Edit: 30/07/19 | Rev A | Page: 1

Contents

Introduction...................................................................................................................................................2

Section 1: COMMISSIONING..........................................................................................................................3

I. Area of use..............................................................................................................................................3

II. Installation and commissioning.............................................................................................................3

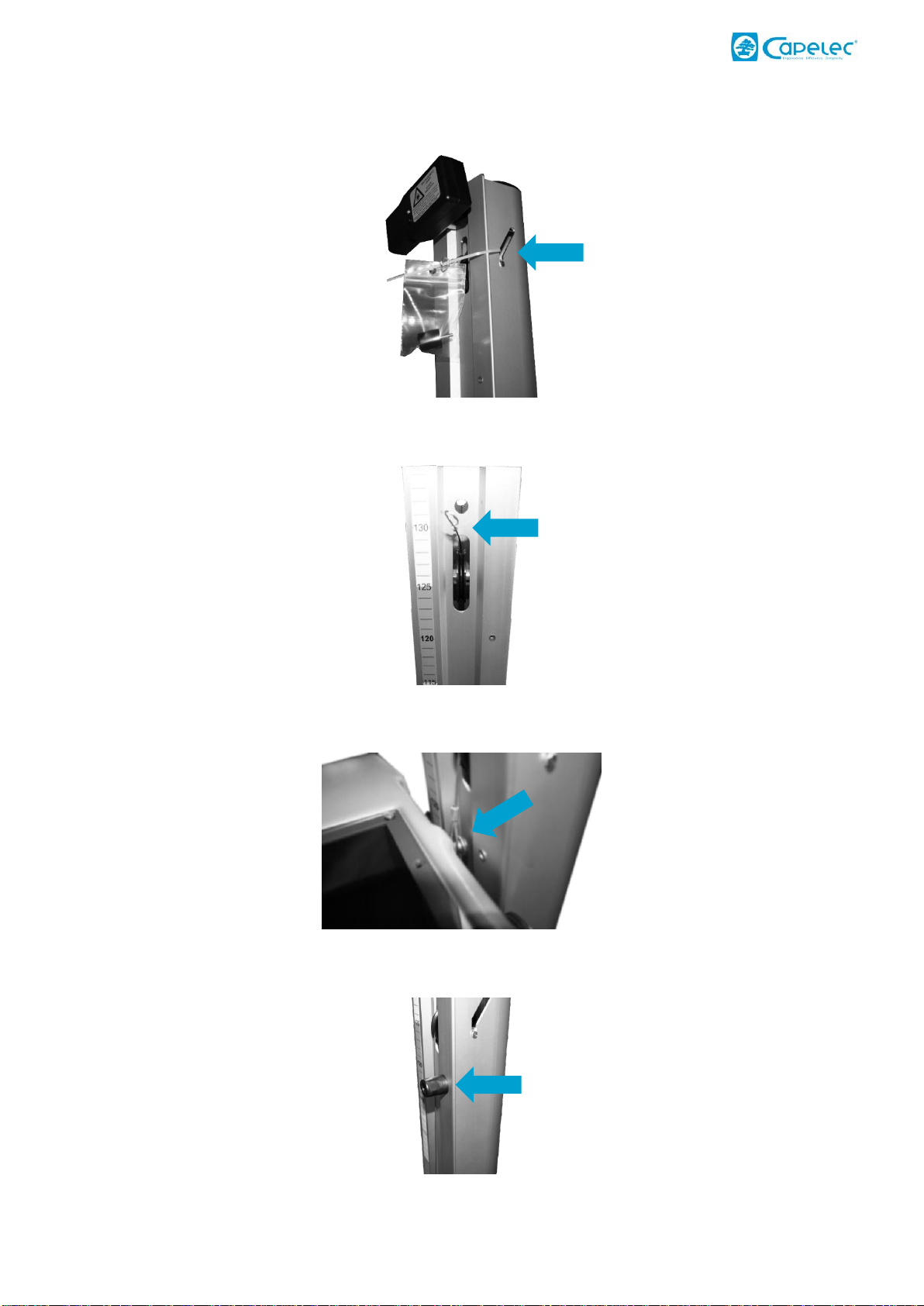

2.1 Assembly instructions......................................................................................................................3

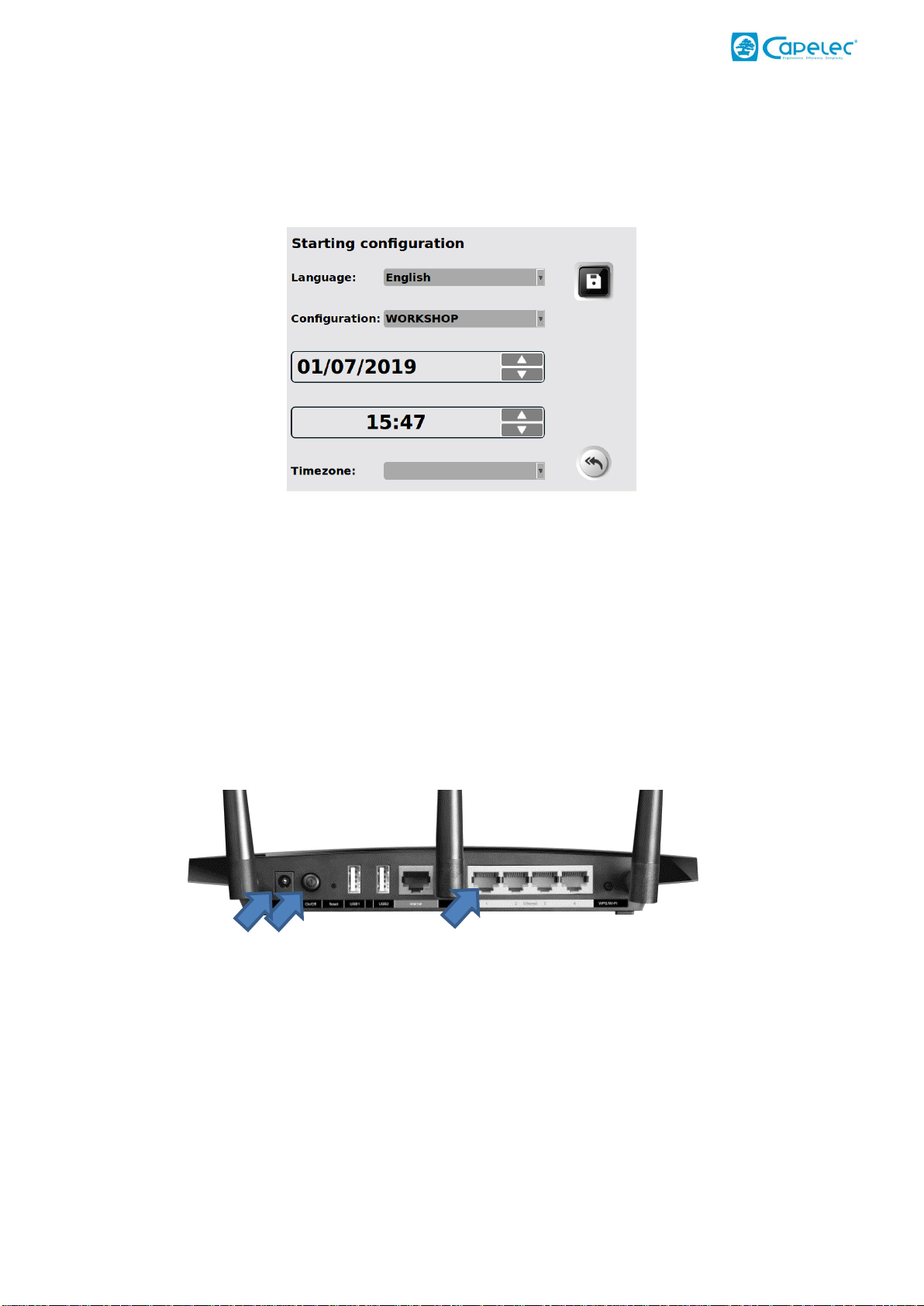

2.2 Configuration: first start up .............................................................................................................5

2.3 Computer links.................................................................................................................................5

2.4 Without a connection......................................................................................................................9

2.5 Customising and entering the garage header ...............................................................................10

Section 2: USER MANUAL ............................................................................................................................11

I. Overview...............................................................................................................................................11

II. Positioning the CAP2600 Workshop™.................................................................................................14

2.1 Vehicle preparation .......................................................................................................................14

2.2 Positioning in the vehicle length axis ............................................................................................15

2.3 Positioning the optical block in front of the headlamp.................................................................16

III. Lamp inspection..................................................................................................................................17

3.1 Inspection sequence......................................................................................................................17

3.2 Expert report..................................................................................................................................23

3.3 Advice when using the expert function.........................................................................................27

IV. Configuration......................................................................................................................................28

V. Care and maintenance recommendations..........................................................................................29