BASIC PRINCIPLE OF OPERATION

The Apparatus Flow Test Kit (AFTK) uses the pitot method to measure water flow.

This is where flow is the direct function of the stream velocity (pressure) through a

nozzle tip of known diameter.

One way to read nozzle tip pressure, accurately, is to place the pitot tube tip

securely in the center of the discharge tip diameter and parallel to the direction of the

water flow. The pitot simply measures the flowing water pressure at the point of pick

up and is read in PSI on the pressure gauge. The enclosed Akron Brass Straight

Bore Discharge Data chart converts the PSI reading to the actual flow inGPM.

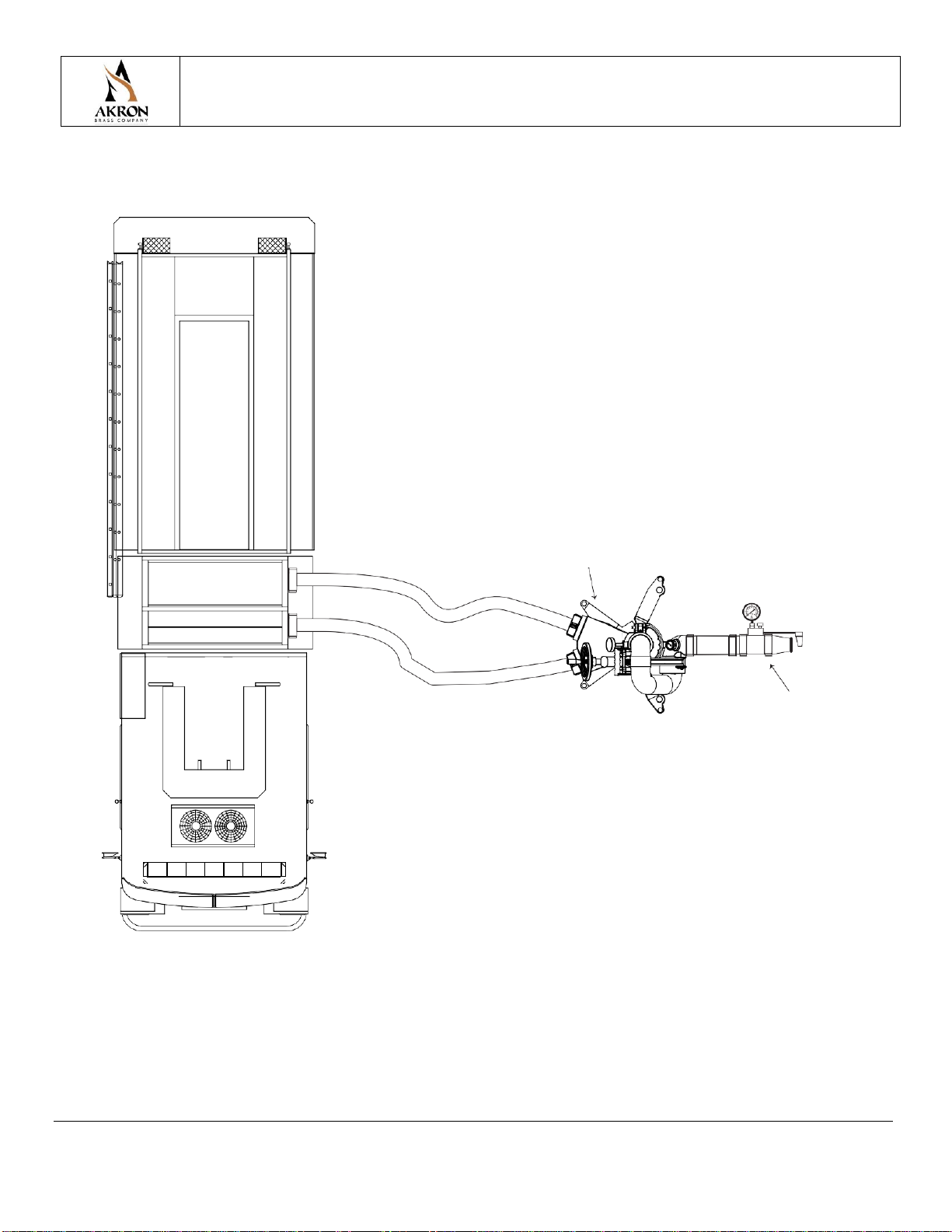

HOW TO USE: Flush the system, totally, prior to testing. Attach the Apparatus Flow

TestKit (AFTK) to a deluge set that has the recommended hose layouts connected

to it. Attach the appropriate discharge tip size you wish to start testing with. Bring

your apparatus up to the proper engine RPM as per the UL TestPlatemounted

on the pump panel. Bleed all entrapped air from pitot blade and gauge using the

bleeder valve. The pitot reading in PSI and its correlation to the corresponding

“Straight Bore Discharge Data” chart will give you the flow in gallons per minute of

your apparatus at that RPM. After use, press the bleeder button to allow the pitot

tube and gauge to drain, this is especially necessary in freezing weather.

If by chance the pitot turns while testing, REALIGNMENT is required. Torealign,

loosen the thumb knob that retains the pitot rotationally, center the pitot tip in the

middle of the discharge tip bore and tighten the knob.

The gauge has an accuracy of plus or minus 1%. If it is dropped or abused in any

way it will need to be replaced. Recalibration of a liquid filled gauge can only be

done by the original manufacturer.

RECOMMENDATIONS: (1) Always follow the most current NFPA 1911 Standard

for “Service Tests of Pumps on Fire DepartmentApparatus” when testing; (2) Direct

flow away from any possible hazards, preferably to an open area; (3) Mount the test

kit to a secured monitor or similar device; (4) Flush the device to be tested prior to

attachment of the flow test kit; (5) Check all connections prior to flowing water; (6)

Never interchange nozzle tips while the flow test kit is in operation; (7) Water flow

shall be straightened using a style 3488 stream staightener; (8) All reducers and/or

adapters connected to the flow test kit must have a minimum of a 2-1/2” waterway;

(9) Nozzle tips should be screwed on, hand tight, so the gasket is not expanded into

the waterway. There is no need for spanner tightening.

MAINTENANCE and INSPECTION: (1) Inspect the internal surface of the nozzle

tips before and after each use for any nicks or gouges, this may affect the readings.

Use only the nozzle smooth bore tips provided; (2) Inspect the pitot waterway to

ensure that no obstructions are present; (3) Check pitot blade to make certain it is in

the center of the waterway, as this may affect the reading; (4) In the event the pitot

blade becomes damaged, a new blade can be ordered from your local distributor.