Lincoln Electric LT-7 Tractor User manual

Other Lincoln Electric Welding Accessories manuals

Lincoln Electric

Lincoln Electric IM359-G User manual

Lincoln Electric

Lincoln Electric OMNISHIELD User manual

Lincoln Electric

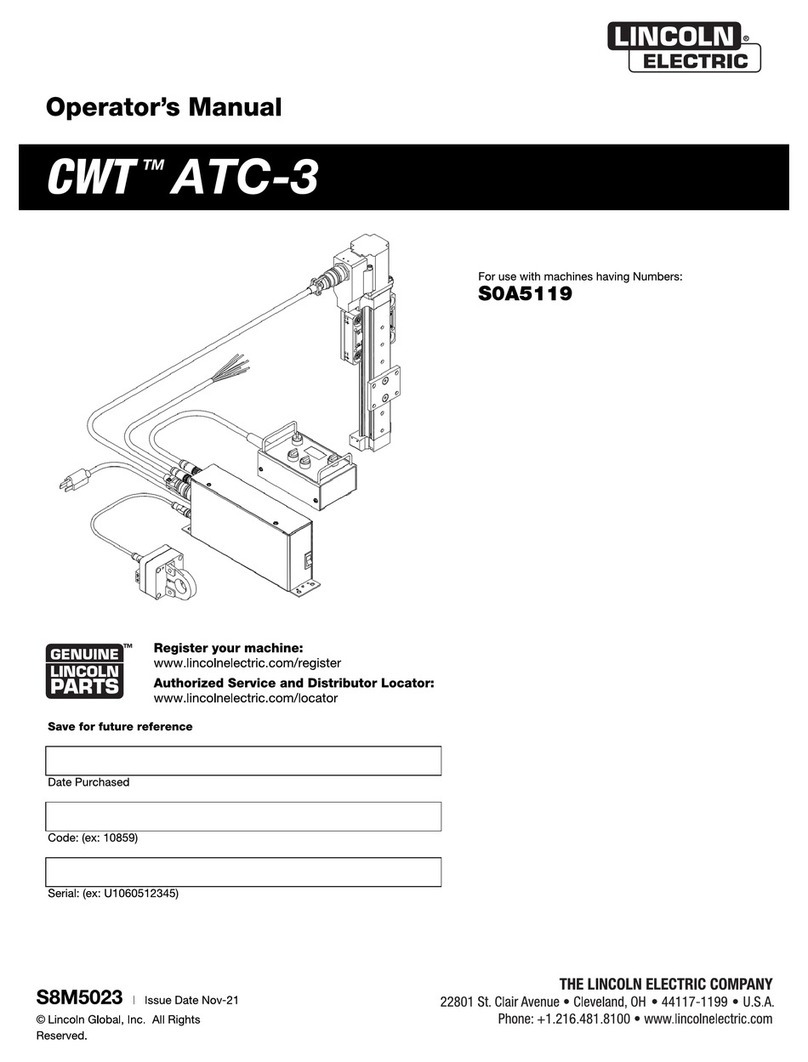

Lincoln Electric CWT ATC-3 User manual

Lincoln Electric

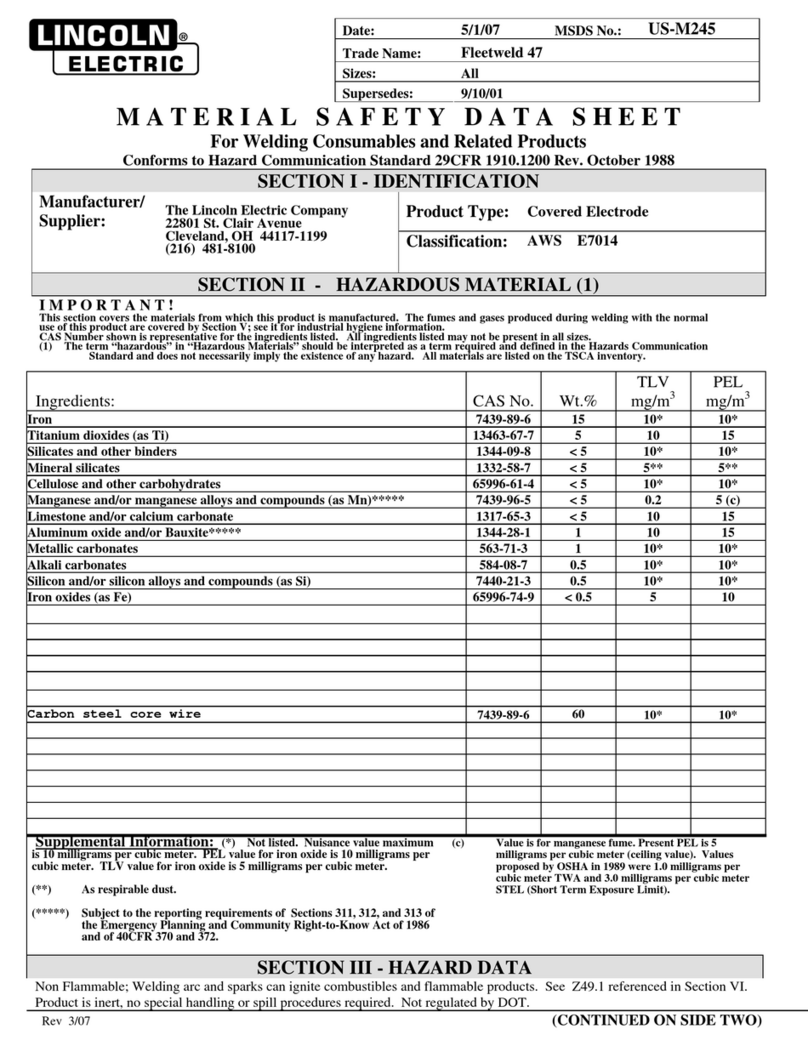

Lincoln Electric Fleetweld 47 User manual

Lincoln Electric

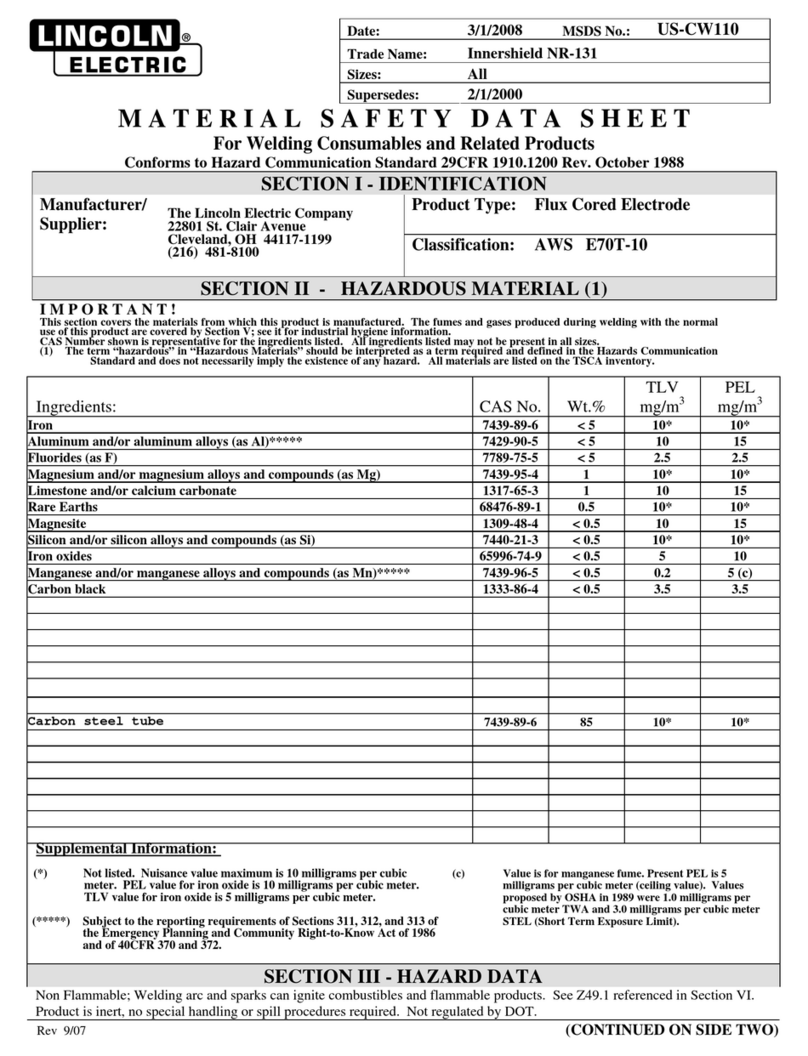

Lincoln Electric Innershield NR-131 User manual

Lincoln Electric

Lincoln Electric K2391-1 User manual

Lincoln Electric

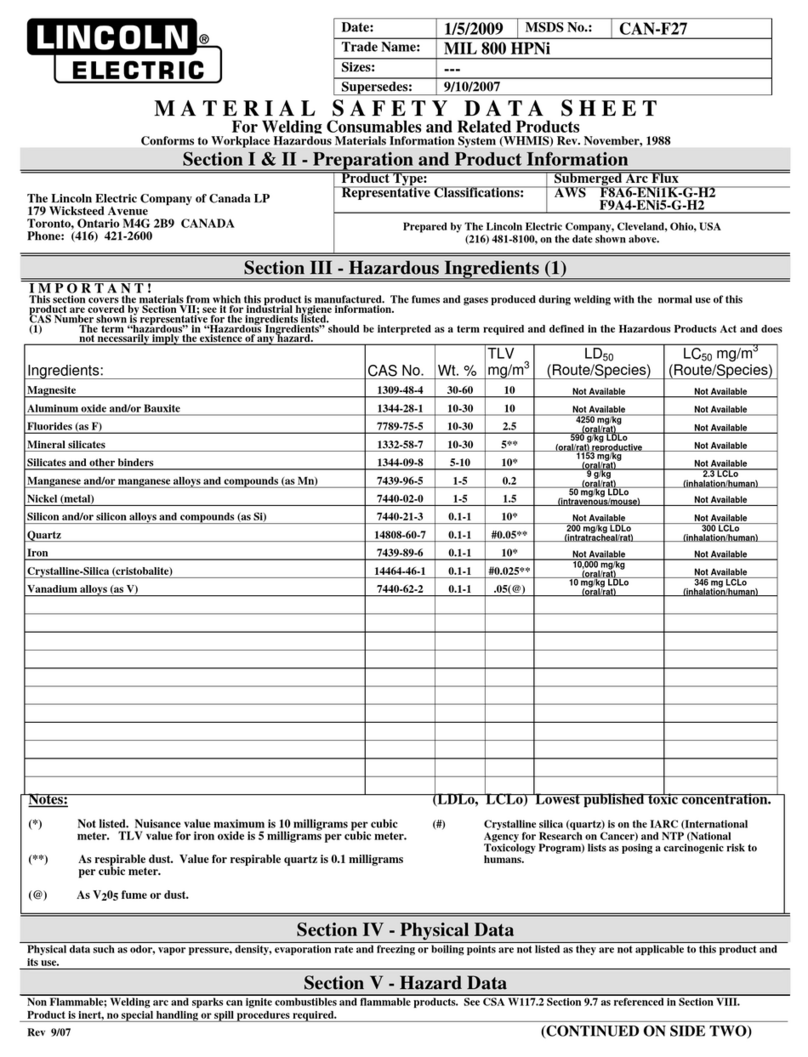

Lincoln Electric MIL 800HPNi User manual

Lincoln Electric

Lincoln Electric Harris Port-A-Torch 19601 User manual

Lincoln Electric

Lincoln Electric X-Tractor 3A User manual

Lincoln Electric

Lincoln Electric POWER FEED 10M User manual

Lincoln Electric

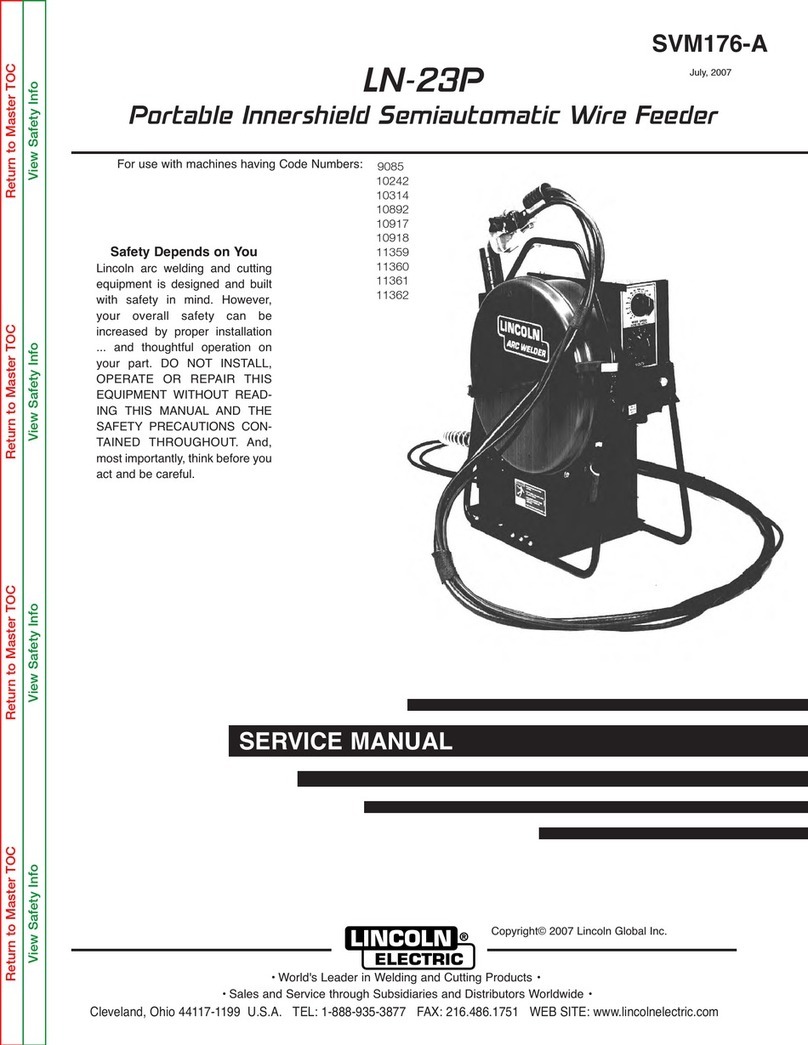

Lincoln Electric SVM176-A User manual

Lincoln Electric

Lincoln Electric K2613-5 User manual

Lincoln Electric

Lincoln Electric DownFlex 100-NF User manual

Lincoln Electric

Lincoln Electric Activ8X User manual

Lincoln Electric

Lincoln Electric PIPELINER LN-23P User manual

Lincoln Electric

Lincoln Electric 180C User manual

Lincoln Electric

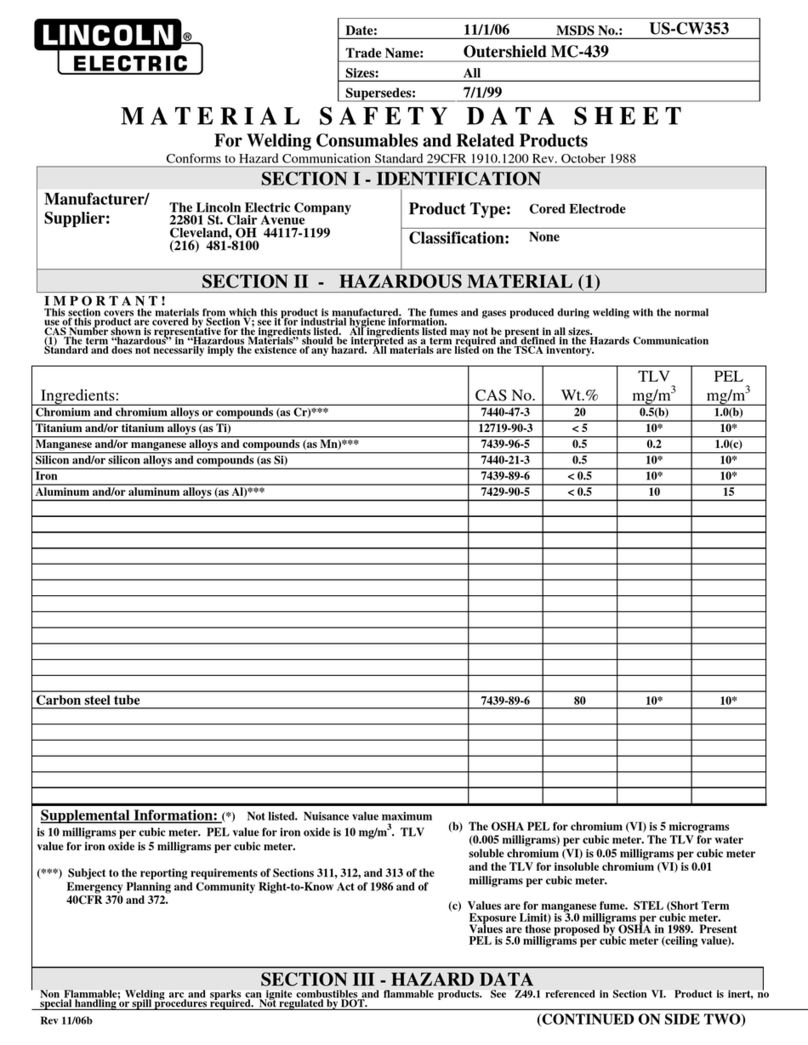

Lincoln Electric Outershield User manual

Lincoln Electric

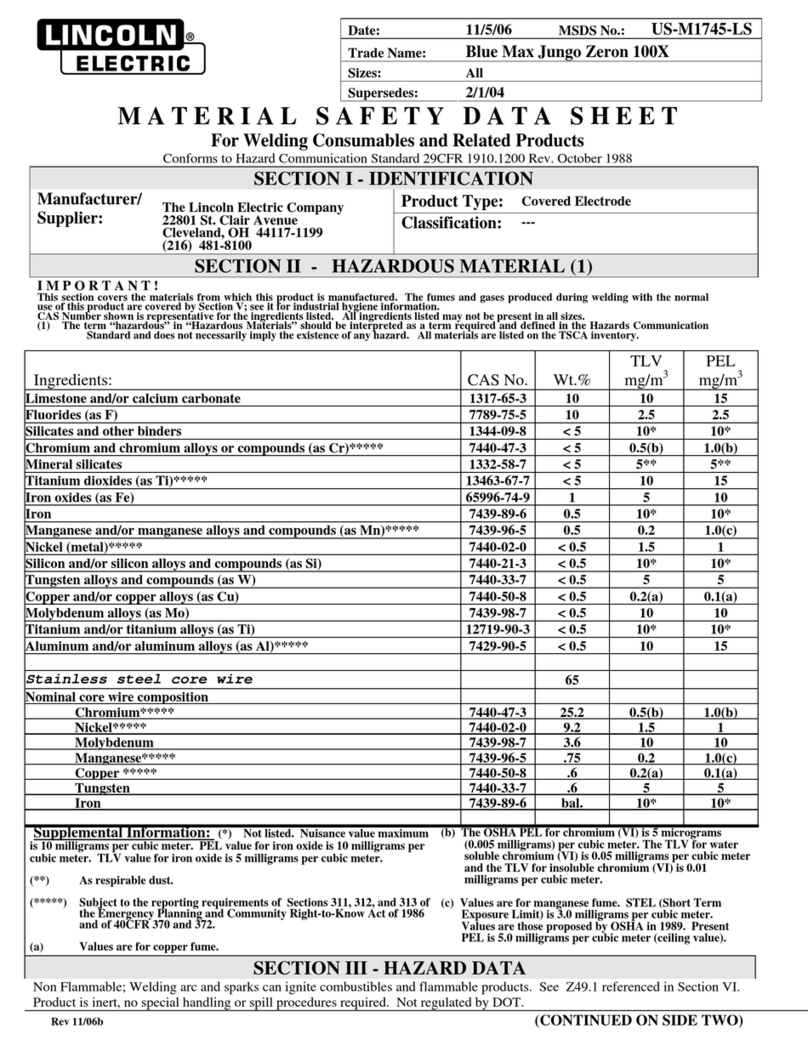

Lincoln Electric US-M1745-LS User manual

Lincoln Electric

Lincoln Electric VIKING 1740 Series User manual

Lincoln Electric

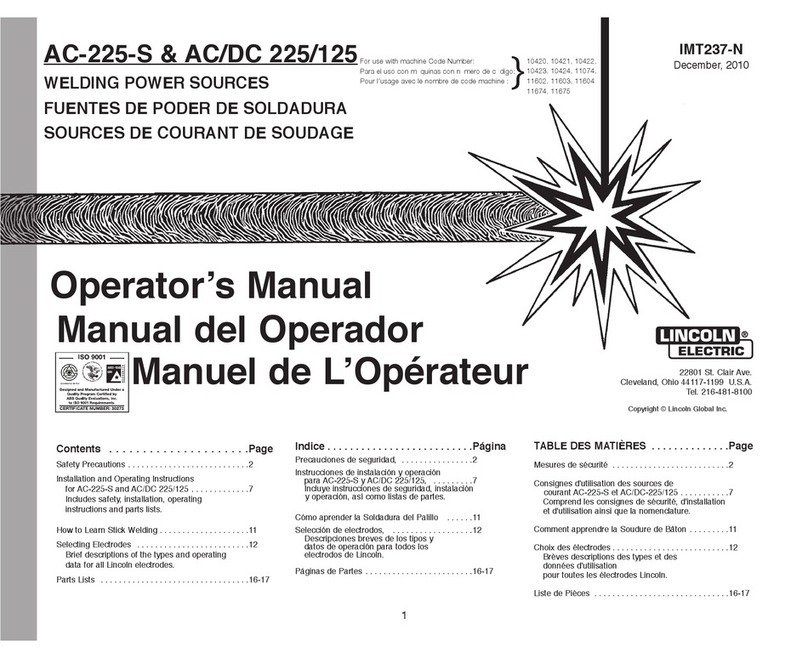

Lincoln Electric WELDING POWER SOURCES AC-225-S User manual