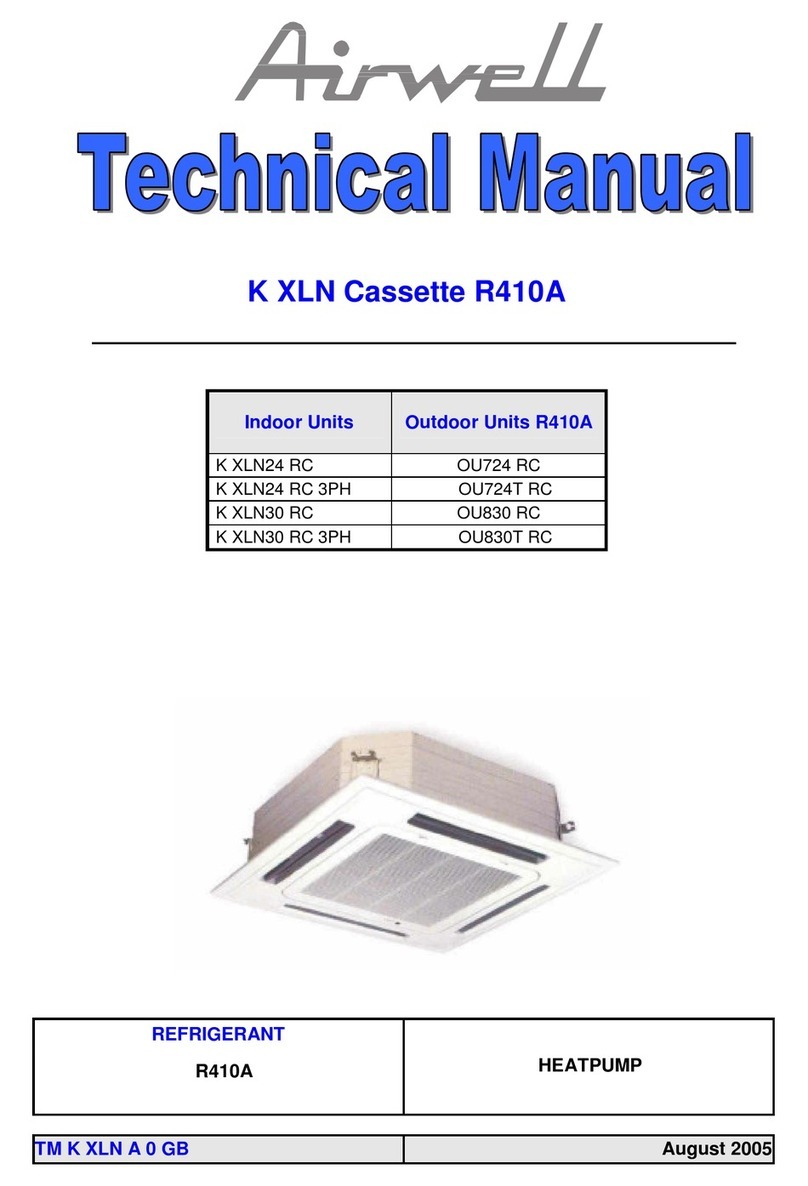

Technical Features

General

Pre-assembled waterproof single package, designed with R410A

refrigerant to save energy with high EER.

Heat pump with additional electrical heaters as an option if necessary.

A full run test is performed at the factory before shipping ensuring units

good working order.

Cabinet

Compact, light and single piece design.

All panels are made of galvanized steel. External panels and drain pans are

coated with powder-based epoxy paint (RAL9001) for improved weather

resistance.

Easy removable service panels for full unit access and ease of

maintenance.

Fork lift slots on the base rails to facilitate transportation and handling.

Fully insulated air treatment compartment with M1 polyethylene foam to

reduce energy loss, thermal bridge and sound disturbance.

Weatherproof technical compartment independent from airflows such

that running high and low pressures can be measured without disturbing

the normal unit operation.

Refrigerant equipment

R410A benefits

Higher heat transfer.

Environmental friendly refrigerant with zero ODP (Ozone Depleting

Potential).

Stable composition compared to R407C (2 refrigerant mixture instead of

3 with R407C).

Temperature glide less than 0.2 K during evaporation.

Smaller liquid line pipe.

Lower refrigerant charge.

Refrigerant circuit

Reversible refrigerant circuit designed for reliable operation in both cooling

and heating modes and composed of components optimized for R410A

refrigerant.

All refrigerant components are shown in the functional diagram illustrated

in "Refrigerant flow diagram" section.

Compressors

Each unit is equipped with one hermetic Scroll compressor for high

efficiency and robustness.

Compressors are mounted on rubber anti-vibration pads.

The motors, gas cooled type, are equipped with automatic reset internal

thermal protection.

Crankcase base heater is supplied on each compressor for improved start

up in winter.

Coils

Direct expansion coil type made of seamless copper tubes arranged in a

staggered row pattern. Each coil is mechanically expanded into aluminium

fins with full fin collars.

Condenser coil fins are hydrophilic coated for better water droplet

removing during defrosting cycles.

Fans

Air treatment side fans are single centrifugal wheels mounted on self-

aligning bearings.

On models 10 and 13 air treatment side fans are of multispeed direct drive

type.

On models 15 to 31 air treatment side fans are of belt driven type with

variable pitch pulley.

Available external static pressure goes up to 250 Pa (depending on

models).

On condenser side, units are equipped with direct drive propeller fans

consisting of plastic or painted steel blades. They are driven by single

phase motors.

Electrical box

All electrical equipment required for proper unit operation is located in a

weatherproof electrical control box including :

Main disconnect switch

Control circuit transformer

Phase controller (rotation and missing phase control)

Outdoor motor automatic reset thermal protection

Indoor motor contactor and thermal relay on models 15 to 31

Compressor contactor

CAC controller electronic control board.

Options and accessories

Factory fitted low ambient control to ensure cooling operation down to -10

°C outdoor temperature is available as an option.

Synthetic media type G2 (75%-80%) M1 air filter offered as a kit for field

installation.

Additional electrical heater for indoor installation on the air duct offered as

a kit for field installation.

RCW2 electronic programmable controller.