Inspect the box and pump carefully for any signs of damage incurred in transit. Since all pumps are ordinarily

shipped F.O.B. from our factory or regional warehouse, such damage is normally the responsibility of the

carrier and should be reported to them.

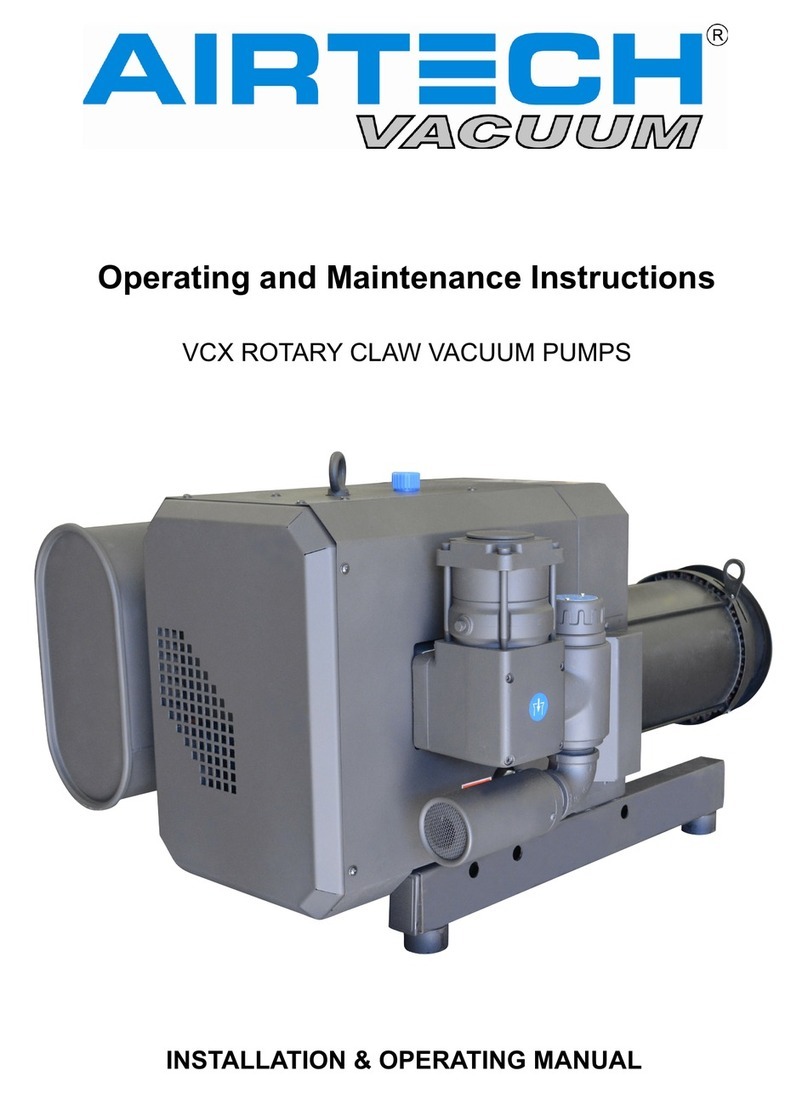

The vacuum pump is bolted to the skid with studs that are connected through the rubber feet of the

pump. Remove the nuts from the underside of the crate and remove the pump. Unscrew the studs

from the rubber feet.

The inlet and exhaust of the pump are covered with plastic caps to prevent dirt and other foreign

substances from entering the pump. Leave these caps in place until you are ready to pipe the pump

to your equipment.

1.2 Location

Install the pump in a horizontal position on a level surface so that the pump is evenly supported on its

rubber feet. Leave 12-18” of access around the pump to allow proper cooling. Also, adequate

ventilation must be provided for the fans, radiator, and motor.

Allow access to the oil sight glass in order to inspect the oil level, and the exhaust port for easy access

to change the exhaust filters.

Do not tip the pump over if filled with oil.

1.3 Power Requirements

A schematic diagram for the electrical motor terminal connections is located in the junction box of the

motor or on the motor nameplate.

The motor must be connected according to the electrical codes through a fused switch in order to protect the

motor against electrical or mechanical overload conditions. The overload of the motor starter must be set at

a level equal to the full load motor current listed on the motor nameplate.

If the pump is supplied with a motor starter, it is preset at the factory according to customer specifications.

It is advisable to check that these settings are in line with the voltage at your location. If the voltage is

different, please contact Airtech for motor and starter information.

Correct direction of rotation is marked by an arrow on the motor fan housing and is counterclockwise when

looking at the motor from the motor’s fan side.

After electrical connections have been made, but prior to filling with oil, the rotation of the motor should be

checked. If backward, reverse any two leads of the three at the power connection.

1.4 Vacuum Connections

Use a pipe size that is at least the size of the pump inlet connections. Smaller lines result in a reduced

pump capacity.

Pumps operating in parallel on a common main line should have a manual or automatic operated shut-off valve

or positive action check valve, installed in the suction line adjacent to the pump suction flange. The built-in anti-

suck back valve should not be used as a shut-off valve for the vacuum system.

Remove the plastic protective cap from the inlet port prior to connection of the pump to the system.

Should process gas contain dust or other foreign particles, a suitable in line (inlet) filter should be connected to

the inlet port. Consult Airtech Inc. for recommendations.

The vacuum piping should be designed to ensure that no liquids such as condensate or liquid carried over from

the process can reach the pump. If this possibility exists, a knock-out liquid separator should be installed.

Consult Airtech Inc. for recommendations.

If an exhaust manifold is connected, install a drip leg and drain near the pump exhaust to prevent exhaust

condensation from entering the exhaust box. The following thread sizes are standard on the Airtech pumps: