Alfalaval Alfie User manual

Other Alfalaval Other manuals

Alfalaval

Alfalaval Toftejorg SaniMicro User manual

Alfalaval

Alfalaval Toftejorg MultiJet 65 User manual

Alfalaval

Alfalaval Toftejorg MultiJet 25 User manual

Alfalaval

Alfalaval Toftejorg MultiJet 40 User manual

Alfalaval

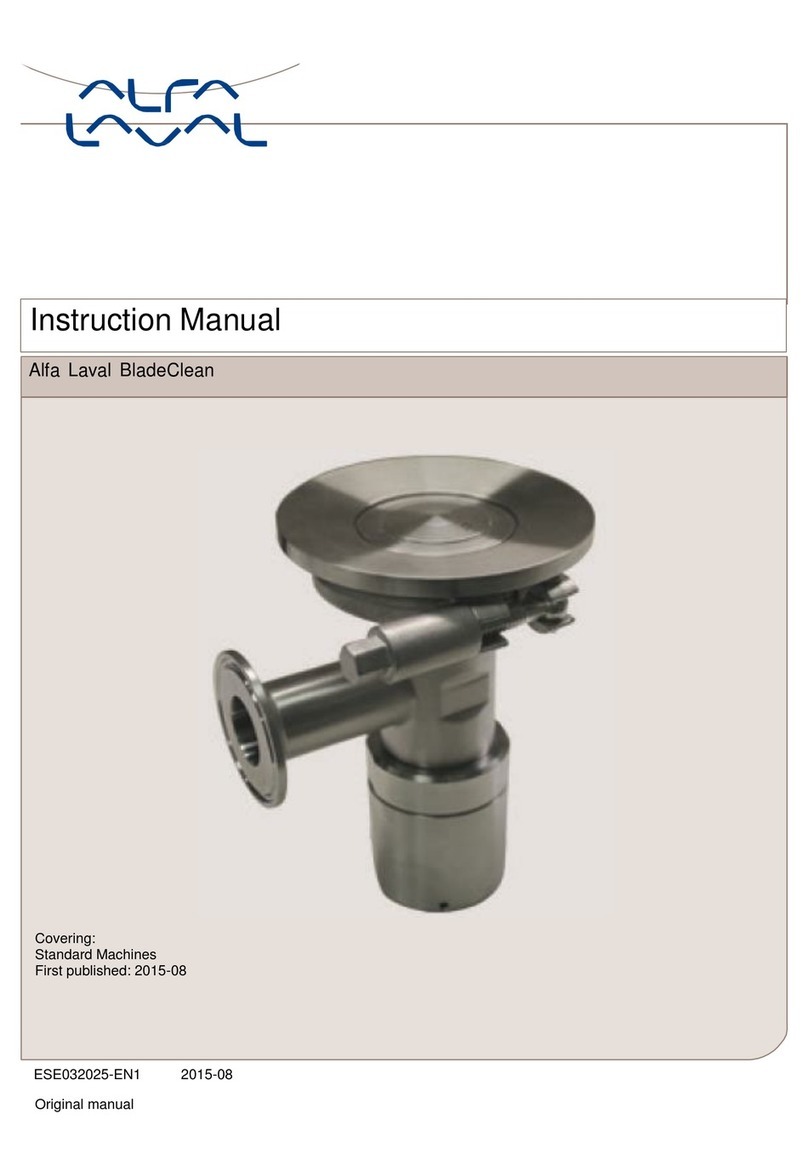

Alfalaval BladeClean User manual

Alfalaval

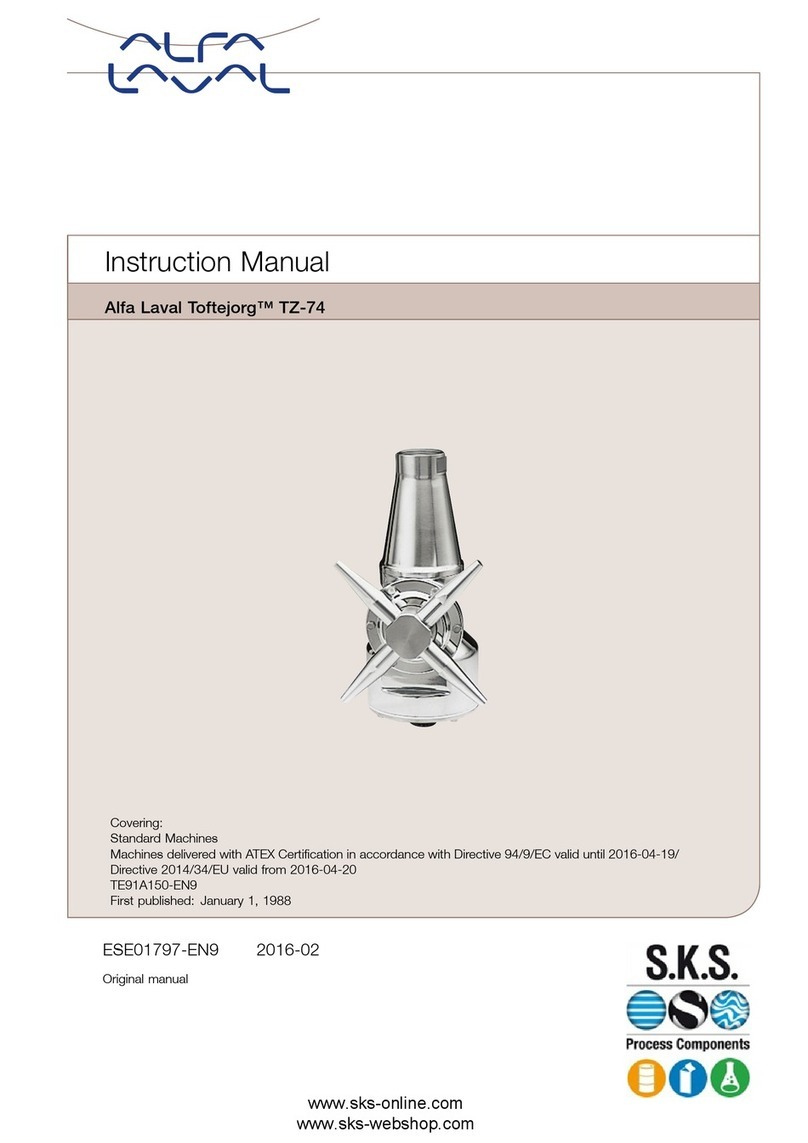

Alfalaval Toftejorg TZ-74 User manual

Alfalaval

Alfalaval Toftejorg MultiJet 40 User manual

Alfalaval

Alfalaval Toftejorg TZ-74 User manual

Alfalaval

Alfalaval Toftejorg SaniMidget SB Series User manual

Alfalaval

Alfalaval Toftejorg SaniMega User manual