LIMITED PRODUCT WARRANTY

Airsled, Inc. (warrantor) uses the utmost care in the manufacturing of its products, and this is warranted to

be free from defects in material and workmanship, subject to the following limitations, qualifications and

conditions.

IDENTITY OF PARTY COVERED BY WARRANTY

This warranty extends only to the first customer purchaser and not to any subsequent transferee.

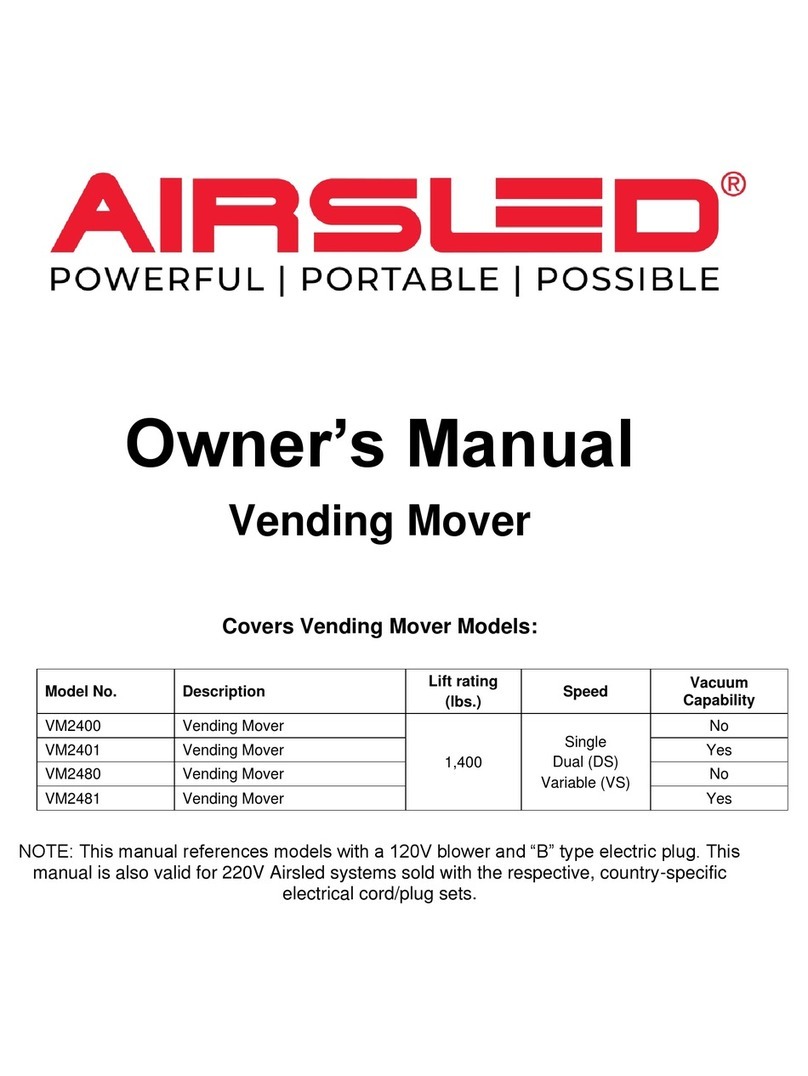

DESCRIPTION AND IDENTIFICATION OF PRODUCT

This warranty covers the following products of the warrantor; Airsled Vending Movers.

WARRANTY STATEMENT

Airsled, Inc. (warrantor) offers a thirty-day money back satisfaction warranty from the date of purchase,

excluding all shipping costs. In the event of a defect, malfunction, or failure to conform to this warranty, the

warrantor, at its election, will replace or repair such merchandise, including parts and labor, the warrantor

shall provide return labels. Defects, malfunctions, failure, or damage to the product caused by improper

unreasonable or negligent abuse are specifically excluded from this warranty. In the event any repair or

modification is done to this product during the term of the warranty by anyone other than the Warrantor, the

defect applicable to such repair or modification shall be specifically excluded from this warranty, and

Warrantor, in its sole operation, may determine if this exclusion shall be applicable. This warranty shall not

apply to expendable parts, filters, and the finish of painted parts. If products are returned within the 30-day

period with visible signs of heavy usage and/or damage, Airsled reserves the right to withhold 15% of the

purchase price to cover repair and refurbishment costs.

TERM OF WARRANTY

This warranty shall extend for a period of one (1) year from the date of original purchase by the first

consumer purchaser but shall expire prior thereto if the same shall be transferred to another person.

TO OBTAIN PERFOMANCE OF WARRANTY

To obtain performance of this warranty obligation, the eligible consumer must deliver the defective product,

with shipping and delivery charges prepaid, to:

Airsled, Inc.

70-A Aleph Dr.

Newark, DE 19702

Attn: Customer Service Dept.

The eligible consumer should also provide satisfactory evidence of the purchase date. In the event the

defect involves a not too labor intensive or costly correction, the warrantor shall replace or repair the product

and return the same to the consumer, with all return shipping and delivery charges prepaid.

LIMITATION ON REFUND

The Warrantor reserves the right to elect a refund in lieu of repair or replacement of the product provided

the Warrantor is unable to provide replacement and repair is not commercially practical or cannot be timely

made.

EXCLUSION OF ALL OTHER WARRANTIES

Other than as expressly provided herein, warrantor makes no other warranty express or implied with respect

to the product sold. Warrantor makes no warranty of product merchantability and no warranty of fitness of

the product for a particular purpose.

EXCLUSION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES