6

4.0 In use

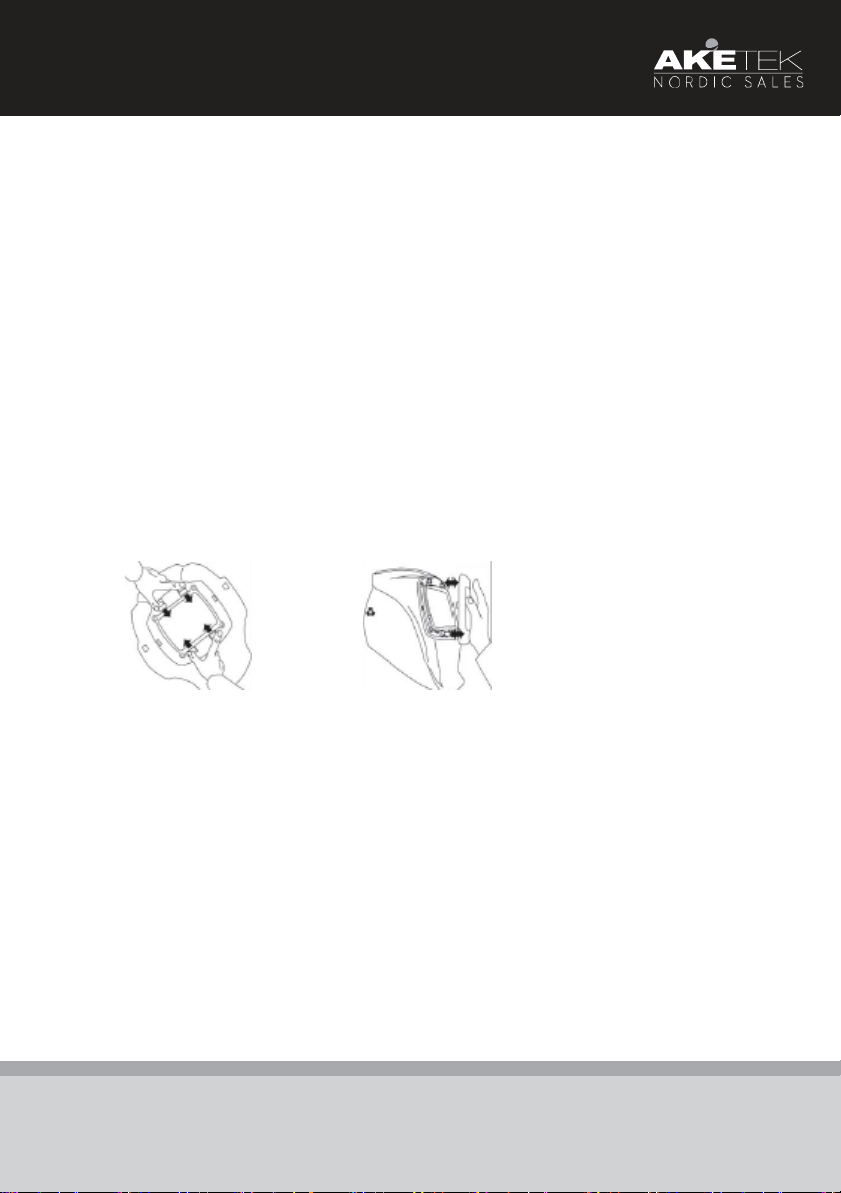

There are two knobs with adjustment options on the inside of the welding filter cassette.

The knob on the left affects the sensitivity of the light detectors. Counterclockwise rotation

reduces the sensitivity and clockwise rotation increases the sensitivity. The detectors do

not respond to sunlight and constant ambient light, but only to rapidly varying lights such

as the welding arc. Therefore, it is recommended to normally use maximum sensitivity.

The knob on the right is for setting the shade number, with the lowest shade 8 (lightest

setting) at counterclockwise rotation to stop, and with the highest shade of 12 (darkest

setting) at clockwise rotation to stop. When welding, select position welding on the

welding filter cassette, and when grinding select grind.

Automatically darkening welding filter must be used with outer and inner protection

plates. The protection plates protect against heat, dirt, welding splashes and welding

spatter. The outer and inner protection plates must be replaced if they become scratched or

damaged in any way that impairs the view. The protection plates from Aketek are made of

polycarbonate plastic (PC) with a scratch-resistant surface coating. If protection plates are

not used, the welding filter cassette will be damaged by weld spatter and the warranty

will be invalidated.

5.0 Maintenance and cleaning

Inspect the welding helmet regularly, both before and after use. Do not use the equipment

until any damaged or defective parts have been replaced, as this can affect the work

negatively. The welding filter cassette is sensitive to water.

5.1 The welding helmet must be handled with care. Do not leave it in a dirty

environment.

5.2 The welding helmet has an outer protection plate of polycarbonate plastic (PC) with

a scratch-resistant coating that protects against mechanical particles and welding spatter.

Over time, however, the transparency will deteriorate and the protection plate will then

need to be replaced, see info under 7.0. If cleaning is required, clean with a damp cloth and

wipe with a clean cloth.