Table of contents

0. FOREWORD ................................................................................................................................................... 7

0.1. HOW TO USE THE MANUAL .................................................................................................................. 7

0.1.1. IMPORTANCE OF THE MANUAL ..................................................................................................... 7

0.1.2. HOW TO KEEP THE MANUAL .......................................................................................................... 7

0.1.3. HOW TO CONSULT THE MANUAL .................................................................................................. 7

0.1.4. SYMBOLS USED IN THE MANUAL .................................................................................................. 8

0.1.5. PROCEDURE FOR UPDATING THE MANUAL IN CASE OF MODIFICATIONS TO MACHINE ...... 8

0.2. INSTRUCTIONS FOR ORDERING ORIGINAL SPARE PART AND CONSUMABLES .......................... 8

0.3. SAFETY INFORMATION ......................................................................................................................... 9

0.3.1. PRECAUTIONS AND USAGE REGULATIONS ................................................................................ 9

0.3.2. GENERAL SAFETY WARNINGS ...................................................................................................... 9

0.3.3. USERS AND ACCESS LEVELS ...................................................................................................... 10

0.3.4. RESIDUAL RISKS AND HAZARDOUS AREAS .............................................................................. 11

0.3.5. CONTACT WITH COLOURANTS .................................................................................................... 11

0.3.5.1. GENERAL FIRST AID MEASURES ................................................................................................. 11

0.4. TECHNICAL SPECIFICATIONS ............................................................................................................ 12

0.4.1. ELECTRICAL SPECIFICATIONS .................................................................................................... 12

0.4.2. EQUIPMENT CLASSIFICATION AND REFERENCE STANDARDS ............................................... 12

0.4.3. OPERATING CONDITIONS ............................................................................................................. 12

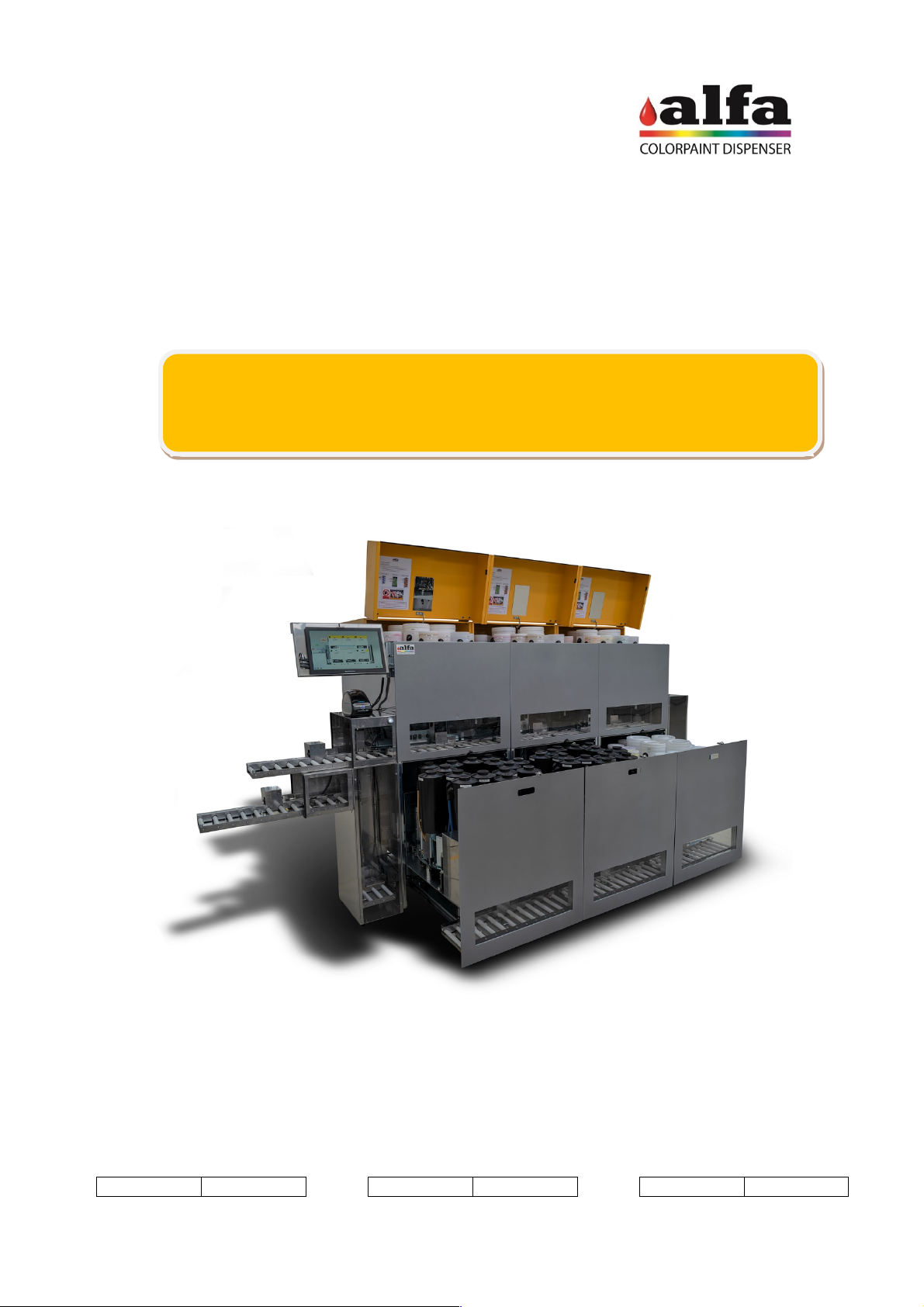

1. DESCRIPTION OF THE MACHINE .............................................................................................................. 13

1.1. MAIN COMPONENTS ............................................................................................................................ 13

1.1.1. MAIN COMPONENTS ...................................................................................................................... 13

1.1.2. ROTATING COLOURANT TABLE ................................................................................................... 13

1.1.3. ACCESSING THE GROUPS ........................................................................................................... 14

1.1.4. LOADING AND UNLOADING ROLLER CONVEYORS ................................................................... 15

1.1.5. AUXILIARY FUNCTIONS ................................................................................................................. 16

1.1.6. LIFTERS ........................................................................................................................................... 16

1.1.7. ELECTRICAL CONTROL PANEL .................................................................................................... 17

2. REMOVAL AND REPLACEMENT OF PARTS ............................................................................................ 18

2.0. SAFETY REGULATIONS FOR MAINTENANCE ................................................................................... 18

2.0.1. AUTHORISED PERSONNEL ........................................................................................................... 18

2.0.2. SWITCHING THE MACHINE OFF ................................................................................................... 18

2.0.3. ACCESSING THE REPAIR AND MAINTENANCE OPERATIONS ................................................. 18

2.0.4. RESTORING NORMAL MACHINE OPERATION FOLLOWING MAINTENANCE .......................... 18

2.0.5. DISPOSAL OF PRODUCTS ............................................................................................................ 18

2.1. REMOVING PANELS ............................................................................................................................. 19

2.1.1. SIDE AND REAR PANELS .............................................................................................................. 19

2.1.2. FRONT PANEL ................................................................................................................................ 20

2.2. ACCESSING THE ELECTRICAL PARTS .............................................................................................. 20

2.3. REMOVING COMPONENT CIRCUITS .................................................................................................. 21

2.3.1. CLEANING THE FILTERS ............................................................................................................... 22

2.4. REPLACING THE AUXILIARY ACTUATORS AND SENSORS ............................................................ 23

2.4.1. REPLACING A SENSOR ................................................................................................................. 23

2.4.2. SERVICING/CLEANING THE NOZZLE CLEANING UNIT .............................................................. 23

2.4.3. REPLACING THE HEATER ............................................................................................................. 24

2.4.4. SERVICING THE DISPENSING/RECIRCULATION MOTOR .......................................................... 25

2.4.5. REPLACING THE CERAMIC VALVE DRIVE MOTOR .................................................................... 26

2.4.6. REPLACING THE ROTATING TABLE ROTATION HOME PHOTOCELL ...................................... 27

2.4.7. REPLACING THE DOOR SENSORS .............................................................................................. 27

2.5. REPAIR PROCEDURES ON THE COLOURANT ROTATING TABLE .................................................. 28

2.5.1. REPLACING/ADJUSTING THE ROTATING TABLE MOTOR ......................................................... 28

2.5.2. REPLACING THE STIRRING BELT AND/OR THE DRIVE COUPLING ......................................... 28

2.5.3. REMOVING THE ROTATING TABLE, REPLACING THE BEARINGS AND THE BELT ................ 30

2.7. LIFTER ADJUSTMENTS ........................................................................................................................ 35

2.7.1 LIMIT SWITCH ADJUSTMENT ........................................................................................................ 35

2.7.2 ROLLER CONVEYOR TRANSMISSION O-RING TENSIONING .................................................... 36