appears, the machine enters the automatic protection state, you must press the

reset button or restart, if you can not measure, please long press the set button,

enter the password: up, down, press the set button Restore the factory settings

interface, choose to restore the factory settings, press the setting button to

restore (if you can not restore, please contact the manufacturer).

Nine, operating environment

1. Operating temperature: -10 ℃~40 ℃.

2. Operating humidity: ≤90% RH.

3. There is no vibration source and no corrosive environment around.

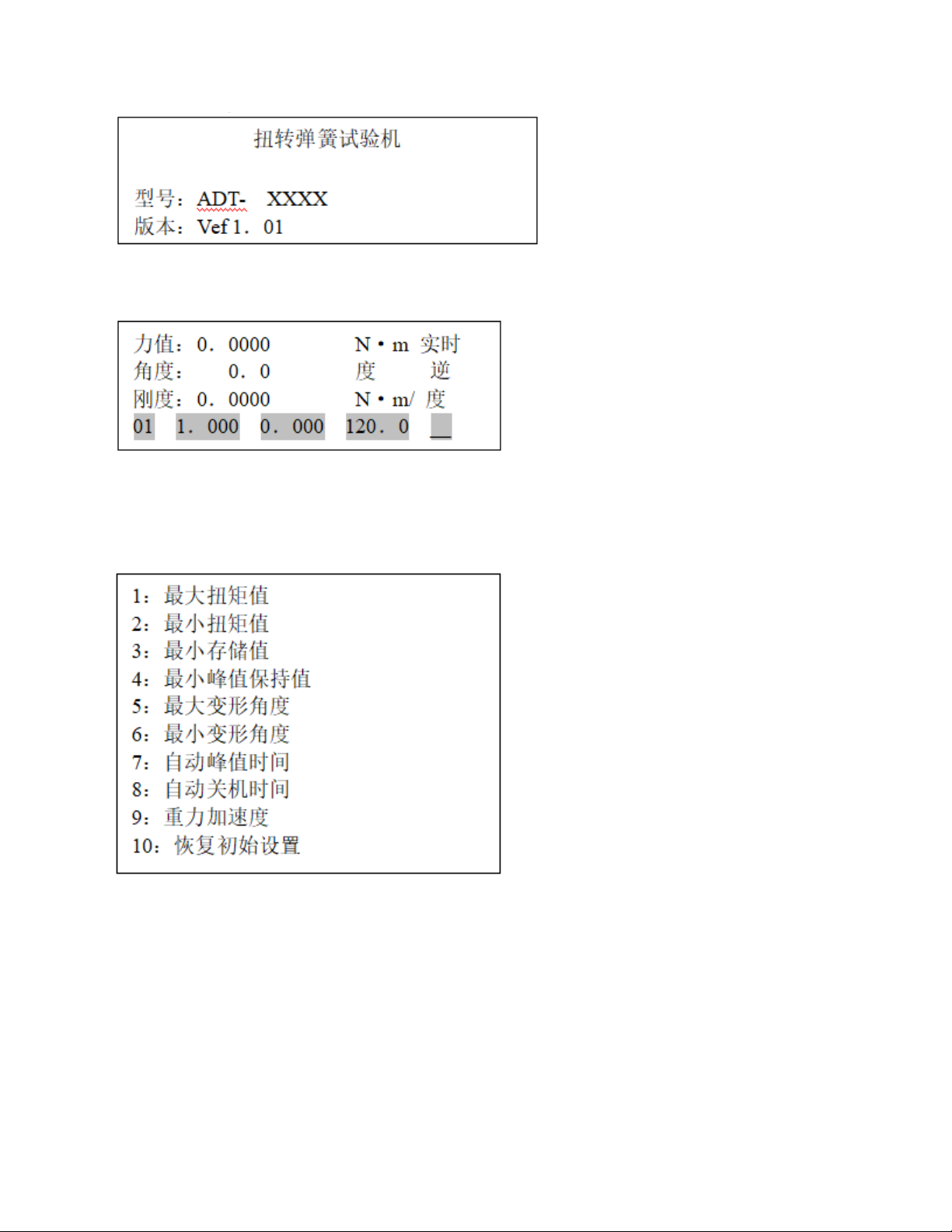

4. Minimum peak hold value setting: the user needs to set freely according to the

peak value, automatic peak measurement, data less than this value will not be

saved by the peak value.

5. Maximum deformation angle setting: The user sets the maximum value of the

angle, which can be freely set as required. When the upper limit value is

reached, the number above the parameter name \"angle maximum value \"

flashes.

6. Minimum deformation angle setting: the user sets the minimum angle, and can

freely set it as required.

7. Automatic peak time setting: the user can set the time from 1 second to 99

seconds freely according to the peak time required for automatic peak

measurement.

8. Automatic shutdown time setting: under no operation state, the automatic

shutdown time can be freely set from 1 minute to 99 minutes.

9. Gravity acceleration setting: The user can set the gravity acceleration value

according to the location of the region. The machine defaults to 9.794.

10. Restore the initial setting: improper user operation or chaos when changing

the data multiple times, you can use this setting to restore the data of 1 ~ 9 to the

factory state.

10. Operation steps