ALL-TEST PRO AT31 User manual

©2011, ALL-TEST Pro, LLC rev 2011-11F

ALL-TEST Pro, LLC

ALL-TEST PRO® 31

©2011, ALL-TEST Pro, LLC rev 2011-11F

©2011, ALL-TEST Pro, LLC rev 2011-11F

Table of Contents

I. Introduction.....................................................................................................5

II. Safety.............................................................................................................6

Instrument Warnings and Considerations .........................................................6

General Safety Considerations .........................................................................6

III. ALL-TEST PRO® 31 Kit Components.......................................................7

Instrument Operation .......................................................................................7

Input Section................................................................................................7

Display Section............................................................................................8

Indicator Light Section.................................................................................8

Display Screen.............................................................................................8

Keypad Section............................................................................................9

Instrument Test Leads................................................................................10

IV. Testing a Three Phase Induction Squirrel Cage Motor..........................11

Operating Procedure 3-Phase Motors.............................................................11

Winding Test .................................................................................................11

Turn the Instrument On..............................................................................12

Select the Motor Test .................................................................................12

Observe/Record the Test Data....................................................................12

ERROR CODES........................................................................................13

Continue with Other Phases .......................................................................14

Continue with Last Phase ...........................................................................15

Phase Balance Test ........................................................................................17

Insulation Resistance Testing.........................................................................20

Rotor Test......................................................................................................22

Bar Test .....................................................................................................22

Wave Form Test.........................................................................................23

Changing the Motor Test Frequency ..............................................................24

V. Additional Functions and Features...........................................................26

Electro-Magnetic Interference (EMI): ............................................................26

Resetting the Unit ..........................................................................................27

VI. Charging Your ALL-TEST PRO® 31.......................................................28

VII. Data Interpretation Three Phase Motors................................................29

Data Interpretation Tables..............................................................................29

Additional Data Interpretation Considerations Three Phase Motors............30

Test Location .............................................................................................30

Rotor Windings..........................................................................................30

Confirming Suspected Winding Shorts.......................................................30

Method 1: Rotor Compensation..................................................................31

Method 2: Variable Frequency Test............................................................31

VIII. DC Motor Testing....................................................................................32

Testing an Assembled DC Motor ...............................................................33

Series DC motor.........................................................................................33

Compound or Shunt DC motor...................................................................33

©2011, ALL-TEST Pro, LLC rev 2011-11F

Testing Shunt Field ....................................................................................33

Armature Testing .......................................................................................33

DC Motor Analysis........................................................................................34

IX. Additional Test Methods...........................................................................35

Wound Rotor Motors.....................................................................................35

Wye-Delta Motors .........................................................................................35

Capacitor Testing...........................................................................................36

X. Tech Support and Information...................................................................37

XI. Available Accessories for the ALL-TEST PRO® 31...............................37

XII. Training Class...........................................................................................37

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F5

I. Introduction

The light-weight, hand-held instrument can be used for immediate detection of winding shorts,

insulation to ground faults, cable faults and more on AC/DC electric motors, transformers, coils,

machine tool equipment, linear motors and much more. Testing can be performed at the motor

connection box, the disconnect, or motor control center hundreds of feet away.

The ALL-TEST PRO® 31 (AT31) is designed to provide a simple test method for:

·troubleshooting faults

·commissioning new and rebuilt machines

·verifying quality assurance in electric motors and other wound equipment.

The patented tests performed for early winding fault detection:

·winding impedance test

·phase angle

·I/F current frequency response tests

·EMI (Electro-Magnetic Interference) test for detection of low-level EMI currents that can

affect readings and may be the result of other faults within the motor circuit

Note: The ALL-TEST PRO® 31 provides real time measurements of the on-going test. When

combined with the ALL-TEST IV PRO™provides the most comprehensive off-line motor analysis

system available at any price.

Insulation Resistance to ground: To prevent electrical shocks and to assure safety of personnel the AT31

provides an insulation to ground test. The insulation resistance test provides either 500 or 1,000 VDC, to

measure the insulation resistance up to 500 Meg-Ohm.

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F6

II. Safety

CAUTION: The AT31 is designed to test de-energized equipment safely and quickly.

Improper application of the AT31 on live circuits is a danger to the user and will result in

the destruction of the testing circuit, requiring instrument replacement.

Instrument Warnings and Considerations

The ALL-TEST PRO® 31 is a CE registered instrument.

The following is a list of considerations for equipment life and accurate data collection:

Ensure that all power has been removed from the circuit being tested, including static power

stored in capacitors –Discharge all capacitors being tested.

Attaching the AT31 to live voltage will destroy the unit and void the warranty.

Do not attempt to change the batteries. Contact your distributor of the AT31, ALL-TEST Pro. LLC

at 860-399-4222 or via email, support@alltestpro.com, to have the battery pack replaced.

Do not open the instrument. Electrostatic charges may damage surface mount electronics. Please

contact your vendor or ALL-TEST Pro authorized repair center.

Use only the supplied charger for charging the instrument. It is an integral part of the charging

circuit. Using the wrong charger will damage your instrument.

General Safety Considerations

Following are general safety considerations for using the AT31 motor tester:

The AT31 is an off-line motor tester. All power and residual power must be disconnected. It

provides a safe method of testing your electric motors.

Follow all safety rules of your company and OSHA (or country equivalent) for off-line testing

methods, including appropriate Personal Protective Equipment (PPE). Improper or unsafe operation of

the equipment is the sole responsibility of the user.

For MCA testing, the AT31 sends out a low voltage, high frequency signal not harmful to the

technician or most electronic equipment (variable frequency drives and soft starts). However, electronic

equipment and personnel must observe appropriate safety considerations (disconnect electronic

equipment) when performing the insulation to Ground resistance test (Meg-Ohm) test.

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F7

III. ALL-TEST PRO® 31 Kit Components

Figure 1: AT 31 Kit

The AT31 Kit contains all of the necessary components necessary to test most electrical machinery:

A. ALL-TEST PRO® 31 instrument

B. Batteries (installed)

C. Test leads and clips

D. Charger (115 or 230 Volt)

E. Manual on CD Rom

F. Carrying Pouch

G. Reset Key (Only sent with units before Serial number 2029)

Instrument Operation

The instrument is divided up into three working areas:

1. Input Section

2. Display Area

3. Keypad

Input Section

The input section provides all the external connections to the ALL-TEST PRO® 31

A. Test lead port

B. Charger port

C. Ground test lead port for Insulation to Ground

Measurements

D. Reset Button (Serial number 2029 and higher)

AB C

D

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F8

Display Section

The display section is divided into 2 sections:

1. Indicator Lights

2. Display Screen

The Indicator Lights (section 1) informs the operator when an operation or test is being performed.

The Display screen (section 2) allows the operator to select tests to be performed by the AT31.

Indicator Light Section

1. Charging light –Indicates that the unit is charging, light is illuminated red while charging, light

is green when fully charged.

2. Test indicator light –Light is illuminated green when the unit is testing

3. Insulation Test indicator light –The light illuminates yellow when the instrument is testing

insulation resistance. Caution –Applied voltage is 500 or 1,000 Volts DC.

Display Screen

The display screen has individual icons to select and perform the various motor and winding tests.

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F9

1. Z/ψIcon performs the Impedance (Z), Phase Angle (ψ), Current/Frequency (I/F) and Phase

Balance tests (used to identify developing winding faults).

2. ROT Icon performs the Rotor test (used to find squirrel cage induction motor rotor faults).

3. INS Icon performs the Insulation to ground resistance test (used to verify that the insulation to

ground resistance is sufficient to prevent electrical shock).

4. Battery charge level indicator. A fully charged battery will have 7 bars (it is recommended to

keep the AT31 on charge when not in use to ensure proper operation).

5. PWR OFF Icon turns the instrument off (the AT31 will automatically shut-off after about 5

minutes).

6. EMI Icon tests for EMI signals within the Motor System that could cause errors in the AT31 test

results.

Keypad Section

The keypad section provides keys to operate and control the functions of the AT31.

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F10

1. Up direction and MODE key returns the AT31 display screen to the main menu.

2. F1/ON and Left direction key turns the AT31 on and moves the curser across the display screen

toward the left.

3. ZERO /OK (Selection) key selects which test to perform and provides reference selection to

calculate % difference of the measured impedance value.

4. Down direction and TEST key toggles between display screens and performs selected tests.

5. Right direction and F2/Hz key allows the operator to change the test frequency for the winding

test and moves the cursor across the display screen to the right.

Instrument Test Leads

The ALL-TEST PRO® 31 uses a 15 pin DB connector for winding testing. The red test lead is the

output and the black test lead, is the return. For insulation testing, the yellow test lead should be

connected to ground.

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F11

IV. Testing a Three Phase Induction Squirrel Cage Motor

Testing can be performed remotely from the motor control center, the motor disconnect or at the motor

itself. This instruction is provided to demonstrate all of the features of the ALL-TEST PRO® 31, which

can also be used to evaluate other types of electric machines.

Note: The M2000 demo motor is used in this manual for procedural purposes only, it is not designed to

simulate faults or test other features of the ALL-TEST PRO® 31

Materials for Testing with the ALL-TEST PRO® 31Figure 2: Equipment and Materials

To perform a motor test with the ALL-TEST PRO® 31 requires:

·ALL-TEST PRO® 31

·Test leads and lead clips

·A pen and paper (or a copy of the Motor Test Form on page 38).

Testing can be performed directly at the motor, at the nearest motor control center or disconnect. For

purposes of this manual, we will test at the motor using an M2000 training motor, this is for procedure

only (the M2000 is not designed to simulate faults with the AT31).

Operating Procedure 3-Phase Motors

Winding Test

Measures and displays the winding impedance (Z), Phase Angle (ψ), Current Frequency response (I/F)

and Impedance phase balance.

1. Label the three motor leads T1, T2, T3.

Note: It is very important to take the data in the same order

for long term trending.

2. Connect the Test leads to the Motor leads T1 & T2.

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F12

Note: For quick trouble shooting the order of the readings is not important. However, for long

term trending of the data, testing should be performed in the same order each time.

Optional: Connect the Yellow lead to ground, this is only required for measuring insulation to ground.

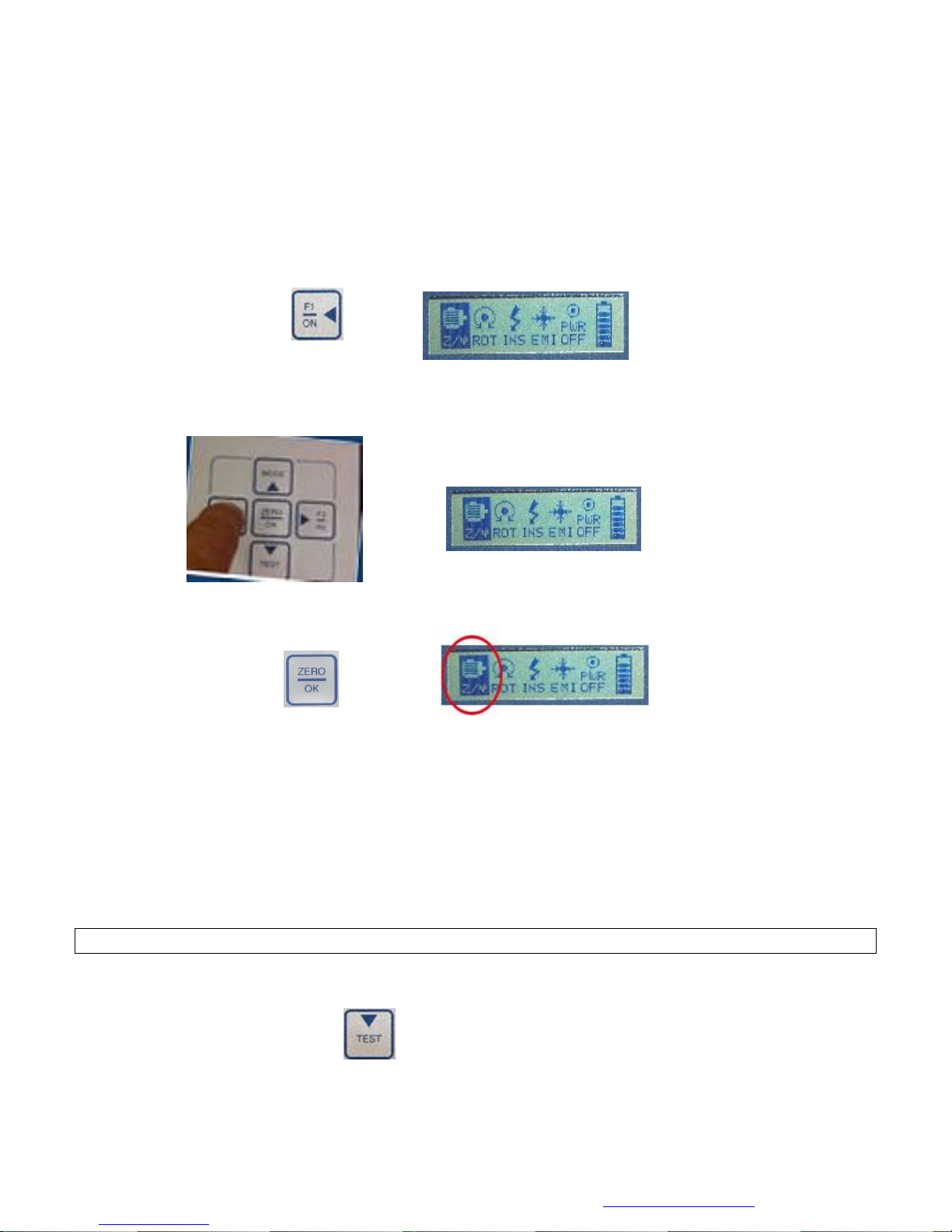

Turn the Instrument On

Press and hold the F1/ON key for 1 to 3 seconds. This will bring up the main display screen.

Select the Motor Test

1. Using the ◄F1 and ►F2, keys highlight the Winding Test icon

2. Press the ZERO/OK Key to select the Winding Test icon (Z/ψ)from the main menu.

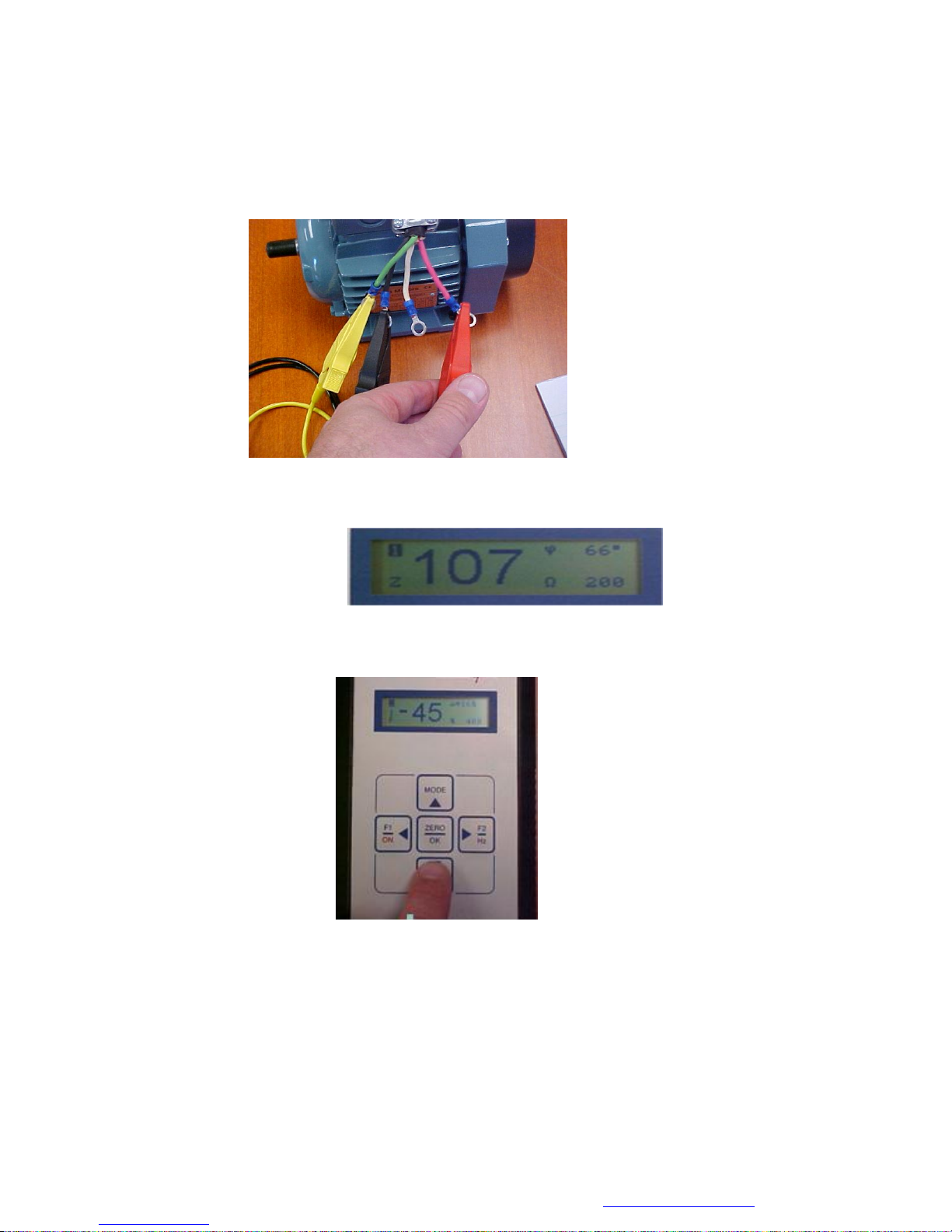

Observe/Record the Test Data

1. The default value is 200 Hz, as displayed in the bottom right corner of the display screen.

a. The value of the impedance should be between 1 and 999 Ω. If the Z is less than 1 or

greater than 999 Ωchange the test frequency of the winding test (see Changing the

Motor Test Frequency on page 24).

b. The current frequency response value (I/F) must be between -15 and -50, if it is not

change the frequency of the winding test.

c. If the phase angle (Fi) is less than 15°, change the winding test frequency.

Note: If any of the measurements fall outside the above ranges, the test is not valid.

2. Display screen 2 displays the results of the current frequency test. To view display screen 2

Press the TEST key.

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F13

Display Screen 1

Display screen 1: Displays the measured impedance in ohms 107, phase angle in degrees 66°, and the

frequency of the winding test, 200 Hz. The screen number (1) is displayed in the upper left hand corner.

Display Screen 2: Displays the results of the Current Frequency (I/F) response test (-45), (the current at

400 Hz is 45% lower than the current at 200 Hz). The doubled test frequency is displayed in the lower

right hand corner; screen number (2) is displayed in the upper left hand corner. Note: The 16% shown

in upper right corner is the change in phase angle when the test frequency is doubled. Not used for

analysis purposes.

1. To return to the Display Screen 1 Press the TEST key again, this displays the impedance and

phase angle measurement.

2. Record the measured values on the Motor Test Form.

ERROR CODES

If the impedance readings are out of range an error code will be displayed on the measurement screen.

·E1 error code means the impedance value is greater than 1000 ohms.

·E2 error code means the impedance value is greater than 10,000 ohms.

ALL

-

TEST

Pro®

31 Motor Test

Form

Motor ID:

Location:

Test Date:

Test Frequency

Phase

1-2 Phase

1-3 Phase

2-3

Impedance

(Z) 107

Phase

Angle (°) 66

Z-Test or

I/F -45

Display Screen 2

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F14

Continue with Other Phases

1. Move the test leads to T1 & T3 to make the measurements on the next phase.

2. Read the Impedance (Z) and Phase Angle (ψ) values from display screen 1 for winding. Do not

fill in the phase balance until all three phases have been measured.

3. Depress the TEST key to display the Current Frequency Response (I/F).

Winding 2 Current

Frequency Response

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F15

4. Record these test results on the Motor Test Form.

Continue with Last Phase

1. Move the Test Leads to T2 & T3

ALL-TEST Pro® 31 Motor Test Form

Motor ID:

Location:

Test Date:

Test Frequency

Phase

1-2 Phase

1-3 Phase

2-3

Impedance (Z) 107 107

Phase Angle (°) 66 66

Z-Test or I/F -45 -45

Phase balance (opt)

Ins Resistance Test

Voltage

Was rotor set to lowest value during phase balance test? Y__ N__

Rotor test performed? Y___ N___

Comments:

© ALL-TEST PRO

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F16

2. Read the Impedance (Z) and Phase Angle (ψ) values from display screen 1 for winding. Do

not fill in the phase balance until all three phases have been measured.

3. Press the TEST key to display the Current Frequency Response (I/F).

4. Record these test results on the Motor Test Form.

ALL-TEST Pro 31 Motor Test Form

Motor ID: Test Motor

Location: Warehouse

Test Date: 8/8/06

Test Frequency 200 Hz

Phase

1-2 Phase

1-3 Phase

2-3

Impedance (Z) 107 107 109

Phase Angle (°) 66 66 66

Z-Test or I/F -45 -45 -45

Phase balance (opt)

Ins Resistance Test

Voltage

Was rotor set to lowest value during phase balance test? Y__ N__

Rotor test performed? Y___ N___

Comments:

© ALL-TEST PRO

Winding 3 Current Frequency

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F17

Phase Balance Test

This calculates the impedance unbalance between phases. This value can be used to relate energy,

reliability and production-cost avoidance potential to electric motor systems impedance unbalance. The

Impedance Unbalance Calculator (IUC) is available from ALL-TEST Pro. The concept of the IUC

comes from Keeping the Spark in Your Electrical System: An Industrial Electrical Distribution

Maintenance Guidebook published by the US Department of Energy, Bonneville Power Administration,

Pacific Gas & Electric, PacifiCorp and Tacoma Public Utilities. As impedance varies with each phase,

the current in each leg of the motor varies. This generates increased losses in the form of heat. Heat

reduces both insulation life and the life of the lubricant.

(The Impedance Unbalance Calculator is available from ALL-TEST Pro).

1. Place the Test leads on any 2 motor leads, for discussion purposes use T1 & T3.

2. Press the ZERO key to set the reference phase to zero. This establishes (T1-T3) as the reference

phase.

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F18

3. Turn the motor shaft until the highest impedance value is obtained.

4. Press the ZERO key again. This sets the reference phase (T1-T3) to “0”. Enter 0 on the Motor

Test Form

5. Move the Test leads to T2 & T3. This determines the Impedance Phase Balance or Unbalance

Referenced to (T1-T3).

6. Turn the shaft slowly until the lowest percentage value is obtained. (The percentage should be

less than 3% of phase unbalance. A percentage > 5% indicates a fault in the winding and

should be investigated further).

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F19

7. Record this value on the Motor Test Form for Phase 2-3. In this case the value is “0”.

8. Move the test leads to T1 & T2, this checks the Impedance Balance/Unbalance of Phase of the

final phase winding T1-T2 to T1-T3.

9. Turn the shaft slowly until the lowest percentage value is

obtained.

10. Record this value on the Motor Test Form for Phase 1-2. In this case the value is “2”which is

acceptable. Refer to the “Data Interpretation”Section of this manual for Acceptance criteria.

ALL-TEST PRO®31 User Manual

©2011, ALL-TEST Pro, LLC www.alltestpro.com rev 2011-11F20

Insulation Resistance Testing

To prevent electrical shocks and to assure safety of personnel the AT31 provides an insulation to ground

test. The insulation resistance test provides either 500 or 1,000 VDC, to measure the insulation resistance

up to 500 Meg-Ohm.

NOTE: The following tables provide the recommended voltages and Minimum Insulation Resistance to

Ground values. If these values differ from your equipment manufacturers, follow their guidelines.

Insulation Resistance Test Voltage

Insulation Resistance Values (IEEE 43-2000)

1. Using the ON key or the MODE key from the keypad section to navigate to the display screen

(This is the main menu).

2. Use the ◄►to highlight the INS icon from the display screen. This

sets the ALL-TEST PRO® 31 up to measure insulation resistance to

ground.

3. Connect both the Red lead & the Yellow lead to ground.

4. Press the ZERO/OK key to select the Insulation Resistance Test. This displays screen 8, the

insulation resistance test screen.

5. View the insulation test voltage selected (upper right hand corner of the insulation resistance

display screen). Refer to the insulation resistance test voltage table above for the correct voltage.

Motor Voltage Rating

Insulation Test Voltage

<

1000

Volts AC

500 V

100

0 to

25

00 Volts AC

1000 V

2501 to 5000 Volts AC

1000

–

2500 V

Application

Pass/Fail

Value

Insulation systems prior to 197

0

> 1 Meg

-

O

hm + 1 Meg

-

Ohm per kV rating of motor

Random Wound motors less than 600 V

> 5 Meg

-

Ohms

DC Armatures and Form Wound motors over 600 V

> 100 Meg

-

Ohms

Table of contents

Other ALL-TEST PRO Measuring Instrument manuals