Thank you for purchasing our Dual Blade - Industrial Series Tenon Cutter!

Lumberjack Engineers, along with our craftsmen, have designed the safest,

easy-to-use self-centering tenon cutter on the market. By combining old-

world skills, along with DFMA principles and CNC technology, we’ve

eliminated the issues of off-center tenons and side-load cutting associated

with single-blade designs.

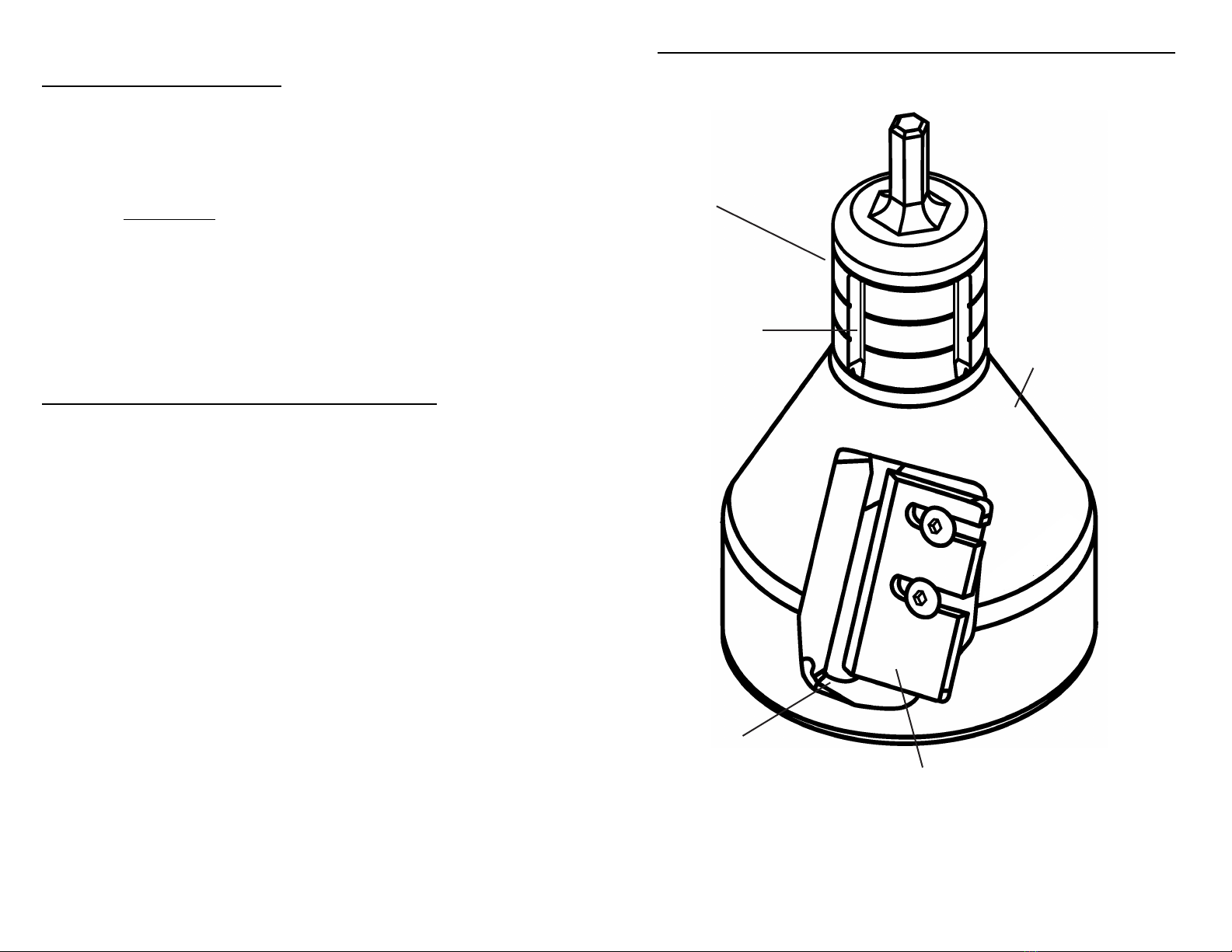

We’ve added value with the dual-blade technology which will cut the

tenon in half the time, and the two blades stay sharper, longer. The In-

Sight measurement system allows the craftsmen to cut the tenon to length

without the process of measuring with a tape measure each and every

piece before it is worked.

Our solid billet of aircraft-grade aluminum is designed to last a lifetime

under normal operating conditions. The aluminum body is CNC machined

to ensure precise cutting each and every time. The blades are stamped,

heat treated and precision ground to provide years of service when

properly maintained.

Before beginning any project, carefully read and follow all safety and

operational instructions for any tools or devices you will be using. Failure

to follow all safety instructions may cause bodily harm to yourself or

those around you. If you feel uncomfortable using our tenon cutter or

any other tools, stop immediately. We assume no responsibility for injury

caused to the operator, bystander or tools used in conjunction with the

use or misuse of our tenon cutters.

WARRANTY:

Our lifetime guarantee covers the tool body and shank. The blades are

covered for 90 days from the date of purchase for breakage under normal

working conditions. Blade sharpness is based on the type of wood, peeled

or unpeeled. Grit, dirt, etc will impact how long your blades stay sharp

and is not covered under this warranty. When making a claim, you must

show proof of purchase from an authorized distributor. This is valid only

to the original buyer and not for tools sold secondhand, used or sold “as

is” to a second party.

•WARNING: IF THE LOG COMES LOOSE OR UNCLAMPED

WHILE MAKING A TENON, DO NOT DROP THE DRILL OR

TRY TO GRAB THE LOG. HANG ON TO THE DRILL AND

POINT IT IN A SAFE DIRECTION (usually toward the ground)

AWAY FROM EVERYONE UNTIL IT COMES TO A

COMPLETE STOP.

• Do not remove the tool from the log until the drill comes to a

complete stop. Failure to do so will waffle cut the tenon or cause

harm to the operator. Do not place hands or body parts near the

tool or blades while in operation.

• Do not drop or allow the tool to fall to the floor by itself or while

in the drill. Doing so may bend the shank or damage the tool. This

damage is not covered by the warranty.

MAINTENANCE:

It is best if you keep the tenon cutter body clean of sap & build up.

Carefully clean the tool with the solvent or cleaner of your choice and

dry when done. Wear all protective safety devices including safety

glasses, gloves, etc. while cleaning tool.

Our blades are made from high-quality tool steel and may form oxidation.

This is a natural occurrence and will vary depending on your geographic

location, climate and shop environment, etc. You should periodically

clean the blades and apply a thin lm of oil. Every time you resharpen

the blades you must also apply a thin lm of oil. Use extreme caution

when doing this so you don’t cut yourself.