2Subject to technical amendments without prior notice | 83059300iUK | ait-deutschland GmbH

Table of contents

1 About this operating manual ...................... 3

1.1 Validity....................................................... 3

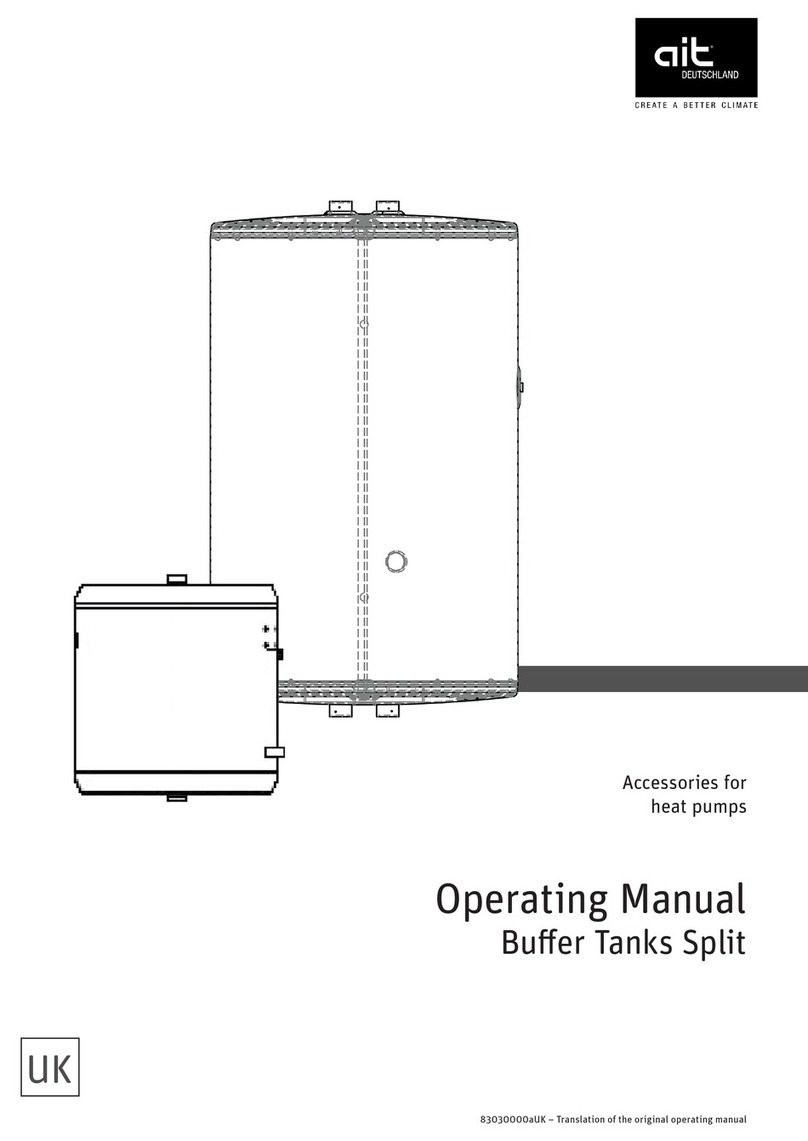

1.2 Reference documents............................... 3

1.3 Symbols and markings.............................. 3

1.4 Contact...................................................... 4

2 Safety ............................................................... 4

2.1 Intended use ............................................. 4

............................ 4

2.3 Personal protective equipment ................. 4

2.4 Residual risks............................................ 5

2.5 Avoid damage to property......................... 5

3 Operation and care....................................... 5

3.1 Energy and environmentally conscious

operation ................................................... 5

3.2 Care .......................................................... 6

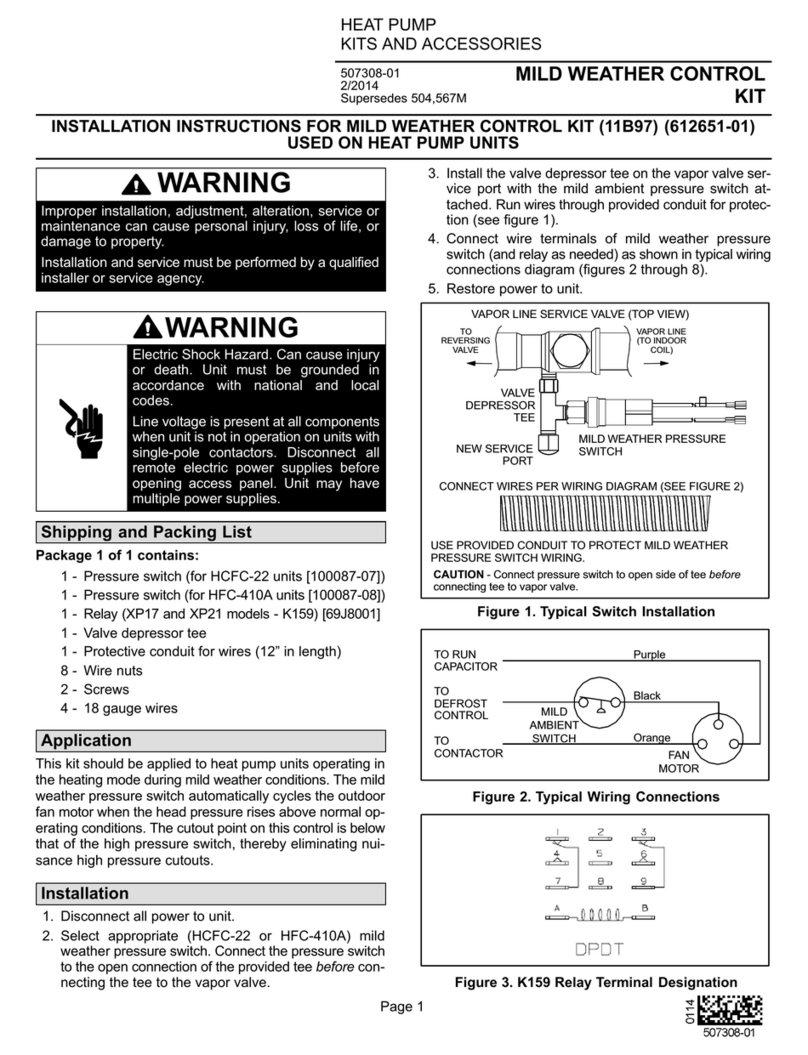

4 Scope of supply............................................. 6

4.1 Accessories............................................... 6

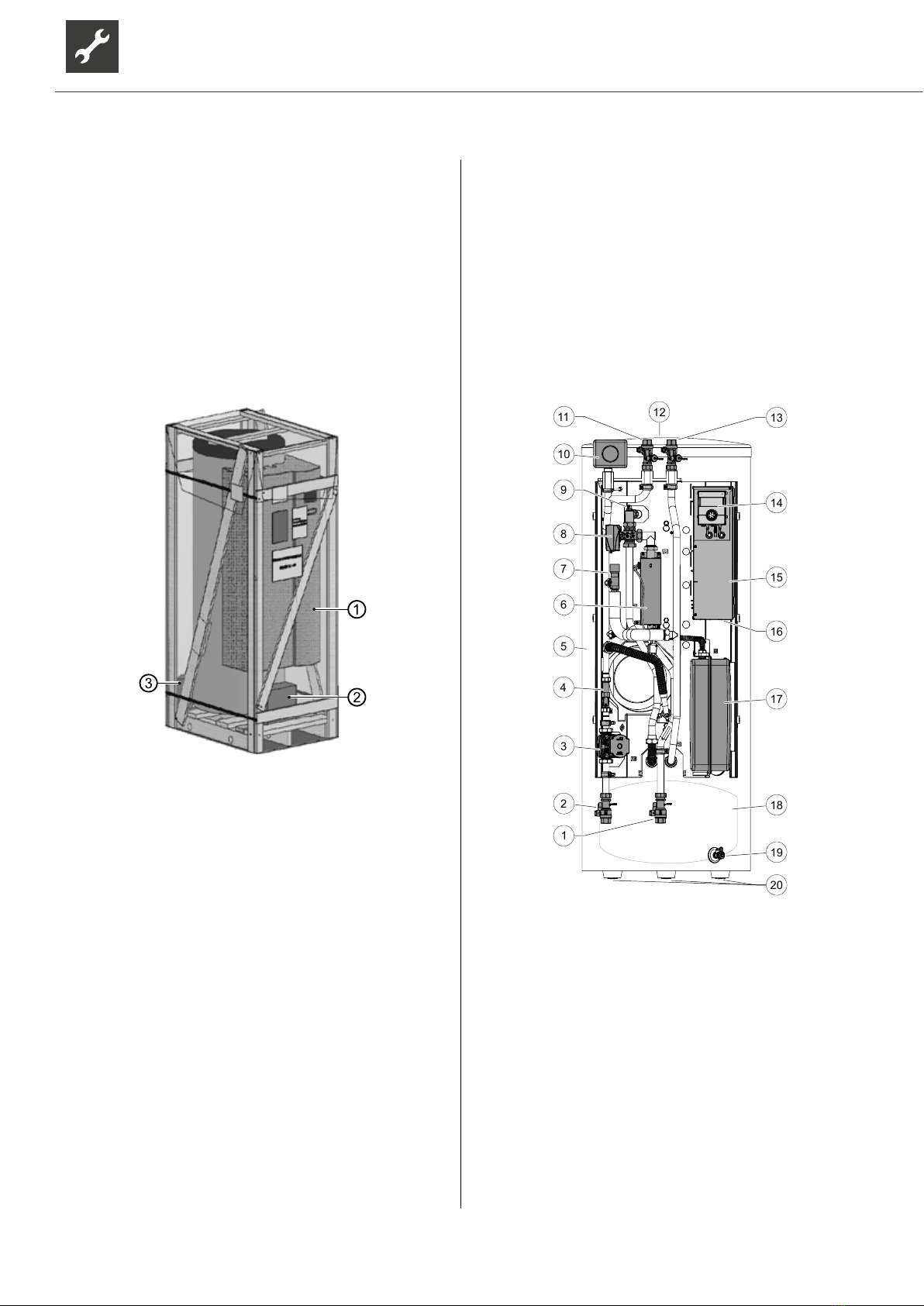

4.2 Components of the device ........................ 6

5 Storage, transport, installation................... 7

5.1 Storage...................................................... 7

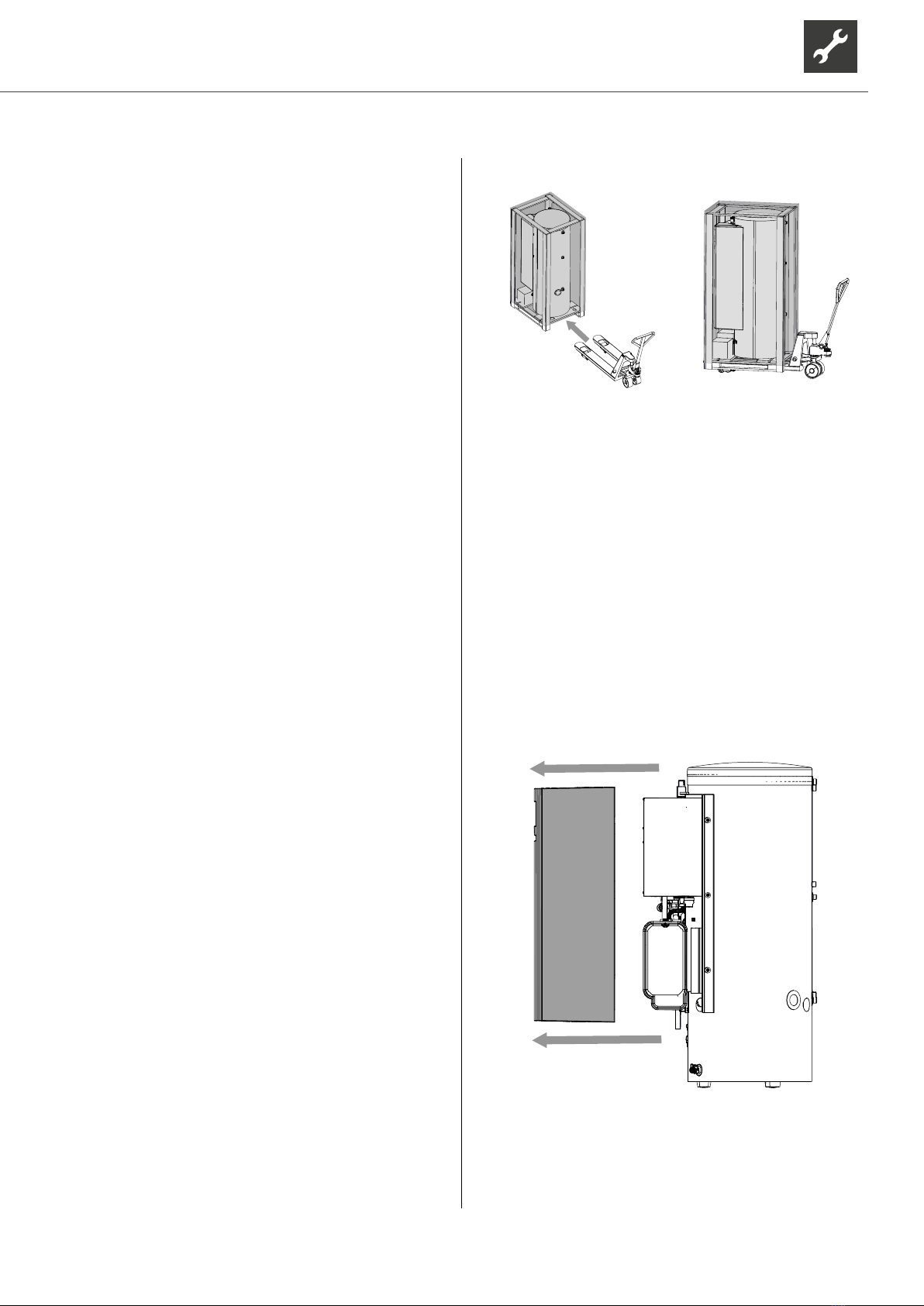

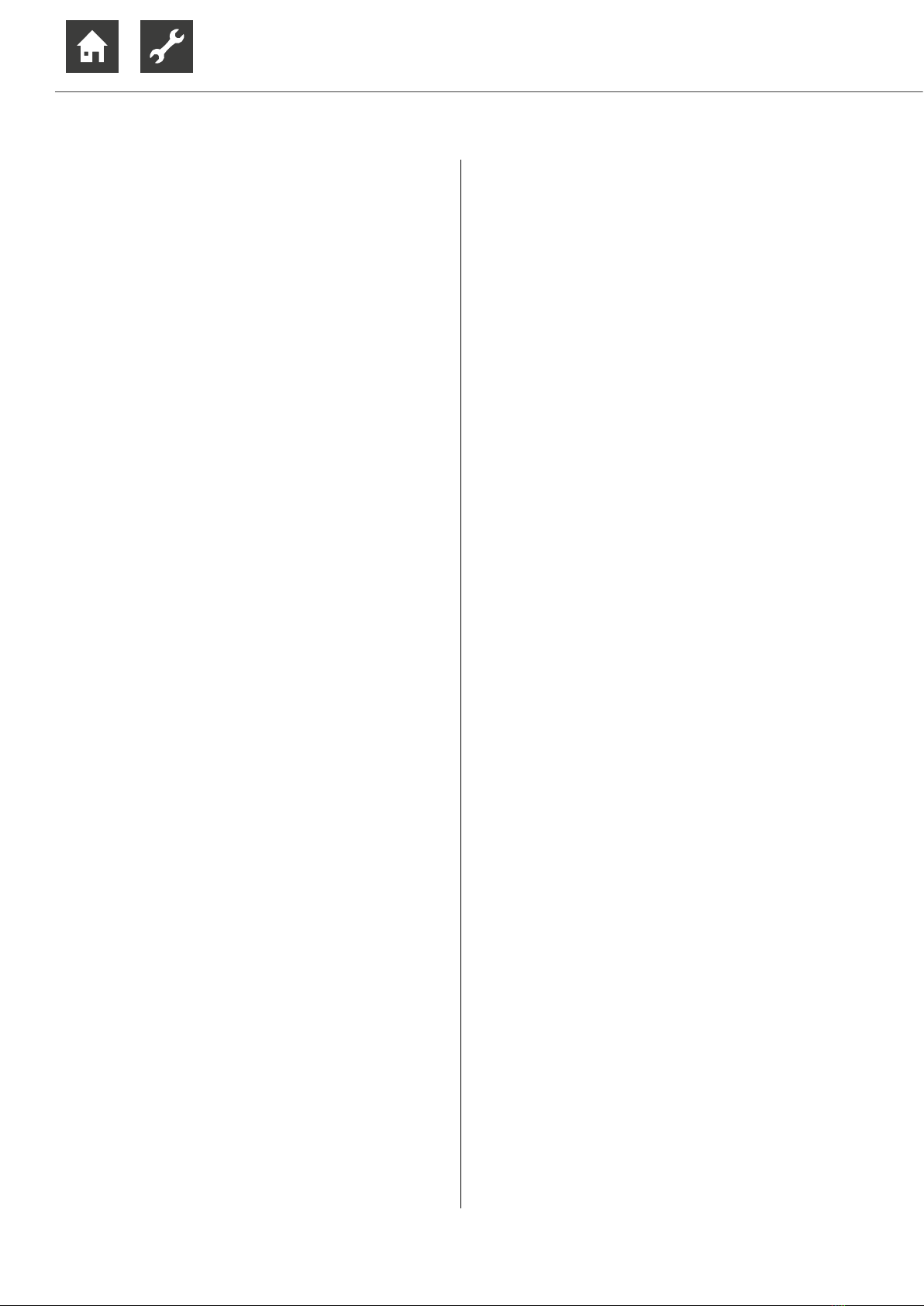

5.2 Unpacking and transport........................... 7

5.3 Installation................................................. 9

6 Installing the hydraulic connections ....... 10

6.1 Heating circuit ..........................................11

6.2 Expansion vessel .....................................11

6.3 Hydraulic connection for the

domestic hot water tank ...........................11

7 Electrical installation................................... 12

7.1 Connect the electrical cables.................. 12

7.2 Electrical connection............................... 12

8 Installing the control panel........................ 14

...................... 14

9.1 Heating water quality .............................. 14

domestic hot water charging circuit......... 15

the domestic hot water tank .................... 16

10 Insulate hydraulic connections ................ 16

............................................. 17

........ 17

13 Commissioning ............................................ 17

14 Faults.............................................................. 18

14.1 Unlock the safety temperature limiter ..... 18

15 Dismantling and Disposal......................... 18

15.1 Dismantling ............................................. 18

15.2 Disposal and Recycling........................... 18

................... 19

HSV… ............................................................. 19

HSDV… ............................................................ 20

Free pressing ...................................................... 21

....................................................... 21

..................................................... 21

HSV 12.1M3...................................................... 21

HSDV 12.1M3 ................................................... 21

Dimensioned drawings ..................................... 22

.................................................. 22

HS(D)V 12.1M3 ................................................. 23

Installation plans................................................. 24

.................................................. 24

HS(D)V 12.1M3 ................................................. 25

Terminal diagrams ............................................. 26

HSV… ............................................................. 26

HSDV… .......................................................... 28

Terminal diagram, mains connection

heat pump 1~230V

+ electric heating element 3~400V ......... 30

Terminal diagram, mains connection

heat pump 1~230V

+ electric heating element 1~230V ......... 31

Terminal diagram, mains connection

heat pump 3~400V

+ electric heating element 3~400V ......... 32

Circuit diagrams.................................................. 33

HSV… ............................................................. 33

HSDV… .......................................................... 37