IO-123114 Effective 12-04-2014 9

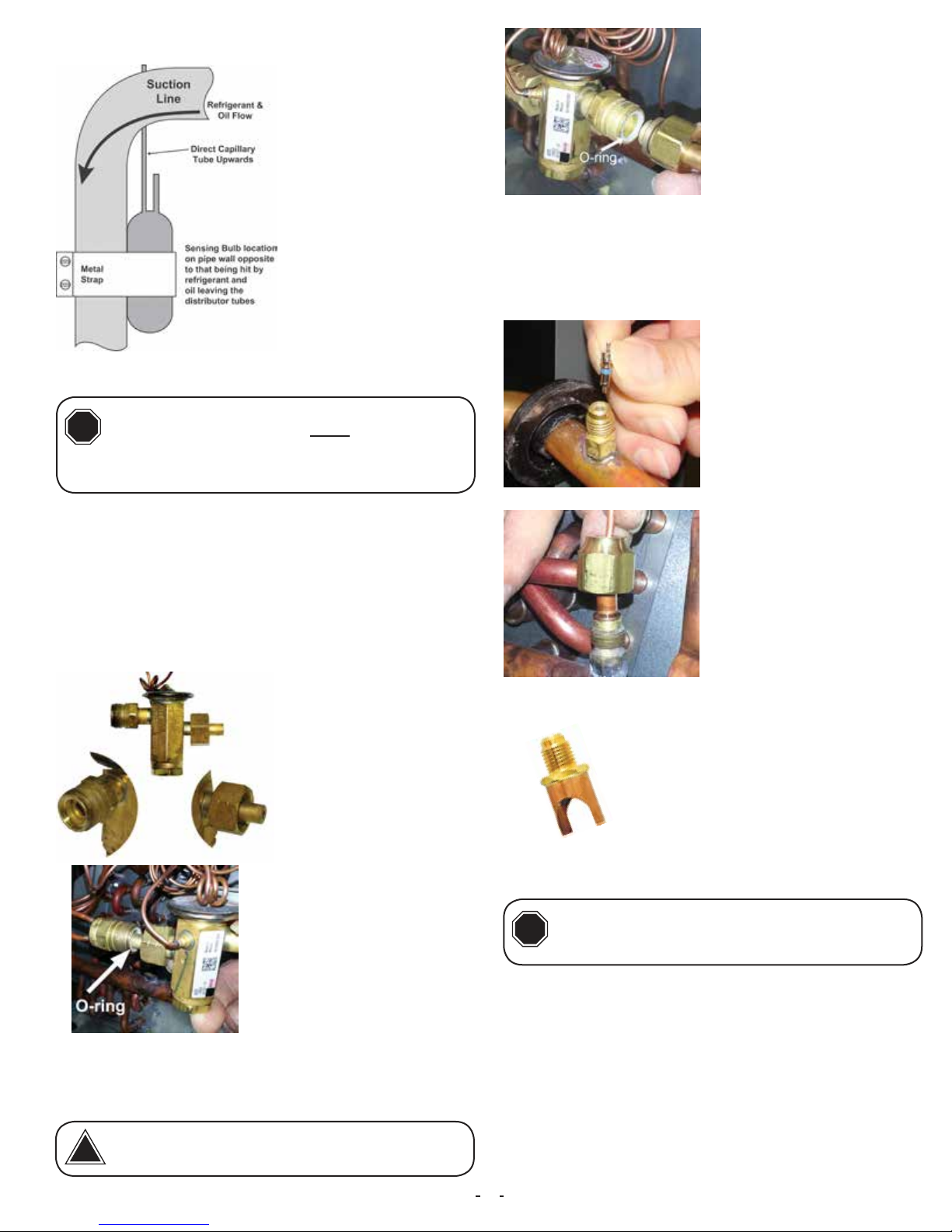

Line voltage wiring should be routed through the access holes at the

side of the air handler. Proper electrical conduit connection ttings

should be used. Connect the power wiring to the line side connec-

tions on the air handler. The electrical ground wire should be con-

nected to the grounding lug. Ensure both the eld supplied ground

wire and air handler GREEN ground wire are both secured to the

grounding lug of the air handler (Fig 11-2).

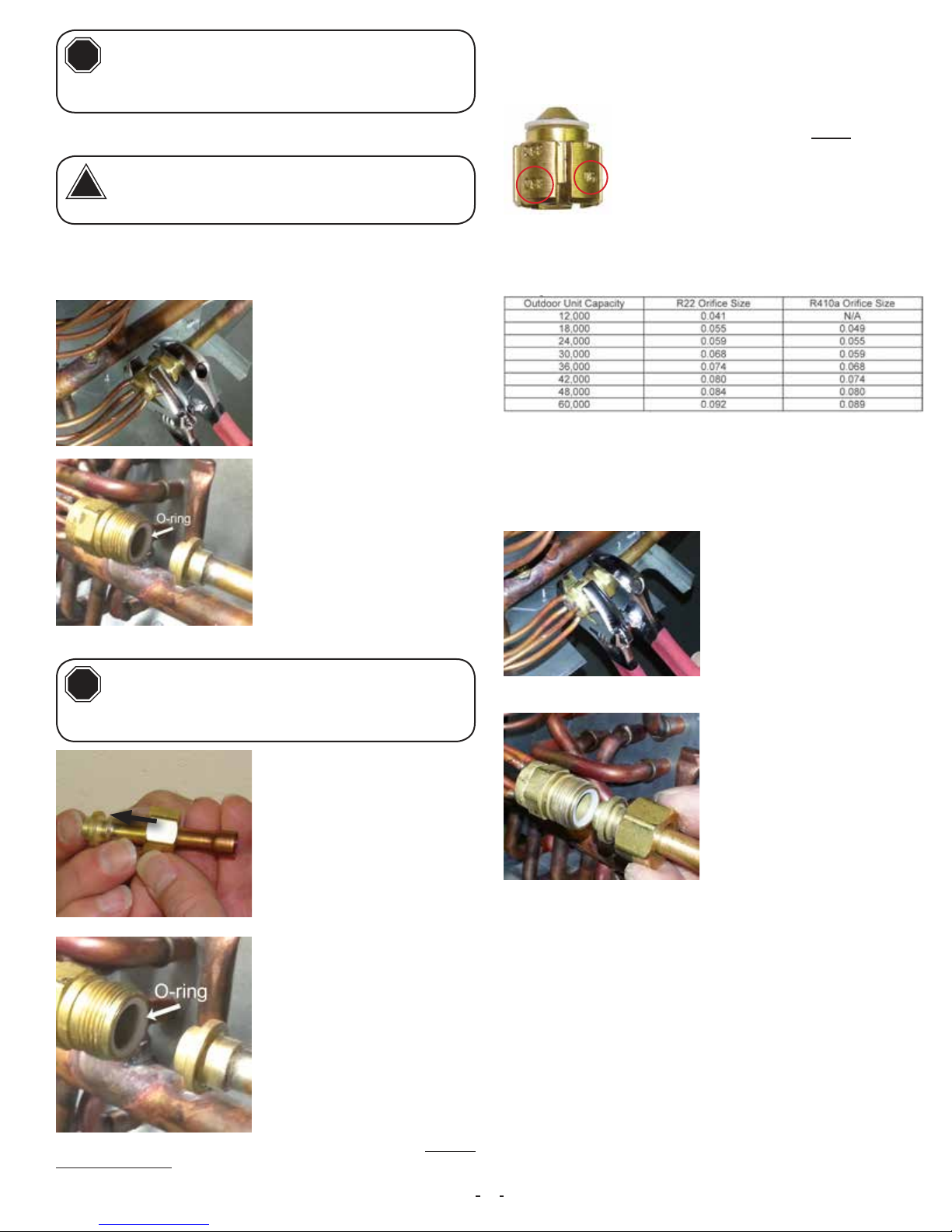

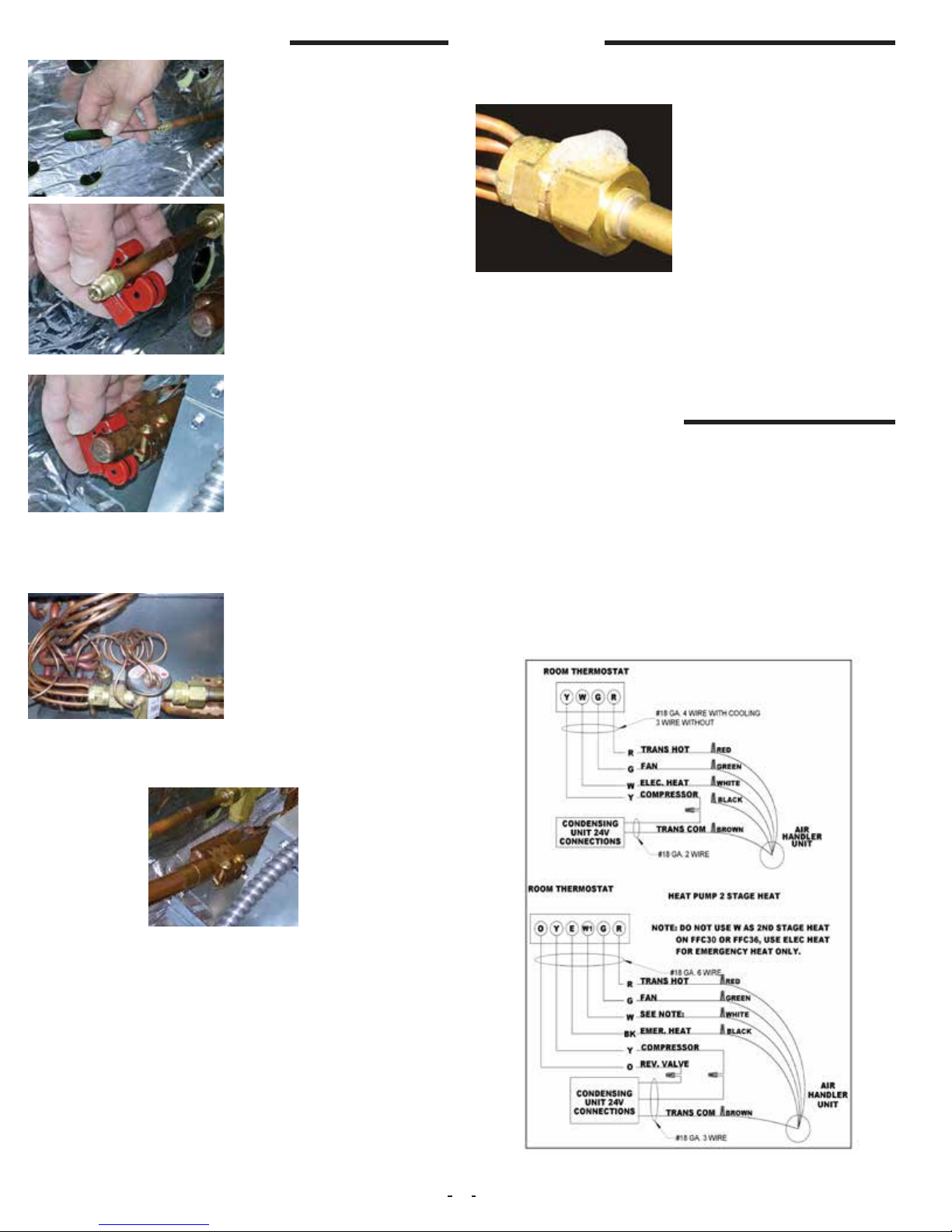

If the line voltage being supplied to the air handler is 208 volt single

phase, the line voltage tap on the low voltage transformer needs to

be moved from the 240 volt tap to the 208 volt tap. If this is not done,

the secondary output voltage of the transformer will be too low (Fig

11-3).

Fig 11-2.

Fig 11-3.

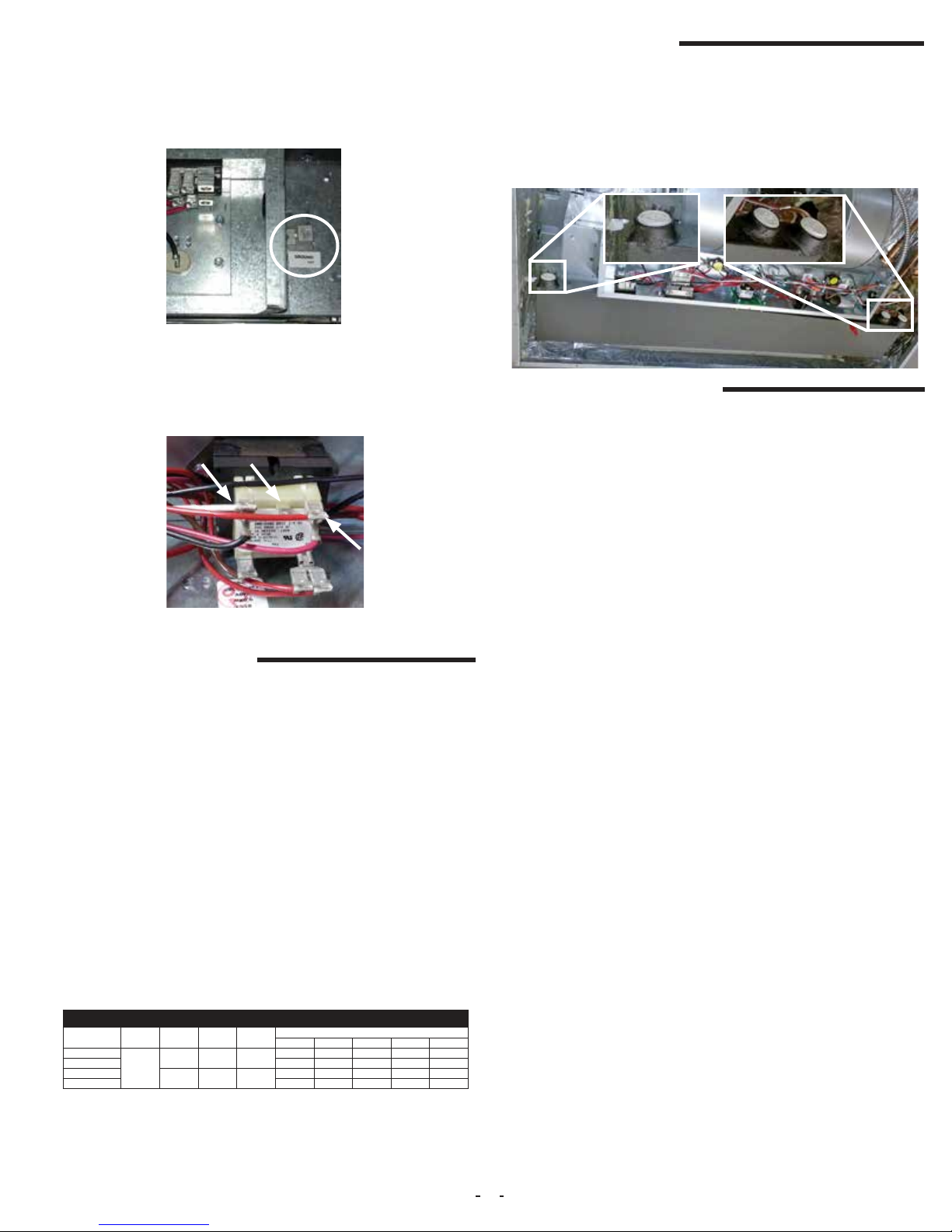

Final air volume adjustments should be made by referencing total

external static pressure (Table 11A-1).

Table 11A-1.

11A. Single Stage Cooling

During cooling mode operation, indoor blower wire “G” will energize

a time delay relay located on the control board inside the air han-

dler. After a short time delay period, the time delay relay will apply

240VAC to the motor via the “MTR“ terminal. (See Schematic Fig

20-1.) Fan time delay periods are 30 seconds ON delay and 120

seconds OFF delay.

The Y wire from the thermostat is not connected at the air handler.

This wire goes directly to the outdoor unit 24 volt wiring to turn on

the outdoor condensing unit when a call for cooling takes place. The

24 volt common for the outdoor unit circuitry is connected at the air

handler brown wire. (See Fig 11-1.)

The heater low voltage wiring terminal “W” is wired directly from the

thermostat to the air handler. The indoor blower, on a call for heat,

will ON delay for a period of 5 seconds. When the call for heat has

been satised, the indoor blower will have an OFF delay time period

of 60 seconds.

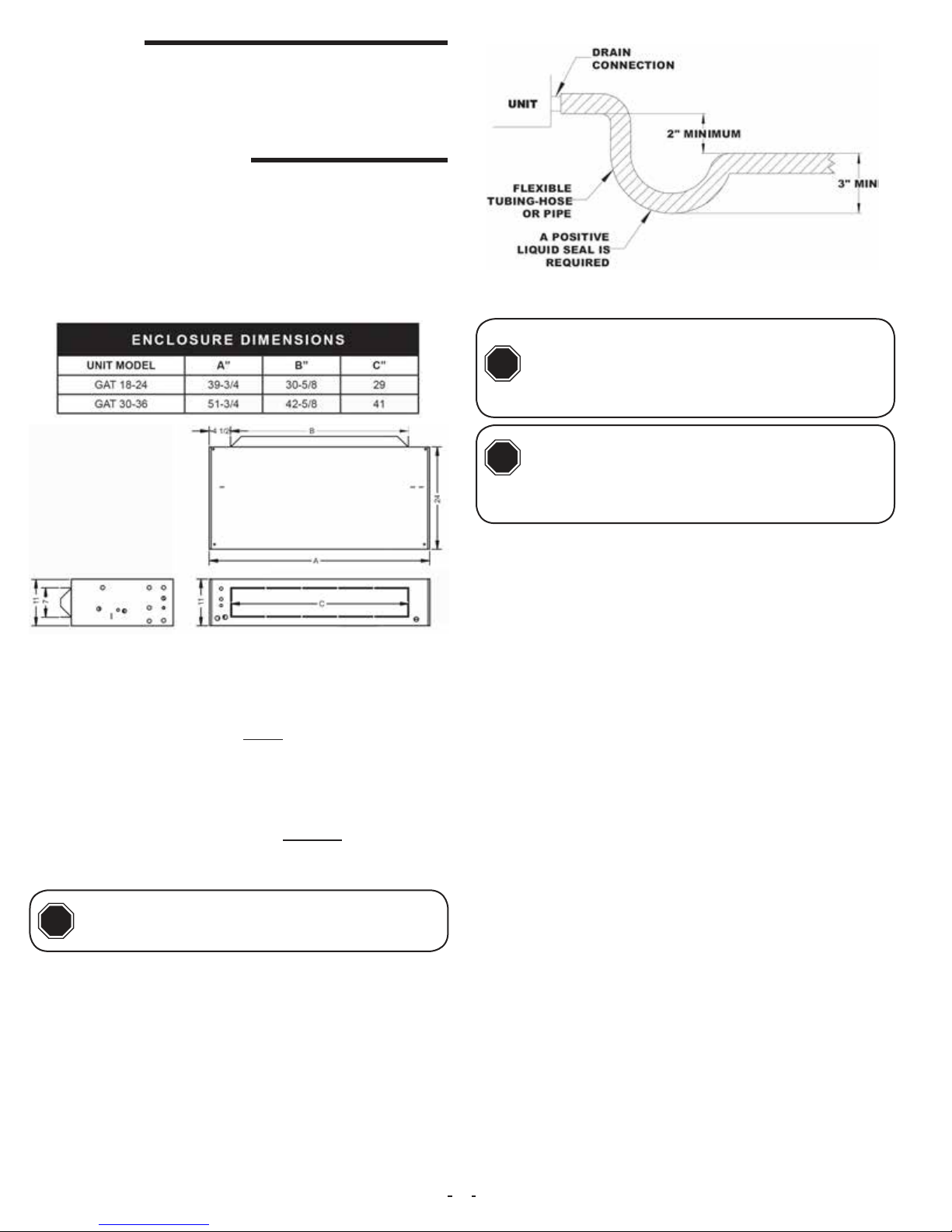

12. Condensate Drain

1. Select desired condensate drain openings according to air han-

dler orientation. Both Primary and Secondary outlets can be used.

2. Pipe condensate system using proper PVC ttings.

3. Ensure a minimum 2” trap is installed in the condensate drain. Lo-

cate the trap near to the connection opening on the air handler. See

illustration.

13. Air Volume Adjustment

Air volume needs to be set to the level recommended by the outdoor

unit equipment manufacturer. Most systems will require around 400

CFM of indoor air for every 1 ton of system cooling capacity. The air

volume must be set prior to attempting system charge.

This air handler uses a PSC type motor. The speed of this motor

is set by placing the appropriate winding lead wire on the “MTR”

terminal of the control board. Unused motor winding leads are to

be placed on the “BLANK” terminals on the control board. The air

volume level produced by the air handlers at varying external static

pressure levels is shown in Table 11A-1.

240VAC

Tap

208VAC

Tap

ELECTRIC H EAT KIT NOMENCLATURE

H C S 10

H = Fits GAS, GAT, GES*, GET* Power Connection

C = Circuit Breaker

L = Large Cabinet (42 - 61)

S = Small Cabinet (18 - 36)

Heat Strip

00 = NO Heat

03 = 3 KW

05 = 5 KW

06 = 6 KW

08 = 8 KW

10 = 10 KW

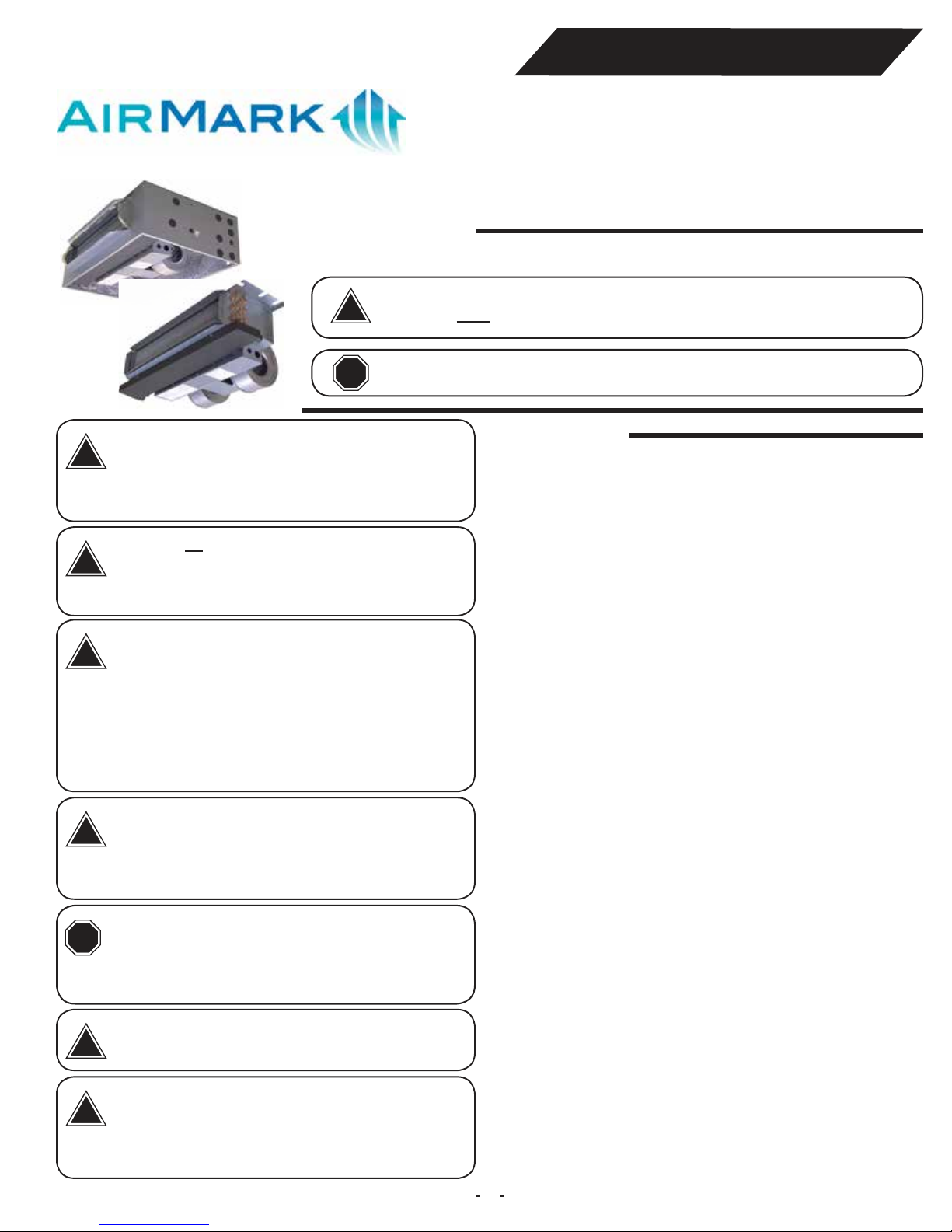

BLOWER DATA

UNIT MODEL RPM AMP VOLT HP CFM VS. STATIC PRESSURE

0.00 0.10 0.20 0.30 0.40

GAT 18

1625

1.4 240 1/4 850 775 700 675 600

GAT 24 1000 900 850 775 700

GAT 30 2.15 240 1/3 1200 1150 1100 1050 975

GAT 36 1600 1500 1400 1300 1200

HEATING AND COOLING PERFORMANCE & ELECTRICAL DATA

MODEL HEAT KIT

PERFORMANCE DATA ELECTRICAL DATA

NOMINAL

COOLING

(TONS)

HEATING

(KW)

HEATING

CAPACITY

(MBTUH)

MIN-CIRCUIT

AMPACITY

MAX FUSE OR

CIRCUIT

BREAKER

208V 204V 208V 204V 208V 204V 208V 204V

GAT 18

HCS00

1.5

0.0 0.0 0.0 0.0 1.9 2.3 15.0 15.0

HCS03 2.3 3.0 7.7 10.3 15.0 17.0 15.0 20.0

HCS05 3.8 5.0 13.0 17.1 24.0 29.0 30.0 30.0

HCS08 6.1 8.0 20.8 27.3 28.0 43.0 40.0 50.0

HCS10 7.6 10.0 25.9 34.1 47.0 54.0 50.0 60.0

GAT 24

HCS00

2.0

0.0 0.0 0.0 0.0 1.9 2.3 15.0 15.0

HCS03 2.3 3.0 7.7 10.3 15.0 17.0 15.0 20.0

HCS05 3.8 5.0 13.0 17.1 24.0 29.0 30.0 30.0

HCS08 6.1 8.0 20.8 27.3 28.0 43.0 40.0 50.0

HCS10 7.6 10.0 25.9 34.1 47.0 54.0 50.0 60.0

GAT 30

HCS00

2.5

0.0 0.0 0.0 0.0 2.0 3.0 15.0 15.0

HCS03 2.3 3.0 7.7 10.3 15.0 18.0 15.0 20.0

HCS05 3.8 5.0 13.0 17.1 25.0 29.0 30.0 30.0

HCS08 6.1 8.0 20.8 27.3 40.0 45.0 40.0 50.0

HCS10 7.6 10.0 25.9 34.1 49.0 55.0 50.0 60.0

GAT 36

HCS00

3.0

0.0 0.0 0.0 0.0 2.0 3.0 15.0 15.0

HCS03 2.3 3.0 7.7 10.3 15.0 18.0 15.0 20.0

HCS05 3.8 5.0 13.0 17.1 25.0 29.0 30.0 30.0

HCS08 6.1 8.0 20.8 27.3 40.0 45.0 40.0 50.0

HCS10 7.6 10.0 25.9 34.1 49.0 55.0 50.0 60.0

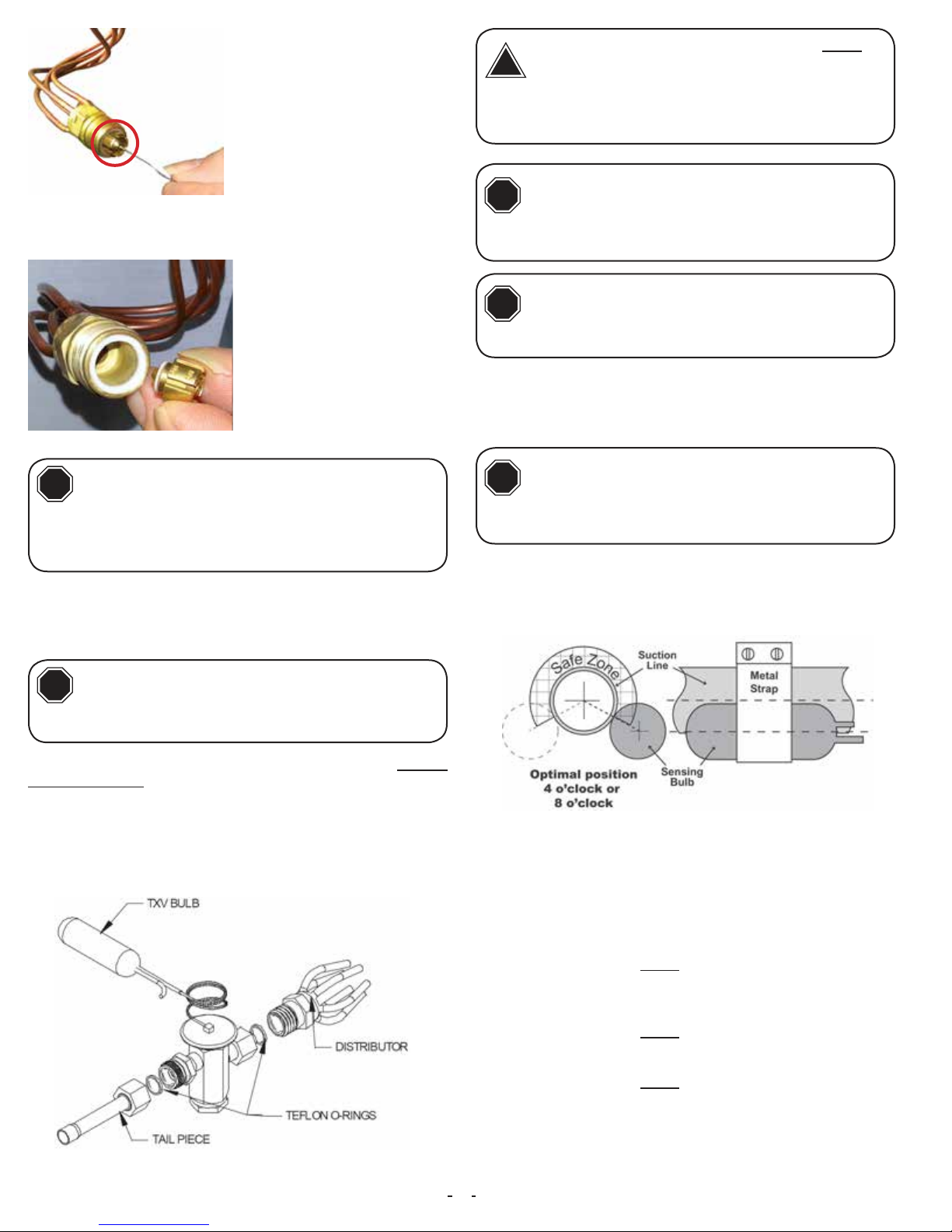

AIR H ANDLER C HASSIS N OMENCLATURE

G A T 18 G -001

AirMark

Air Handler

Voltage

A = 240V PSC Motor

B = 120V PSC Motor

Conguration

T = Cased Ceiling Mount

Nominal

Tonnage

(MBTUH)

Metering Device

4 = non-bleed A/C or H/P R410 TXV

6 = 20% bleed A/C or H/P R410 TXV

B = 20% bleed A/C or H/P R22 TXV

F = R-22 Flo-rater

G = R-410A Flo-rater

X = non-bleed A/C or H/P R22 TXV

Option Code

1. Select a speed tap from the CFM table and connect appropriate

motor lead wire to the “MTR“ terminal on the control board.

2. Call for fan only operation at the thermostat.

3. Read the external static pressure level on the Magnehelic gauge.

4. Make speed tap selection change to get the air volume as close

as possible to the required level.

5. If the static pressure is above .5” wc, excessive turbu-

lence or duct friction needs to be reduced. (Obstructions in

the duct system can also cause excessive static pressure.)

6. When proper air volume is established, move on to the charging

procedure.

Use a Magnehelic Gauge with a 1” scale and two static pressure

tips to measure the static pressure during the air volume adjustment

procedure. The high port static pressure tip should be placed in the

supply duct near the outlet of the air handler. The low port static pres-

sure tip should be placed in the return air duct near the entrance to

the air handler.

Use a Magnehelic Gauge with a 1” scale and two static pressure

tips to measure the static pressure during the air volume adjustment

procedure. The high port static pressure tip should be placed in the

supply duct near the outlet of the air handler. The low port static

pressure tip should be placed in the return air duct near the entrance

to the air handler. The factory provided air lter should be in place

inside of the air handler.

COM