8/15Alcatel Vacuum Technology France - User’s Manual ACC 2009

12/15Alcatel Vacuum Technology France - User’s Manual ACC 2009

9/15Alcatel Vacuum Technology France - User’s Manual ACC 2009 10/15Alcatel Vacuum Technology France - User’s Manual ACC 2009 11/15Alcatel Vacuum Technology France - User’s Manual ACC 2009

13/15Alcatel Vacuum Technology France - User’s Manual ACC 2009 14/15Alcatel Vacuum Technology France - User’s Manual ACC 2009 15/15Alcatel Vacuum Technology France - User’s Manual ACC 2009

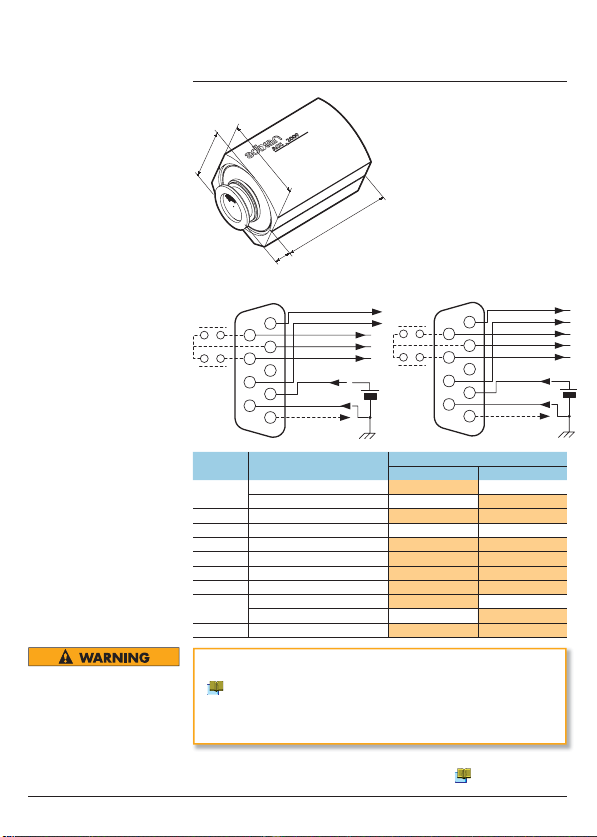

The analog output signal (0/10V) is available on Pins 1(+) and 8(–).

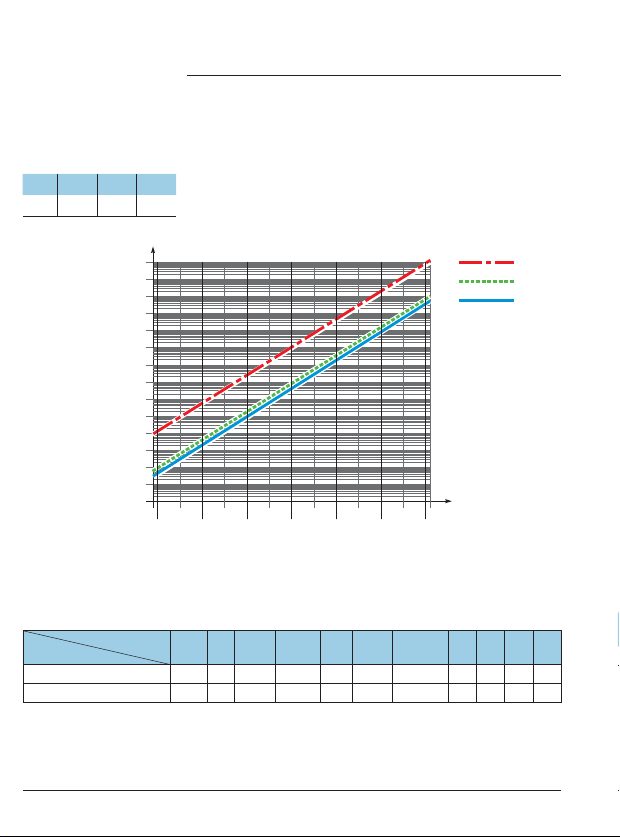

The analog signal can be converted to pressure according to the

formula:

P = 10(1.667x U–d) where : P= pressure, U= analog signal

voltage,

d= constant.

Measurement limits: 8.6 V = 1000 mbar and 1.8 V = 5x10–9 mbar

Analog Signal output

0/10 V

(ACC 2009 - 0/10 V + SP)

RS485 communication is available on the connector Pins 1(+)

and 8(–) .

Refer to the RS485 Communication Manual for details.

RS485 Signal output

(ACC 2009 - RS485 + SP)

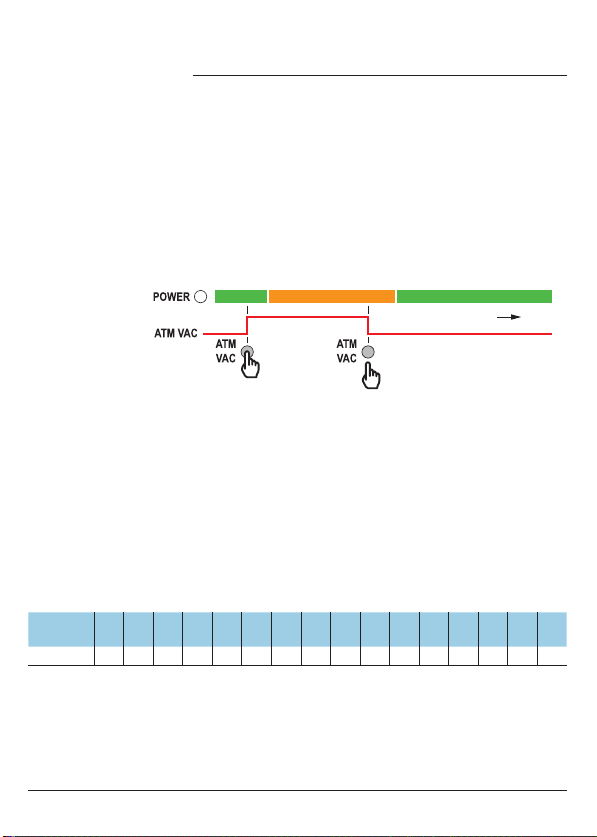

The Pirani gauge can be adjusted at two points, atmospheric

pressure (ATM) and at the low pressure limit of the gauge (VAC).

The gauge automatically determines whether the conditions are at

atmosphere or under low pressure (zero). Before adjustment, the

gauge must be mounted in the same orientation and conditions

it will be used in. It must be held in these conditions for at least

10 minutes before proceeding.

To adjust the zero, be sure the gauge current pressure is below

1 x 10-4 mbar (7.6 x 10-5 Torr).

Adjustment of the

gauge readings

6- Operation (ctd)

Set points 1 and 2 are modified using the switch selector:

- To set up the mantissa, use the digits 1 to 9 directly.

- To set up the exponent value (from +6 to –9) use the values in

the table below:

- To set up the measurement units, use:

mbar= 2 , torr = 1 or Pascal = any other position.

Set Point set up

Switch

selector

ABCDEF 0123456789

Exponent +6 +5 +4 +3 +2 +1 0 –1 –-2 –3 –4 –5 –6 –7 –8 –9

6- Operation (ctd)

Set Point set up (ctd)

(ACC 2009 - 0/10 V + SP)

Follow this example to set up the set points (refer also to table

next page):

set point 1: 5x10+2 = 500 mbar

set point 2: 8x10–1 = 0.8 mbar

Example values

Note: For the ACC2009 - RS485 + SP models, the set points are modified only via the RS485

interface (refer to the RS485 Communication Manual).

Set point output

6- Operation (ctd)

8- Maintenance

- 1.5 mm and 3 mm hexagonal key wrenches

- Long-nose pliers; inside circlip pliers (18-60 mm); Ohmmeter.

Tools required

- The sensor and/or the electronics can be replaced. Proceed as

follows:

- Loosen the set screw without removing it (1)

- Pull out the sensor (2) as shown.

- Replace the sensor (2) or the electronic (3) as needed.

- Carefully align the holes in the electronics to the pins on the

sensor, then push the sensor into the electronics. Take care not to

bend the pins on the sensor. Secure the sensor to the electronics

with the set screw.

- Be sure to calibrate the sensor after assembly ( 6 p. 9).

11 - Declaration of Conformity

10 - Decontamination and Product

Recycling

8- Maintenance (ctd)

If it is necessary to check the Pirani filament of the Sensor,

proceed as follows:

- Remove the sensor from the electronics as described above

- Using an ohmmeter, check the filament resistance between the

pin of the Pirani sensor and its ground spring.

- If the measured value is out of this range, replace the sensor.

Checking the filament

Item Description P/N

2

Sensor DN25 ISO KF ACC 2009 113046

Sensor DN40 ISO KF ACC 2009 113047

Sensor DN40 CFF ACC 2009 113048

Maintenance kit ( 8 p. 13) 113042

Trigger kit 118808

3Electronics 0/10 V + SP ACC 2009 113039

Electronics RS485 + SP ACC 2009 113040

Products that are not clearly declared as “free of harmful substances“ are decontaminated

at the expense of the customer. Products not accompanied by a duly completed “Safety

Questionnaire“ are returned to the sender at his own expense.

In compliance with Directive 2002/96/CE concerning the handling

of electrical and electronic

equipment waste and Directive 2002/9/CE concerning restrictions on hazardous substances,

Adixen products that have reached the end of their service life must

be returned to the

manufacturer for decontamination and reuse. The manufacturer’s obligation to recover such

equipment applies only to complete items of equipment that have been neither modified nor

retrofitted and have used only spare parts from Alcatel Vacuum Technology sold by Alcatel

Vacuum Technology and including all their assemblies and sub-assemblies. This obligation

does not include the cost of transporting the product to a reprocessing centre, nor the cost of

the service which will be invoiced on to the customer. All equipment returned to the service

centre, must have a properly filled in safety questionnaire. The questionnaire is available

separately, or on our Web site.

Separating the components

After disassembling the product, separate its components according to the following criteria:

Contaminated components: Contaminated components (radioactive, toxic, caustic, or

biological hazard etc.) must be decontaminated in accordance with the relevant local

regulations, separated according to their materials, and disposed of.

Other components: Such components must be separated according to their materials and

recycled.

Unit Pa mbar Torr

d9.33 11.33 11.46

For use with gasses other than Air, O2, N2, or CO, multiply the pressure reading by the

conversion factor from the table below: This formula is useful only for pressures under 1 mbar.

Peffective = Pread x C

10–8

10–6

10–4

10–2

1

102

104

2.5 3.0 4.0 5.0 6.0 7.0 8.0 8.6

3.5 4.5 5.5 6.5 7.5 8.5

10–8

10–6

10–4

10–2

1

102

104

2.5 3.0 4.0 5.0 6.0 7.0 8.0 8.6

3.5 4.5 5.5 6.5 7.5 8.5

Pa

mbar

Torr

Pressure P

10–8

10–6

10–4

10–2

1

102

104

2.5 3.0 4.0 5.0 6.0 7.0 8.0 8.6

3.5 4.5 5.5 6.5 7.5 8.5

Measurement

signal U (V)

9- Returning the Products

Replacement procedure:

1-

Remove the sensor from the electronics

( 8 p. 12). 2-

Unscrew and remove the magnet

(1).

3-

Remove the 3 screws

(2)

and remove the items to be replaced

(3. 4-

Pull out the protection

screen

(4)

with a bent paperclip or similar tool, then remove the circlip

(4b)

with appropriate

circlip pliers, then slide out the disk

(4c). 5-

Clean the interior of the sensor, the screen, circlip

and disk with isopropol alcohol and lint free wipes, swabs and /or scrubbing pads. Do not

scratch the interior finish of the metal.

6-

Reassemble the sensor in the reverse order of dis-

assembly, replacing items with those supplied in the maintenance kit.

7-

If possible, test the

reassembled sensor for leaks

. 8-

Attach the gauge to a vacuum pump or vessel and evacuate for

one hour before calibrating the gauge ( 6 p. 9)

6- Operation (ctd)

Set

the dial

Validate

with the SP SEL

button

Check

the confirmation

SP1 SP2

Initial state

1Start the process

2Set the dial to ‘5’ for the

mantissa of set point 1 (5x10+2)

3Set the dial to ‘E’ for the exponent

of Set point 1 (5x10+2)

(+2 = ‘E’ from the previous table)

4Set the dial to ‘8’ for the

mantissa of set point 2 (8x10–1)

5

5) Set the dial to ‘1’ for the

exponent of set point 2 (8x10–1)

(-1 = ‘1’ from the previous table)

6Set the dial to ‘2’ for mbar

(1 = Torr, any other setting = Pascal)

– End of process –

LED off

LED on steady

LED flashing

The set point relay output has a fixed 10% hysteresis.

Pressure Signal

Off Off

On On

Set Point Value

Relay Output

Hysteresis

+ 10 % of S. P. value

When removing this gauge from the vacuum system, do not touch

the inside of the connecting flange of the gauge or vacuum system

with bare hands. Fingerprints will increase outgassing in the gauge

and cause erroneous pressure readings

- Vent the vacuum system to atmospheric pressure.

- Turn off the power to the gauge.

- Remove the electrical connector.

- Remove the gauge from the vacuum system.

- Place a protective cap on the fitting to prevent foreign

substances from entering the gauge.

- If the gauge must be stored, we advise to keep it away from

heat, moisture an dust ( 4 p. 4).

Parts on a vacuum processing system can be contaminated with

material that is detrimental to health and environment.

Before removing this gauge, confirm whether or not the gauge

is contaminated with any harmful gasses or vapors. If it is

contaminated with any harmful substances, be sure the gauge and

equipment are purged and cleaned thoroughly before removal of

the gauge.

Take the necessary precautions when handling contaminated parts,

refer to 9 p. 13.

7- Gauge Removal

Dirt and damages can impair the function of vacuum

components. Disregard can lead to an increase of out gassing in

the vacuum system and it may have negative effects on the vacuum

process itself. Keep the gauge clean.

Do not clean the measurement device except the connecting flange.

Only use denatured alcohol to clean the outside of the gauge.

Substances detrimental to the environment.

Products or parts thereof (mechanical and electriccomponents,

operating fluids etc.) can be detrimental to the environment. Dispose

of such substances in accordance with all relevant local regulations.

Contaminated parts

Contaminated parts can be detrimental to health and the

environment. Before working on any parts, find out if they are

contaminated. Adhere to any relevant regulations and take the

necessary precautions when handling contaminated parts.

There is no adjustment for the cold cathode gauge.

Note: For ACC2009 – RS485 + SP models, the adjustments can

also be donevia the RS485 interface.

Allow to restore the

ATM or VAC stored

value.

Press

and hold Release

time

green greenorange

ATM or VAC adjustments

Sub-assembly

replacement

57 Ω

1

3

2

The items required for maintenance of the sensor are available

in a kit.

Maintenance of the

sensor

Maintenance Kit P/N 113042

Triger Kit (3 triggers) P/N 118808

Item Description

3a Spring

3b Pirani gauge

3c JO-ring

3d Anode

3e O-ring

5Trigger

Contaminated products (e.g. with radioactive, toxic, caustic

or microbiological hazard) can be detrimental to health and the

environment. Products returned to the manufacturer should be

cleaned and free of harmful substances. Be sure to follow the

shipping regulations of all involved countries and forwarding

companies and enclose a duly completed «Safety Questionnaire»

available on our web site before shipping any products back to the

manufacturer.

Error catalog

Error Gauge ACC 2009

Power Led & Voltage (V)

Controller

Message Probable Error Action

AV 9,5 V red ErrHi Broken filament of Pirani Check Pirani filament

Replace sensor head

B* 8,582 ≤V < 9,5 V green Or If correct ATM/VAC

adjustment is not possible

or in case of erractic mea-

surements

=

sensor contaminated

Check sensor head

Replace sensor head

C* 2,199 V < 8,582 V green 1x2 +2

D* 0,5 V < 2,199 V green Ur

E0,2 V < 0,5 V red Err06 Electronic error Replace electronics

GV 0,2 V red ErrL0 Electronic error Replace electronics

(*) = minor errors degraded working of the gauge

Pressure

Gas H2H2O CCl2F2He CO2Air, O2

CO, N2

Ne Ar Kr Xe

10-3<P<1mbar C 0,5 0,5 0,7 0,8 0,9 1,0 1,4 1,7 2,4 3,0

< 10-5 mbar C 2,4 - - 5,9 - 1,0 4,1 0,8 0,5 0,4

4

3

2

1

4a

4b

4c

5

3c

3b

3a