www.AkuaInks.com 1

The Akua Pin Press

It is a common misconception that one needs to make a large

investment in equipment in order to create high quality prints.

The Pin Press offers high performance at a fraction of the cost of

a traditional press and mobility that allows you to create prints

wherever you want to go. The Pin Press’ ergonomic design allows

artists to minimize impact on the body and provides an ideal

storage solution when the Press is not in use.

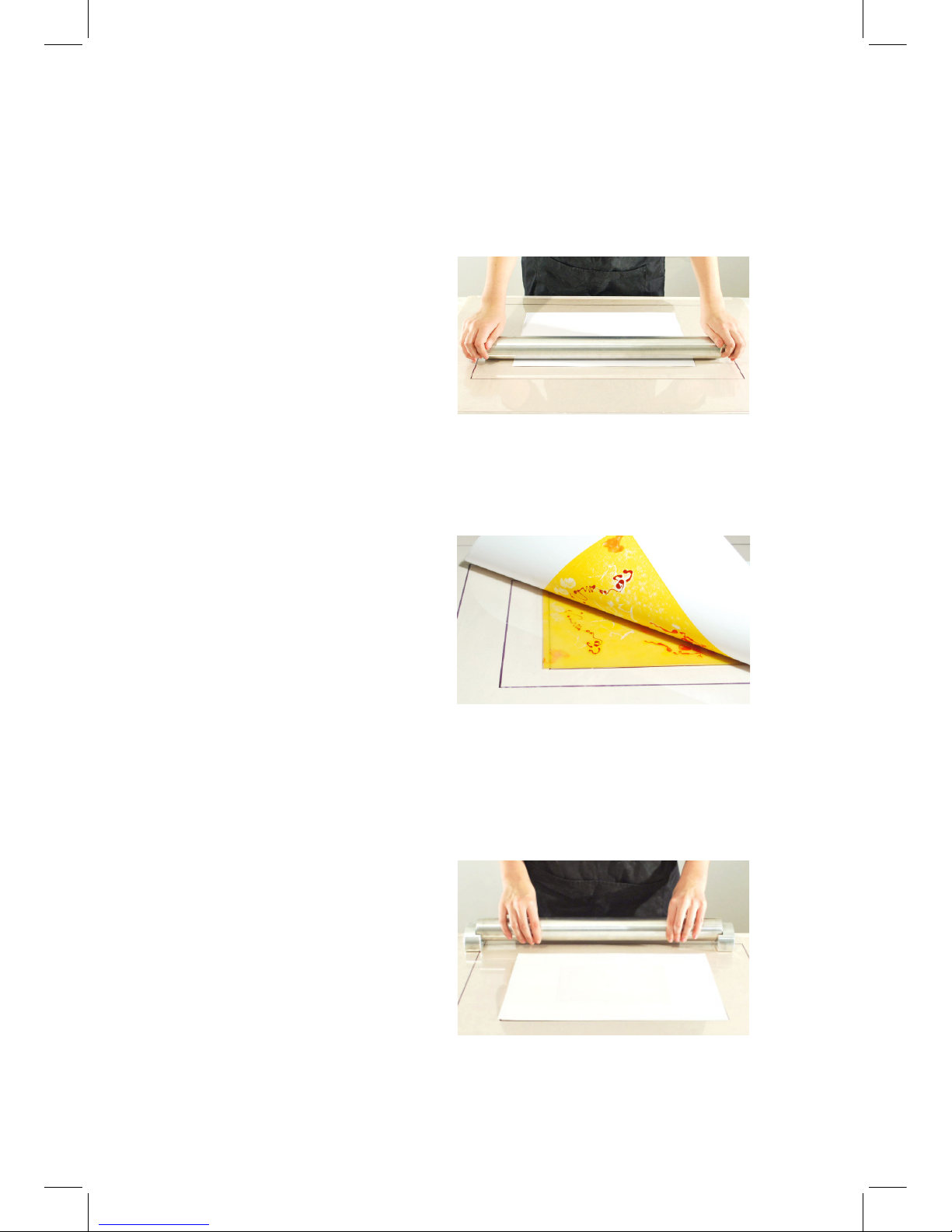

Less pressure is required when printing the surface of the plate

(e.g. monotype), as opposed to printing the depths of the plate

(e.g. an intaglio/etching) which requires the pressure of an etching

press. Therefore, the Pin Press is an ideal tool for all monotype

techniques. Additionally, great results can also be obtained from

incised plates (e.g. for drypoint printmaking) this is because the

burr of the drypoint holds the ink.

The crescent-shaped

handles swivel and act stand

when not in use.

Rest the palm of your hands

on the flat side of the crescent-

shaped handles when printing.

PREFACE

Writing instructions for a creative thinker is a challenging task. I

wonder, “How can I cover so many printmaking possibilities and

variables in just a 14 page booklet? Will I be able to help the wide

range of personalities who flip these pages looking for the answers on

how to pull a successful print with the Pin Press?” Then, I remember

that printmakers are problem solvers and will understand that the

information in this user guide is intended to be used as a starting point.

I am certain you will contribute your own innovations and discoveries.

Pick up your Pin Press and roll with it!

-Susan Rostow, Inventor of Akua Inks & Accessories

The Akua Pin Press, received the “Best New Product” Award at the

International Art Materials Trade Association Conference in 2011.