CONNECTION DIAGRAM....................................................................................................................................3

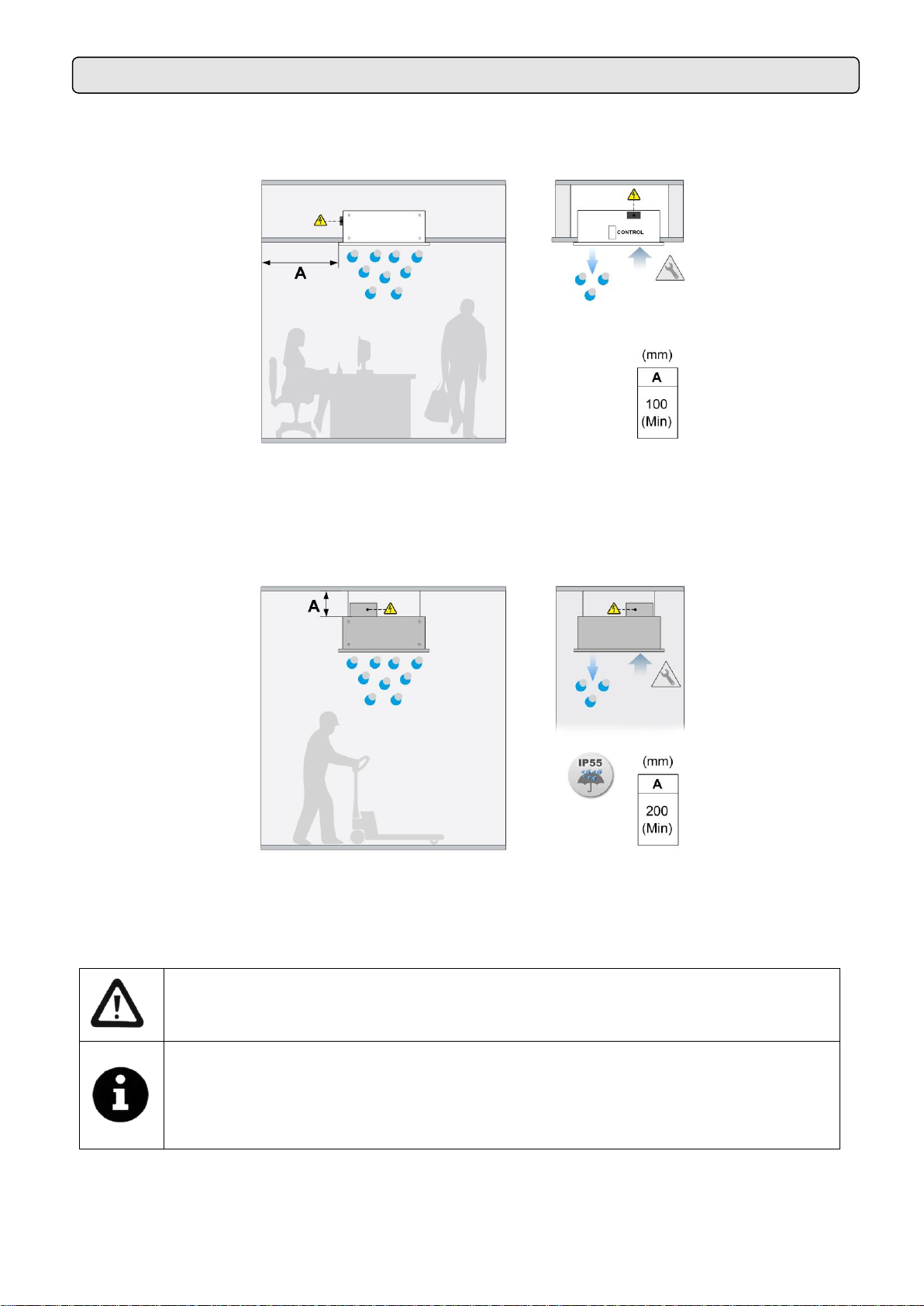

INSTALLATION ....................................................................................................................................................5

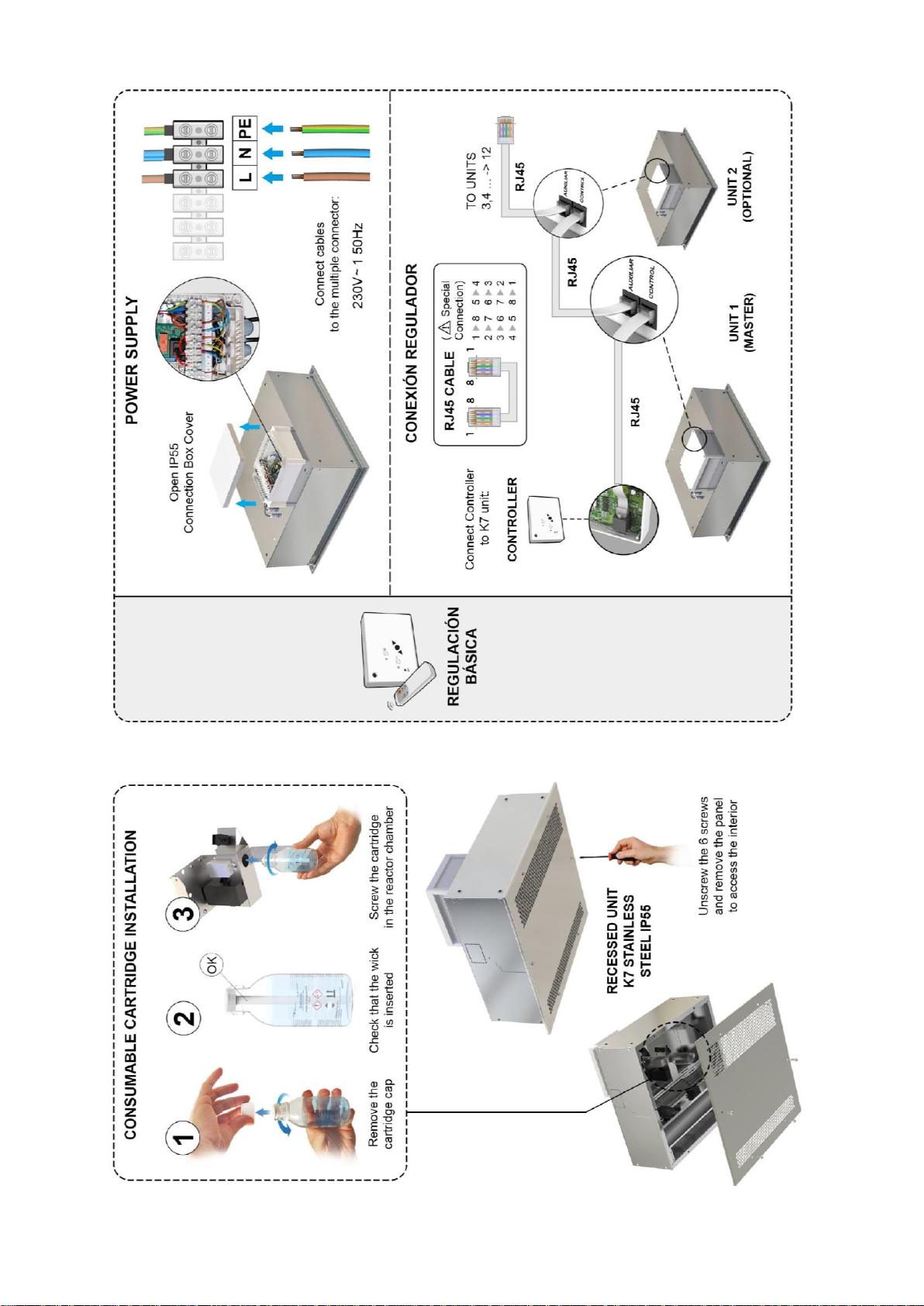

Power supply....................................................................................................................................................6

PCB and control ...............................................................................................................................................6

Fixings..............................................................................................................................................................6

TRANSPORT AND STORAGE ............................................................................................................................7

OPERATING INSTRUCTIONS ............................................................................................................................7

Control board features......................................................................................................................................7

Standard controller features.............................................................................................................................7

Special controls................................................................................................................................................8

Remote control features...................................................................................................................................8

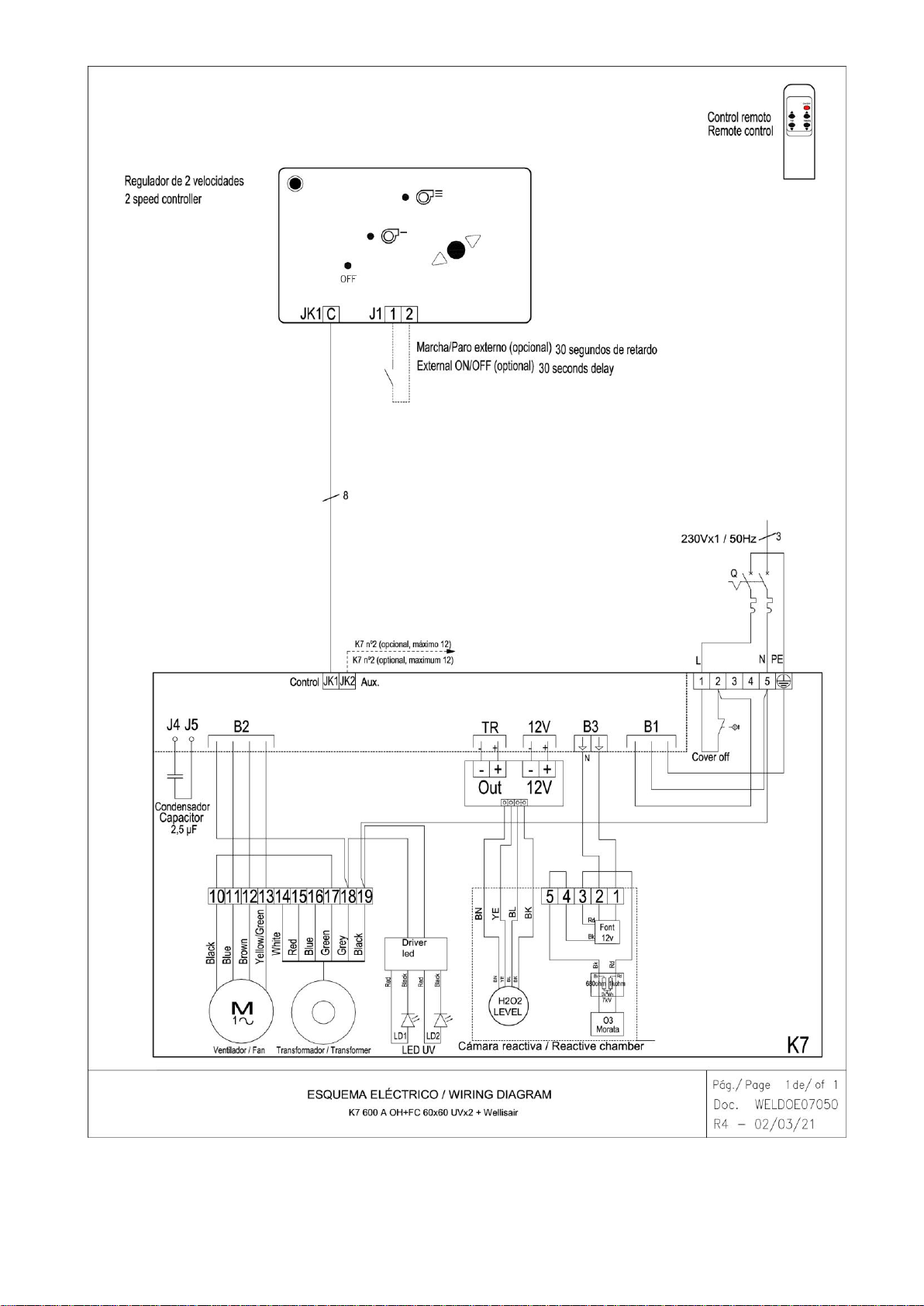

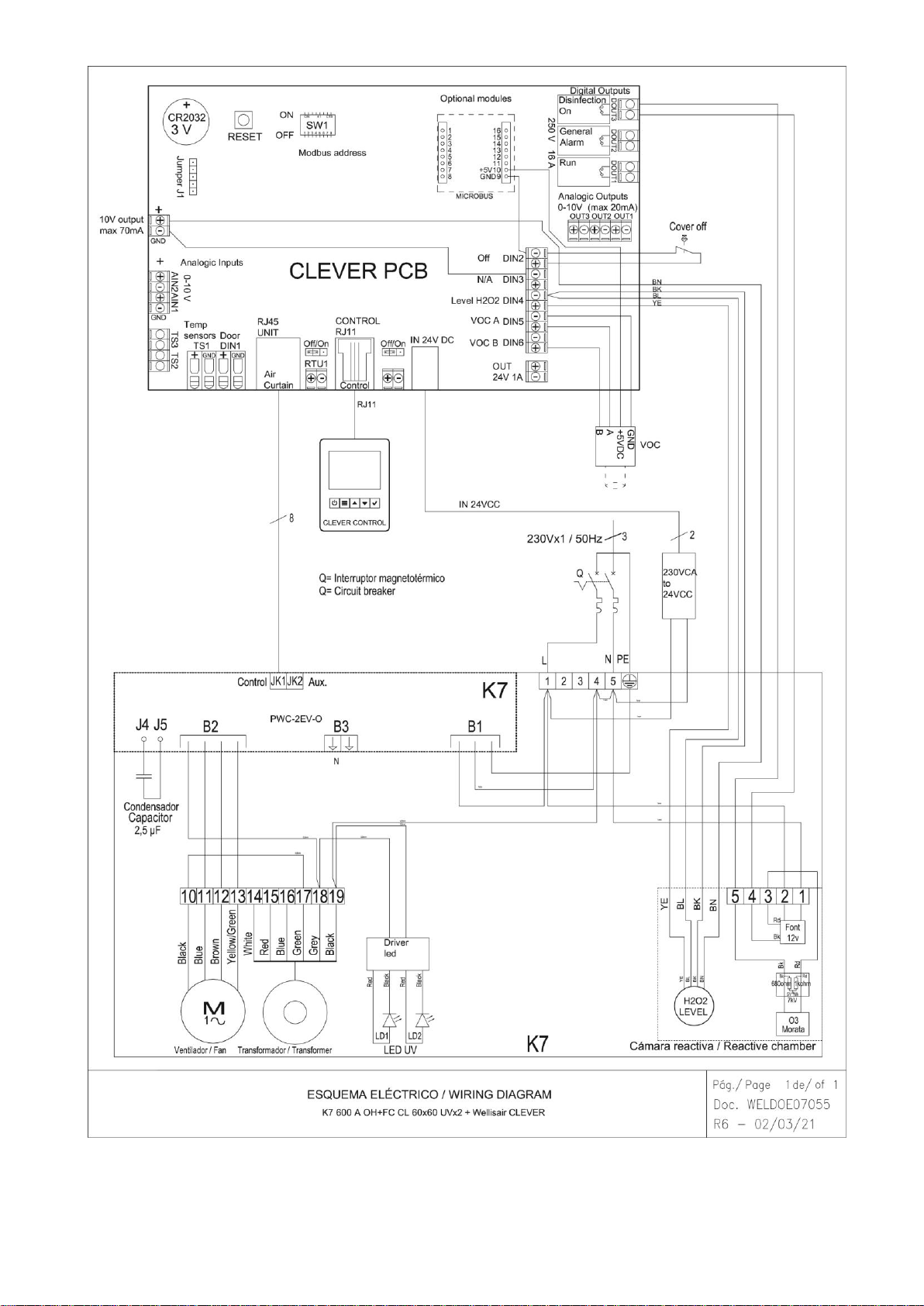

WIRING DIAGRAMS............................................................................................................................................8

DATASHEET ......................................................................................................................................................12

Exterior cleaning.............................................................................................................................................14

Internal cleaning.............................................................................................................................................14

REPAIRS AND REEMPLACEMENTS ...............................................................................................................15

Replacement of the consumable....................................................................................................................15

Standard purifier motor or turbine replacement .............................................................................................16

Fuse replacement...........................................................................................................................................17

PCB replacement ...........................................................................................................................................18

FAILURES AND SOLUTIONS............................................................................................................................19

ACCESSORIES..................................................................................................................................................20

DECLARATION OF CONFORMITY...................................................................................................................21

Purifier identification.......................................................................................................................................22

GUARANTEE .....................................................................................................................................................22