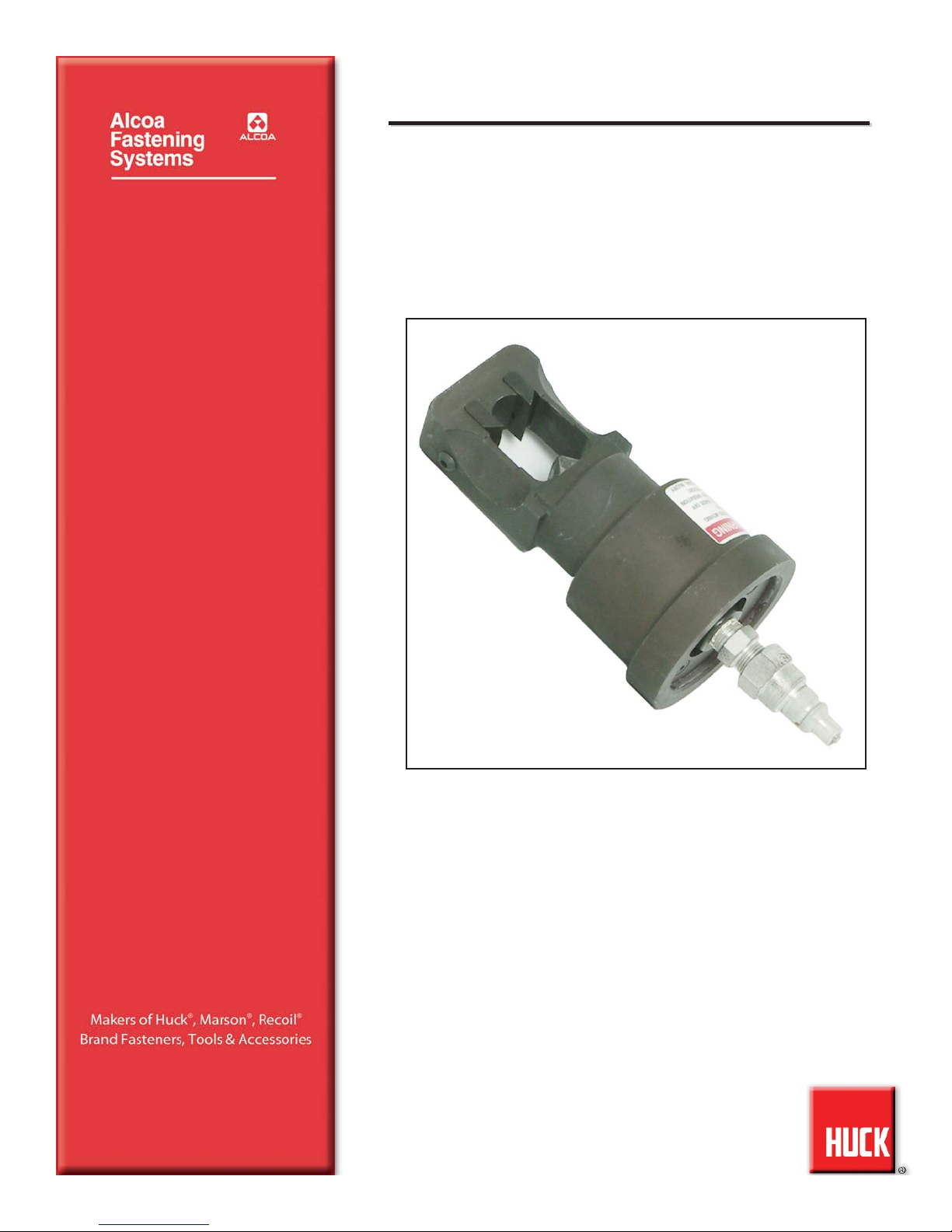

516, 520, 524, 528, 532, 536, M524 Hydraulic Collar Cutters Alcoa Fastening Systems

9

M

MAINTENANCE

AINTENANCE

Good Service Practices

The efficiency and life of any installation or removal tool

depends upon proper maintenance and good service

practices. Tools should be serviced by personnel who

are thoroughly familiar with them and how they operate.

A clean well lighted area should be available for servic-

ing the tool. Special care must be taken to prevent con-

tamination of hydraulic systems.

All parts must be handled carefully and examined for

damage or wear. Perishable parts such as o-rings and

seals should be kept on hand for replacement whenever

tool is disassembled.

See S

SPECIFICATIONS

PECIFICATIONS for fluid type. Dispose of fluid in

accordance with local environmental regulations.

Recycle steel, aluminum, and plastic parts in accordance

with local lawful and safe practices.

Components should be disassembled and assembled in

a straight line without bending, cocking or undue force.

Disassembly and assembly procedures outlined in this

manual should be followed. Appropriate hand tools and

soft materials to protect tools must be available. Only

standard hand tools are required. A half inch brass drift,

wood block and a vise with soft jaws will prevent damag-

ing tool.

Preventive Maintenance

Refer to the applicable section for A

ASSEMBLY

SSEMBLY and

D

DISASSEMBLY

ISASSEMBLY. For supplementary information refer to

T

TROUBLESHOOTING

ROUBLESHOOTING and illustrations.

With proper care, the cutter will remove 100 collars

before it may be necessary to replace the blades. The

estimated life of the Collar Cutter is 10,000 cycles or 5

years, depending on service conditions.

System Inspection

Operating efficiency of the cutter is directly related to the

performance of the complete system, including the cut-

ter, hydraulic hoses, trigger assembly and the POW-

ERIG® Hydraulic Unit. Therefore, an effective preventive

maintenance program includes scheduled inspections of

the system to detect and correct minor defects.

1. Inspect cutter for external damage.

2. Verify that hoses, fittings and trigger connections

are secure.

3. Inspect hydraulic hoses for signs of damage.

Replace if required.

4. Inspect cutter, hoses and POWERIG® during oper-

ation to detect abnormal heating, leaks or vibration.

POWERIG® Hydraulic Unit Maintenance

Hydraulic fluid should have a maximum contamination

level of ISO CODE 18/15 or SAE LEVEL 6. Portable fil-

tration on smaller powerigs and maintaining filters on

larger powerigs is recommended. Maintenance and

repair instructions are in applicable POWERIG Hydraulic

Unit instruction manuals.

Cutter Maintenance

At regular intervals, depending upon use, replace all

seals in the cutter. Spare seals and parts should be kept

on hand. Inspect cylinder bore and piston for scored sur-

faces, excessive wear or damage, and replace as neces-

sary.

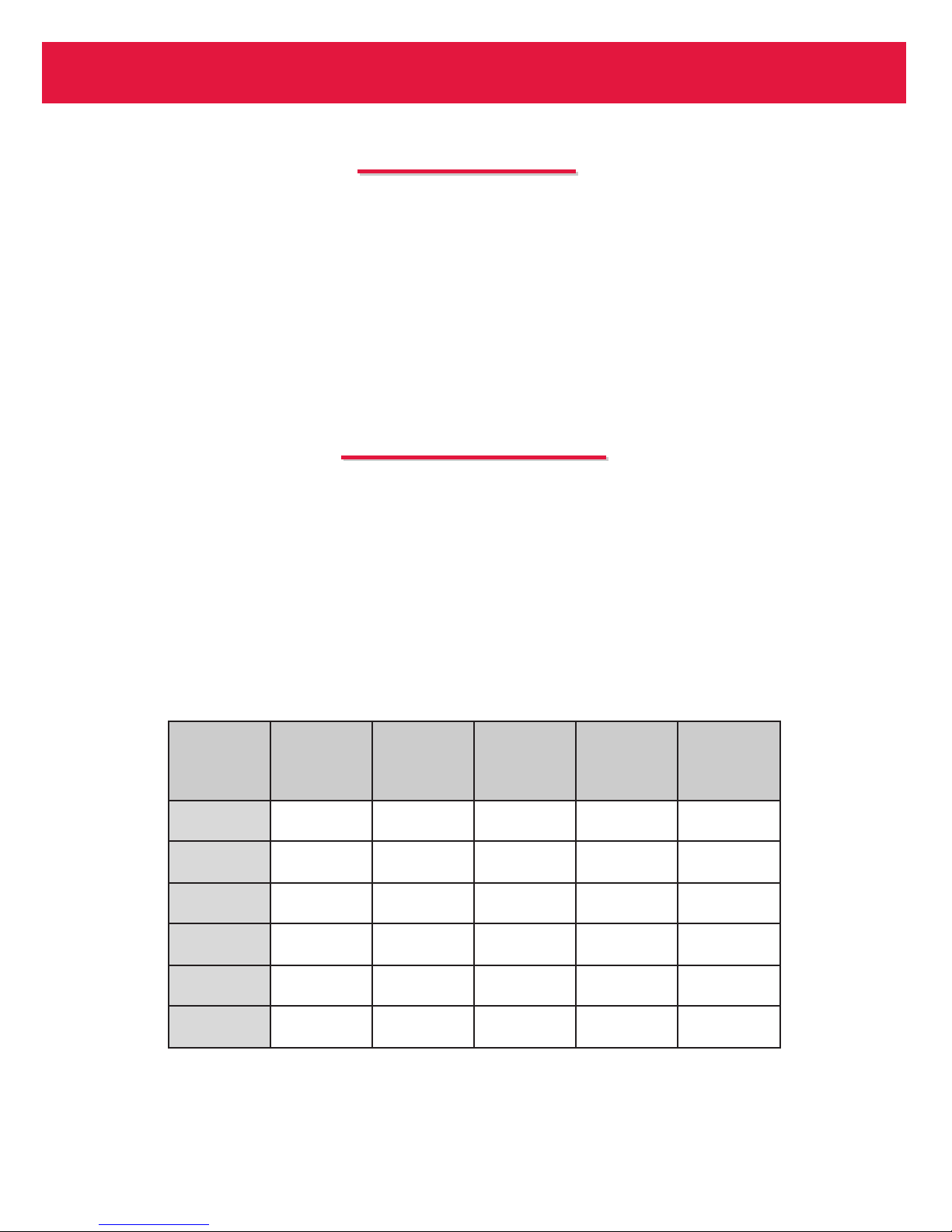

Notes and Specifications for Standard Parts

All part numbers shown are available from Huck. The

500000 series numbers are standard parts which can

generally be purchased locally.

Needle Valve Adjustment

A needle valve has been designed into the hydraulic

cylinder of some of the cutters. The adjustment provides

for the proper piston RETURN stroke when using various

hydraulic units and hose combinations. Tool is shipped

with the valve set in the closed position.

Needle Valve Adjustment for the 940 POWERIG®

Hydraulic Unit: Turn needle valve clockwise to the closed

position.

Needle Valve Adjustment for the 918 POWERIG®

Hydraulic Unit:

1. Close needle valve clockwise. Depress trigger until

piston stops forward.

2. Open needle valve by turning slightly counterclock-

wise. Jog or activate switch. If valve is correctly

adjusted, piston will return to rear and pump shuts

off. Repeat procedure until cutter cycles normally.

3. If normal cutter operation cannot be attained, close

needle valve completely and start over at 1. Repeat

until requirements are met.

Needle Valve Adjustment Trouble-shooting:

Note: A normal piston cycle is when the piston goes fully

forward and fully back with one actuation of the switch.

Q. Piston partially returns and pump shuts off.

A. Needle valve not open enough.

Q. Piston partially or fully returns and pump will not shut

off.

A. Needle valve is open too far.

* Slic-Tite is a registered trademark of LA-CO Industries, Inc.

* TEFLON is a registered trademark of DuPont Corp.

CAUTIONS:

●Consult MSDS before servicing tool.

●Keep dirt and other material out of hydraulic

system.

●Separated parts most be kept away from dirty

work surfaces.

●Dirt/debris in hydraulic fluid causes failure in

POWERIG® Hydraulic Unit’s valves.

CAUTION: Do not use TEFLON®* tape on pipe

threads. Pipe threads may cause tape to shred

resulting in tool malfunction. (Slic-Tite is avail-

able in stick form as Huck P/N 503237.)

CAUTION: Always replace seals, wipers, and

back-up rings when tool is disassembled for any

reason.