Installation and Wiring Instructions for the

Air+ Wall Positive Ventilation Unit.

INTRODUCTORY NOTES

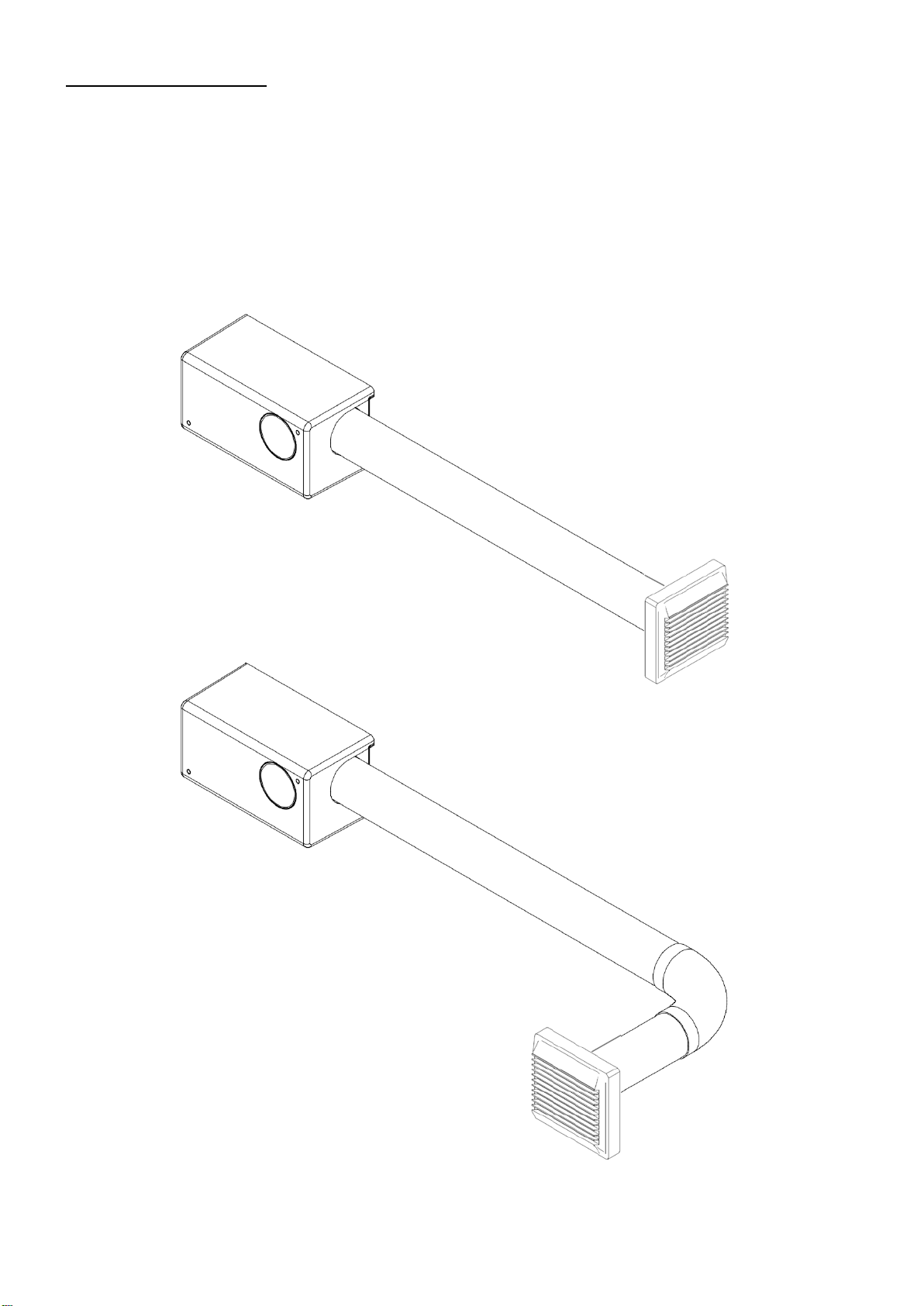

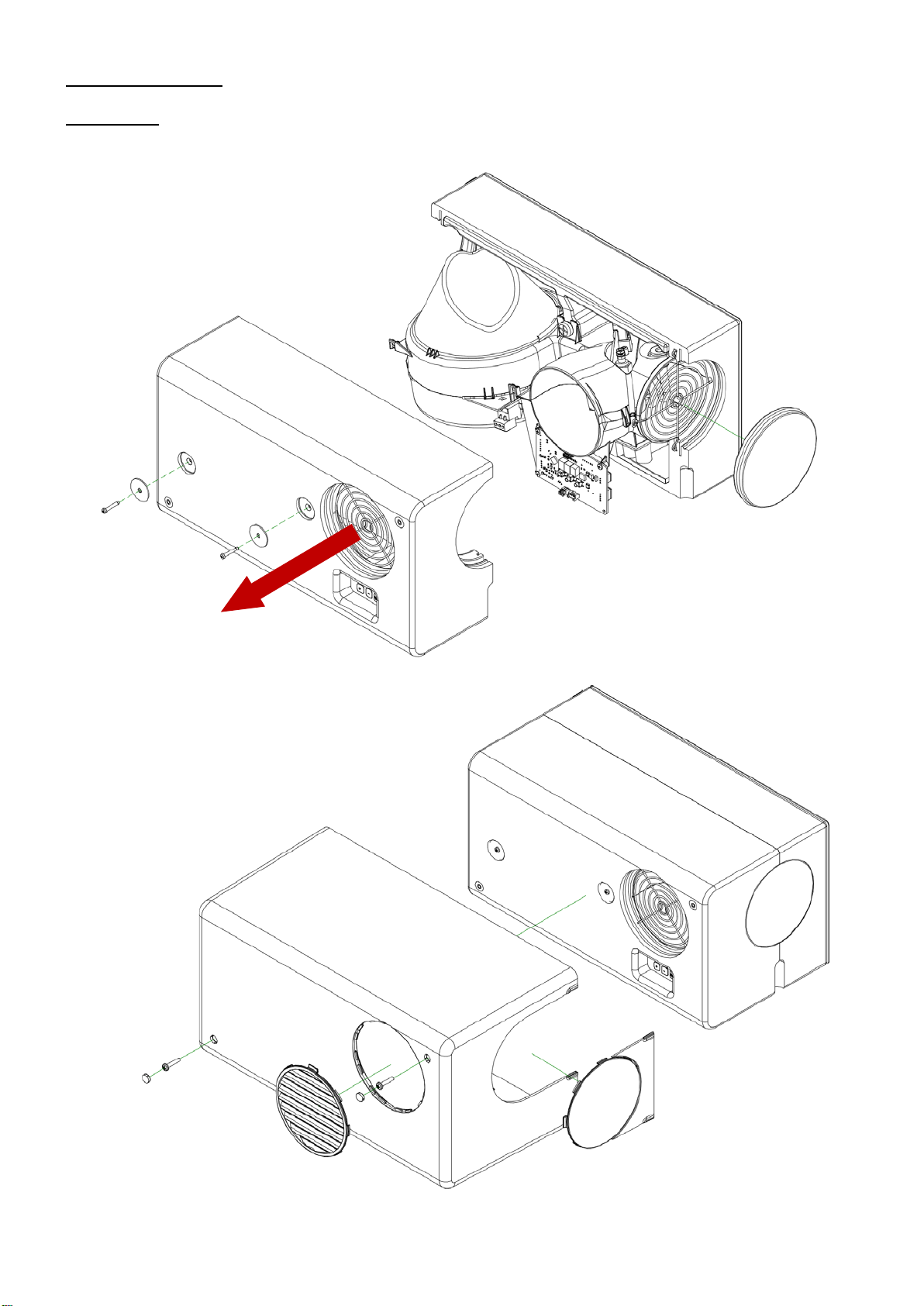

The Unit is a positive input ventilation unit, designed to be installed on a wall of a

dwelling to continually supply filtered fresh air into the building. The system

consists of a fan unit with heater.

The Unit has an adjustable speed settings. These speeds are set during installation;

there are 4 pre-set speeds or an option allowing the speeds to be chosen manually from

10 L/s - 30 L/s. The Unit uses a sensor to monitor the supply temperature into the

room. If the ambient room temperature exceeds 27°C (adjustable during commissioning),

the unit will automatically switch to standby (no airflow), unless installed in radon

mode (selectable during commissioning).

All models are supplied with a heater; the element is activated by default when the

supply air temperature drops below the adjustable threshold. The heater will try and

maintain the supply air temperature at the threshold temperature. The threshold

temperature can be adjusted during commissioning.

The unit also incorporates a data logging function. This function will display total

runtime of system, energy consumption of the fan and energy consumption of the heater.

This data is resettable (when in data logging menu, hold the + and – button for 15

seconds until you see the word “RESET” on the display).

SAFETY AND GUIDANCE NOTES

IMPORTANT: READ THESE INSTRUCTIONS BEFORE

COMMENCING THE INSTALLATION

1.

DO NOT install this product in areas where the following may be

present or occur:

1.1.

Excessive oil or a grease laden atmosphere.

1.2.

Corrosive or flammable gases, liquids or vapours.

1.3.

Ambient temperatures higher than 40°C or less than -10°C.

1.4.

Possible obstructions which would hinder access or removal

of the Fan.

1.5.

Relative humidity above 90%

1.6.

Sudden ductwork bends or transformations close to the Unit.

1.7.

To achieve optimal airflow, the unit should be mounted 1.8m

from floor level.

2.

All wiring to be in accordance with the current I.E.E.

Regulations, or the appropriate standards of your country and MUST

be installed by a suitably qualified person.

3.

The fan must be provided with a 3A fused, isolator switch capable

of disconnecting all poles, having a contact separation of at

least 3mm.

4.

Ensure that the mains supply (voltage, frequency, and phase)

complies with the fan’s rating label.

5.

The fan should not be used where it is liable to be subjected to

direct water spray.

6.

This appliance can be used by children aged from 8 years and above

and persons with reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they have been given

supervision or instruction concerning use of the appliance in a