Installation in a Cored Fiberglass Hull

The core (wood or foam) must be cut and sealed carefully. The

core must be protected from water seepage, and the hull must be

reinforced to prevent it from crushing under the hull nut allowing

the housing to become loose.

CAUTION: Completely seal the hull to prevent water seepage into

the core.

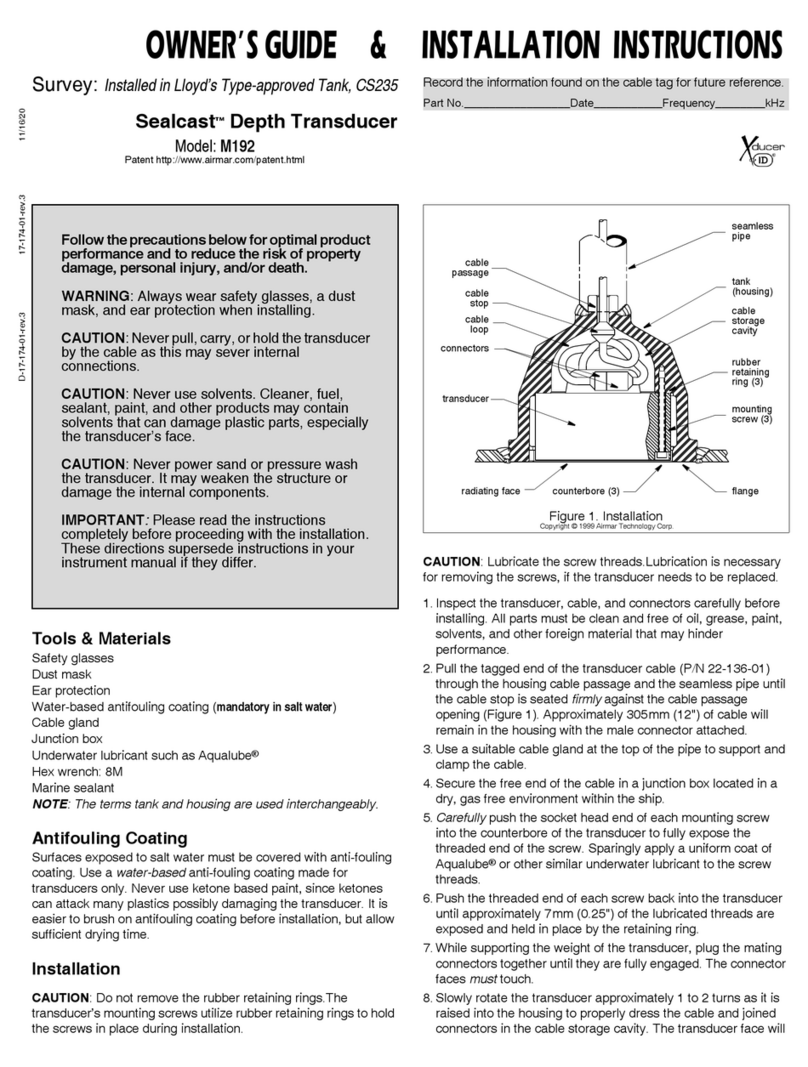

1. Drill a Ø 3mm or 1/8" pilot hole from inside the hull. If there is a rib,

strut, or other hull irregularity near the selected mounting location,

drill from the outside. (If the hole is drilled in the wrong location, drill

a second hole in a better location. Apply masking tape to the outside

of the hull over the incorrect hole and fill it with epoxy.)

2. Using a Ø 51mm or 2" hole saw, cut the hole from outside the hull

through the outer skin only (Figure 6).

3. From inside the hull using a Ø 60mm or 2-3/8" hole saw, cut through

the inner skin and most of the core. The core material can be very

soft. Apply only light pressure to the hole saw after cutting through

the inner skin to avoid accidentally cutting the outer skin.

4. Remove the plug of core material so the inside of the outer skin and

the inner core of the hull are fully exposed. Sand and clean the inner

skin, core, and the outer skin around the hole.

5. If you are skilled with fiberglass, saturate a layer of fiberglass cloth

with a suitable resin and lay it inside the hole to seal and strengthen

the core. Add layers until the hole is the correct diameter.

Alternatively, a hollow or solid cylinder of the correct diameter can

be coated with wax and taped in place. Fill the gap between the

cylinder and hull with casting epoxy. After the epoxy has set, remove

the cylinder.

6. Sand and clean the area around the hole, inside and outside, to

ensure that the marine sealant will adhere properly to the hull. If

there is any petroleum residue inside the hull, remove it with either

mild household detergent or a weak solvent (alcohol) before sanding.

7. Proceed with “Bedding” (page 2).

Operation & Maintenance

How the Valve Works

THE VALVE IS NOT A WATERTIGHT SEAL! The sensor

incorporates a self-closing valve which minimizes the flow of water

into the boat when the insert is removed. The curved flap valve is

activated by both a spring and water pressure. Water pushes the

flap valve upward to block the opening, so there is no gush of water

into the boat. Always install the insert or the blanking plug secured

with the cap nut and safety wire for a watertight seal.

Using the Blanking Plug

To protect the insert, use the blanking plug:

• When the boat will be kept in salt water for more than a week.

• When the boat will be removed from the water.

• When aquatic growth buildup on the insert is suspected due to

inaccurate readings from the instrument.

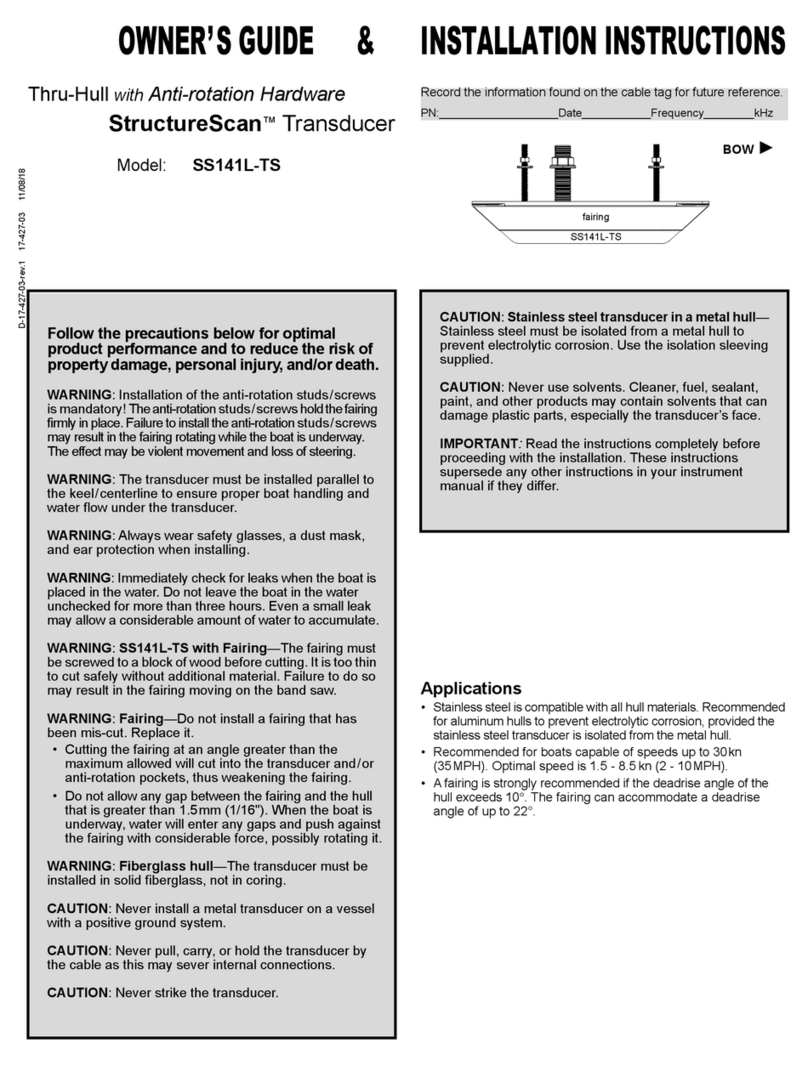

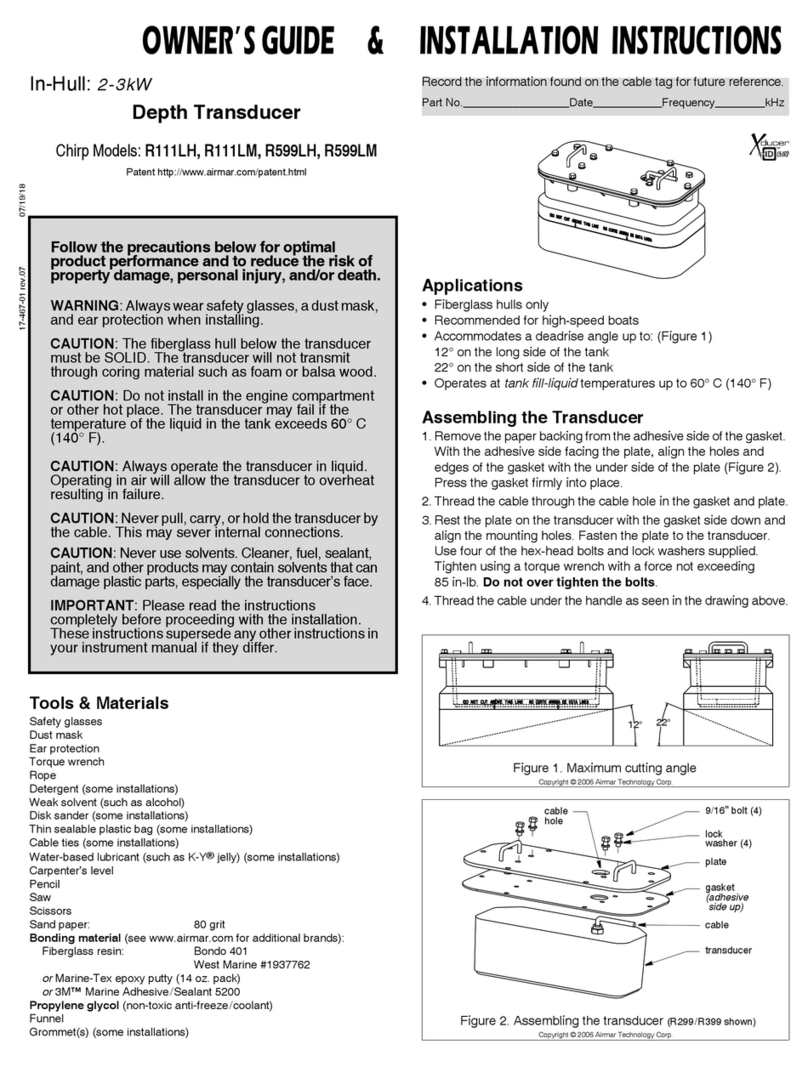

1. All the O-rings must be intact and well lubricated to make a

watertight seal. On the blanking plug, inspect the O-rings

(replace if necessary) and lubricate them with the silicone

lubricant supplied or petroleum jelly (Figure 7).

2. Remove the insert from the housing by removing the safety wire

and unscrewing the cap nut (Figure 5). This will raise the insert.

Remove the insert with a slow pulling motion. Replace it by

sliding the blanking plug into the housing.

NOTE: In the very unlikely event that the valve breaks, replace

the housing the next time the boat is hauled.

3. With the blanking plug fully inserted, screw the cap nut several

turns until the threads are engaged. Continue to tighten the cap

nut completely. Hand tighten only. Do not over tighten.

NOTE: The blanking plug must be fully inserted in the housing

and the cap nut screwed on completely for a watertight seal.

4. Reattach the safety wire to prevent the blanking plug from

backing out in the unlikely event that the cap nut fails or is

screwed on incorrectly.

Winterizing

After the boat has been hauled for winter storage, remove the

blanking plug to let the water drain away before reinserting it. This

will prevent any water from freezing around the blanking plug,

possibly cracking the plastic.

Cleaning & Replacing O-rings

Aquatic growth can accumulate rapidly on the sensor’s face

reducing performance within weeks. Clean the insert with a

Scotch-Brite®scour pad and mild household detergent, being

careful to avoid making scratches. If fouling is severe, lightly wet

sand it with fine grade wet/dry paper.

All the O-rings must be intact and well lubricated to make a

watertight seal. Install the O-rings on the insert and blanking plug

as shown (Figure 7).

Replacement Sensor & Parts

The information needed to order a replacement Airmar sensor is

printed on the cable tag. Do not remove this tag. When ordering,

specify the part number, date, and frequency in kHz. For convenient

reference, record this information on the top of page one.

Lost, broken, or worn parts should be replaced immediately. If you

have purchased a plastic housing and have a wood hull or desire

greater strength, purchase an Airmar metal housing. Obtain parts

from your instrument manufacturer or marine dealer.

Gemeco USA

Tel: 803-693-0777

Airmar EMEA Europe, Middle East, Africa

Tel: +33.(0)2.23.52.06.48

Email: sales@airmar-emea.com

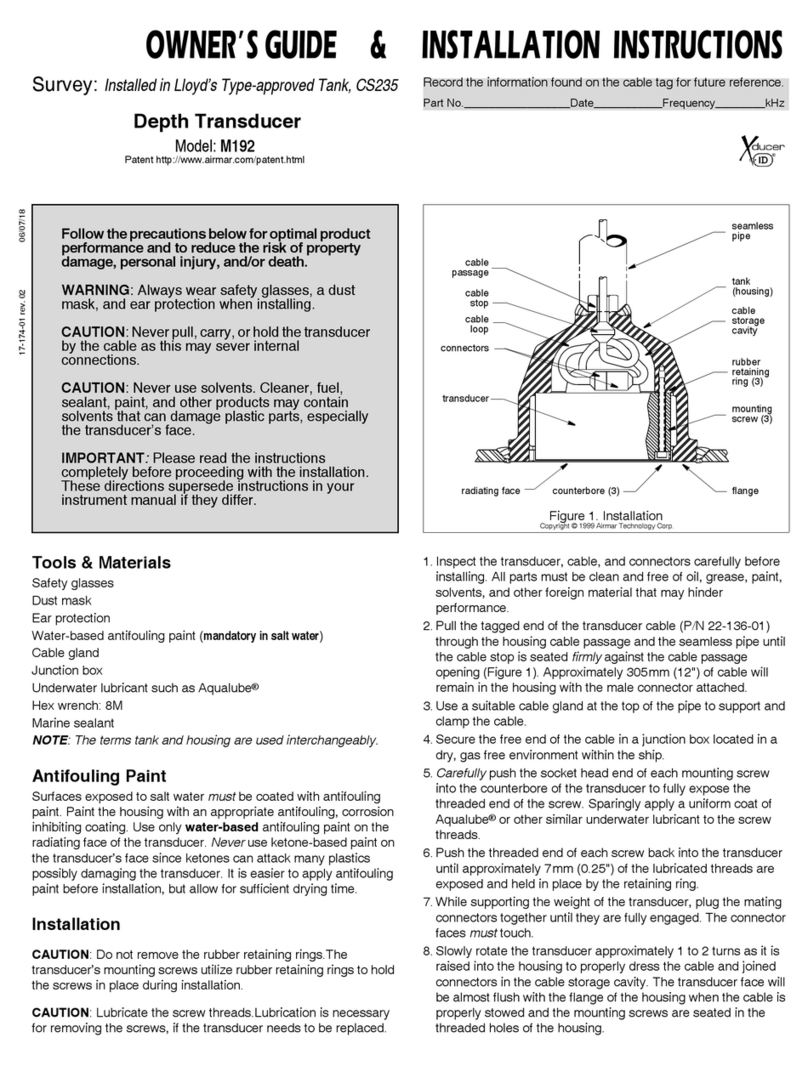

Figure 6. Preparing a cored fiberglass hull

inner skin

core

outer skin

solid or hollow cylinder

pour in

casting

epoxy

Ø 9-12 mm

(3/8-1/2")

larger than the

hole through the

hull’s outer skin

hull thickness

Copyright © 2004 - 2022 Airmar Technology Corp.

Figure 7. Replacing the O-rings

blanking

insert

yellow

O-ring

small

black

plug

O-ring(s)

Copyright © 2005 - 2022 Airmar Technology Corp.

4

NOTE: O-rings

must be intact

and well

lubricated to

make a watertight

seal.

Copyright © 2006 - 2022 Airmar Technology Corp. All rights reserved.

35 Meadowbrook Drive, Milford, New Hampshire 03055-4613, USA

www.airmar.com