GB 00871 - Edition 03 - January 2007

3/3

A 20

Alcatel Vacuum Technology France - Drytel 1025 User’s Manual

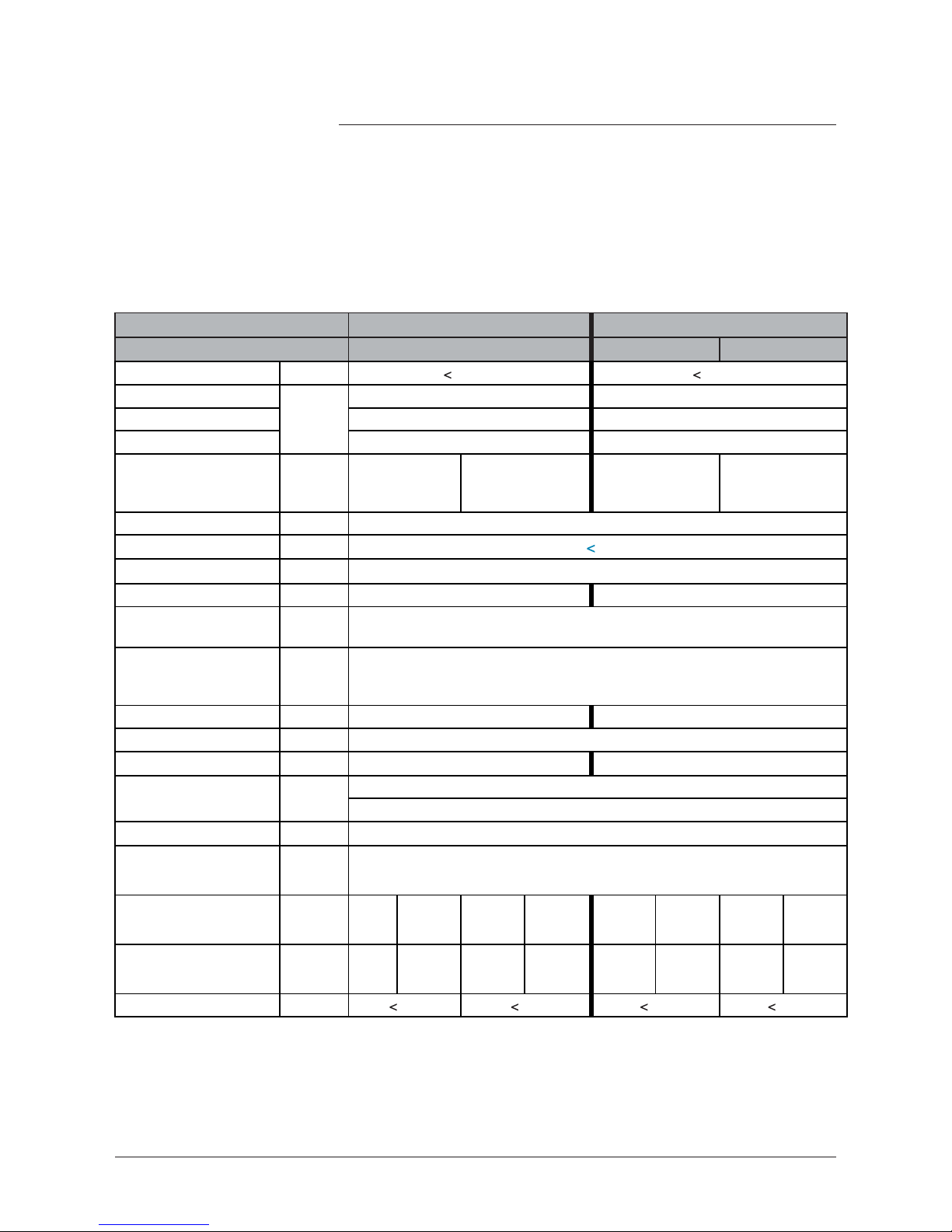

Description

Automatic air ballast

operating principle

Principle diagram

Powering up the solenoid valve opens it and introduces a calibrated

quantity of air via a nozzle parallel to the pumped gas.

The sintered metal PORAL disks protect the nozzle from dust or foreign

bodies carried by the gas or from the atmosphere.

The air inlet filter protects against dust or foreign bodies from the

atmosphere.

In case of accident or if the pump stops, a valve closes this inlet and

keeps the pump anti-suck back.

For more efficiency, it is possible to use a dry neutral gas as a purge

gas.

See sheet B 30 Connecting the automatic air ballast (option)

See sheet C 40 Using the automatic air ballast (option)

When condensable gases are pumped, depending on the nature of

the pumped gases, pressure and temperature conditions, they may

condense in the dead volumes of the primary pump.

When the pumping unit is at low pressure, the primary pump is at

the limit vacuum. The gases no longer pass through, its check valves

no longer open and the condensates remain inside.

These condensates mix with dust and create a destructive abrasive

for the pump diaphragm.

The introduction of gas at the last stage of the pump has various

effects:

ythe dilution of the pumped gas and the reduction of the partial

vapor pressure of the residual gas in the pump.

yit increases the compression of the pump and heats it, reducing the

risk of condensation by increasing of the temperature of the

internal pump.

yit reduces in the last stage the partial pressure if the pumped

gas and it stops its condensation when the gas reaches the

atmospheric pressure.

yin case of pumping at low pressure, when there is no flow, it gives

the possibility to open the valves and evacuate the residual gases.