Instruction Manual IM-TE91K010-EN4 Page 1

System with digital load cells

Version: 2012-06-12, rev.:0a

1) CONTENTS

1) CONTENTS............................................................................................................................................................1

2) General information................................................................................................................................................3

2.1 Information on the Instruction manual........................................................................................................................3

2.2 Target group..............................................................................................................................................................3

2.3 Limitation of liability....................................................................................................................................................3

2.4 Intended use..............................................................................................................................................................3

3) INTRODUCTION ....................................................................................................................................................4

3.1 Introduction................................................................................................................................................................4

4) TE67X000002010 DESCRIPTION.........................................................................................................................5

5) TE67N000002029 Description ...............................................................................................................................7

5.1 Display, lamps and keyboard.....................................................................................................................................7

5.2 Display modes ...........................................................................................................................................................8

5.2.1 LoAd mode ...........................................................................................................................................................8

5.2.2 OutPut mode ........................................................................................................................................................8

5.2.3 PASS mode..........................................................................................................................................................8

5.2.4 ZEro mode ...........................................................................................................................................................9

5.2.5 CAL.L. mode ........................................................................................................................................................9

5.2.6 CAL. mode ...........................................................................................................................................................9

5.2.7 CAL.F. mode ........................................................................................................................................................9

5.2.8 N.Lc. mode ...........................................................................................................................................................9

5.2.9 N.Crn. mode .........................................................................................................................................................9

5.2.10 Int.PEr. mode .......................................................................................................................................................9

5.2.11 Unit mode...........................................................................................................................................................10

5.2.12 dPno mode .........................................................................................................................................................10

5.2.13 div mode.............................................................................................................................................................10

5.2.14 SP. 1 and SP. 2 mode ........................................................................................................................................10

5.2.15 An.SP. mode ......................................................................................................................................................10

5.2.16 An.Err. mode ......................................................................................................................................................10

5.2.17 An.tyPE. mode ...................................................................................................................................................10

5.2.18 rS485 mode........................................................................................................................................................10

5.2.19 dAc.tSt. mode.....................................................................................................................................................10

5.2.20 LC x mode..........................................................................................................................................................11

5.2.21 Err.rEg. mode .....................................................................................................................................................11

5.3 Level alarms ............................................................................................................................................................12

5.4 Filtering....................................................................................................................................................................12

5.5 RS485 serial communication...................................................................................................................................13

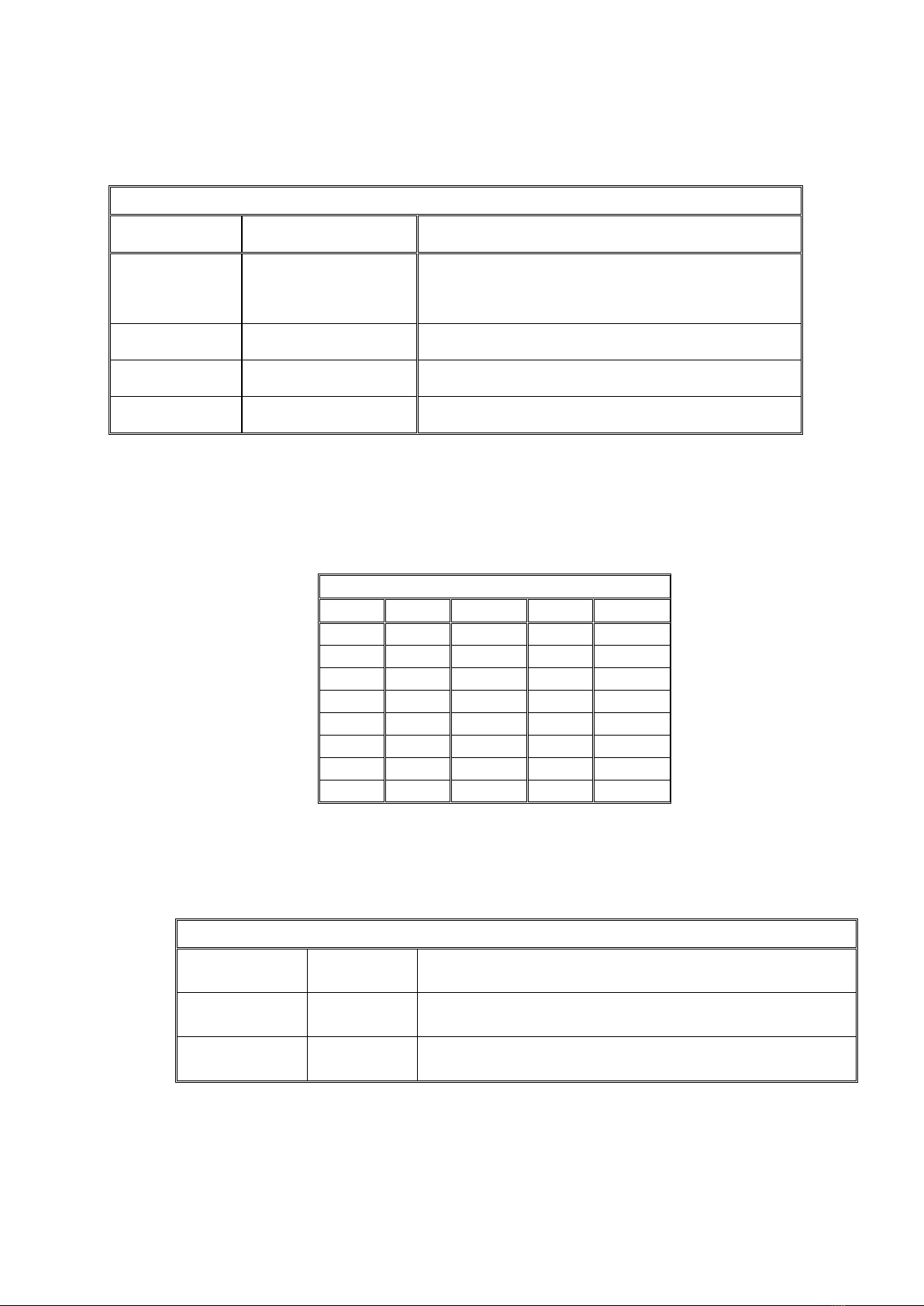

6) STATUS CODES .................................................................................................................................................14

7) ERROR CODES...................................................................................................................................................15

8) TROUBLE SHOOTING ........................................................................................................................................16

8.1 Status code indication..............................................................................................................................................16

8.2 Error code indication................................................................................................................................................16

8.3 Analog output error..................................................................................................................................................16

9) INSTALLATION OF SYSTEM ..............................................................................................................................17

9.1 Checklist during installation .....................................................................................................................................17

9.2 Calibration procedure ..............................................................................................................................................18

10) HARDWARE DESCRIPTION.............................................................................................................................19

10.1 TE67X000002029 overview...................................................................................................................................19

10.2 Connection of power and load cells.......................................................................................................................20

10.3 DIP-switch settings ................................................................................................................................................20

10.4 Light Emitting Diodes.............................................................................................................................................21

10.5 Jumpers.................................................................................................................................................................21

10.6 JTAG connector.....................................................................................................................................................22

10.7 RS485 connector...................................................................................................................................................22

10.8 Analog output connector........................................................................................................................................22

10.9 Digital output and input connector .........................................................................................................................23

10.10 Hardware Selftest ................................................................................................................................................23

10.11 Update times .......................................................................................................................................................23

10.12 Component layout................................................................................................................................................24

11) Maintenance, Service / Repair & Warranty ........................................................................................................25

11.1 Maintenance ..........................................................................................................................................................25

11.2 Service / Repair .....................................................................................................................................................25

11.2.1 Return ................................................................................................................................................................25

11.3 Warranty conditions...............................................................................................................................................25

12) How to contact Alfa Laval Tank Equipment A/S.................................................................................................26

13) EC Declaration of conformity..............................................................................................................................27