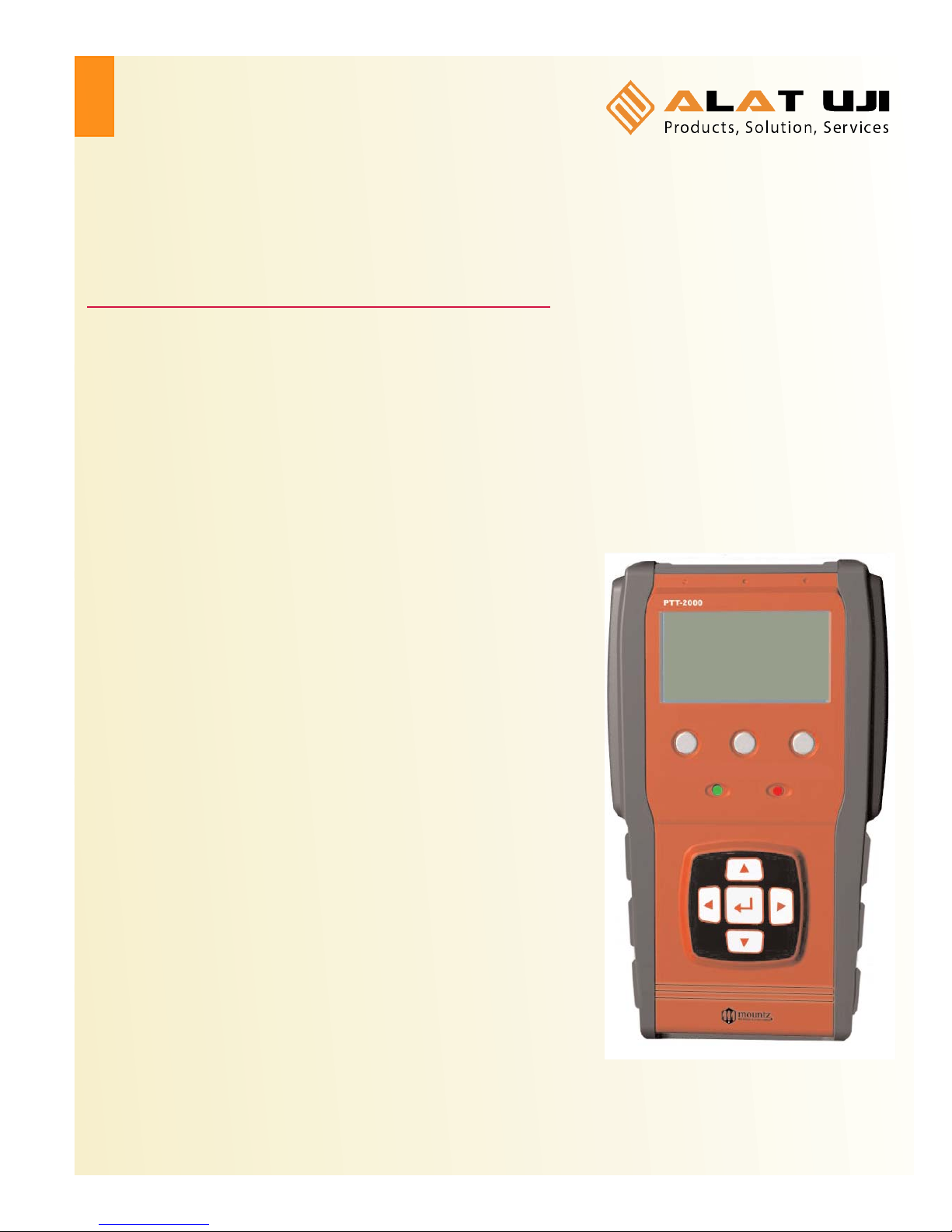

Features

System Accuracy +/- 0.5% of reading from 20% to 100% of full scale.

System Accuracy +/- 1% of reading from 10% to 20% of full scale.

Recommended for all hand screwdrivers, wrenches or power tools.

Provides “EZ-Plug & Play” with Mountz Transducers. Features “ARCII” technology, an instant auto-recognition

system of the transducer connected to the PTT.

Selection of six operating modes: (Track, Peak, First Peak, Audit, Torque + Angle, and Tool Test).

Seven units of torque measurements: (ozf.in, lbf.in, lbf.ft, cN.m, N.m, kgf.m, kgf.cm).

Features built-in Tool Tests operation.

Includes two PC Windows based software programs:

PTT Interface Program- for sensor calibrations, meter calibration and tool tests,

PTT Bootloader - for updating the PTT operating systems.

Mountz Statics Calculator - for SPC, CP & CPK calculations.

“Flash" memory allows upgrades to be done by the user in the field & internet through the USB port.

Five low-pass filter selections (3000, 2000, 1500, 500 and 200 Hz).

Easy to use Menu Structure.

Real Time Clock for time stamping of readings.

Six-digit display.

USB interface to download readings to PC.

High Capacity Li-Ion Batteries for long life (30 hrs with standard transducers and 16 hrs with brushless rotary).

Can connect to most mv/v transducers and can store calibration data for up to 50 non smart torque sensors.

The 5VDC capability allows unit to be used with a Brushless Rotary Transducer for testing pulse tools and high

RPM tools.

Torque and Angle readings are displayed simultaneously and supports up to 8000 RPM.

Stores a total of 2500 data points.

Real time graph of torque vs. time using associated PC Windows software.

Features a Buzzer and Go / No Go LEDs that illuminate when high or low setting is achieved.

Display Accuracy is better than +/- 0.0625 of reading.

Page 1

Heading Page

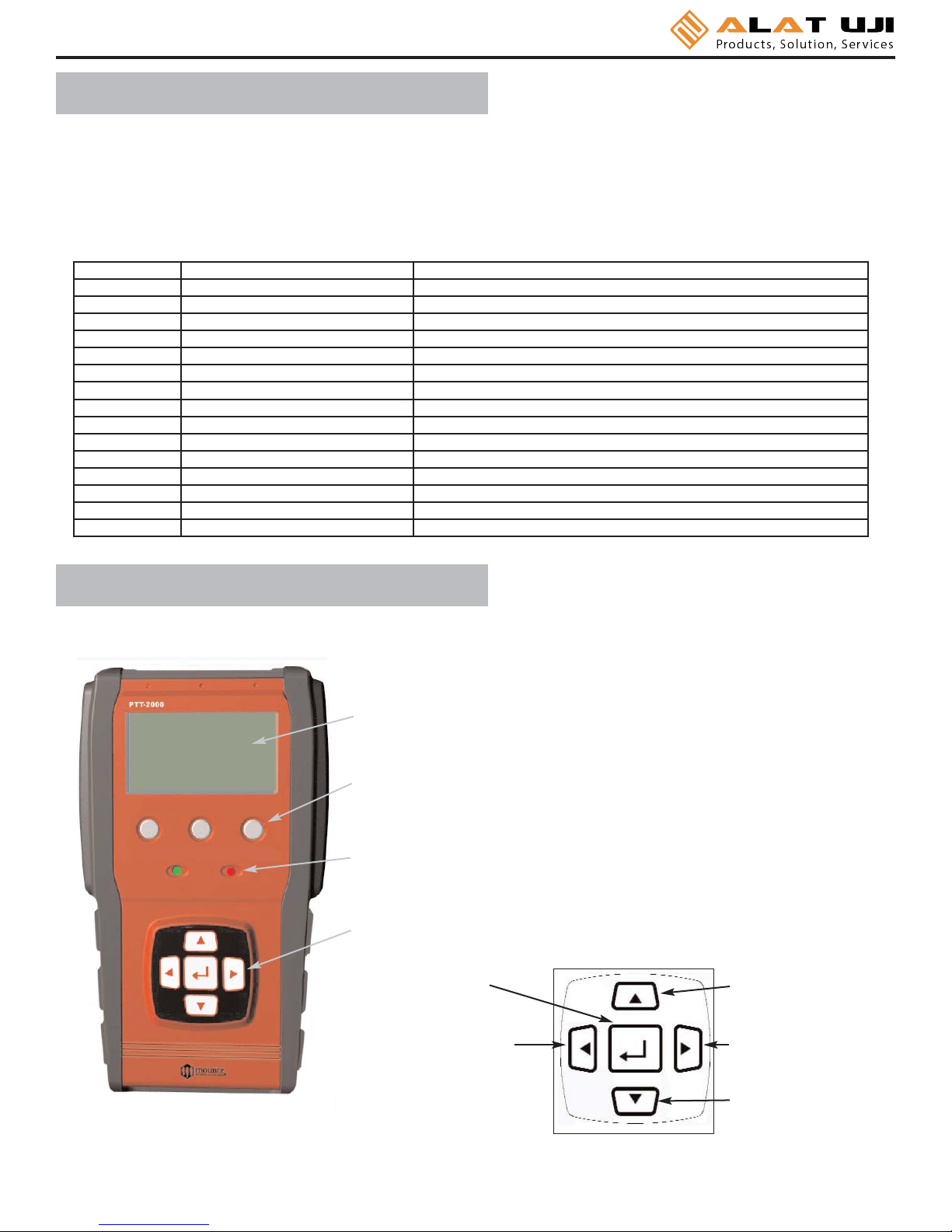

External Connections 2

User Interface 2

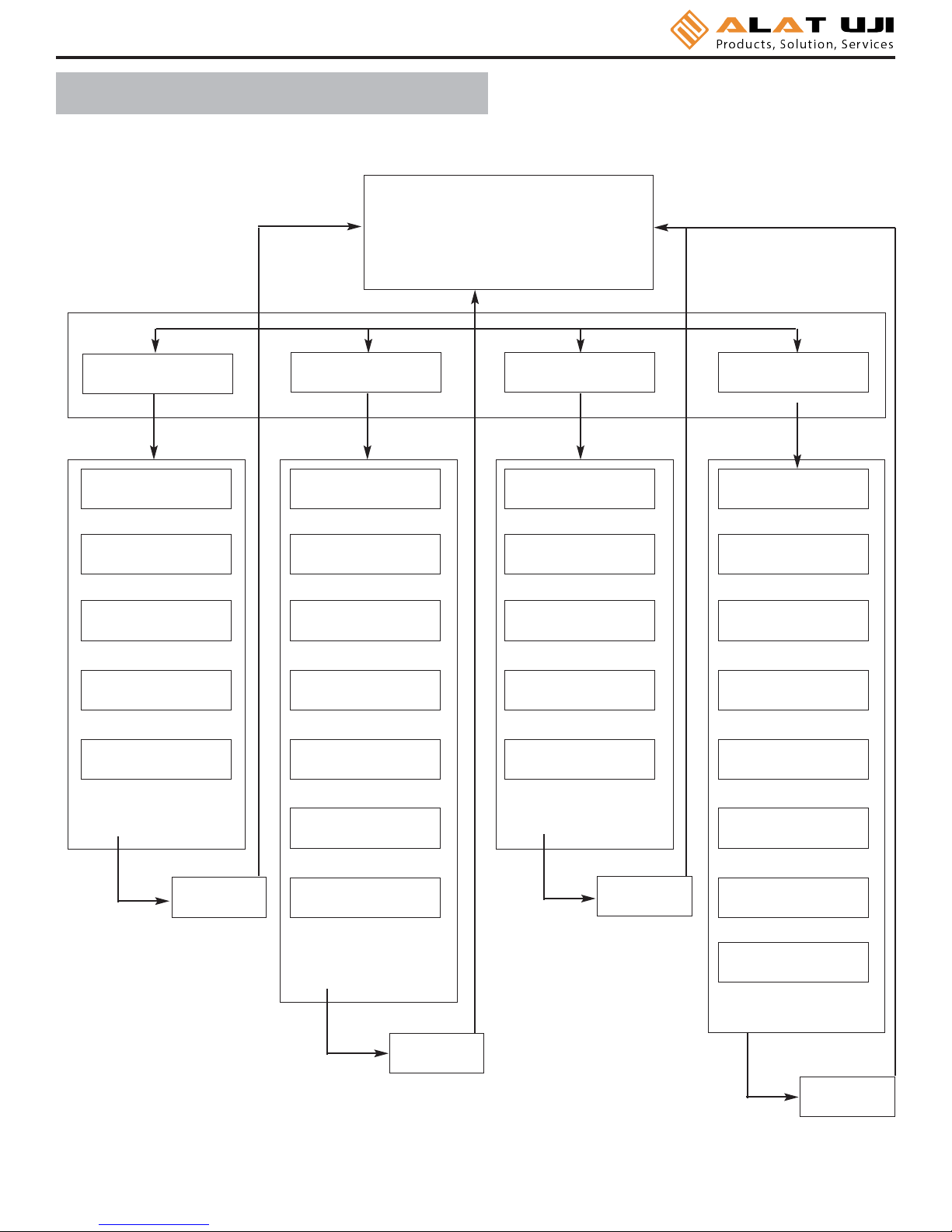

Quick Menu Structure 3

Screen Display 4

Menu Selections 4

Mode Selections 7

Set-Up Selections 8

Power On & Batter Operation 14

Installation of PTT Interface Software 14

Tool Test Operation 17

Transducer Calibration 20

PTT Calibration 21

Data Logging (Graphing) 21

Bootloader 23