Table of contents

0. FOREWORD.....................................................................................................................................................6

0.1. HOW TO USE THE MANUAL ...................................................................................................................6

0.1.1. IMPORTANCE OF THE MANUAL ......................................................................................................6

0.1.2. HOW TO KEEP THE MANUAL...........................................................................................................6

0.1.3. HOW TO CONSULT THE MANUAL ...................................................................................................6

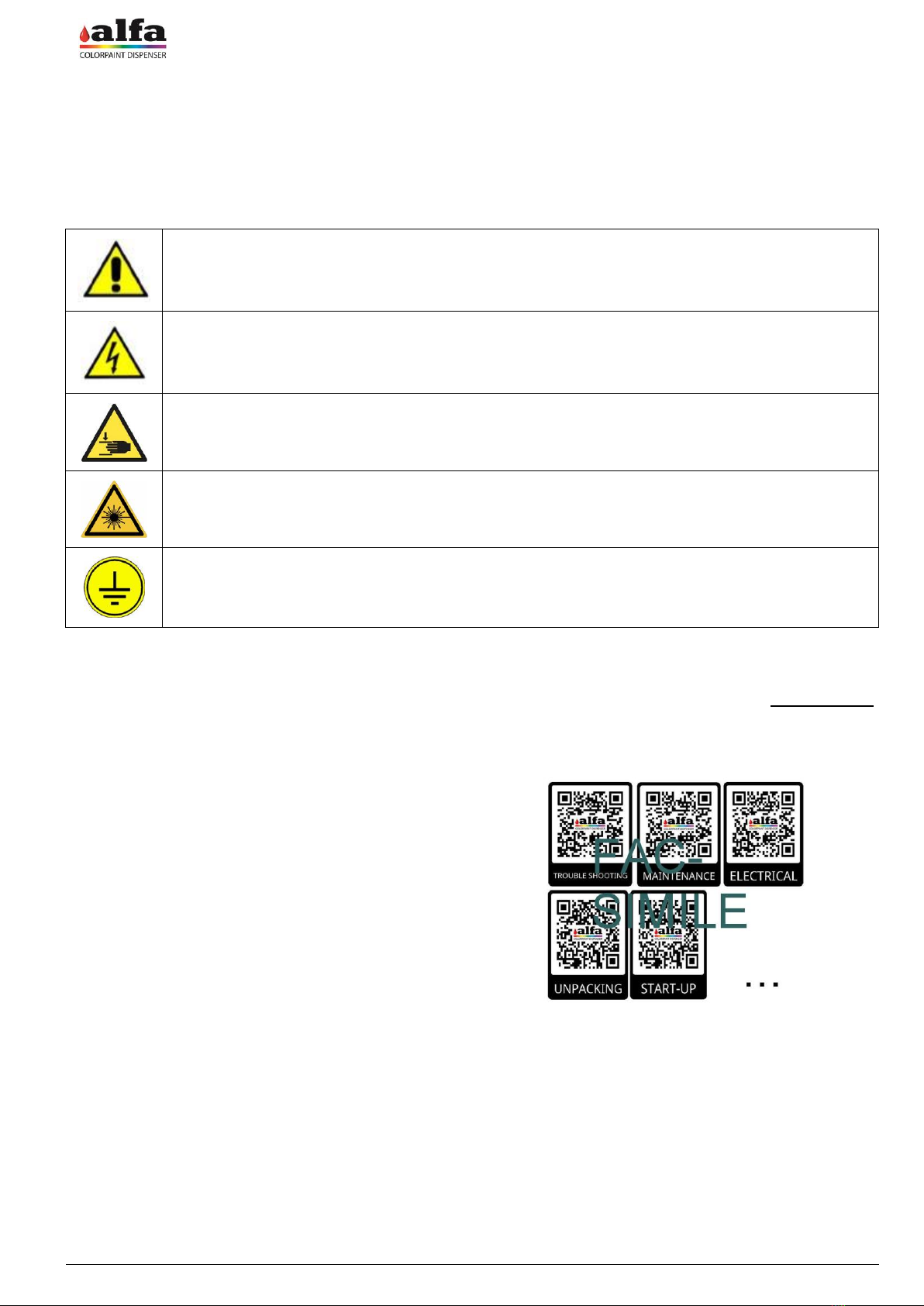

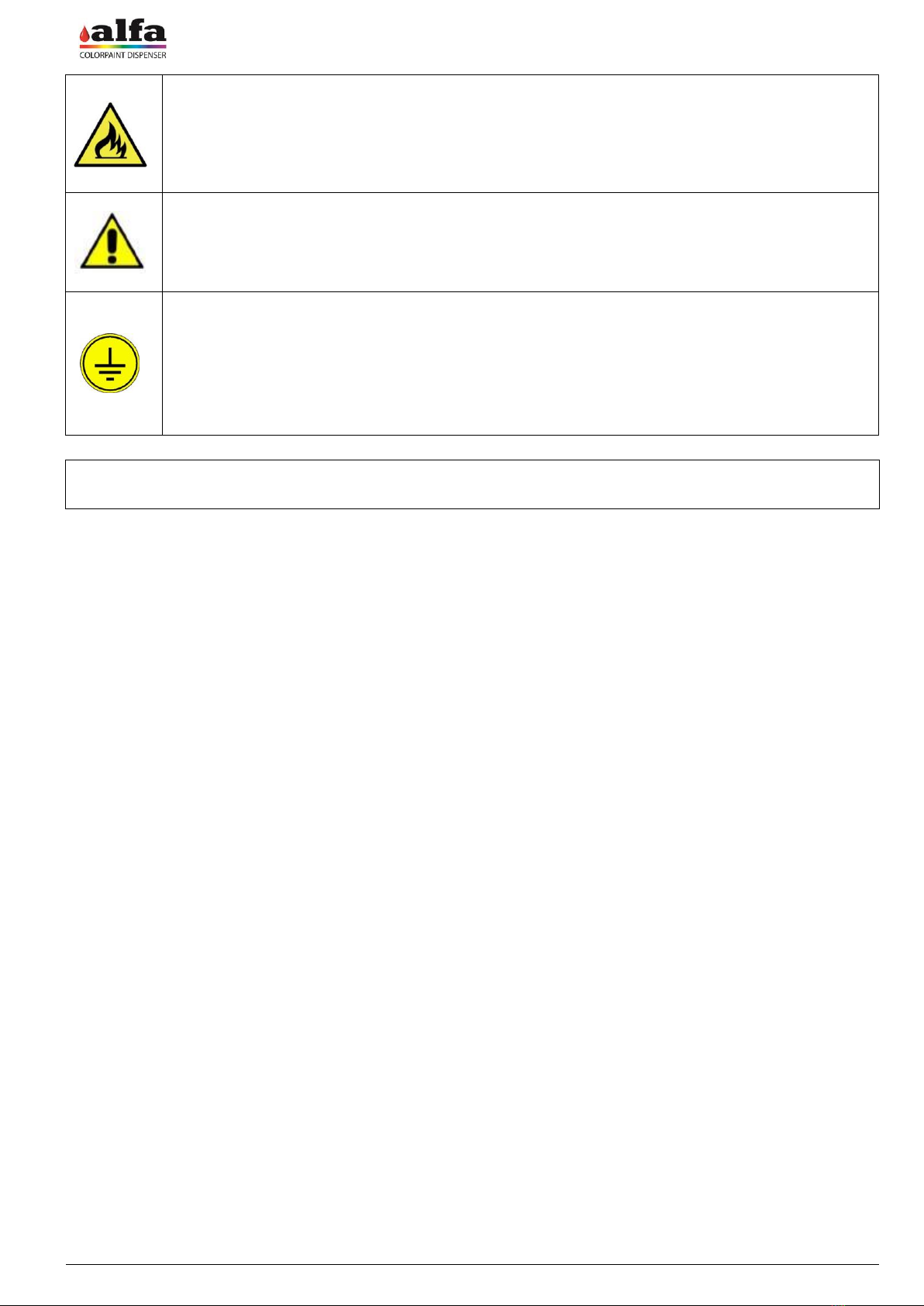

0.1.4. SYMBOLS USED IN THE MANUAL ...................................................................................................7

0.1.5. UPDATING THE MANUAL IN CASE OF MODIFICATIONS TO MACHINE.......................................7

0.1.6. OTHER INFORMATION SUPPORTS.................................................................................................7

0.2. INSTRUCTIONS FOR ORIGINAL SPARE PART AND CONSUMABLE ORDER....................................8

0.3. SAFETY INFORMATION...........................................................................................................................8

0.3.1. PRECAUTIONS AND USAGE REGULATIONS .................................................................................8

0.3.2. GENERAL SAFETY WARNINGS........................................................................................................8

0.3.3. USERS AND ACCESS LEVELS.........................................................................................................9

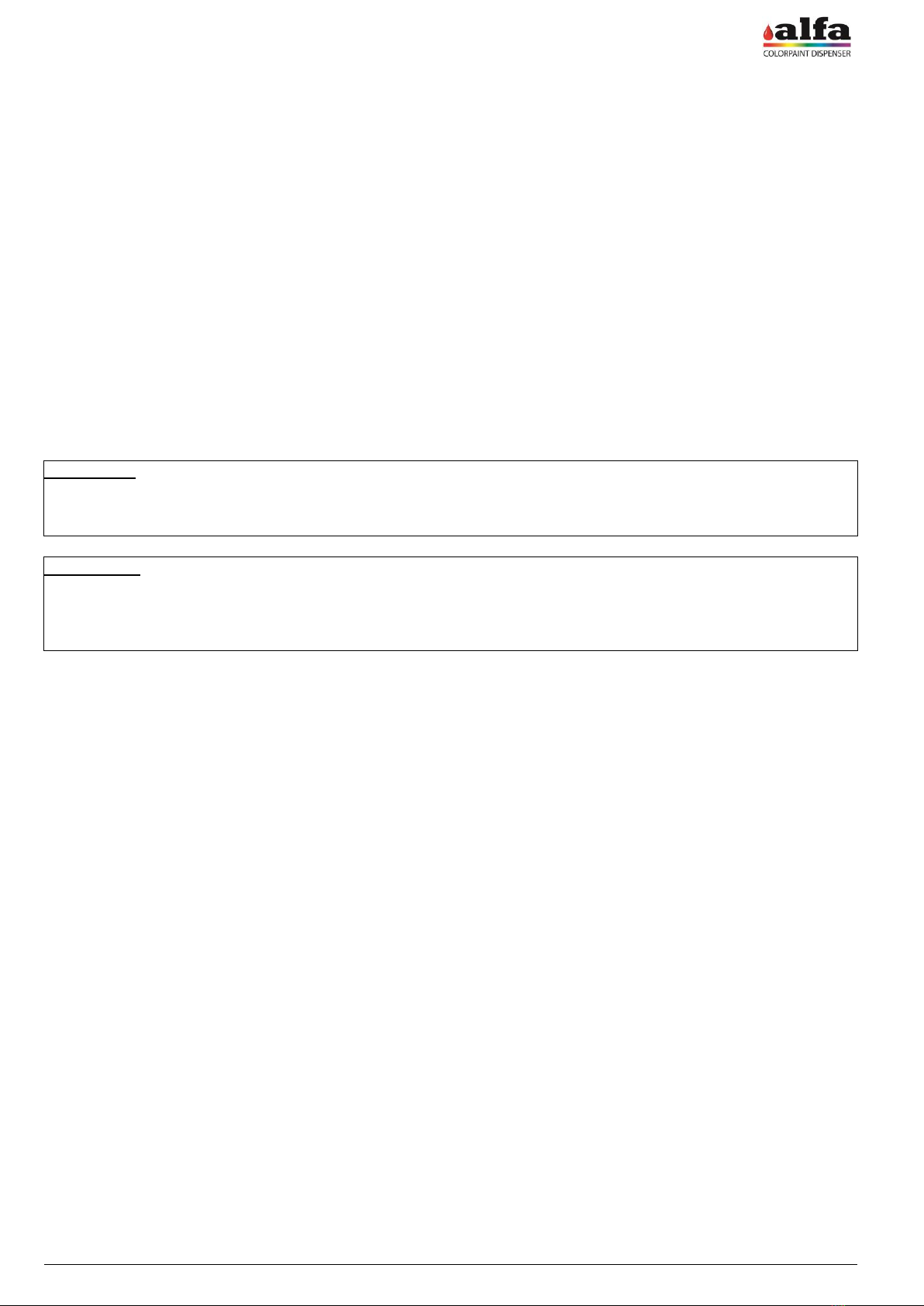

1. GENERAL INFORMATION............................................................................................................................10

1.1. INTRODUCTION .....................................................................................................................................10

1.1.1. MODELS AND VERSIONS...............................................................................................................10

1.1.2. COLORANT TURNING TABLE CONFIGURATIONS.......................................................................11

1.2. INTENDED AND UNINTENDED USE.....................................................................................................11

1.3. DESCRIPTION OF THE MACHINE ........................................................................................................11

1.3.1. MAIN COMPONENTS.......................................................................................................................11

1.3.2. COLORANT TURNING TABLE.........................................................................................................12

1.3.3. ACCESSING THE GROUPS.............................................................................................................12

1.3.4. LOADING AND UNLOADING ROLLER CONVEYORS....................................................................13

1.3.5. AUXILIARY FUNCTIONS..................................................................................................................13

1.3.6. LIFTERS............................................................................................................................................14

1.3.7. ELECTRICAL CONTROL PANEL.....................................................................................................14

1.3.8. CONTROL INTERFACE....................................................................................................................15

1.4. WORK CYCLE.........................................................................................................................................15

1.4.1. SWITCH-ON - RESET.......................................................................................................................15

1.4.2. OPERATOR INTERFACE AND MAINTENANCE INTERFACE .......................................................15

1.4.3. ALARMS............................................................................................................................................16

1.4.4. STAND-BY.........................................................................................................................................16

1.4.5. PRODUCT STIRRING AND RECIRCULATION ...............................................................................16

1.4.6. WORKING CYCLE............................................................................................................................17

1.5. TECHNICAL SPECIFICATIONS .............................................................................................................17

1.5.1. ELECTRICAL SPECIFICATIONS .....................................................................................................17

1.5.2. EQUIPMENT CLASSIFICATION AND REFERENCE STANDARDS ...............................................17

1.5.3. OPERATING CONDITIONS..............................................................................................................17

1.5.4. DIMENSIONS AND WEIGHTS .........................................................................................................18

1.5.5. PRODUCTION CAPABILITY AND TECHNICAL SPECIFICATIONS ...............................................18

1.5.6. CONSUMABLE STORAGE...............................................................................................................18

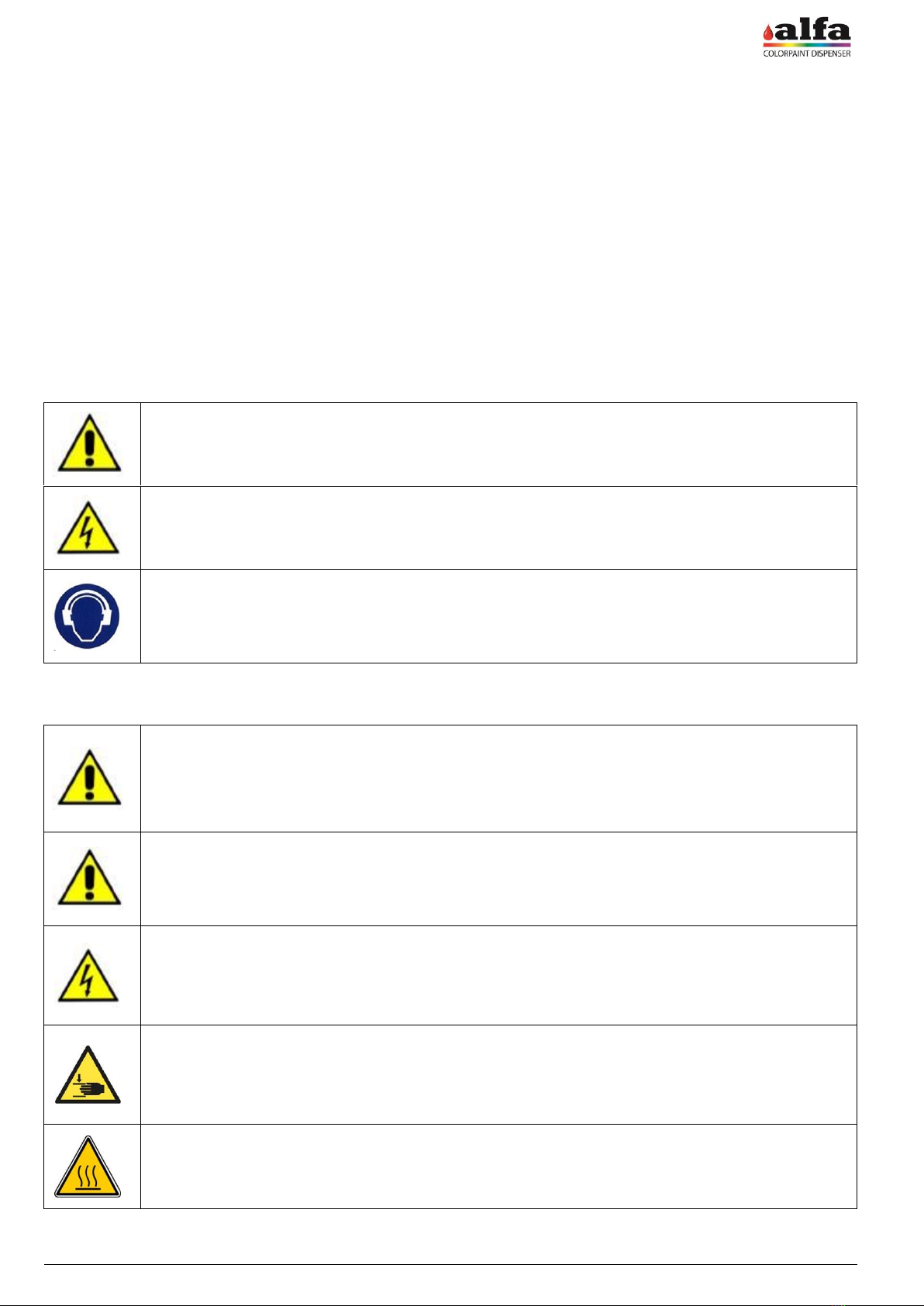

1.6. RESIDUAL RISKS AND DANGEROUS AREAS.....................................................................................19

1.6.1. CONTACT WITH PAINTS AND COMPONENTS .............................................................................20

1.6.2. GENERAL FIRST AID MEASURES..................................................................................................20

1.7. CERTIFICATIONS...................................................................................................................................21

1.7.1. END OF LIFE TREATMENT - WEEE DIRECTIVE ...........................................................................21

1.7.2. FCC ...................................................................................................................................................21

1.7.3. ROHS CHINA DECLARATION .........................................................................................................21

1.7.4. EC / UKCA DECLARATIONS............................................................................................................22

2. UNPACKING ..................................................................................................................................................24

2.1. GENERAL RECOMMENDATIONS.........................................................................................................24

2.1.1. DIMENSIONS OF THE PACKAGE...................................................................................................24

2.2. UNPACKING ...........................................................................................................................................25

2.3. OPENING PACKAGE AND CHECKING THE CONTENT......................................................................26

2.4. MOVING THE MACHINE (CR2 VERSION) ............................................................................................27

2.5. MOVING THE MACHINE (CR4 AND CR6 VERSIONS).........................................................................27