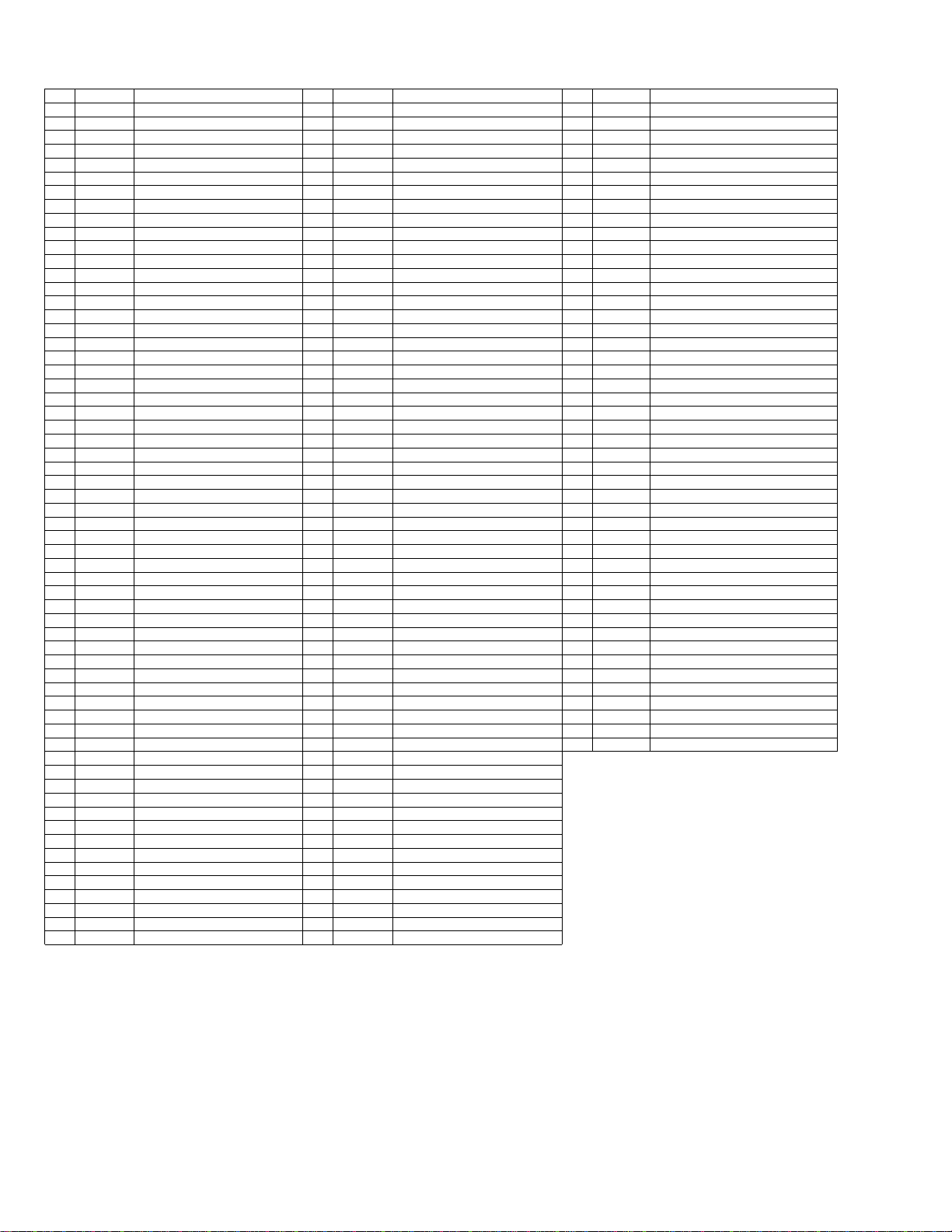

RB655 Parts list

IND Code Description IND Code Description IND Code Description

1 RB70025 PLANET CAGE B UNIT 84 RB70081 SENSOR BOAD E UNIT 149 RB10795 GRIP COVER L

2 BB40427 T-BOLT 4 X 8 85 KK33329 TORSION SPRING 3329 150 RB10796 GRIP COVER R

3 KK23847 COMP. SPRING 384

86 LL62013 PLAIN BEARING B-F3-1 153 RB10854 TRIGGER

4 RB10344 KEY PLATE 87 RB11768 ARM B SET SCREW 154 RB10855 TRIGGER LOC

6 RB70027 SUN GEAR UNIT 88 RB10739 ARM A SET SCREW 155 RB70367 MAIN BOARD UNI

7 RB70029 MAGAZINE HOLDER UNI

89 RB10740 WIRE GUIDE LEVER 157 RB70101 TRIGGER SWITCH

8 AA21102 PAN-HEAD SCREW 3X4 90 CC49118 HEX NUT 3X7.

160 RB10423 LABEL, MAIN SWITCH

9 FF51652 PIN 1652 95 RB70278 FEEDING GEAR BASE ASSY 161 RB10421 LABEL, FCC (USA)

10 AA31714 SCREW 2X4 96 RB70299 FEEDING GEAR B UNIT 162 RB10799 TORQUE ADJUSTMENT LABEL

11 CC41104 HEX.NUT 1-3 FOR HD-12/1

97 FF41728 STEP PIN 1728 163 RB11921 NAME LABEL (USA)

16 CC41101 HEX NUT 1-5 98 RB10775 RELEASE LEVER 164 RB10846 WIRE LOADING LABEL

19 JJ21603 C-RING 20 99 BB40420 BOLT 4 X 16 165 RB10847 WIRE SETTING LABEL

31 RB10725 INTERNAL GEAR B 100 EE39121 PLAIN WASHER 5 166 RB10962 ARM CAUTION LABEL

32 RB10726 PLANET GEAR B 101 EE39168 WASHER 4.2X1.3X1 167 RB70084 HARNESS 11P UNIT

33 RB10776 GEAR RETAINER 102 FF51628 HOLLOW PIN 1628 168 RB70085 HARNESS 7P UNIT

36 BB40481 BOLT 3X5 103 JJ10514 E-RING 3 CF 169 RB70086 HARNESS 3P UNIT

38 FF41822 STEP PIN 1822 104 KK23851 COMP. SPRING 3851 170 RB70339 FAN UNIT

39 JJ10113 E-RING 2.5 105 LL11181 WHEEL 6704 171 RB11884 FILTER

40 KK33249 TORSION SPRING 3249 106 RB10043 STEP PIN 172 RB11885 FILER B

41 RB10370 JAW BASE 107 RB10338 INTERNAL GEAR 173 RB11004 PROTECTOR C

42 RB10735 JAW B 108 RB10341 PLANET GEAR 174 EE39830 WASHER 5.1X 9

43 RB10779 JAW A 109 RB10484 GEAR PRESS WHEEL 175 RB11777 STOPPER PLATE

44 RB70056 MOTOR GEAR B UNIT 110 RB10770 FEED GEAR A 176 RB10718 SLEEVE GUIDE

45 RB70026 ARM A UNIT 111 RB10774 WIRE GUIDE C 177 RB11762 HOOK L

46 RB70036 WIRE GUIDE A2 UNIT 112 RB10852 RELEASE STOPPER 178 RB11763 HOOK R

47 RB70276 WIRE GUIDE UNIT 113 RB70079 SENSOR BOARD C UNIT 179 RB11886 FAN PROTECTOR

48 AA22415 SCREW 3X8 114 RB70087 WARNING LED UNIT 180 RB11883 FILTER COVER

49 AA71408 SCREW 3 X 3 115 RB70341 MAIN SWITCH UNIT 181 RB10724 SLEEVE COVER

50 EE31801 WASHER 3.2X7 116 AA31721 SCREW 3X6 182 RB11003 PROTECTOR B

51 FF41729 SETP PIN 1729 117 AA74410 SCREW 3X6 183 CK10198 SCREW 3X10

52 KK23849 COMP. SPRING 384

118 RB10400 LEAF SPRING 184 RB11775 BINDING HEAD SCREW

53 RB10737 WIRE GUIDE A1 119 RB10536 MAIN SWITCH BASE 185 RB11776 MAGAZINE LEAF SPRING

54 RB10743 WIRE GUIDE BASE 120 RB10537 JOINT, DIAL 187 RB81108 MAGAZINE COVER KI

55 RB70039 ARM B UNIT 121 RB10853 TORQUE DIAL 188 FF31559 PIN 1559

56 BB40425 BOLT 3X10 122 RB81102 MAGAZINE ASS

189 FF51656 PIN 1656

57 BB40810 BOLT 3X16 123 RB10783 PROTECTOR 191 JJ10510 RETAINING RING 2.

58 CC41103 HEX. NUT 1-4 124 RB10785 BUSH A 192 RB70217 MAGNET HOLDER UNIT

59 FF41730 STEP PIN 1730 125 RB10786 BUSH B 193 RB11666 ARM COVER

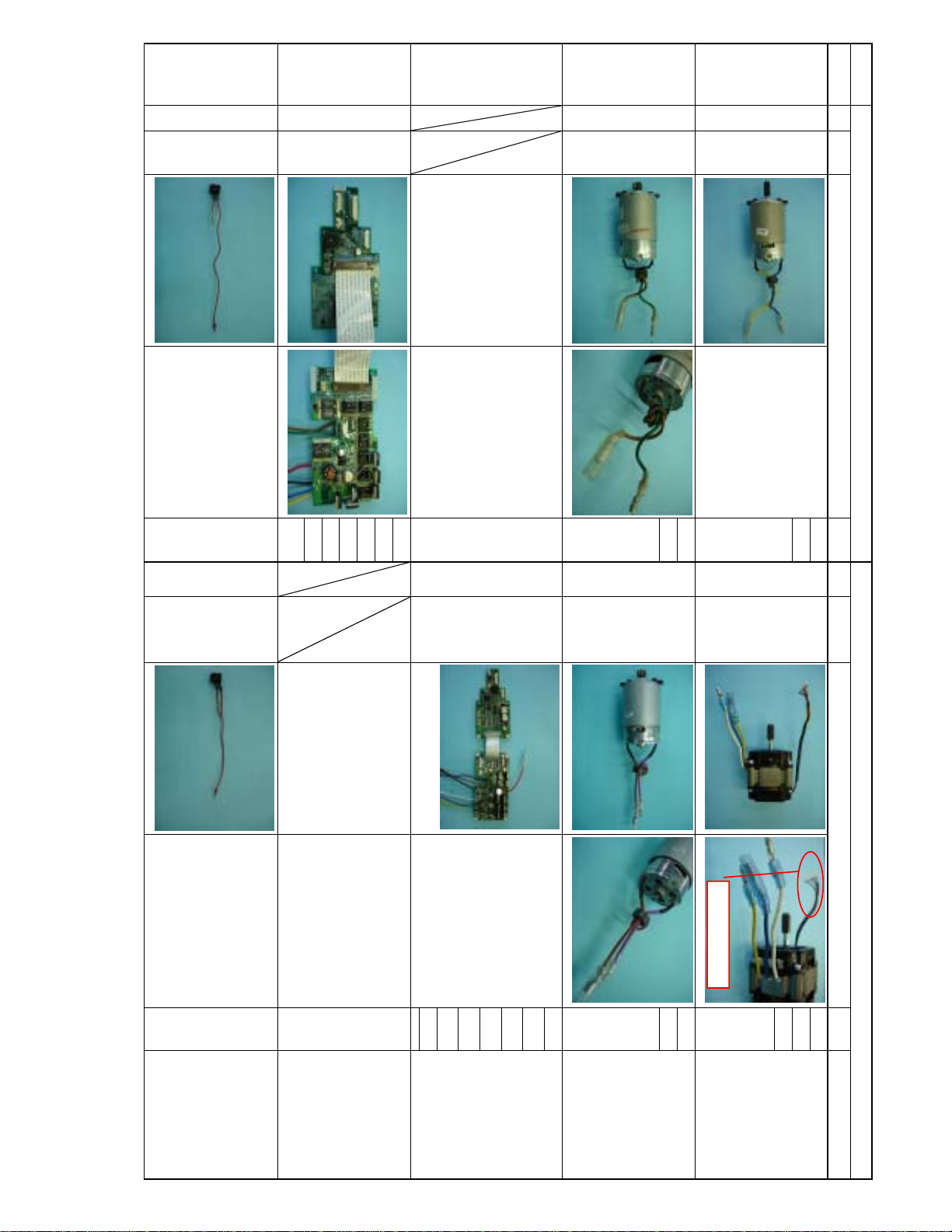

60 JJ10509 E-RING 4CF 126 RB10787 SENSOR COVER 201 RB70349 TWISTING MOTOR TD5046 UNIT

61 RB10746 WIRE GUIDE B 127 RB10791 SENSOR COVER PLATE 202 RB70351 FEEDING MOTOR RS-55VC UNI

62 RB10747 ARM C 128 RB10792 RETAINING RING 203 RB70222 FEED GEAR SHAFT

63 RB10748 FIXED CUTTE

129 RB70082 SENSOR BOARD F UNIT 205 RB70113 MAIN SWITCH BASE ASSY

64 RB10749 CUTTER 130 AA32708 SCREW 2.6X6 207 RB70284 TWISTER ASSY

65 RB10750 CUTTER CONNERCTING ROD 131 RB81103 MAGAZINE COVER ASS

208 RB70033 FINGER BASE ASSY

66 RB70277 CUTTER LEVER UNIT 132 RB11774 MAGAZINE COVER LOC

209 RB70281 ARM A ASS

67 RB11767 CUTTER SHAFT 133 RB10806 ADJUST RING 210 RB70285 ARM B ASS

69 RB10754 CURL GUIDE

134 BB40405 BOLT 5X25 211 RB70283 TWISTER A ASSY

70 RB10755 CURL GUIDE B 135 EE32104 WASHER 2-3

71 RB70041 COVER L UNIT 136 EE39172 WASHER 5.1X12X1.2

72 RB70042 MAGNET HOLDER L UNIT 137 EE39602 WASHER 7

73 KK23850 COMP. SPRING 3850 138 FF31289 PIN 1289

74 KK33328 TORSION SPRING 3328 139 KK33327 TORSION SPRING 3327

75 RB70369 TWIST GUIDE COVER L 140 RB81106 FRAME L ASSY (USA)

76 RB10759 TWIST GUIDE SHAFT 141 RB81107 FRAME R ASSY (USA)

77 RB11667 SENSOR ROD 142 BB40410 BOLT 3X8

78 RB70044 COVER R UNIT 143 BB40811 BOLT 3X25

79 RB70045 MAGNET HOLDER R UNIT 144 RB10970 ELECTRODE BLOCK

80 KK33330 TORSION SPRING 3330 145 KK23656 COMPRESSION SPRING 365

81 RB70370 TWIST GUIDE COVER R 146 RB10213 WINDOW

82 RB10765 SENSOR BASE 147 RB81034 MOTOR COVER ASSY

83 RB70080 SENSOR BOARD D UNIT 148 RB11769 ELECTRODE PLATE

- 2-

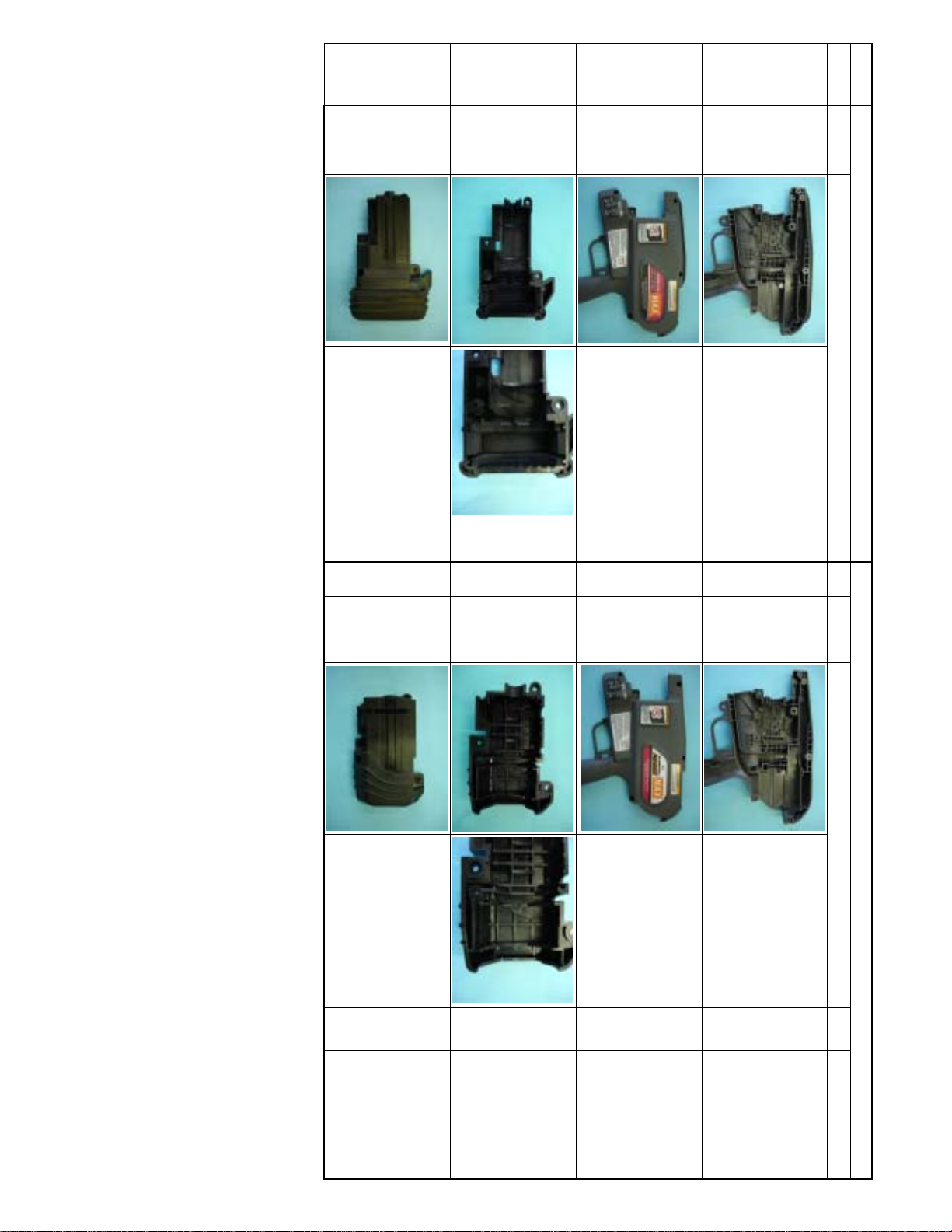

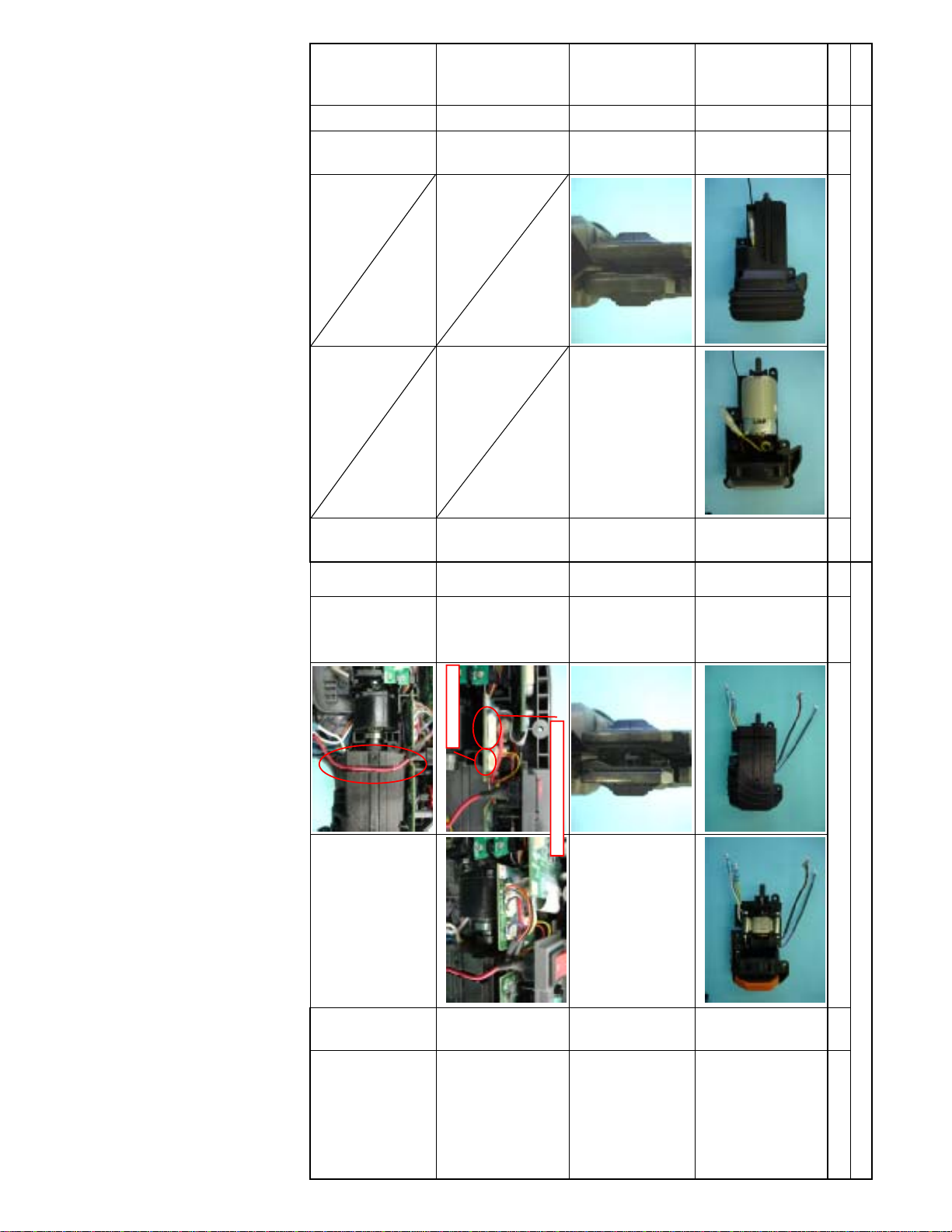

* You can get most updated list at www.maxusacorp.com