EP-KE-77-0019E

http://www.autonics.com

Satisable Partner For Factory Automation

HEAD QUARTERS :

116, Ungbigongdan-gil, Yangsan-si, Gyeongsangnam-do, Korea

OVERSEAS SALES :

#402-404, Bucheon Techno Park, 655, Pyeongcheon-ro,

Wonmi-gu, Bucheon, Gyeonggi-do, Korea

TEL:82-32-610-2730 / FAX:82-32-329-0728

E-mail : sales@autonics.com

The proposal of a product improvement

and development : product@autonics.com

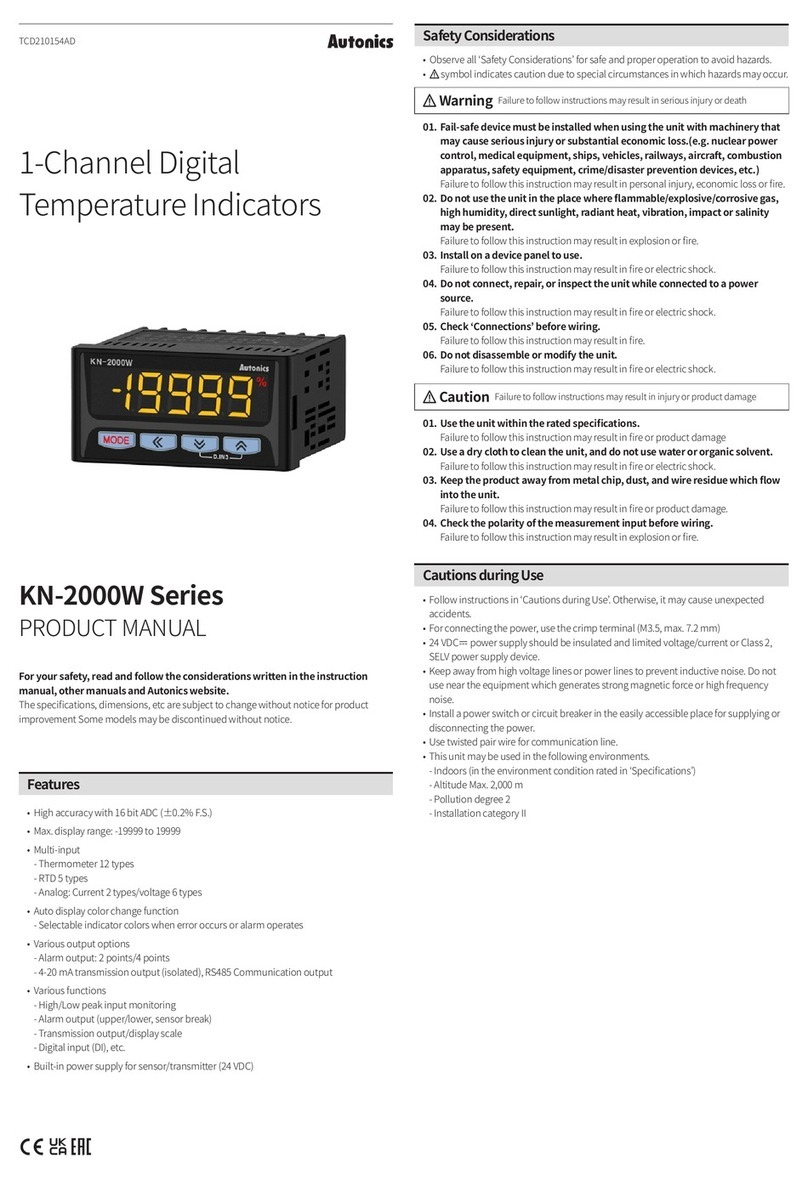

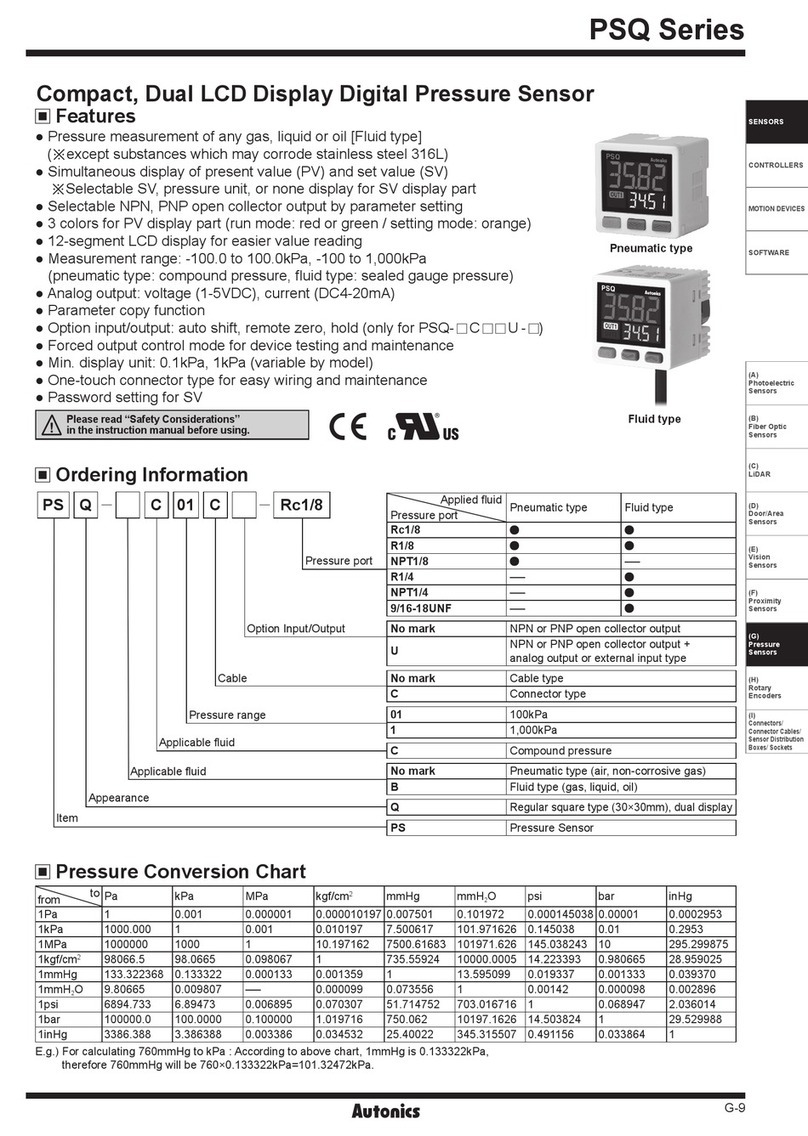

DIGITAL PRESSURE SENSOR(Fluid type)

PSAN SERIES

※Please keep these instructions and review them before using this unit.

※Please observe the cautions that follow;

Caution for your safety

※

The following is an explanation of the symbols used in the operation manual.

Caution: Injury or danger may occur under special conditions.

1. This unit shall not be usde outdoors.

It might shorten the life cycle of the product or give an electric shock. This unit is proper indoor environmnet.

2. Do not apply the pressure beyond rated pressure.

It may cause damage to this unit.

3. Do not use it beyond power supply.

It may cause damage to this unit.

4. Do not make a short circuit for the load.

It may cause damage to this unit.

5. Do not wire incorrectly in power polarity etc.

It may cause damage to this unit.

6. Do not use corrosive gas or liquid as it is only for non-corrosive gas.

It may cause damage to this unit.

7. Do not give power to its case or twist its case strongly.

It may cause damage to this unit.

Warning

Caution

Output operation mode

Parameter setting

Preset Setting

Input/Output circuit and diagram

Installation

Part descriptions

Error

Functions

M A N U A L

Thank you very much for selecting Autonics products.

For your safety, please read the following before using.

Warning

Serious injury may result if instructions are not followed.

Caution

Product may be damaged, or injury may result if instructions are not followed.

Specications Setting

Caution for using

Major products

1. In case of using this unit with machinery(Ex: nuclear power control, medical equpment, ship, vehicle,

train, airplane, combustion apparatus, safety device, crime/disaster prevention equipment, etc) which

may cause damages to human life or property, it is required to install fail-safe device.

It may cause a fire, human injury or damage to property.

2. Do not use it in flammable gas because it does not have an explosion proof construction.

It may cause explosion.

※A: PT1/8" model(Standard): 8, NPT1/8" model: 8, 7/16"-20 UNF model: 11

※1: Only for PT1/8" model, NPT1/8" model

1. Do not insert any sharp or pointed object into pressure port.

It may cause malfunction and damage the sensor.

2. Be sure that this unit must avoid direct touch with water, oil, thinner etc.

3. It is ready to operate 3 sec. after it is turned ON. Be sure not to use the product within 3 sec.

4. When using switching mode power supply, frame ground (F.G.) terminal of power supply

should be grounded.

5. To avoid inductive noise, keep the wiring away from power line, high voltage line.

It may cause malfunction.

6. When moving this unit from warm place to cold place, please remove the humidity on the

cover then use it.

7. Do not press the setting button with sharp or pointed object.

8. Do not apply a tensile strength in excess of 30N to the cables or connector.

9. When using mmH2O unit, please multiply display value by 100.

10.Installation environment

① It shall be used indoor. ② Altitude Max. 2,000m

③ Pollution Degree 2 ④ Installation Category II

Hysteresis mode[ HYS.M]

It is able to set certain value for pressure detection

level(ST1, ST2) and hysteresis(HYS1, HYS2).

Hysteresis mode

Window comparison output mode

Hysteresis-Window comparison output mode

Zero point adjustment

1.Please press + keys for over 1sec. at the same time

putting an applied pressure in state of the atmospheric

pressure.

2.When the zero point adjustment is completed, it will

display

)0

and return to RUN mode automatically.

※If executing zero point adjustment on external pressure

being at pressure port

ERR1

flashes 5times. Please

execute it in the atmospheric pressure after removing

external pressure.

※Please execute zero point adjustment regularly.

※1: PSAN-L H - Displayed only when D-IN is set

to SHFT. Auto shift reference pressure can be set within

display error range.(Low_Range ≤ SH.IN ≤ High_Range)

• Low_Range = Min.display pressure - Min. preset setting value

• High_Range = Max.display pressure - Max. preset setting value

※If pressing + keys for over 1sec. in case of High peak

/ Low peak/ Auto shift reference pressure value, setting value

will be erase and return to next operation.

※ [ RUN] flashes twice, then return to RUN mode.

Peak Hold / Auto Shift Check/Change

Hysteresis-window comparison output mode[ HY-W]

①It is available to set hysteresis mode(ST1, HYS1)

and window comparison output mode when both

hysteresis mode and window comparison output

mode(LOW, HIGH) are necessary.

②Detection hysteresis is fixed to min. display range.

Forced output control mode[ fOUT]

①Used to display pressure with forcibly holding comparing output OFF regardless of setting value.

②In parameter setting, if output operation mode setting OUtN is changed to fOUT, forced output control mode is operated.

③OUT1, 2 can be ON/OFF manually by pressing , key While the forced output control mode is applied.

Analog output type (Voltage output PSAN-L□□□□V-□, Current output PSAN-L□□□□A-□)

Hold / Auto Shift input type (PSAN-L□□□□H-□)

● NPN open collector output type

● NPN open collector output type

1.Pressure port is divided as basic and option specification.

Therefore, be sure that to use commercially available one touch

fitting. (Standard: R(PT)1/8", Option: NPT1/8", 7/16" - 20 UNF)

2.Please connect it by using spanner(17mm) at the metal part in

order not to overload on the body when connecting one touch

fitting.

3.Two different fixing brackets are provided for PSAN model.

Select proper one with considering your application environments.

4.At first, please unscrew hexagon wrench bolt and assemble

the bracket on this unit by fixing hexagon the wrenchbolt. In

this case, tightening torque of hexagon wrench should be max.

30kgf.cm. It may cause mechanical problems.

5.Bracket(PSO-B02) and front protection cover(PSO-P01)

are optional to sell.

Please see the figure for installation.

● PNP open collector output type

● PNP open collector output type

Window comparison output mode[ WIN]

①It is able to set the range for high(HI-1, HI-2)/

low(LO-1, LO-2)limit of pressure detection level when

it is required to detect pressure at a certain range.

②Detection hysteresis is fixed to min. display range.

Automatic sensitivity setting mode

Automatic sensitivity setting mode[ AUTO]

①This function is to set pressure detection level to the

proper position automatically. It is set by applied

pressure from two positions(ST1, ST2).

②Detection hysteresis is fixed to min. display range.

③The pressure detection level(SET) is shown in the

following calculation.

●Bracket A

●Option

●Accessory

. Pressure unit label

●Mounting bracket

Pressure unit change Function

PSAN-LV01C(P) and PSAN-LC01C(P) has 7 kinds of pressure unit, PSAN-L01C(P) and PSAN-L1C(P) has 5 kinds

of pressure unit. Please select the proper unit for application.

• PSAN-LV01C(P), PSAN-LC01C(P) : kPa, kgf/cm2, bar, psi, mmHg, inHg, mmH2O

• PSAN-L01C(P), PSAN-L1C(P) : MPa, kPa, kgf/cm2, bar, psi

※ When using mmH2O unit, please multiply display value by 100.

Output mode change Function

There are 5 kinds of control output mode in order to realize the various pressure detection.

• Hysteresis mode [ HYsM] : When needed to change hysteresis for detecting pressure.

• Window comparison output mode [ WIN] : When needed to detect pressure in certain area.

• Hysteresis - Window comparison output mode [ HY-W] : When both hysteresis mode and window comparison output

mode are required.

• Automatic sensitivity setting mode [ AUTO] : When needed to set detection sensitivity automatically at proper position.

• Forced output control mode [ fOUT] : When needed to display pressure with remaining comparison output OFF regardless

of setting value.

Control output change function

Type of control output for Out1 and Out2 can be able to set Normally Open and Normally Closed.

※ Note that Normally Open and Normally Closed provide opposite output.

Response time change function(Chattering prevention)

It can prevent chattering of control output by changing response time.

It is able to set 5kinds of response time(2.5ms, 5ms, 100ms, 500ms, 1000ms) and if the response time is getting

longer, the detection will be more stable by increasing the number of digital filter.

Analog output scale setting and Hold/Auto Shift setting function

• Analog voltage output scale setting: The scale function for analog output voltage (1-5VDC) is not fixed to the rated

pressure range. It can be changed for User's application. Analog output is 1-5VDC within the pressure range from

the pressure point(A-1V) for 1VDC to the pressure point (A-5V) for 5VDC.

• Analog current output scale setting: The scale for analog output Current (DC4-20mA) is not fixed to the rated pressure

range. It can be changed for User's application. Analog output is 4-20mA within the pressure range from the pressure

point (A-04) for 4mA to the pressure point (A-20) for 20mA.

• Hold/Auto Shift input setting

- Hold function: A function to hold PV and Control output while signal is input.

- Auto Shift function: A function to compensate the setting value for changed value of reference pressure as threshold

level if reference pressure of the device changes.

Key lock function

The key lock function prevents key operations so that conditions set in each mode. [preset/parameter mode are not

inadvertently changed. There are 2 kinds of key lock functions available.

• LOC1: All keys are locked; therefore it is not available to change parameter settings, preset value, zero adjustment,

High/Low peak check and SH.IN data initialization. (Lock setting change is available)

• LOC2: Partially locked status; therefore it is not available to change parameter settings only(Lock setting change is

available). Other settings are still available.

• OFF: All of the setting is available, all keys are unlocked.

Zero point adjustment function

The zero point adjustment function forcibly sets the pressure value to "Zero" when the pressure port is opened to

atmospheric pressure. When the zero adjustment is applied, analog output [Voltage or Current] is changed by this

function.(Press + keys over 1 sec. in RUN mode.)

High Peak / Low Peak Hold Function

This function is to diagnosis malfunction of the system caused by parasitic pressure or to check through memorizing

the max./min. pressure occurred from the system.

(unit:mm)

. Bracket A . Bracket B

. Connector cable (PSO-C01, 2m)

. Mounting bracket

(PSO-B02)

. Front protection

cover(PSO-P01)

1. Range of rating pressure: It is possible to change the pressure unit in Pressure

sensor. Please use different unit as label for your application.

2. 4digit LED display(Red): Used to indicate measured pressure value, setting value

and error message.

3. Output1 indicator(Red): Output 1 is ON, LED will be ON.

4. Output2 indicator(Green): Output 2 is ON, LED will be ON.

5. key: Used to enter into Preset/Parameter setting mode and to save Setting mode.

6. , key: Used to set parameter and preset, peak value check mode, function

setting or output operation mode.

+ key: Used for zero point adjustment function by pressing + keys over

1 sec. simultaneously in RUN mode.

※

The above specifications are subject to change without notice.

※1: (P) is PNP output type, of model name is as pressure port.

R1/8: PT1/8"model(Standard), NPT1/8: NPT1/8"model(Option)

7/16-20UNF: 7/16"-20 UNF model(Option)

※2: In hysteresis output mode, detection difference is variable.

※3: It is allowed to select one analog output type only.

※4: Resolution(1000/2000) of min. Display interval is automatically selected

depend on pressure units.

※5: This weight is with packaging and the weight in parentheses is only unit weight.

※F.S.: Rated pressure.

※There may be ±1digit error in hysteresis

by pressure unit calculation error.

※Environment resistance is rated at no

freezing or condensation.

(ST1+ST2)

2

SET

=

※ If the key lock is set (lock1 or lock2), unlock the key lock before setting parameters.

※ Press , key to change setting values.

※ Press key to save setting value in each parameter and move to next parameters.

※ When pressing key for 3 sec in the middle of parameter setting, current setting value will be saved in

EEPROM and [ RUN] will flash twice, then returned to RUN mode.

※ [ RUN] flashes twice when returning to RUN mode.

※ Press , key to change setting values.

※ Press key to save setting value in each parameter and move to next parameters.

※If there is no additional key operation within 60 sec. while setting,

it is returned to Run mode (Except for force output mode).

Previous set values are remained.

※In case of changing output operation mode, no preset values

will be initialized. Instead, previous output operation settings will

become the preset values.

※When changing pressure display unit, resolution and Hold/Auto

Shift input function, preset values will be initialized as shown the

table below. (When changing pressure display unit, preset value

will be automatically switched to changed pressure unit.)

※ If there is no additional key operation within 60 sec. while setting, current setting value is not valid and previous setting value

will be remained.

< Preset Default >

※When using the forced output function, Hold/Auto shiftfunction is

not available to use in Hold/Auto shift mode.

(unit: kPa)

Spring washer

Hexagon wrench bolt

(M3×6)

Protection

cover

(PSO-P01)

Bracket panel

Panel bracket

(PSO-B02)

Body

(PSAN)

The tightening torque of one touch

fitting should be max. 100kgf.cm.

It may cause machanical problems.

Caution

17mm

Spanner Switching

mode Power

Supply

Ground

. Panel cut-out

(Panel thickness 0.8mm to 3.5mm)

※Min.display pressure

≤ [ ST1] ≤Max. display

pressure - 1% of rated

pressure

※[ ST1]+1% of rated

pressure≤ [ ST2] ≤

Max. display pressure

※[ SET]

= ([ ST1]+[ ST2])/2

※Press , key for

manual adjustment

※ [ ERR3] Error flashes 3 times in case setting

conditions are not met, resetting is on standby.

※Setting range :

Min.display pressure

≤ [ LO-1] ≤ Max. display

pressure - (3×Min.display

interval)

※Setting range :

[ LO-1] + (3×Min.display

interval) ≤ [ HI-1]

≤ Max. display pressure

※Setting range

Min.display pressure≤

[ LO-2] ≤ Max. display

pressure-(3×Min. display

interval)

※Setting range

[ LO-2]+(3×Min. display

interval) ≤ [ HI-2]

≤ Max. display pressure

※Setting range

Min. display pressure

< [ ST1] ≤ Max. display

pressure

※Setting range

Min. display pressure

≤ [ HYS1] < [ ST1]

※Setting range

Min. display pressure

≤ [ LOW] ≤ Max. display

pressure - (3×Min. display

interval)

※Setting range

[ LOW] + (3×Min. display

interval) ≤ [ HIGH]

≤ Max. display pressure

※ PSAN series has 5 kinds of output operation mode, please use proper output operation mode in accordance

with detection.

Over current

protection

circuit

Over current

protection

circuit

(Brown)+V

(Blue)0V

(Black)OUT1

(White)OUT2

12-24VDC

Load

Load

Load

Load

※ : For voltage output type only.

1kΩ

(Brown)+V

(Black)OUT1

(White)OUT2

12-24VDC

※ : For voltage output type only.

1kΩ

Main circuit

Main circuit

(Orange)

Analog output

voltage/current

Over current

protection

circuit

Over current

protection

circuit

(Blue)0V

(Orange)

Analog output

voltage/current

Load

Load Load

Load

(Brown)+V

(Blue)0V

(Black)OUT1

(White)OUT2

(Orange)Hold/

Auto shift input

12-24VDC

(Brown)+V

(Blue)0V

(Black)OUT1

(White)OUT2

(Orange)Hold/

Auto shift input

12-24VDC

Main circuit

Main circuit

Over current

protection

circuit

Over current

protection

circuit

Over current

protection

circuit

Over current

protection

circuit

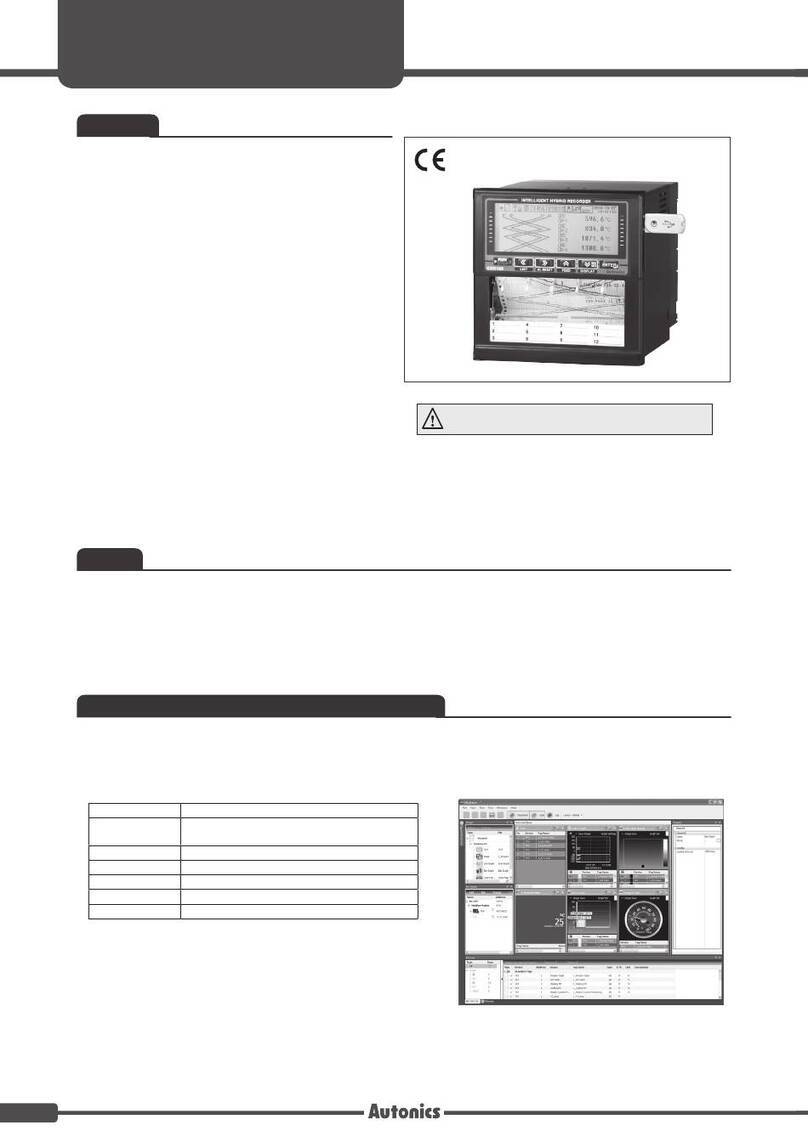

Proximity sensors

Fiber optic sensors

Counter

Display units

Panel meters

Temperature controllers

Tachometer/Pulse(Rate) meters

Temperature/Humidity transducers

Stepping moters/drivers/motion controllers

Laser marking system (CO

2

, ND:YAG)

Laser welding/soldering system

Photoelectric sensors

Door/Door side sensors

Timers

Power controllers

Graphic/Logic panels

Area sensors

Pressure sensors

Rotary encoders

Sensor controllers

Dimensions

※B: PT1/8" model(Standard): 56.3, NPT1/8" model: 56.3, 7/16"-20 UNF model: 59.3

45

45

15

1.6

20

20

6

20

30 2-M4 Bolt

●Bracket B

54

45

20

22

6

20 35

25 2-M4 Bolt

1.6

36+0.5

0

36+0.5

0

23

6

40

30

B

42

44

Pressure type Gauge pressure

Negative pressure Standard pressure Compound pressure

Model ※1

Voltage output PSAN-LV01C(P)V- PSAN-L01C(P)V- PSAN-L1C(P)V- PSAN-LC01C(P)V-

Current output PSAN-LV01C(P)A- PSAN-L01C(P)A- PSAN-L1C(P)A- PSAN-LC01C(P)A-

Hold/Auto shift input PSAN-LV01C(P)H- PSAN-L01C(P)H- PSAN-L1C(P)H- PSAN-LC01C(P)H-

Rated pressure range 0.0 to -101.3kPa 0.0 to 100.0kPa 0 to 1,000kPa -101.3kPa to 100.0kPa

Display pressure range 5.0 to -101.3kPa -5.0 to 110.0kPa -50 to 1,100kPa -101.3kPa to 110.0kPa

Min.display unit 0.1kPa 0.1kPa 1kPa 0.1kPa

Max. pressure range 2 times of rated

pressure

2 times of rated

pressure

1.5 times of rated

pressure

2 times of rated

pressure

Applied uid Air, Non-corrosive gas and fluid that will not corrode SUS316L

Power supply 12V-24VDC ±10%(ripple P-P:Max. 10%)

Current consumption Max. 50mA(Analog Current Output type Max 75mA)

Control output

NPN or PNP open collector output

• Load voltage: Max. 30VDC • Load current: Max. 100mA

• Residual voltage - NPN: Max. 1V, PNP: Max. 2V

Hysteresis ※2Min. display range

Repeat error ±0.2%F.S. ± Min. display range

Response time Selectable 2.5ms, 5ms, 100ms, 500ms, 1000ms

Short circuit protection Built-in

Analog

output

※3

Voltage output

• Output voltage: 1-5VDC ±2% F.S. • Linear: Max. ±1% F.S. • Output impedance: 1kΩ

• Zero point: Max. 1VDC ±2% F.S. • Span: Max. 4VDC ±2% F.S. • Response time: 50ms

• Resolution: Automatically changed to 1/1000 or 1/2000 by pressure unit

Current output

• Output current: DC4-20mA ±2% • Linear: Max. ±1% F.S.

• Zero-point: Max. DC4mA ±2% F.S. • Span: Max. DC16mA ±2% F.S. • Response time:70ms

• Resolution: Automatically changed to 1/1000 or 1/2000 by pressure unit

Display method 7segment LED Display

Min. Display interval ※4

Resolution

Pressure unit

1000 2000 1000 2000 1000 2000 1000 2000

MPa

- -

0.001

-

0.001

- - -

kPa 0.1

-

0.1

-

1

- -

0.1

kgf/cm20.001

-

0.001

-

0.01

- -

0.001

bar 0.001

-

0.001

-

0.01

- -

0.001

psi

-

0.01

-

0.01

-

0.1

-

0.02

mmHg

-

0.4

-

0.8

inHg

-

0.02

-

0.03

mmH₂O 0.1

- -

0.1

Display accuracy 0℃ to 50℃ : Max. ±0.5% F.S., -10 to 0℃ : Max. ±1% F.S.

Dielectric strength 1000VAC 50/60Hz for 1 minute

Insulation resistance Min. 50MΩ(at 500VDC megger)

Vibration 1.5mm amplitude at frequency of 10 to 55Hz(for 1 min.) in each of X, Y, Z direction for 2 hours

Environ-

ment

Ambient temperature

-10 to 50℃, storage : -20 to 60℃

Ambient humidity 30 to 80%RH, storage :30 to 80%RH

Protection IP40(IEC specification)

Material Front case: PC, Rear case: PA6, Pressure port: SUS316L

Cable Connector cable (Ø4, 5-wire, Length: 2m)

(AWG24, Core diameter : 0.08mm, Number of cores : 40, Insulator out diameter: Ø1mm)

Approval

Weight Approx. 173g(Approx. 88g)

1

2

4

6

5

3

ST2

HYS2

ST1

HYS1

Pressure

Time

Time

Time

Time

Time

ST2/ HYS2

ST1/ HYS1

ST1/ HYS1

ST2/ HYS2

OUT1 N.O.

OUT2 N.O.

OUT1 N.C.

OUT2 N.C.

Press key

over 3sec.

Press key

over 3sec.

Press

keys over 1sec.

Press key

Parameter

setting

Pressure

unit setting

Output

operation

mode setting

Output

type setting

Response

time setting

Key lock

setting

Analog output scale and

Hold/Auto Shift input setting

Peak hold

High peak

value check

Low peak

value check

Auto shift input setting

(In case of Hold/Auto shift input type model)

Zero-point

adjustment

Zero-point adjustment

Preset value

setting

Detection level 1 setting (out1) Detection level 2 setting (out2)

Forced output

control mode

setting

The forced output control mode is applied with pressign key after selecting forced output control mode(fOUT)

in output operation mode(OUtM) parameter. For more detailed information, refer to '● Forced output control

mode' ' Output operation mode'

RUN mode

20

20

30

32

17

30

30

11.3

30

A

2-M3 Tap

PT 1/8"

(Standard)

Inside M5 Tap

※

1

※1: Min. display range

Pressure

Time

Time

Time

Time

Time

LO-1/ HI-1

LO-1/ HI-1

LO-2/ HI-2

LO-2/ HI-2

OUT1 N.O.

OUT2 N.O.

OUT1 N.C.

OUT2 N.C.

※1

※1

※1

※1

HI-2

HI-1

LO-2

LO-1

Time

※1: Min. display range

Pressure

Time

Time

Time

Time

LOW/ HIGH

ST1/ HYS1

ST1/ HYS1

LOW/ HIGH

OUT1 N.O.

OUT2 N.O.

OUT1 N.C.

OUT2 N.C.

※1

※1

ST1

HYS1

LOW

HIGH

Time

※1: Min. display range

Pressure

Time

Time

Time

Time

SET=(ST1+ST2)/2

ST1/ ST2

SET

SET

ST1/ ST2

OUT1 N.O.

OUT2 N.O.

OUT1 N.C.

OUT2 N.C.

※1

※1

※1

ST2

SET

ST1

flashing

in turn

flashing

in turn

flashing

in turn

flashing

in turn

flashing

in turn flashing

in turn

flashing

in turn

flashing

in turn flashing

in turn

flashing

in turn

flashing

in turn

※In case of using mmH2O unit,

multiply 100 by display value.

※In case of standard pressure

type model, [ MPA], [ KPA], [ KGF],

[ BAR], [ PSI] parameters are

displayed only.

Parameter OUT1 output OUT2 output

1O2O

Normally Open Normally Open

1O2C

Normally Open Normally Closed

1C2O

Normally Closed Normally Open

1C2C

Normally Closed Normally Closed

※Unit: ms

Analog voltage output

(PSAN-L□□□□V-□)

Analog current output

(PSAN-L□□□□A-□)

Hold/Shift input

(PSAN-L□□□□H-□)

Select Hold(Refer to " Function")

※1: Setting range : Min.rated pressure ≤ [ A-1V, A-04] ≤ 90% of rated pressure

※2: Setting range : [ A-1V, A-04] + 10% of rated pressure ≤ [ A-SV, A-20] ≤ Max.rated pressure

※See setting Function key lock function for more

detailes.

Press key

over 3sec.

Press key

over 3sec.

※1※1

※2※2

RUN mode

Pressure unit

Output operation

mode

Output

Response time

1V Scale

5V Scale

4mA Scale

20mA Scale

External input function

Control output for

Auto shift function

Key lock

(MPa) (KPa) (kgf/cm

2

) (bar)

(psi)

(mmH

2

O) (inHg) (mmHg)

MPA

H2O

KPA

INHG

KGF

MMHG

BAR

PSI

UNIT

OUtM

@5

1O2O

%0

1O2C

100

1C2O

500

1C2C

Hysteresis

mode

Window

comparison

output mode

Auto sensitivity

setting mode Forced output

control mode

Hysteresis-Window

comparison output

mode

HYsM WIN HY-W AUTO fOUT

1000

NoNC

SPD

A-04 HOLD

OUT1

ALL

D-IN

ShOTA-20

A-1V )0 )0 SHFT

OUT210)0A-5V 10)0

OFFLOCK LOC1 LOC2

flashing

in turn

flashing

in turn

flashing

in turn

flashing

in turn

※Setting range :

Min.display pressure

< [ ST1] ≤ Max. display

pressure

※Setting range :

Min. display pressure

≤ [ HYS1] < [ ST1]

※Setting range :

Min.display pressure

< [ ST2] ≤ Max. display

pressure

※Setting range :

Min.display pressure

≤ [ HYS2] < [ ST2]

Hysteresis level 1

Pressure detection

level 2

Pressure detection

level 1

Hysteresis level 2

ST1 2)0

HYS1 1)0

ST2 4)0

HYS2 3)0

RUN mode

flashing

in turn

flashing

in turn

flashing

in turn

Pressure detection

level 1

Pressure detection

level 2

Auto setting value

ST1 1)0

ST2 2)0

STT 1%0

RUN mode

flashing

in turn

flashing

in turn

flashing

in turn

flashing

in turn

Low-limit value of

Pressure detection level 1

Low-limit value of

Pressure detection level 2

High-limit value of

Pressure detection level 1

High-limit value of

Pressure detection level 2

LO-1 1)0

HI-1 2)0

LO-2 3)0

HI-2 4)0

RUN mode

flashing

in turn

flashing

in turn

flashing

in turn

flashing

in turn

ST1 1)0

HYS1 2)0

LOW 3)0

HIGH 4)0

RUN mode

Pressure detection

level 1

Hysteresis level 1

Low-limit value of

Pressure detection level 2

High-limit value of

Pressure detection level 2

Output

mode

Negative

pressure

0.0 to -101.3

Standard

pressure

0.0 to 100.0

Standard

pressure

0 to 1,000

Compound

pressure

-101.3 to 100.0

HYS.M

ST1

:-50.0

ST1

:50.0

ST1

:500

ST1

:50.0

HYS1

:0.0

HYS1

:0.0

HYS1

:0

HYS1

:-50.0

ST2

:-50.0

ST2

:50.0

ST2

:500

ST2

:50.0

HYS2

:0.0

HYS2

:0.0

HYS2

:0

HYS2

:-50.0

WIN

LO-1

:0.0

LO-1

:0.0

LO-1

:0

LO-1

:-50.0

HI-1

:-50.0

HI-1

:50.0

HI-1

:500

HI-1

:50.0

LO-2

:0.0

LO-2

:0.0

LO-2

:0

LO-2

:-50.0

HI-2

:-50.0

HI-2

:50.0

HI-2

:500

HI-2

:50.0

HY-W

ST1

:-50.0

ST1

:50.0

ST1

:500

ST1

:50.0

HYS1

:0.0

HYS1

:0.0

HYS1

:0

HYS1

:-50.0

LOW

:0.0

LOW

:0.0

LOW

:500

LOW

:-50.0

HIGH

:-50.0

HIGH

:50.0

HIGH

:0

HIGH

:50.0

AUTO

ST1

:0.0

ST1

:0.0

ST1

:0

ST1

:-50.0

ST2

:-50.0

ST2

:50.0

ST2

:500

ST2

:50.0

SET

:-25.0

SET

:25.0

SET

:250

SET

:0.0

Error display Description Countermeasures

ERR1 When external pressure is input while adjusting zero

point. Try again after removing external pressure.

ERR2 When overload is applied on control output Remove overload.

ERR3 When setting condition is not met in Auto sensitivity

setting mode.

Check setting conditions and set proper setting

values.

LLLL When applied pressure exceeds Low-limit of display

pressure range. Apply pressure within display pressure range.

HHHH When applied pressure exceeds High-limit of display

pressure range.

-HH-

-LL-

-HL-

Auto shift correction error. Set the corrected setting value within setting

pressure range.

RUN mode

RUN mode

Flashing

in turn

fOUT

Current pressure

8#1

RUN modeRUN mode Forced output control mode

operation status

OUT1

OUT2

Time

Time

ON

OFF

ON

OFF

flashing

in turn

flashing

in turn

flashing

in turn

High Peak value

Low Peak value

Reference pressure

for Auto Shift

hPEK 10)6

lPEK -@7

ShIN 5)0

RUN mode

※1

Press key over 3sec.

※It may cause malfunction if above instructions are not followed.