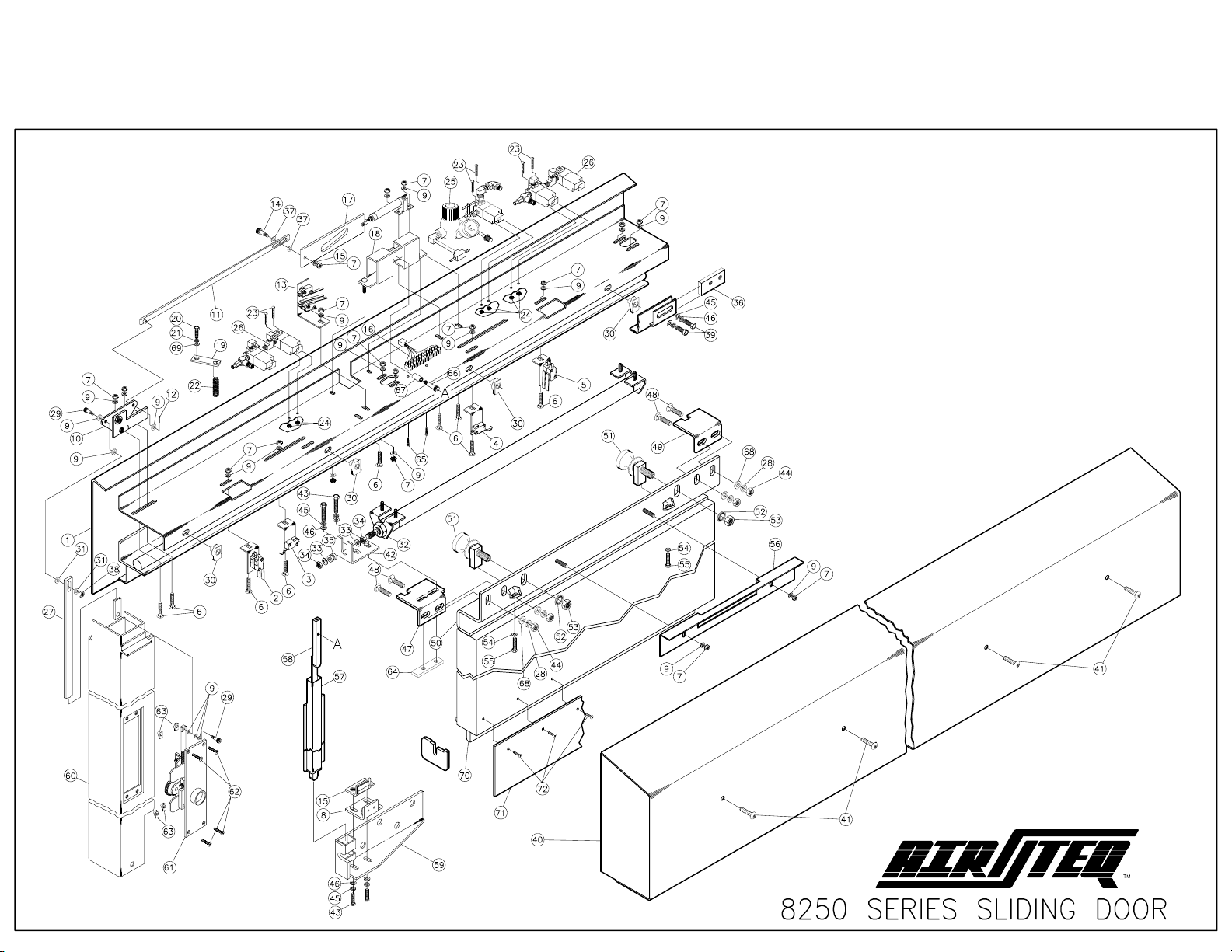

8250 SERIES SLIDING DOOR PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 1 *** BACKPLATE WELDMENT, L/C (SHOWN)

1 1 *** (OR) BACKPLATE WELDMENT, R/C

2 1 82008903 ASSY, LIMIT SWITCH, DBL, LH

3 1 820090 ASSY, SPEED REDUCING SWITCH, LH

4 1 820395 ASSY, SPEED REDUCING SWITCH, RH

5 1 82008904 ASSY, LIMIT SWITCH, DBL, RH

6 9 10001301 SCREW, CARRIAGE, 1/4-20 X 3/4

7 18 10002407 NYLOCK NUT, 1/4-20 ZINC PLATED

8 1 821017 ASSY, OUTSIDE GUIDE

9 23 10000706 FLAT WASHER, 1/4, TYPE B, REG.

10 1 820746 ASSY, BELL CRANK, L/C (SHOWN)

10 1 820747 (OR) ASSY, BELL CRANK, R/C

11 1 *** HORIZONTAL LINKAGE

12 1 10000901 COTTER PIN, 3/32 X 3/4

13 1 82008701 ASSY, LOCK SWITCH, L/C (SHOWN)

13 1 82008702 (OR) ASSY, LOCK SWITCH, R/C

14 1 10002504 SHOULDER SCREW, 5/16 DIA X 3/8 LG, 1/4-20

15 1 821016 ASSY, INSIDE GUIDE

16 1 100072 TERMINAL STRIP

17 1 82004301 ASSY, LOCK CYLINDER, L/C (SHOWN)

17 1 82004302 (OR) ASSY, LOCK CYLINDER, R/C

18 1 820021 LOCKBAR SLIDE BRACKET

19 1 820825 ASSY, BALANCE SPRING

20 1 10001003 SCREW, HEX, CAP, 5/16-18 X 5/8

21 1 10001407 LOCK WASHER, 5/16

22 1 10003201 LOCKBAR SPRING

23 6 10002303 SCREW, RH, SLOTTED, 6-32 X 1

24 6 10002402 HEX NUT, SEMS, 6-32

25 1 820751 ASSY, LOCK CYLINDER VALVE

26 2 82004601 ASSY, DOOR CYLINDER VALVE

27 1 *** VERTICAL LINKAGE

28 4 10001410 LOCK WASHER, 1/2

29 2 10002501 SHOULDER SCREW, 1/4 DIA X 3/8 LG, 10-24

30 4 10006209 SELF RETAINING NUT, SHORT, 3/8-16

31 2 10000704 FLAT WASHER, #10, TYPE B, REG.

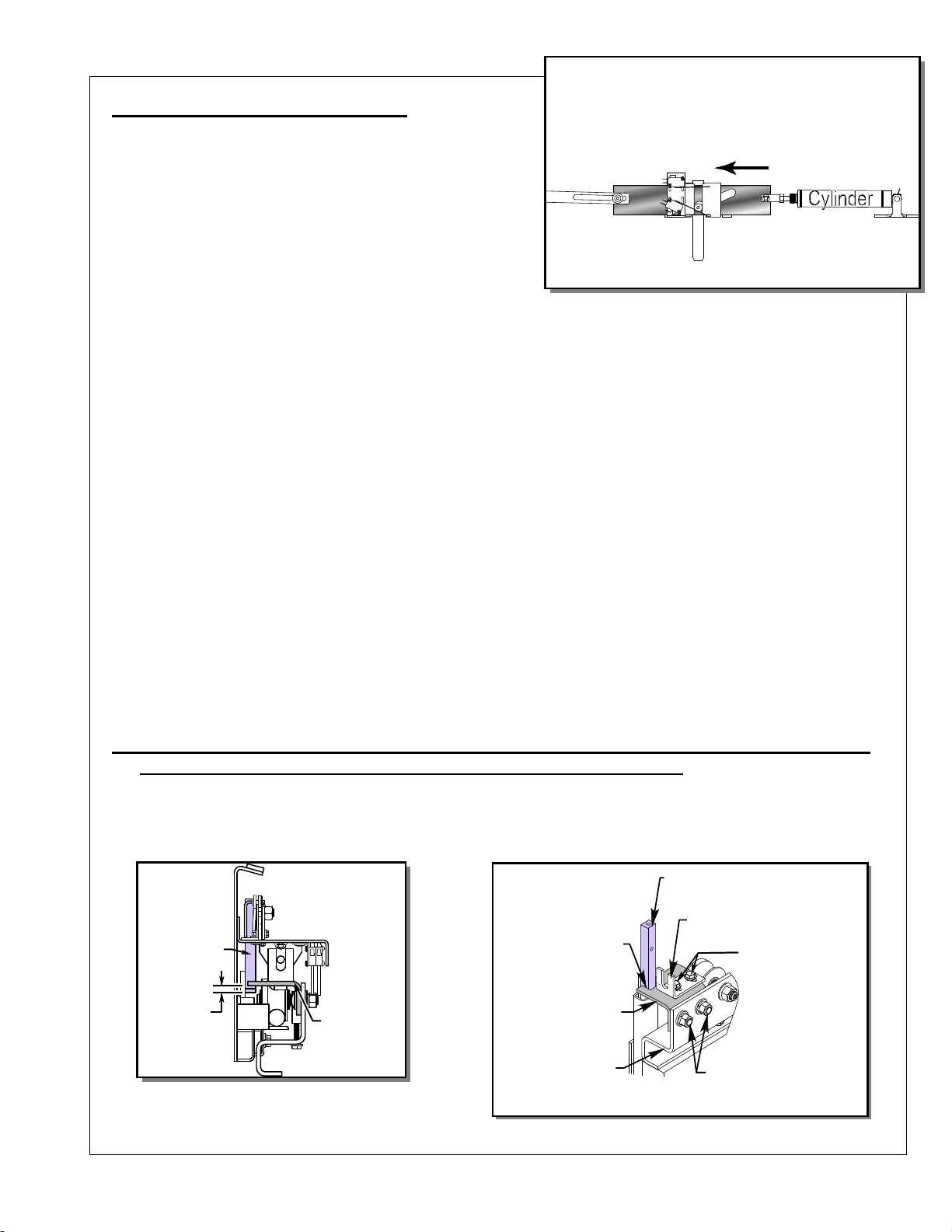

32 1 *** ASSY, AIR CYLINDER

33 2* 10000501 FLAT WASHER, .447 I.D. X .880 O.D. X .030

34 2* 10000306 HEX JAM NUT, 7/16-20

35 1* 10000401 GROMMET

36 1 820072 DOOR STOP PLATE

37 2 10000707 FLAT WASHER, .344 I.D. X .688 O.D. X .060

38 1 10002404 HEX NUT, SEMS, 10-24

39 2 10001001 SCREW, HEX, CAP, 3/8-16 X 5/8, GRD 5

40 1 *** HOUSING COVER, L/C, (SHOWN)

40 1 *** (OR) HOUSING COVER, R/C

41 4 10003401 SCREW, TP, BH, 3/8-16 X 1

42 1 820218 DOOR DRIVE BRACKET

ITEM QTY PART NUMBER DESCRIPTION

43 2 10001006 SCREW, HEX, CAP, 3/8-16 X 1

44 4 10000210 HEX NUT, 1/2-13

45 4 10001408 LOCK WASHER, 3/8

46 4 10000708 FLAT WASHER, 3/8, TYPE B,REG.

47 1 820195 LOCK BRACKET, FRONT, L/C (SHOWN)

47 1 820193 (OR) LOCK BRACKET, FRONT, R/C

48 4 10001302 SCREW, CARRIAGE, 1/2-13 X 1-1/4

49 1 82019401 LOCK BRACKET, REAR, L/C (SHOWN)

49 1 82019201 OR) LOCK BRACKET, REAR, R/C

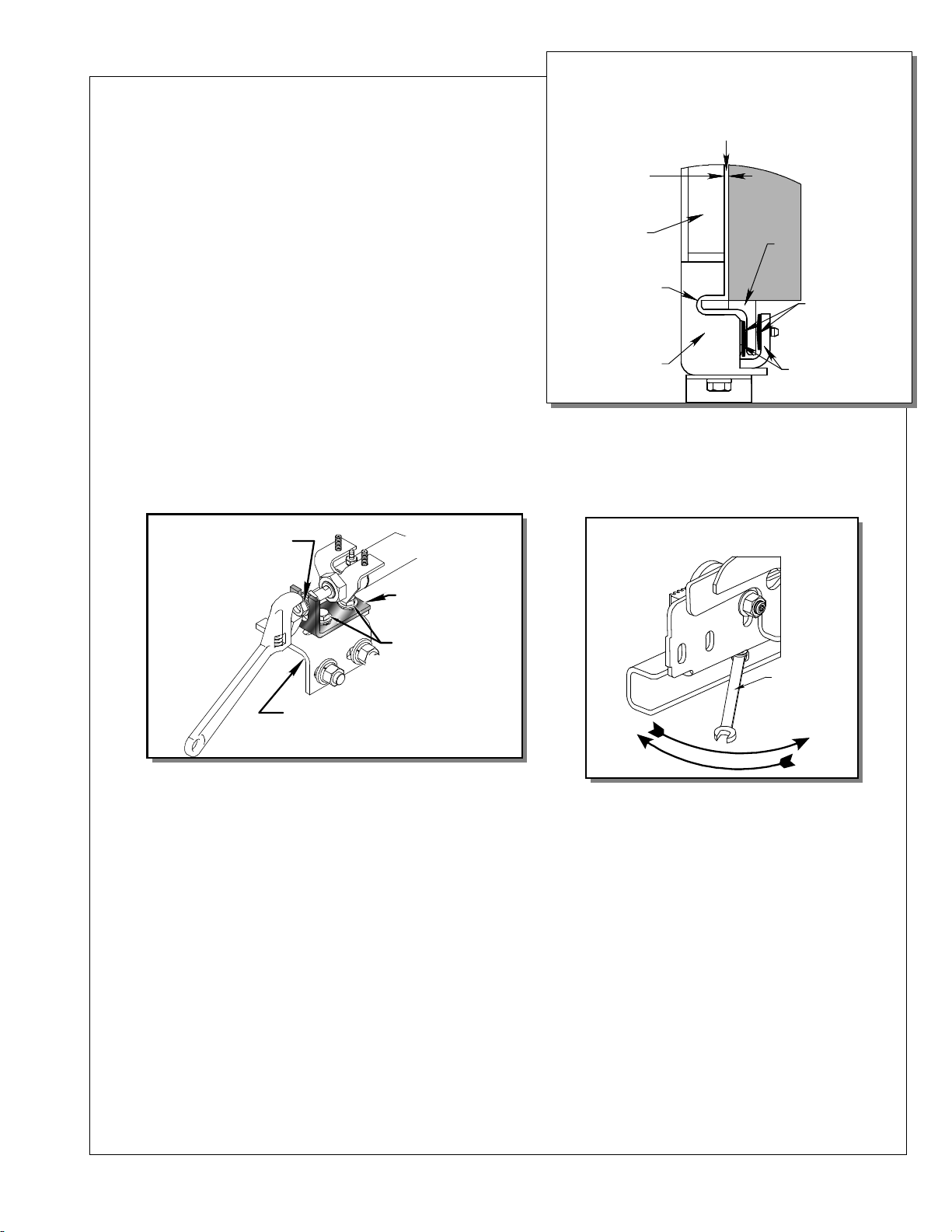

50 1 *** DOOR HANGER

51 2 82009801 ASSY, ROLLER

52 2** 10002803 WASHER, CONICAL, SERRATED, 5/8

53 2** 10000211 HEX NUT, 5/8-11

54 2** 10000707 FLAT WASHER, 5/16, TYPE B, REG.

55 2** 10001004 SCREW, HEX, CAP, 5/16-18 x1-1/2, W/NYLON PATCH

56 1 *** SWITCH ACTUATOR BRACKET

57 1 *** LOCKTUBE WELDMENT

58 1 *** LOCKBAR WELDMENT

59 1 820170 DOOR GUIDE BRACKET, L/C (SHOWN)

59 1 820181 (OR) DOOR GUIDE BRACKET, R/C

60 1 *** RECEIVER JAMB WELDMENT, L/C (SHOWN)

60 1 *** (OR) RECEIVER JAMB WELDMENT, R/C

61 1 *** ASSY, MANUAL OVERRIDE

62 4 10006402 SCREW, TP, FH, 10-24 X 3/4

63 4 10002405 SELF RETAINING NUT, 10-24

64 1 820108 NUT PLATE

65 2 10001000 SCREW, HEX HD, 6-20 X 1/2, TYPE AB

66 1 10002503 SHOULDER SCREW, 3/8 DIA X 1-1/2 LG, 5/16-18

67 1 820107 LOCKBAR SLIDE BEARING

68 4 10000710 FLAT WASHER, 1/2

69 1 10000707 FLAT WASHER, 5/16, TYPE B, REG.

70 1 *** DOOR GUIDE, L/C (SHOWN)

70 1 *** (OR) DOOR GUIDE, R/C

71 1 *** DOOR SKIRT

72 AS REQ'D 10003402 SCREW, TP, BH, 10-32 X 1/2

73 1 820826 WIRING HARNESS, MANUAL OVERRIDE (NOT SHOWN)

74 1 *** 8200 SERIES WIRING HARNESS (NOT SHOWN)

* PART OF ASSY, AIR CYLINDER ITEM #32

** PART OF ASSY, ROLLER ITEM #51

*** PART NUMBER ASSIGNED ON A JOB BY JOB BASIS.

8250-PL1.PM6