Technical Manual –Color Tester

ELECTRIC REPAIRING OPERATIONS

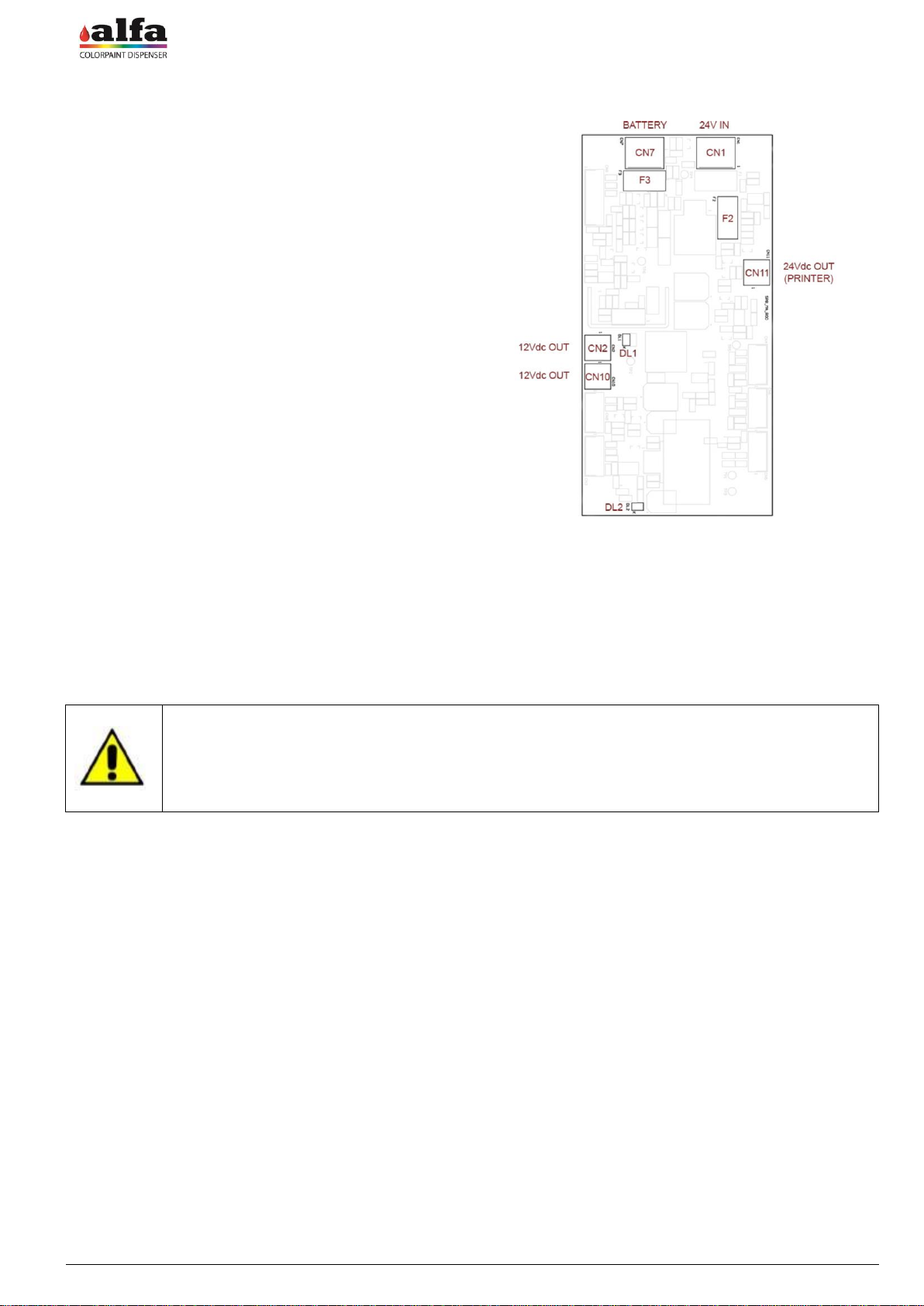

3.4. REPLACING THE POWER SUPPLY UNITS

In case of an electric fault in one or more power supply units of the machine, proceed as follows to replace them:

make sure the machine is disconnected from the

power supply as described in para. 2.0.3.

To reach the power supply unit compartment remove

the rear panel as described in paragraph 2.1.1. to

reach the electric panels, then remove the internal

protections as described in paragraph 2.1.2.

Disconnect the wiring between the power supply unit to

be replaced and the rest of the machine.

Remove the power supply unit by fitting a small flat

screwdriver in the suitable retaining tab and remove

the unit from the DIN bar.

Fit the new power supply unit manually on the DIN bar.

Reconnect the power supply unit to the wiring

according to the attached wiring diagram.

Reposition the previously removed protection panel.

WARNING: use only genuine spare parts supplied by the

manufacturer.

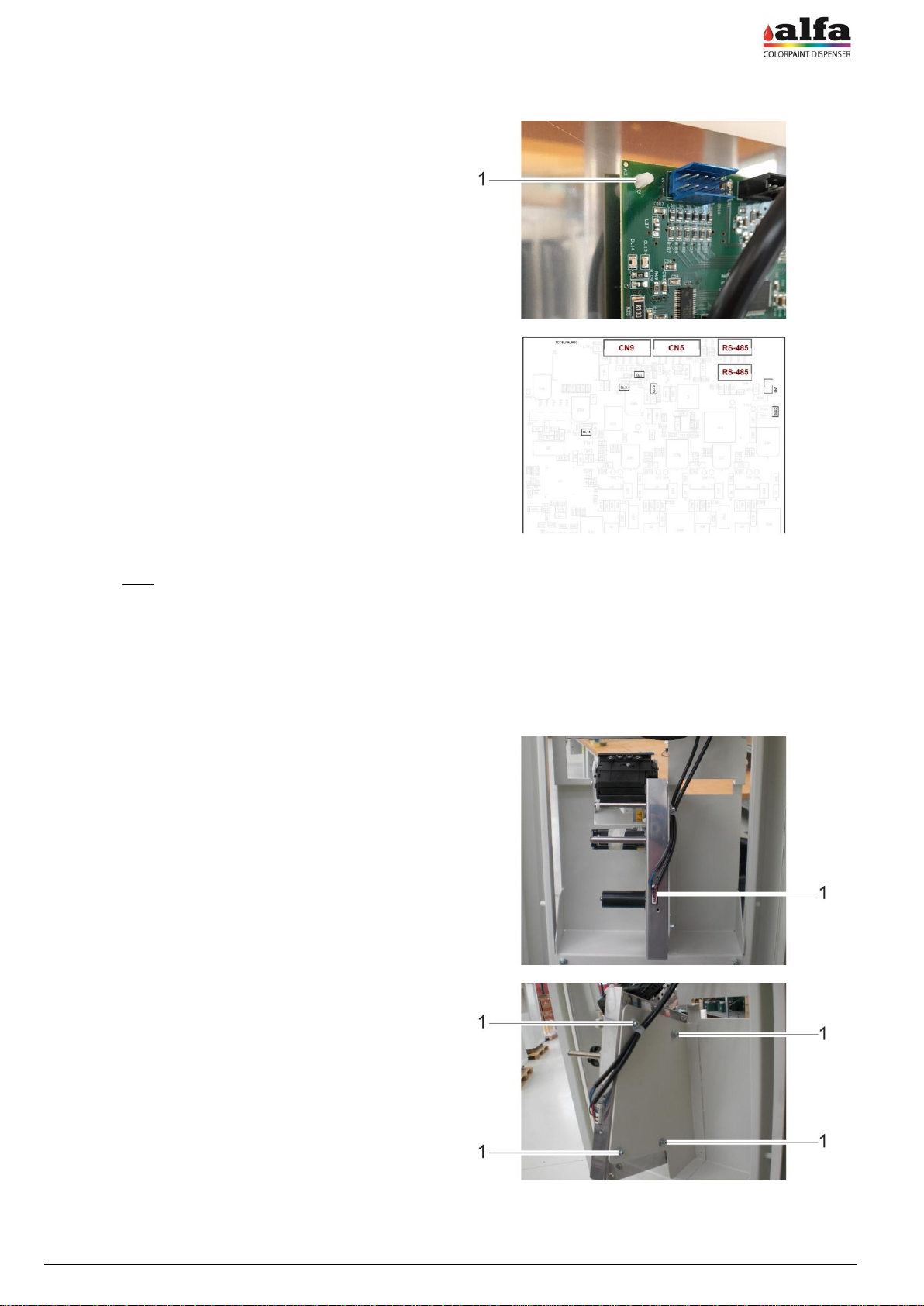

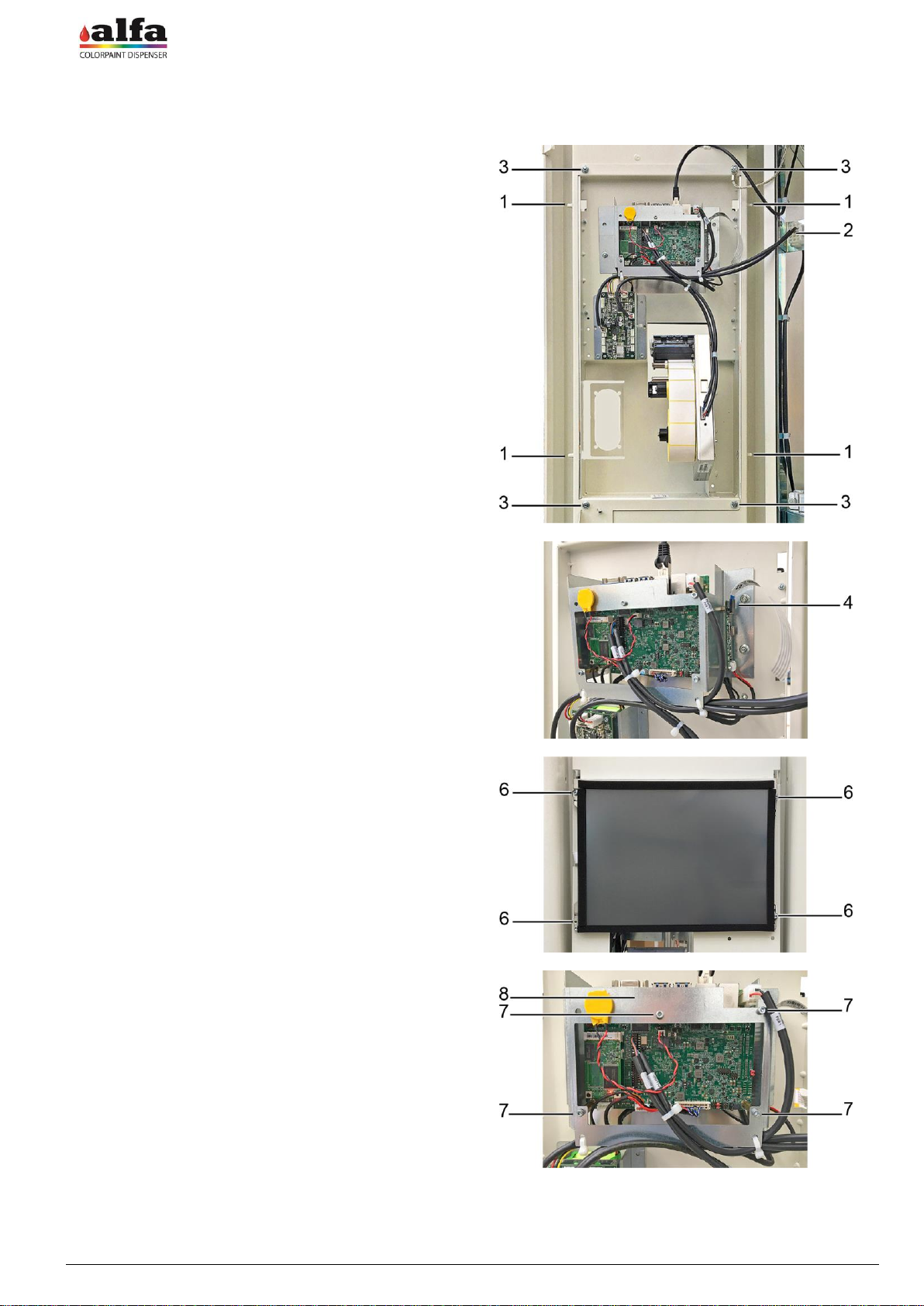

3.5. REPLACING THE MAX BOARD

To replace the MAB boards, proceed as follows:

make sure the machine is disconnected from the

power supply as described in para. 2.0.3.

Remove the rear panel as described in paragraph

2.1.1. to reach the electric panels, then remove the

internal protections as described in paragraph 2.1.2.

Disconnect the power supply and signal cables from

the board (1) to be replaced.

Remove the board by releasing it from the plastic

supports on its corners.

Insert a new board on the supports having care not to

damage its components.

WARNING: Use an already programmed board or the

suitable programmer to install the correct firmware. To

reprogramme the boards refer to chapter 4.

Restore the electric connections.

MAKE SURE THAT THE TERMINATION JUMPER ON

CN7 (2) IS PRESENT ON THE NEW BOARD.