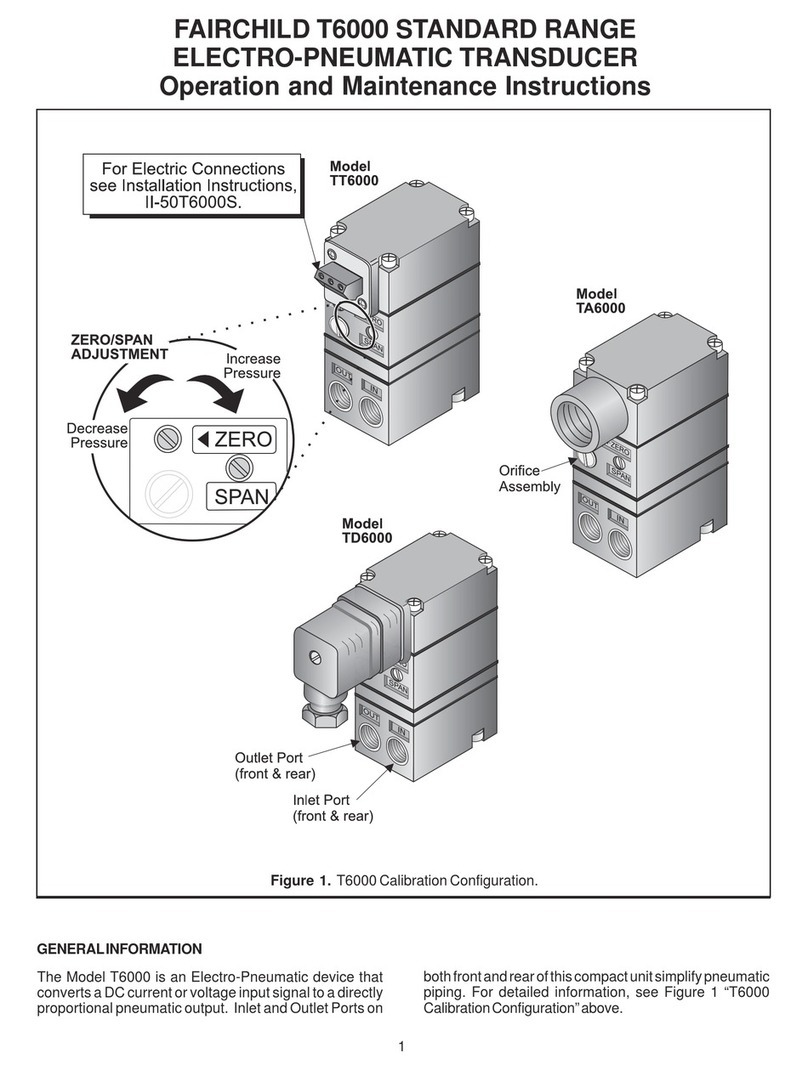

CALIBRATIONS / ADJUSTMENTS

Equipment Required for Calibration:

• Pneumatic Supply capable of delivering up to 150 psig.

• Current Supply capable of delivering up to 50 mA.

• Voltage Supply capable of delivering up to 10 VDC.

• Pressure Gage capable of a digital readout up to 50 psig

with an accuracy of .1%.

• Digital Volt Meter capable of a readout up to 30 mA or

10 VDC with an accuracy of .02%.

The following adjustments are provided:

Full Range Operation

Forward/Reverse Mode

Calibration - Zero and Span

FULL RANGE OPERATION

Forward Acting Mode Adjustment

NOTE: Air Supply must be on before adjustments are

made.

1. Connect the input signal to the transducer as shown

in Figure 6. “Electrical Connections.”

• Forward Acting Calibration-Zero

2. Apply the minimum input signal and adjust the Zero

screw for minimum output pressure. Turn screw

counterclockwise to increase pressure and clock-

wise to decrease pressure.

• Forward Acting Calibration-Span

3. Apply the maximum input signal and adjust the Span

screw on the potentiometer for maximum output

pressure. Turn screw clockwise to increase pres-

sure and counterclockwise to decrease pressure.

4. Repeat steps 2-3 until the desired output range is

obtained. For more information, see Figure 7. “T5220/

TXPD5220Calibration Configuration.”

Reverse Acting Mode Adjustment

NOTE: Intrinsically safe units cannot be set for re-

verse acting mode in field.

5. Connect the input signal to the transducer as shown

in Figure 6. “Electrical Connections.”

• Reverse Acting Calibration-Zero

6. Apply the minimum input signal and adjust the Zero

screw for maximum output pressure. Turn screw

counterclockwise to increase pressure and clock-

wise to decrease pressure.

• Reverse Acting Calibration-Span

7. Apply the maximum input signal and adjust the Span

screw on the potentiometer for minimum output pres-

sure. Turn screw counterclockwise to increase pres-

sure and clockwise to decrease pressure.

8. Repeat steps 6-7 until the desired output range is

obtained. For more information, see Figure 8. “T5200/

TXPD5200 Calibration Configuration.”

Figure 7. T5220 / TXPD5220 Calibration Configuration.

5