ALARM CONTROLS CORPORATION

“QUALITY SECURITY EQUIPMENT SINCE 1971”

19 BRANDYWINE DRIVE, P.O. BOX 280, DEER PARK, NEW YORK 11729

1 800 645-5538 631 586-4220 FAX 631 586-6500

U.L. LISTED MAGNETIC LOCKS

F

FO

OR

R

A

AL

LL

L

A

AC

CC

CE

ES

SS

S

C

CO

ON

NT

TR

RO

OL

L

A

AP

PP

PL

LI

IC

CA

AT

TI

IO

ON

NS

S

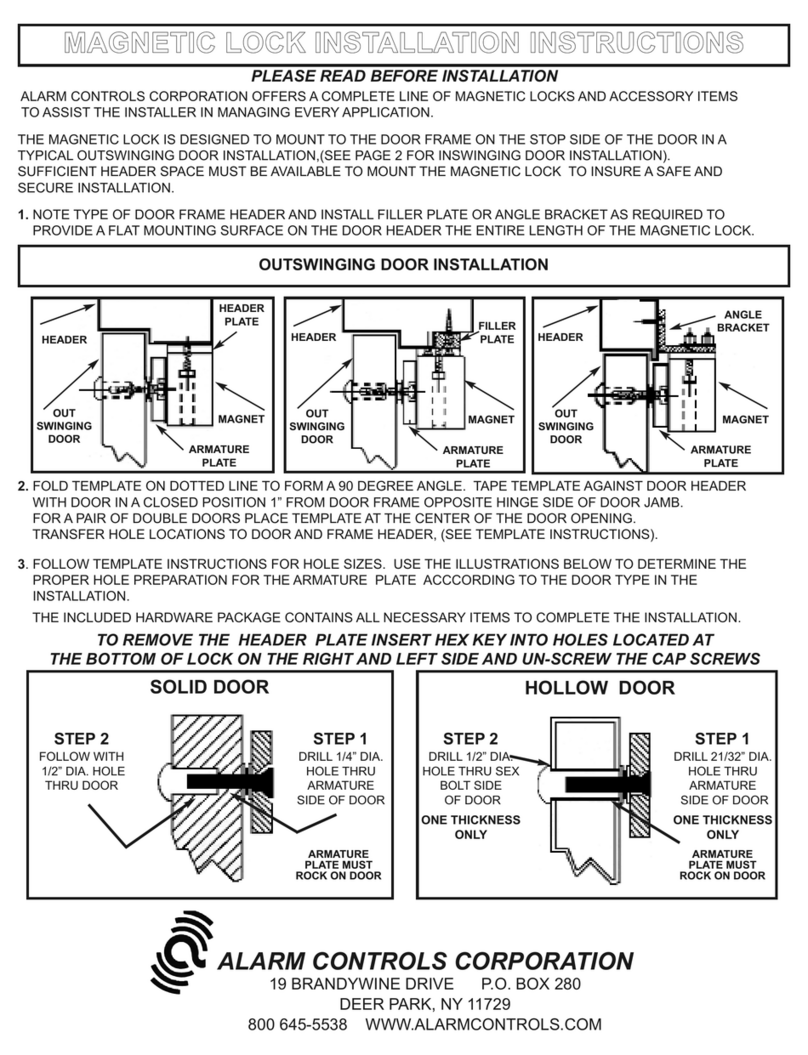

E-Z MOUNT DESIGN

FOR SUPERIOR FASTENING

THE ENHANCED ATTACHING

DESIGN MAKES THE LOCK

MOUNTING QUICK AND EASY.

DOUBLE MOUNTING SCREW

DESIGN PROVIDES A

STRONGER ATTACHING

FORCE.

ALARM CONTROLS CORPORATION MAGNETIC

LOCKS ARE MANUFACTURED TO RIGID

STANDARDS AND ARE ASSEMBLED WITH THE

FINEST MATERIALS AND WORKMANSHIP.

ALL MAGNETIC LOCKS HAVE A LIMITED LIFETIME

WARRANTY, AND WILL BE REPAIRED OR

REPLACED DUE TO DEFECTS IN MATERIAL

OR WORKMANSHIP.

THE 600 AND 1200 SERIES MAGNETIC LOCKS

ARE U.L. AND CANADA U.L. LISTED. THE LOCKS

CONFORM TO U.L. 10B, 10C FOR USE ON SWING-

ING TYPE FIRE DOORS AND CONVENTIONAL

DOORS. ALSO CLASSIFIED IN ACCORDANCE WITH

UNIFORM BUILDING CODE STANDARD 7-2, FIRE

TEST OF DOOR ASSEMBLIES.

A COMPLETE LINE OF STANDARD AND CUSTOM

REQUEST TO EXIT STATIONS ARE AVAILABLE.

IMPORTANT FEATURES

ALL MAGNETIC LOCKS HAVE A LIMITED LIFETIME

WARRANTY

MAGNETIC LOCKS ARE SUPPLIED WITH A THREAD

LOCKING AGENT TO INSURE SECURE ATTACHMENT

MAGNETIC LOCKS ARE SUPPLIED WITH BOTH WOOD

SCREWS AND SELF-TAPPING SHEET METAL SCREWS

ALL MAGNETIC LOCKS OPERATE ON 12 OR 24 VDC

ALL MAGNETIC LOCKS HAVE A LOW CURRENT DRAW

INSTANT RELEASE, NO RESIDULE MAGNETISM

ALL NON-ALIMINUM PARTS ARE PLATED

CLEAR ANODIZED US 28 FINISH STANDARD,

DURONIC US 40 FINISH AVAILABLE.

JBS-1 FOR 1200 SERIES, JBS-2 FOR 600 SERIES

SOUND LEVEL 80 db @ 3 FEET

MODULE REPLACES EXISTING CIRCUIT BOARD

VENTED COVER SUPPLIED

MODEL JBS-1/JBS-2

AUDIO INDICATOR MODULES

THIS MODULE WILL SOUND AS A MAGNETIC LOCK IS

BEING UN-LOCKED. AFTER POWER IS REMOVED FROM

LOCK,A THREE TO FIVE SECOND TONE WILL EMANATE

FROM THE MODULE INSIDE THE LOCK INDICATING

THAT THE LOCK IS UN-LOCKED. THIS MODULE WILL

OPERATE ON THE STANDARD TWO WIRE CONNECTION

TO THE LOCK. NO ADDITIONAL WIRING IS REQUIRED.