��

1. CAUTION......................................................................................................................................... 1

2.WARNINGS ANDSYMBOLS.......................................................................................................... 1

2.1Typesof Symbols and Warn�ngs............................................................................................. 1

3. GENERAL........................................................................................................................................ 2

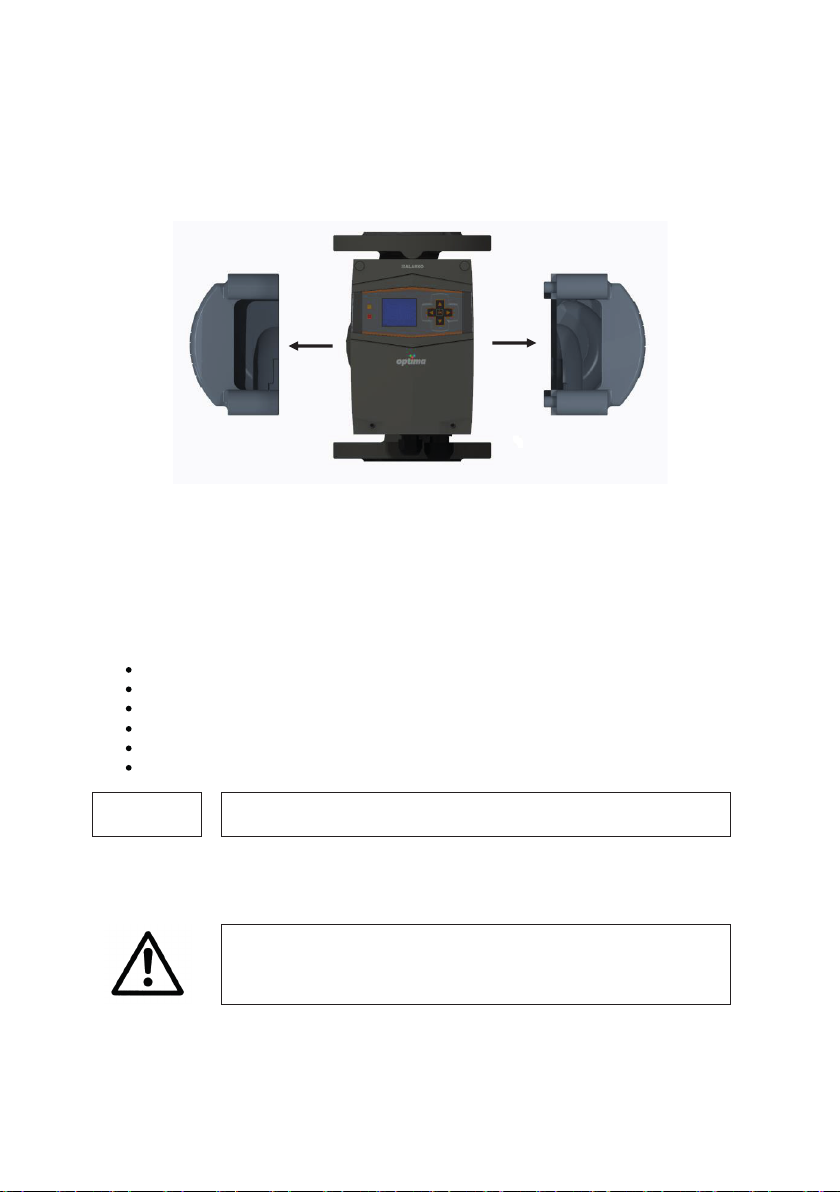

3.1Descr�pt�onof the Pump .......................................................................................................... 2

3.2Appl�cat�ons (Intended Use) .................................................................................................... 3

3.3Pumped L�qu�ds....................................................................................................................... 3

3.4Operat�ng Cond�t�ons............................................................................................................... 3

3.5Insulat�on Shells...................................................................................................................... 4

4. CONTENTS OF THE PACKAGE, LIFTING, TRANSPORTATITON AND STORAGE ................... 4

4.1Contents of the Package ......................................................................................................... 4

4.2L�ft�ng ....................................................................................................................................... 4

4.3Transportat�on and Storage ..................................................................................................... 5

5. PUMP DETAILS .............................................................................................................................. 5

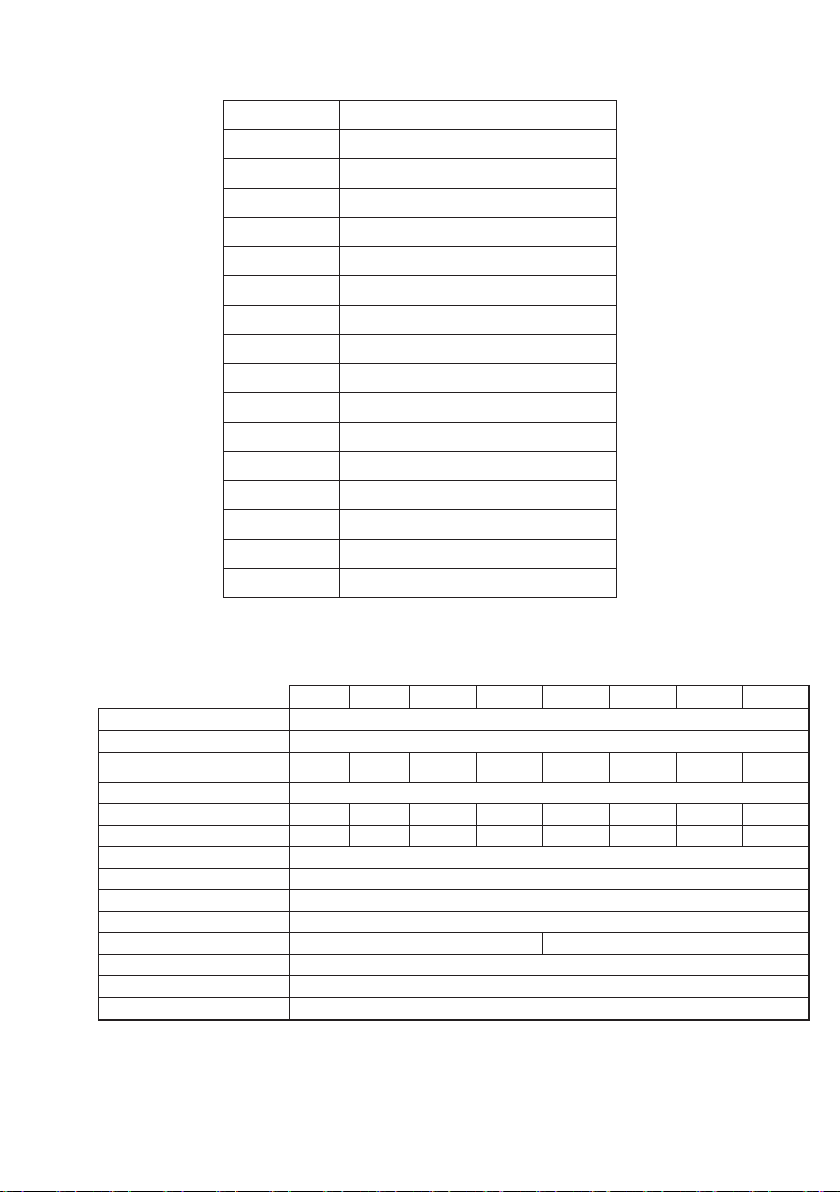

5.1Nameplate ............................................................................................................................... 5

5.2Techn�cal Data......................................................................................................................... 6

6.PUMP INSTALLATION.................................................................................................................... 7

6.1Pos�t�on�ng ............................................................................................................................... 7

6.2Mechan�cal Installat�on ............................................................................................................ 9

6.3F�ll�ng and Vent�ng ................................................................................................................. 11

6.4Cable/Fuse Select�onand Electr�cal Installat�on................................................................... 11

6.5Parallel/Back-up Operat�on.................................................................................................... 14

7. DISPLAY AND SETTINGS............................................................................................................ 15

7.1Graph�cal D�splay .................................................................................................................. 15

7.22-D�g�t D�splay........................................................................................................................ 18

8.FIRST START-UP, CONTINUOUS OPERATION ANDSHUTDOWN.......................................... 20

9. OPERATING MODES ANDSELECTION CRITERIA ................................................................... 21

9.1Manual Operat�ng Mode ........................................................................................................ 22

9.2Constant Pressure Operat�ng Mode ...................................................................................... 22

9.3Var�able Pressure Operat�ng Mode ....................................................................................... 23

9.4Operat�ng Mode Select�onCr�ter�a ........................................................................................ 25

10.ADDITONAL ACCESSIORIES ...................................................................................................... 26

11.WARRANTY, MAINTENANCE AND SERVICE ............................................................................ 26

12.FAULTS, CAUSES AND REMEDIES ........................................................................................... 27

13.DISMALTLING............................................................................................................................... 32

14.DISPOSAL..................................................................................................................................... 33

15.APPANDIX..................................................................................................................................... 34

15.1D�mens�ons ............................................................................................................................ 34

15.2General Select�onChart and Performance Curves ............................................................... 35