Allegion 8310-889 User manual

75.5323.01 ALLEGION SAFETY MODULE 8310-889 20180702 Page 1 of 4

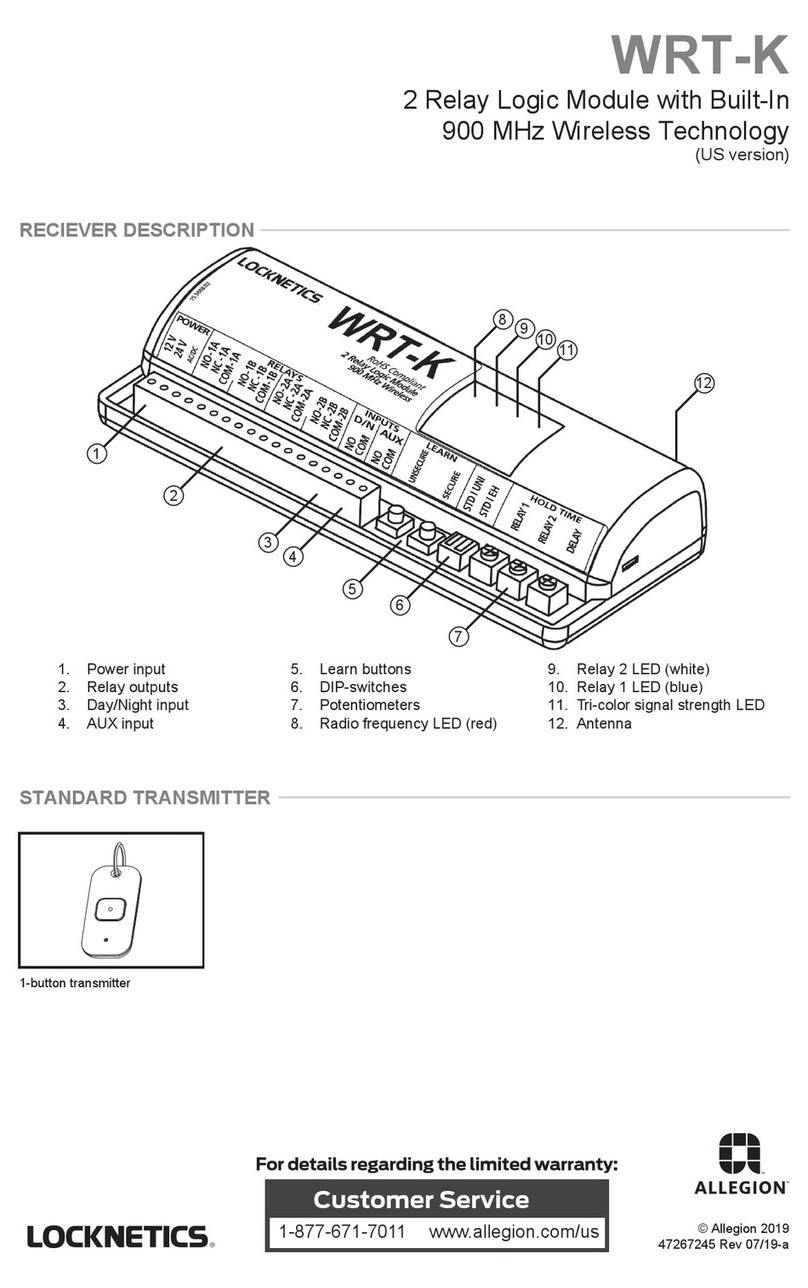

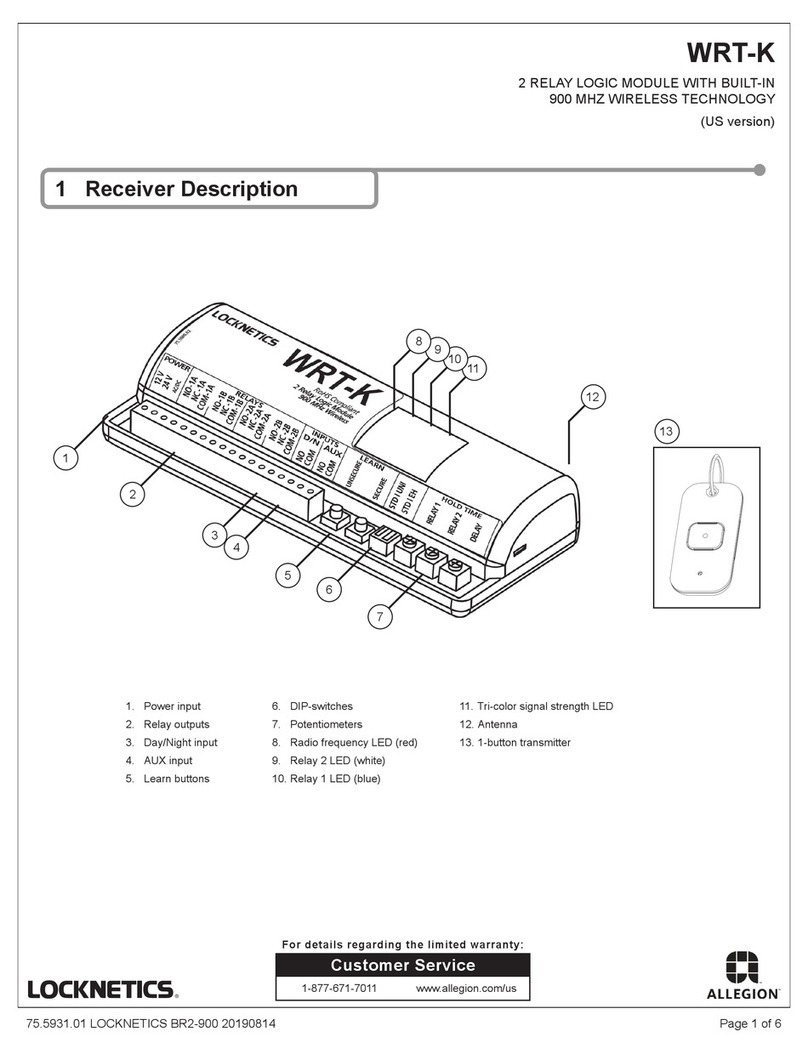

1. DIP swtiches

2. Red LED (safety)

3. Green LED (activation)

1

2 3

8310-889 SAFETY MODULE

PRECAUTIONS

75.5323.01 ALLEGION SAFETY MODULE 8310-889 20180702 Page 1 of 4

Lock-out relay

ENGLISH

DESCRIPTION

TECHNICAL SPECIFICATIONS

Power supply: 12 – 24 VAC/VDC

Operating frequency: 4 MHz (microprocessor)

Power consumption: 10 mA at rest; 50 mA max.

Output: 2 SPST relays

Max. voltage (relay contact): 60 VDC / 120 VAC

Max. current (relay contacts): 2.0A DC / 0.5A AC

Specifications are subject to change without

prior notice.

All values measured in specific conditions.

Shut off all power going to header before attempting any wiring procedures.

Maintain a clean and safe environment when working in public areas.

Constantly be aware of pedestrian traffic around the door area.

Always stop pedestrian traffic through the doorway when performing tests that may result in

unexpected reactions by the door.

ESD (electrostatic discharge): Circuit boards are vulnerable to damage by electrostatic discharge.

Before handling any board, ensure you dissipate your body’s ESD charge.

Always check placement of all wiring before powering up to ensure that moving door parts will not

catch any wires and cause damage to equipment.

Ensure compliance with all applicable safety standards (i.e. ANSI A156.10) upon completion of

installation.

DO NOT attempt any internal repair of the components. Unauthorized disassembly or repair:

1. May jeopardize personal safety and may expose one to the risk of electrical shock.

2. May adversely affect the safe and reliable performance of the product resulting in a voided

warranty.

Page 2 of 4 75.5323.01 ALLEGION SAFETY MODULE 8310-889 20180702Page 2 of 4 75.5323.01 ALLEGION SAFETY MODULE 8310-889 20180702

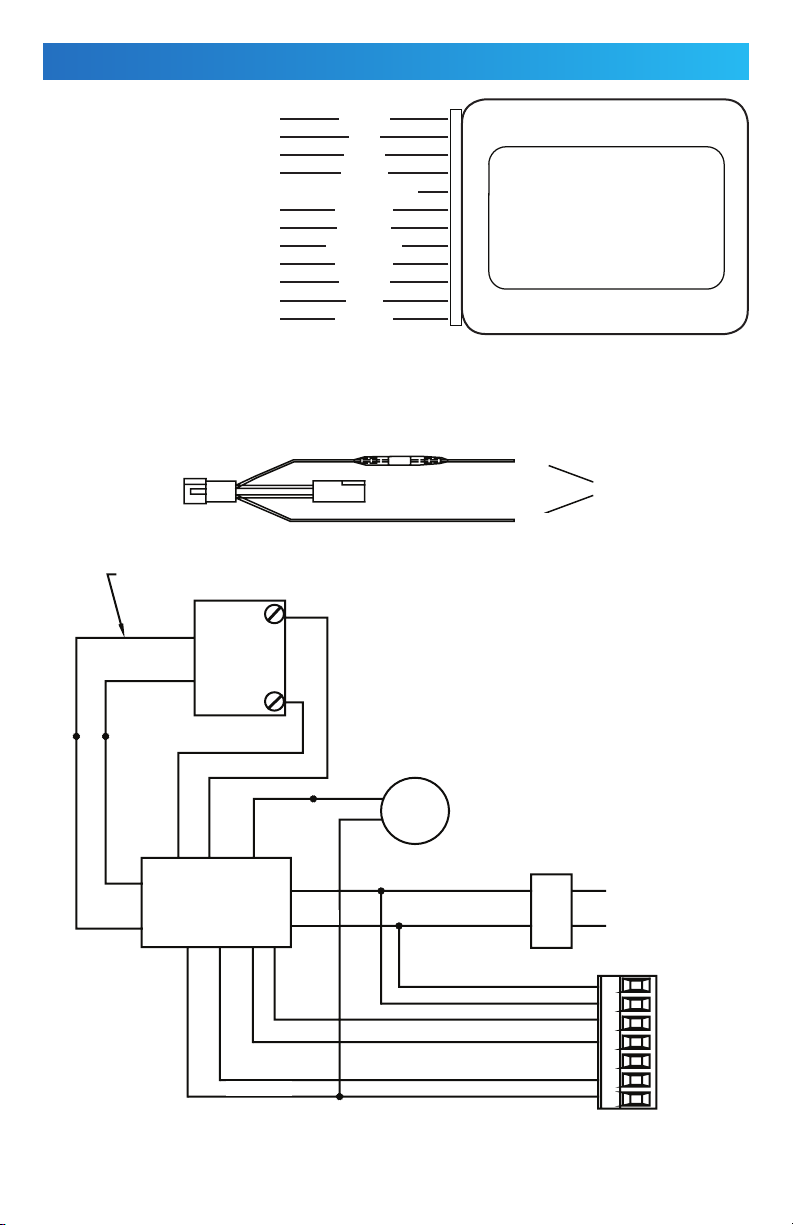

WIRING

MOTOR INPUT

MOTOR INPUT

8310-877 NO

8310-877 COM

12-24 VAC/VDC

8310-877 COM

8310-877 DATA + & ACTIVATION NO

12-24 VAC/VDC

CONTROL BOX COMMON

CONTROL BOX ACTIVE

ACTIVATION COM

MC-15

LOCK OUT RELAY

SAFETY MODULE

BLACK

BLACK

BLACK

BLACK

SAFETY

MODULE

SAFETY

SCANNER

BLUE

GREEN

TRANSFORMER

YELLOW

900/7900 SERIES

CONTROL BOX

ACTIVATION SWITCH

OR SCANNER

10

A

or

B

COM

1234567

N.O.

120 VAC24 VAC

RED

RED

RED

RED

GRAY

WHITE

ORANGE

PURPLE

RED/WHITE

BROWN

GREEN

BLUE

YELLOW

10K Resistor

to A or B

Air Solenoid

HARNESS SHOWN ABOVE

to A or B

connector on

power supply PCB

to Safety Module

BROWN

ORANGE

PURPLE

GRAY

WHITE

RED/WHITE

75.5323.01 ALLEGION SAFETY MODULE 8310-889 20180702 Page 3 of 475.5323.01 ALLEGION SAFETY MODULE 8310-889 20180702 Page 3 of 4

PROGRAMMING

1. Apply power.

RED LED = When the door is closed and someone steps into the safety zone, this indicates that it will ignore

any activation signal it receives. Therefore, the door will remain closed until the HMSS safety zone is clear.

Once the safety zone is clear and the door has been activated, a normal opening cycle will commence.

GREEN LED = If someone steps into the safety zone when the door is open, the Safety Module’s green LED

will indicate that the HMSS will be connected to the activation circuitry of the door thus holding the door open

for as long as someone is in its pattern.

2. SET LOCK-OUT TIME DELAY

The lock-out time delay for the door closing cycle must be set using the six DIP switches located on the front

of the unit. A 0 to 31 second lock-out time delay can be achieved. The lock-out time delay must be set so

that the HMSS does not send a safety signal during the closing cycle. As soon as the door reaches the jamb,

the Safety Module should reactivate the HMSS.

3. SET TIME DELAY ON SAFETY MODULE

Check to make sure that the Safety Module locks out the HMSS for the entire closing cycle of the door. If the

scanner sends a safety signal (scanner red light on) anytime during the closing cycle, the time delay set on the

Safety Module must be increased. If the door goes into safety swing as soon as it starts to close and you have

a time delay set for the length of the closing cycle, ensure that the AC power is being switched on and off at

the point of connection for the red and black wires. Correct any faults before proceeding.

4. SET DIP SWITCHES

Set the DIP switches according to the chart on page 4 to achieve the desired lock out time delay. The DIP

switches are configured to send a binary coded input to the microprocessor to establish the correct lock out

time delay.

For example:

The normal closing cycle of an automatic door lasts about 7 seconds. In order to get the proper closing lock-

out time delay needed for the closing cycle of the door, the DIP switches need to be set according to the chart

on page 4 for 7 seconds (Default Setting). To get the proper lock-out time delay DIP switches 1, 2, and 3 must

be in the ON position and DIP switches 4 thru 8 must be in the OFF position.

OFF

ON

7654321

green LED (safety beams)

red LED (lock-out time)

8

RED LED

(safety)

GREEN LED

(activation)

Page 4 of 4 75.5323.01 ALLEGION SAFETY MODULE 8310-889 20180702Page 4 of 4 75.5323.01 ALLEGION SAFETY MODULE 8310-889 20180702

Do not leave problems unresolved. If a satisfactory solution cannot be achieved after troubleshooting

a problem, please contact Allegion at 1-877-671-7011. If you must wait for the following workday to

call Allegion, leave the door inoperable until satisfactory repairs can be made. Never sacrifice the safe

operation of the automatic door or gate for an incomplete solution.

For more information, visit www.allegion.com.

The sensor manufacturer cannot be held responsible for incorrect installations or inappropriate adjustments of the sensor/device; therefore, the sensor

manufacturer does not guarantee any use of the sensor outside of its intended purpose.

The sensor manufacturer strongly recommends that installation and service technicians be AAADM-certified for pedestrian doors, IDA-certified for

doors/gates, and factory-trained for the type of door/gate system.

Installers and service personnel are responsible for executing a risk assessment following each installation/service performed, ensuring that the sensor

system installation is compliant with local, national, and international regulations, codes, and standards.

Once installation or service work is complete, a safety inspection of the door/gate shall be performed per the door/gate manufacturer recommendations

and/or per AAADM/ANSI/DASMA guidelines (where applicable) for best industry practices. Safety inspections must be performed during each service

call – examples of these safety inspections can be found on an AAADM safety information label (e.g. ANSI/DASMA 102, ANSI/DASMA 107).

Verify that all appropriate industry signage and warning labels are in place.

INSTALLATION/SERVICE COMPLIANCE EXPECTATIONS

PLEASE KEEP FOR FURTHER USE – DESIGNED FOR COLOR PRINTING

75.5323.01ALLEGIONSAFETYMODULE8310-88920180702

TIME DELAY

(sec)

DIP 1

(1 sec)

DIP 2

(2 sec)

DIP 3

(4 sec)

DIP 4

(8 sec)

DIP 5

(16 sec)

1ON OFF OFF OFF OFF

2OFF ON OFF OFF OFF

3ON ON OFF OFF OFF

4OFF OFF ON OFF OFF

5ON OFF ON OFF OFF

6OFF ON ON OFF OFF

7ON ON ON OFF OFF

8OFF OFF OFF ON OFF

9ON OFF OFF ON OFF

10 OFF ON OFF ON OFF

11 ON ON OFF ON OFF

12 OFF OFF ON ON OFF

13 ON OFF ON ON OFF

14 OFF ON ON ON OFF

15 ON ON ON ON OFF

16 OFF OFF OFF OFF ON

17 ON OFF OFF OFF ON

18 OFF ON OFF OFF ON

19 ON ON OFF OFF ON

20 OFF OFF ON OFF ON

21 ON OFF ON OFF ON

22 OFF ON ON OFF ON

23 ON ON ON OFF ON

24 OFF OFF OFF ON ON

25 ON OFF OFF ON ON

26 OFF ON OFF ON ON

27 ON ON OFF ON ON

28 OFF OFF ON ON ON

29 ON OFF ON ON ON

30 OFF ON ON ON ON

31 ON ON ON ON ON

PROGRAMMING (cont.)

Other Allegion Control Unit manuals

Popular Control Unit manuals by other brands

MikroTik

MikroTik R11e-LR2 quick start guide

Manner

Manner MES technical information

SPI Lasers

SPI Lasers redPOWER quick start guide

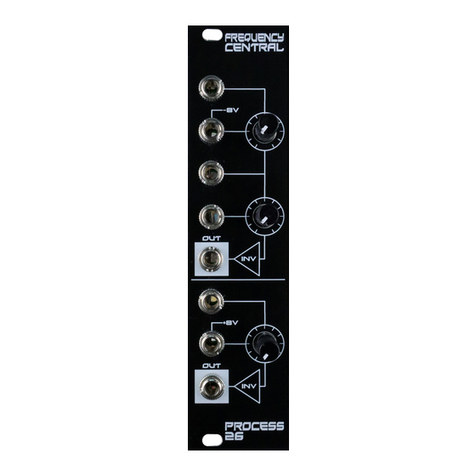

Frequency Central

Frequency Central Process 26 Build documentation

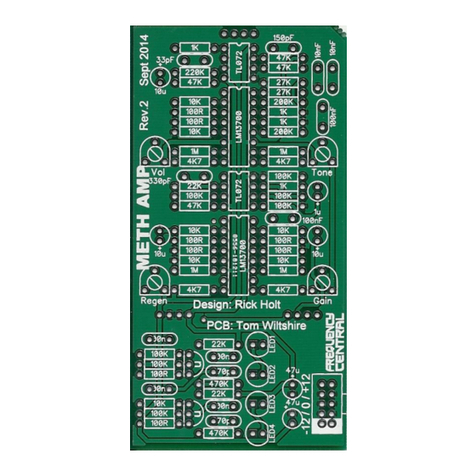

Frequency Central

Frequency Central Meth Amp Rev.2 Build documentation

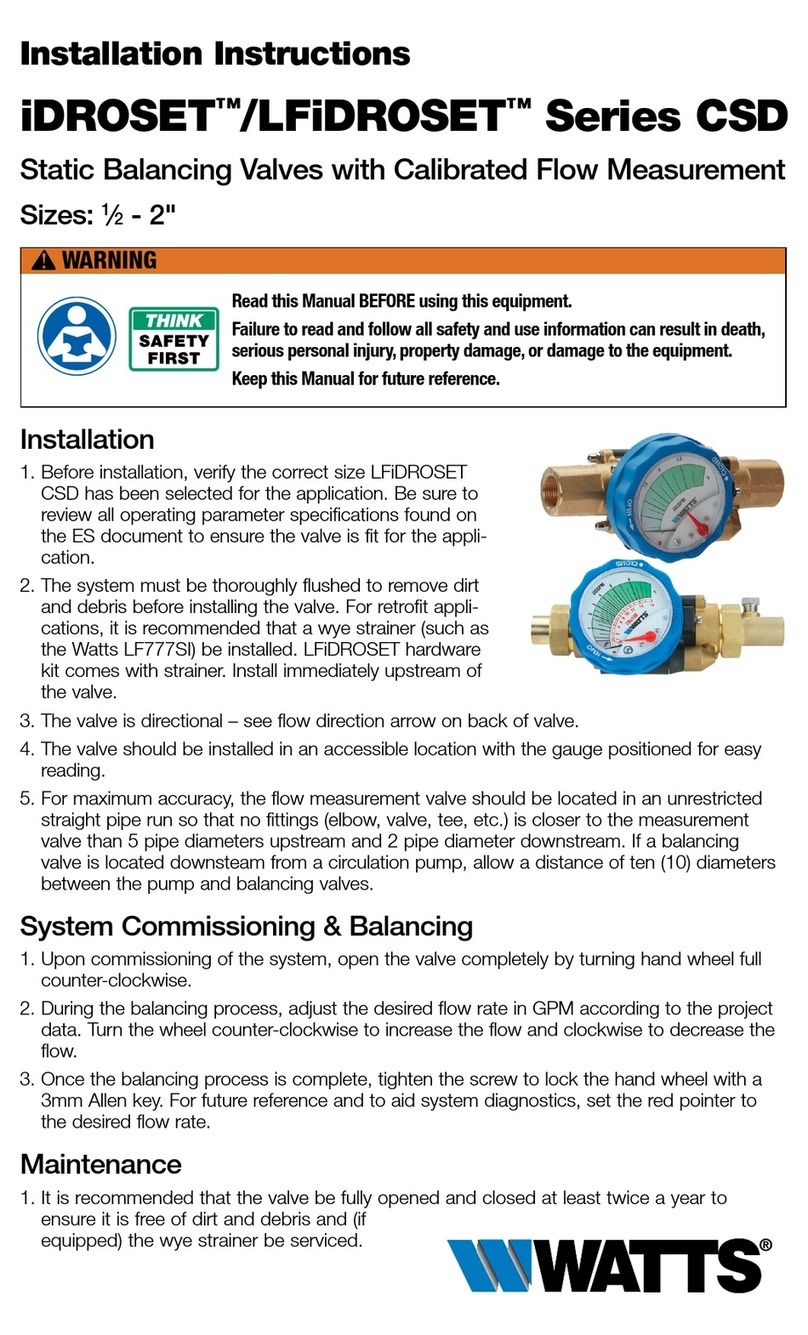

Watts

Watts LFUSG-B-M1 installation instructions