AHE00046EN 1904

5

Alfa Laval is a trademark registered and owned by Alfa Laval Corporate AB.

Alfa Laval reserves the right to change specification without prior notification.

2.3 Options

• Electric defrost (E)

For cold rooms with room temperatures below 4 °C and frost build-up is likely, the application of

a defrosting system is advised. Electric defrost for Optigo CD consists of stainless steel heater

elements mounted in both coil and driptray (CD300 driptray only). The defrost elements are con-

nected to separate terminals in the terminal box.

• Driptray insulation 12 mm + cladding (IS)

Available for CD400 only.

• Coil protection

- Pre-coated aluminium fins (EP)

- Cataphoresis treatment (CA)

• Stainless steel casing and frame (SSC)

• Re-heating coil (RH)

Available for CD300 only.

• Switch on/off (SW)

• Fan motors wired to connection box (CB)

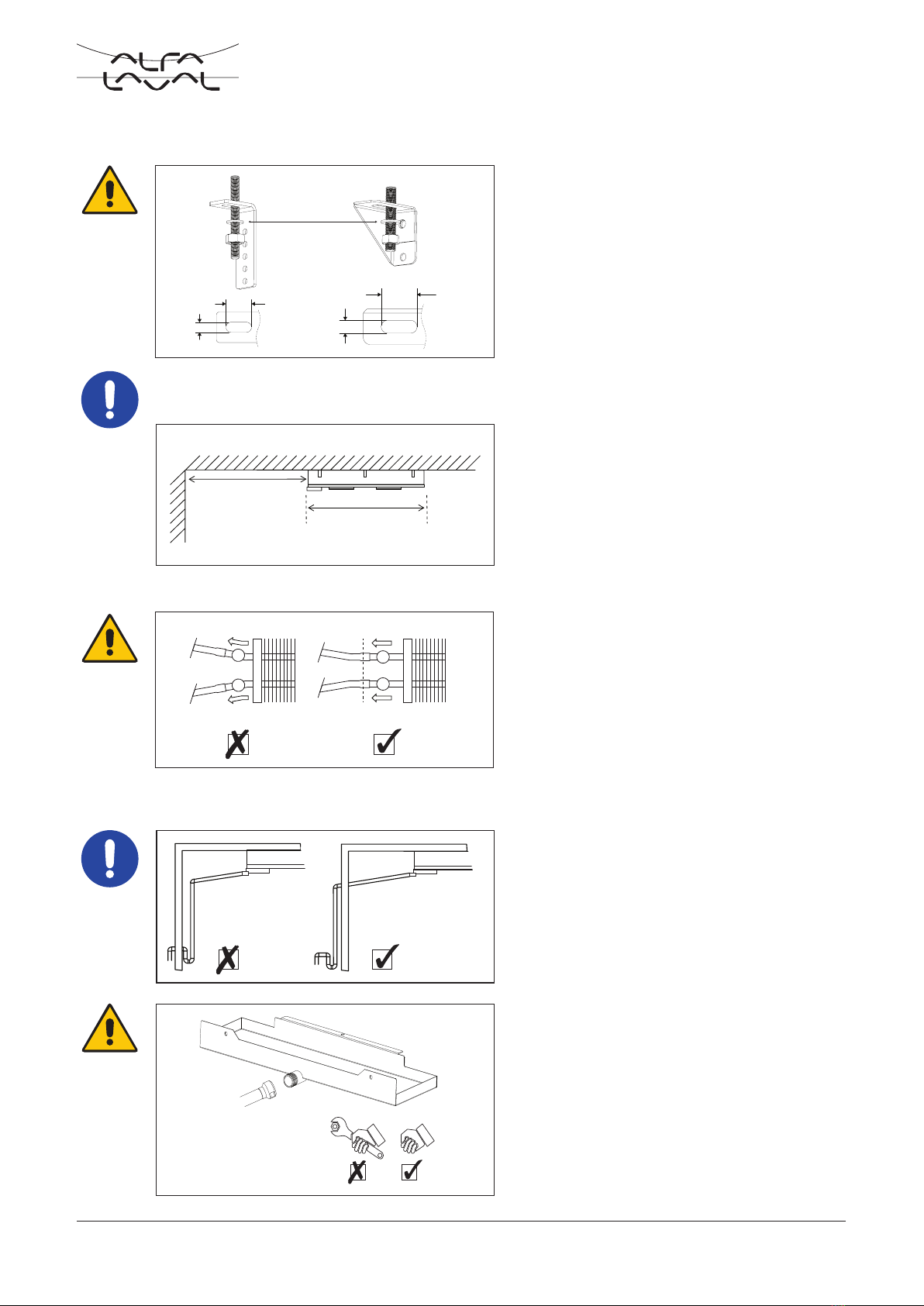

2.4 Code description

CD E H E 40 2 .2 B S 230V BOP PC E CB - AL 7.0 CU IS

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

1 Commercial air cooler - dual discharge

2 Refrigerant system (E=HFO/HFC DX, W=brine, X=CO2 DX)

3 Fan speed (H=high speed, L=low fan speed)

4 Fan motor type (blank=AC, E=EC)

5 Fan diameter (30=300, 40=400 mm)

6 Number of fans (1 to 4)

7 Tube rows code (B, C)

8 CD version

9 No. of phases (S=1, T=3)

10 Motor voltage

11 Packing (BOP=box + pallet, CR=crate)

12 Casing material (PC=epoxy coated aluminium, SS=stainless steel)

13 Defrost system (A=air defrost, E=electric defrost)

14 Connection box (blank=without connection box, CB/CBM=with connection box)

15 Fin material (AL=aluminium, EP=epoxy coated aluminium, CA=cataphoresis)

16 Fin spacing (4, 5.5, 7, 10 mm)

17 Tube material (CU=copper)

18 Options