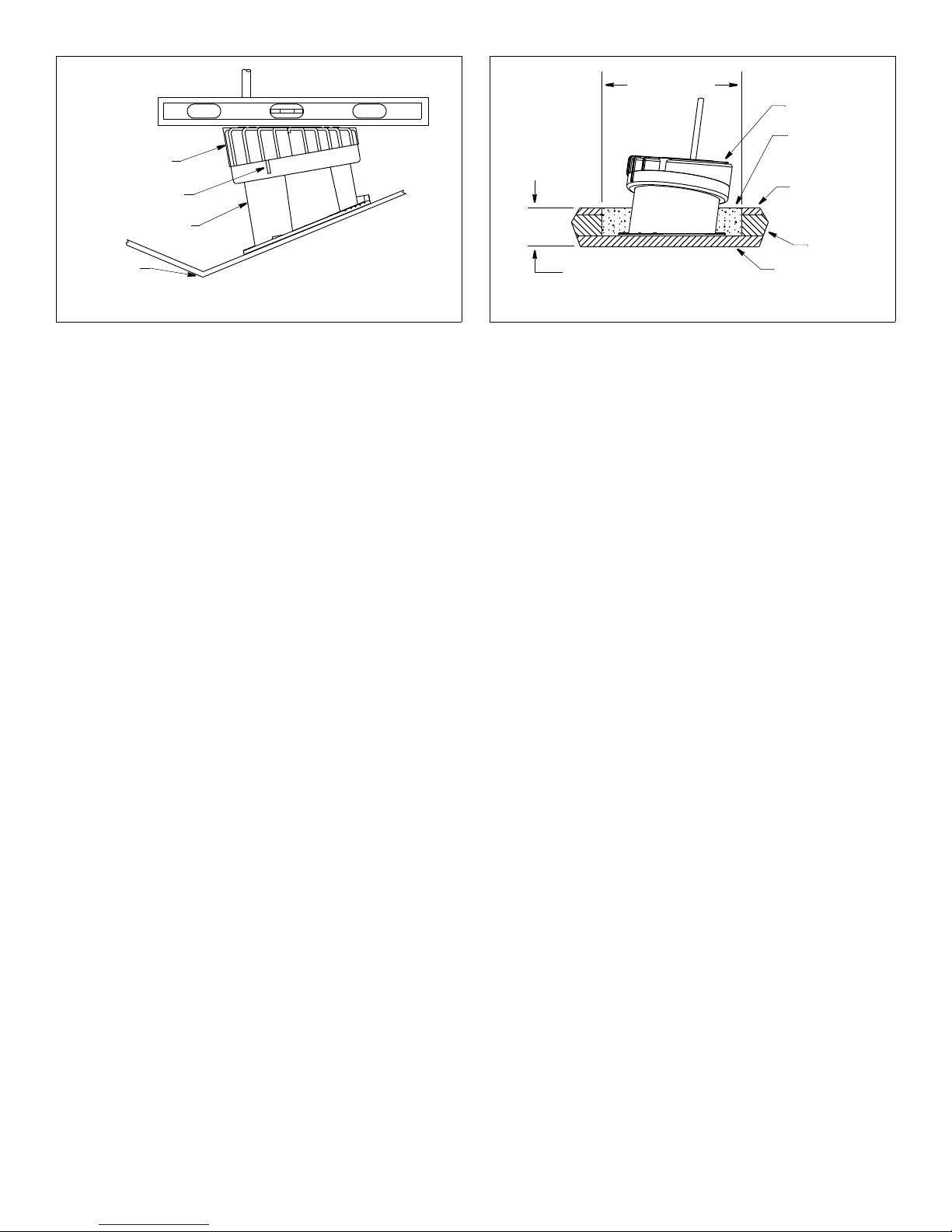

10.With the angle indicator on the keel side, lock the transducer

assembly into the base (see Figure 8). (The bosses on the

locking ring fit into the notches in the base.) Press down and

rotate clockwise until it is seated. When the transducer is

installed correctly, the top will be level. If the deadrise angle is

shallow, the transducer may appear to be level even if it is not.

Use a level to check the installation.

Cable Routing & Connection

CAUTION: If the transducer came with a connector, do not

remove it to ease cable routing. If the cable must be cut and

spliced, use Airmar’s splash-proof Junction Box No. 33-035 and

follow the instructions supplied. Removing the water-proof

connector or cutting the cable, except when using a water-tight

junction box, will void the transducer warranty.

1. Route the cable to the echosounder being careful not to tear the

cable jacket when passing it through the bulkhead and other

parts of the boat. Use grommets to prevent chafing. To reduce

electrical interference, separate the transducer cable from other

electrical wiring and sources of electrical noise. Coil any excess

cable and secure it in place with cable ties to prevent damage.

NOTE: Some transducers are equipped with a short cable,

about 1m (3'), and an extension cable. Be sure to locate the

mated 3 pin connectors well above the bilge waterline. To

facilitate this, use one of the two cable clamps supplied on

either side of the connection.

2. Refer to the instrument owner’s manual to connect the

transducer to the instrument.

Installation in a Cored Fiberglass Hull

Installation in a cored hull is difficult. The objective is to bond the

base to the inside surface of the hull’s outer skin while

preventing any moisture from penetrating the core.

CAUTION: There is no way to determine if the outer skin is solid

(no trapped air bubbles in the fiberglass) at the selected location

before cutting the inner skin.

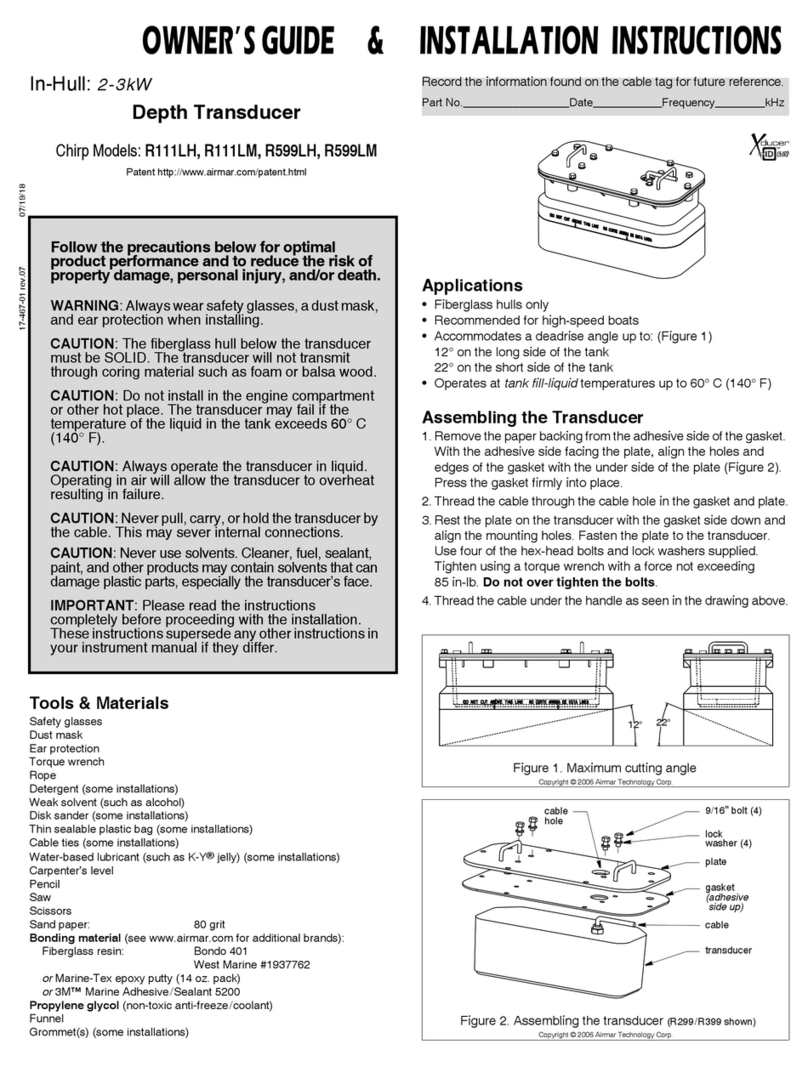

1. Using a 100mm or 4" hole saw, cut through the inner skin and

the core at the selected location (see Figure 9). The core

material can be very soft. Apply only light pressure to the hole

saw after cutting through the inner skin to avoid accidentally

cutting the outer hull.

2. Remove the plug of core material, so the inner core of the hull is

fully exposed. Sand the inside surface of the outer skin using a

miniature disk sander. Slightly undercut the surrounding coring

if possible.

3. Clean and dry both the inside surface of the outer skin and the

transducer with a weak solvent, such as alcohol, to remove any

dust, grease, or oil.

4. Place the base in the cavity. Fill the gap between the base and

the hull with casting epoxy or resin following the manufacturer’s

directions for its use.

5. After the casting epoxy or resin has cured, proceed with

“Installation”, on page 3.

Replacement Transducer & Parts

The information needed to order a replacement transducer is printed

on the cable tag. Donot remove this tag. When ordering, specify the

part number, date, and frequency in kHz. For convenient reference,

record this information on the top of page one.

Lost, broken, or worn parts should bereplaced immediately.

Base & O-ring Kit 33-268-01

transducer

inner skin

core

outer skin

fill with

casting epoxy

or resin

hull thickness

100mm (4")

Figure 9. Installation in a cored fiberglass hull

Figure 8. Completed installation is level

angle

indicator

keel

transducer

assembly

base

NOTE: top of

transducer

is level

Find more Raymarine products on our website. Find out more about marine electronics and navigation we have.